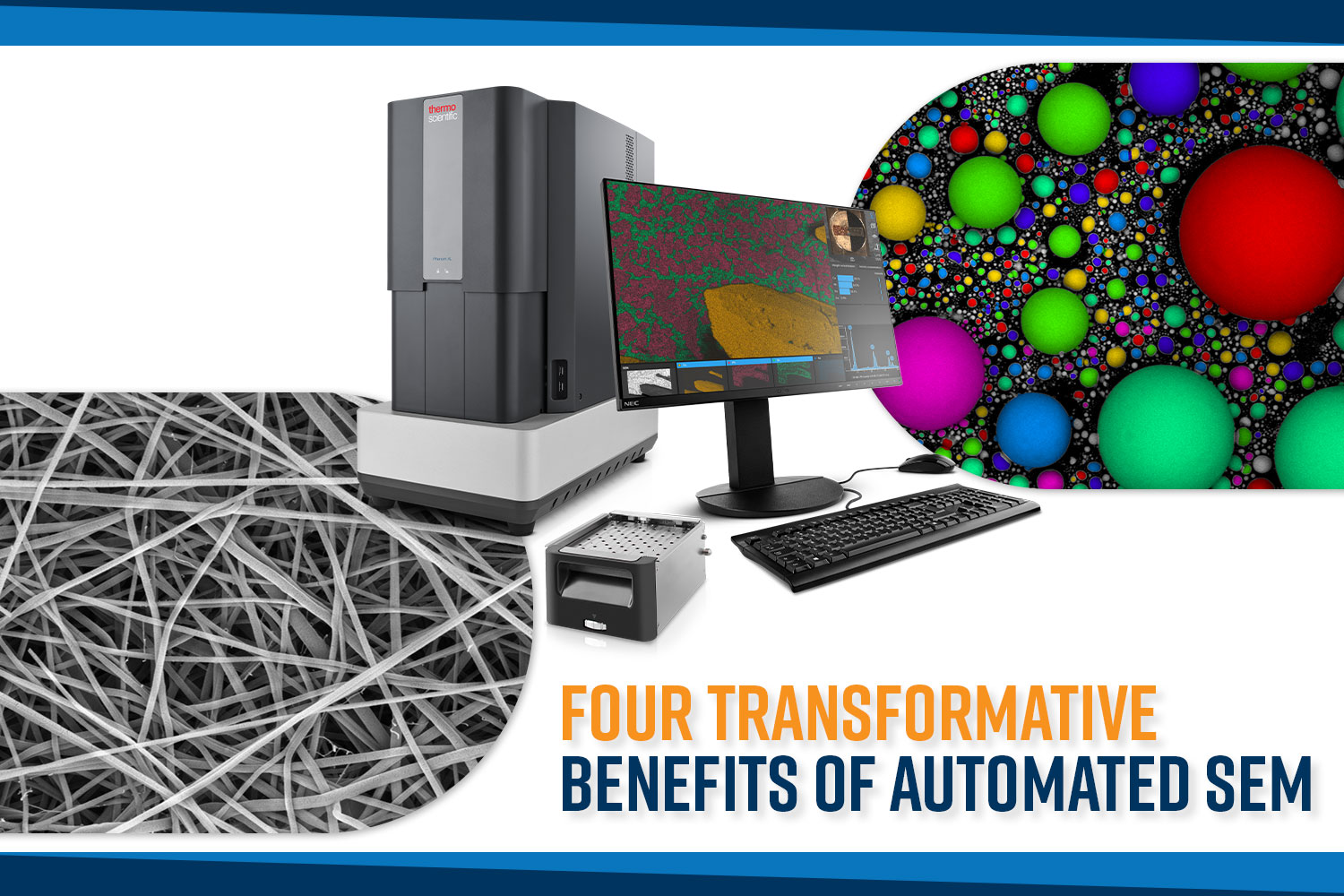

SEM is a high-resolution imaging technique that uses a focused electron beam to generate high-resolution images of the surface morphology and the elemental composition of specimens at a micro- and nanoscale level. First developed in the 1930s, it has since evolved to become an essential tool whenever there is a need to understand detailed microscopic insights into the surface or the immediate subsurface of a material. Today, SEM is being used for routine analysis in a wide variety of applications including failure analysis, quality control, and forensics. However, the collection of large data sets on an SEM is a tedious process because of the numerous manual steps involved in its operation. Automating the data collection and analysis has taken the technique from a largely manual and time-consuming endeavor, requiring highly skilled personnel, to a user-friendly tool that can lead to broader adoption of SEM in industrial settings.

SEM Automation

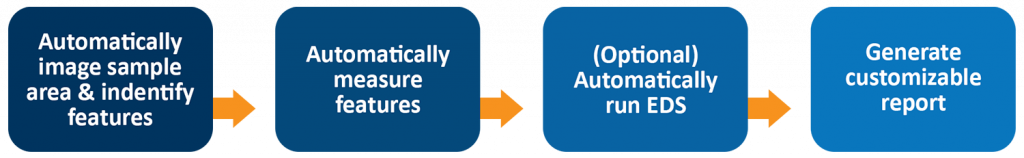

The early days of SEM required manual operation, including everything from sample positioning, beam alignment, focusing and stigmation, image acquisition, and data analysis, resulting in cumbersome workflows that did not find many practical applications beyond academia. The earliest versions of automating the technique involved the use of computers to operate the microscope, record images, and analyze images in separate software programs with relatively limited functionality (e.g., the ability to make manual dimensional measurements). Today, fully automated SEM instruments that also incorporate energy dispersive X-ray spectroscopy (EDS) for elemental analysis are not only physically compact (fitting on a tabletop or desktop) but can also operate 24/7 for continuous data collection and analysis with minimal human intervention. The user only has to load the sample to be analyzed and initiate the automation program. As a result, many organizations are implementing this revolutionary technology to handle repetitive tasks and increase productivity, reduce user bias and fatigue, standardize analyses, and reduce operational costs.

In industrial environments that rely on SEM, automation can ultimately result in profound cost savings by significantly removing the amount of human intervention required to obtain actionable results. Beyond bottom-line improvements, distinct benefits of automating repetitive SEM workflows include:

1. Eliminating User Bias:

