Biophysical Society | Feb 11-13, 2024 | Philadelphia, PA

Biophyisical Society 2024 Annual Meeting Stop by to explore our sample preparation solutions for streamlining your structural biology research workflows. The VitroJet helps reduce your cryo-EM grid preparation costs and solve 3D structures faster by controlling ice thickness. We will also be featuring the Naiad-1, an automated tool for preparing graphene liquid cells within minutes […]

What’s the Difference Between SEM & TEM?

Electron microscopy is best known as a high-powered microscopy technique that utilizes a beam of electrons as a source of illumination. In an electron microscope, a focused electron beam interacts with the sample surface, leading to various beam-sample interactions. Each interaction generates a distinct signal that can be utilized to produce a high-resolution image. Unlike […]

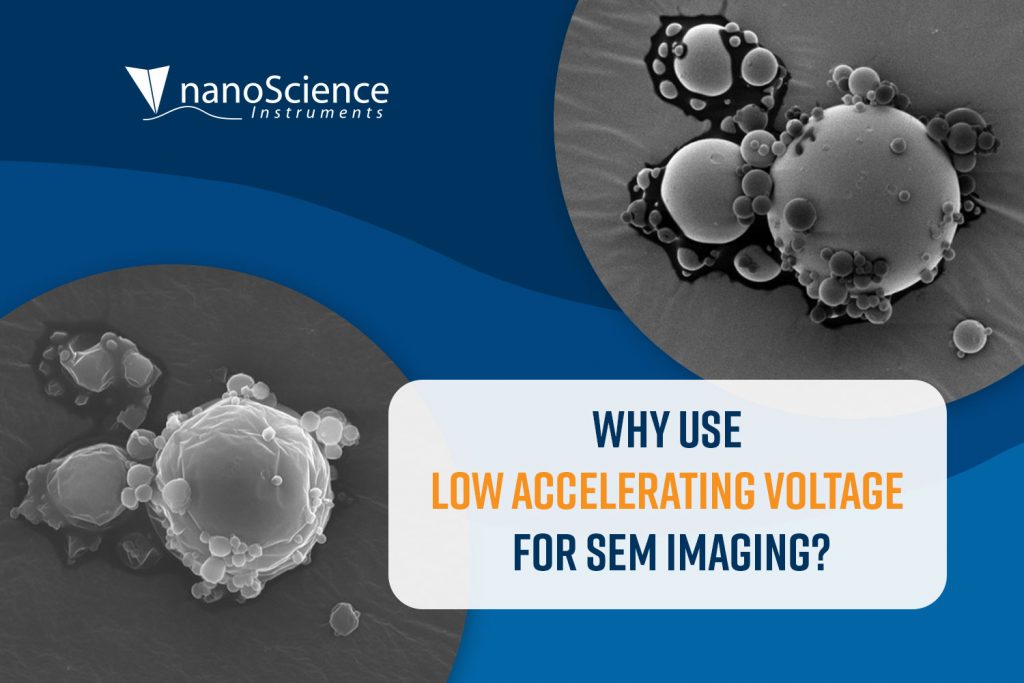

Why Use Low Accelerating Voltage for SEM Imaging?

Scanning electron microscopes (SEM) function by rastering a sample with a focused beam of electrons to produce high-resolution images of the sample surface. The generated signals from these sample-beam interactions are influenced by a multitude of factors, including the energy of the electron beam. The accelerating voltage, or the potential difference between the electron source […]

Four Transformative Benefits of SEM Automation for Handling Repetitive Tasks

SEM is a high-resolution imaging technique that uses a focused electron beam to generate high-resolution images of the surface morphology and the elemental composition of specimens at a micro- and nanoscale level. First developed in the 1930s, it has since evolved to become an essential tool whenever there is a need to understand detailed microscopic insights into the surface or the immediate subsurface of a material.

5 Different Methods Used to Fabricate Nanofibers

Nanofibers, particularly polymeric nanofibers, are a burgeoning frontier in the world of materials science, offering a diverse array of applications across industries. These fibers, typically with diameters ranging from a few nanometers to a few hundred nanometers, represent a transformational leap in material engineering. Their unique properties, which include an extraordinarily high surface area, tunable […]

What Role Does Cyclic Voltammetry Play in Battery Testing?

Cyclic voltammetry (CV) is an important and widely used measurement technique in electrochemistry. CV measures the current that flows through an electrochemical cell as the voltage is varied over a defined range. In most cases, the voltage sweeps over the range repeatedly to study the reversibility, mechanism, and kinetic properties of electrode reactions. The resultant data is plotted as a cyclic voltammogram.

Harnessing the Power of AI for Automated SEM Explorations

Artificial intelligence (AI) is undeniably reshaping the fabric of our world by revolutionizing industries and redefining the way we approach problem-solving. As AI technologies continue to advance, their potential applications in scientific research, particularly in materials science, are becoming increasingly apparent [1].

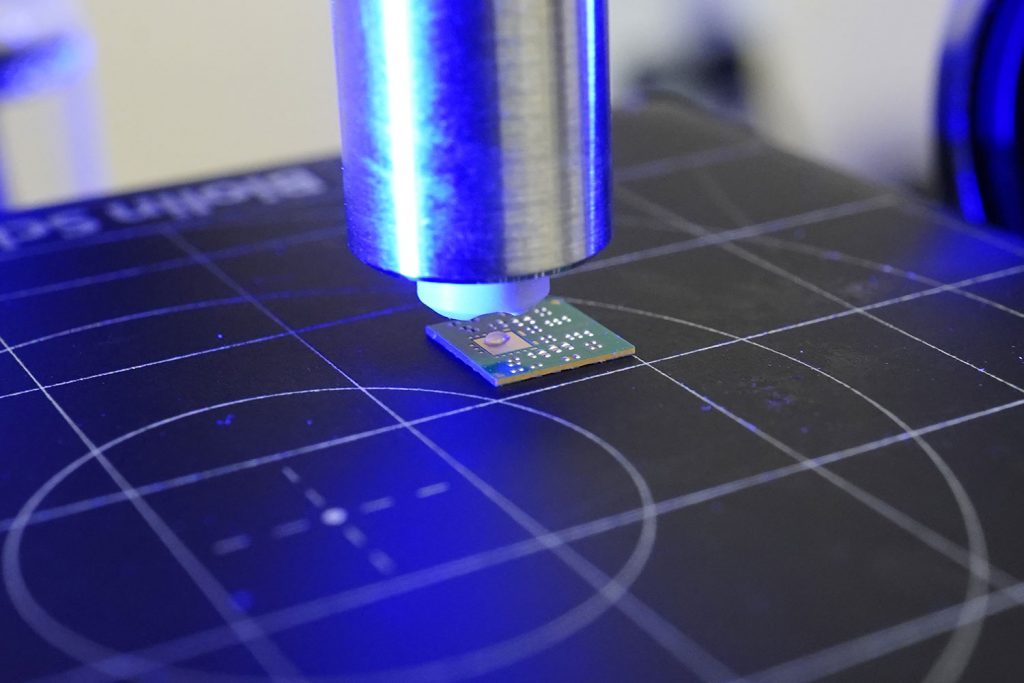

Wettability Analysis of Small Surfaces with Picoliter-Sized Droplets

The interaction between a liquid and a solid surface is a critical descriptor for a surface’s chemistry with important technological implications: it can determine how well coatings will adhere, detect the presence of soils or contaminants, and ascertain the compatibility of surfaces with biologics to name a few.

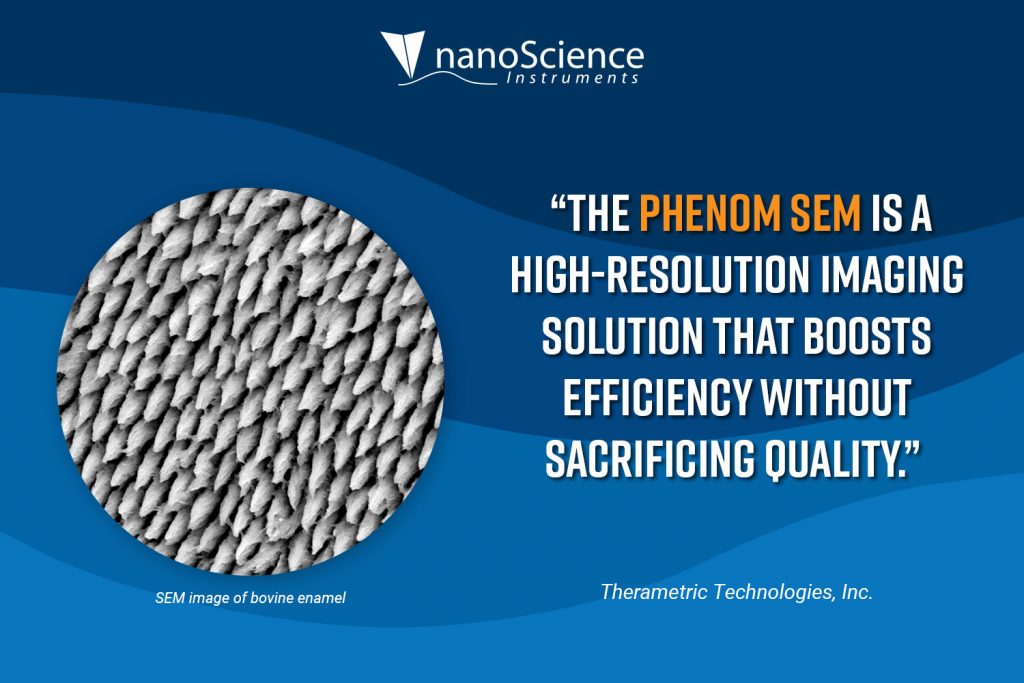

Therametric Technologies, Inc. Pushing the Envelope of Dental Innovation with SEM

Therametric Technologies, Inc. is a leading pioneer in dental product testing and research. For over two decades, this trusted industry partner has advanced dental care through meticulous science, providing the expertise that dental manufacturers depend on to validate product performance and safety. To reaffirm their commitment to unpacking dental excellence from the bottom up, Therametric is now equipped with a Phenom Desktop Scanning Electron Microscope (SEM) to delve deep into dental microstructures, functionality, and composition – moving well beyond the limits of what they could do with only light microscopy.

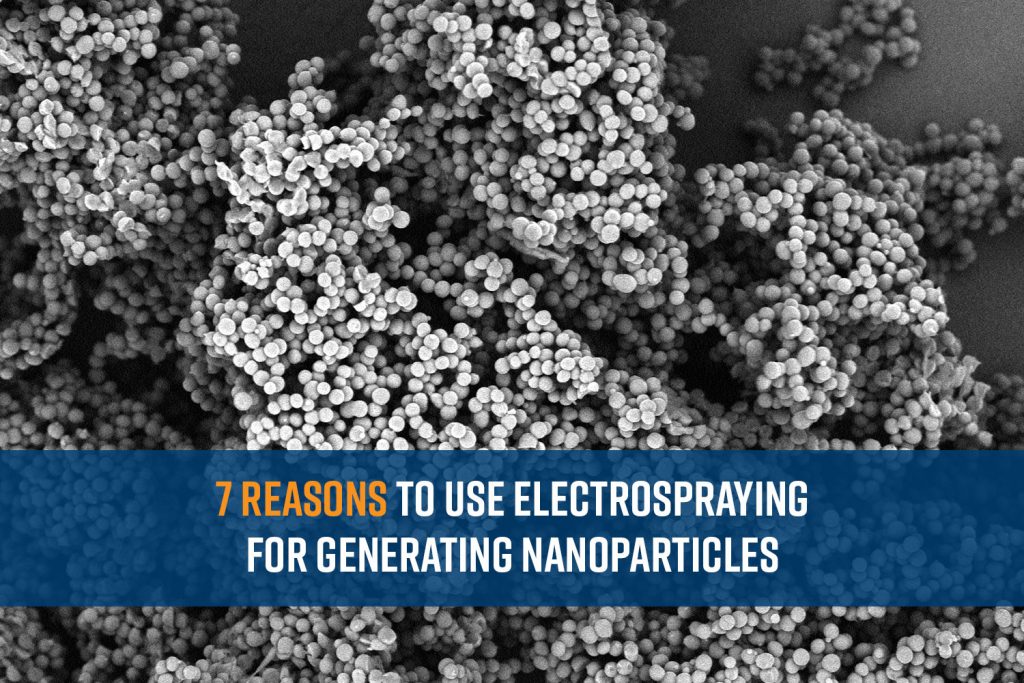

7 Reasons to Use Electrospraying as a Reproducible Method to Generate Nanoparticles

Particles are used daily in a wide variety of applications including coating surfaces and encapsulation of active ingredients. Coating surfaces can impart additional functionality and modulate the mechanical properties of the surface. Encapsulation of active pharmaceutical ingredients (APIs) is an effective method of delivering drugs to the site of action, especially water-insoluble drugs. Encapsulation of […]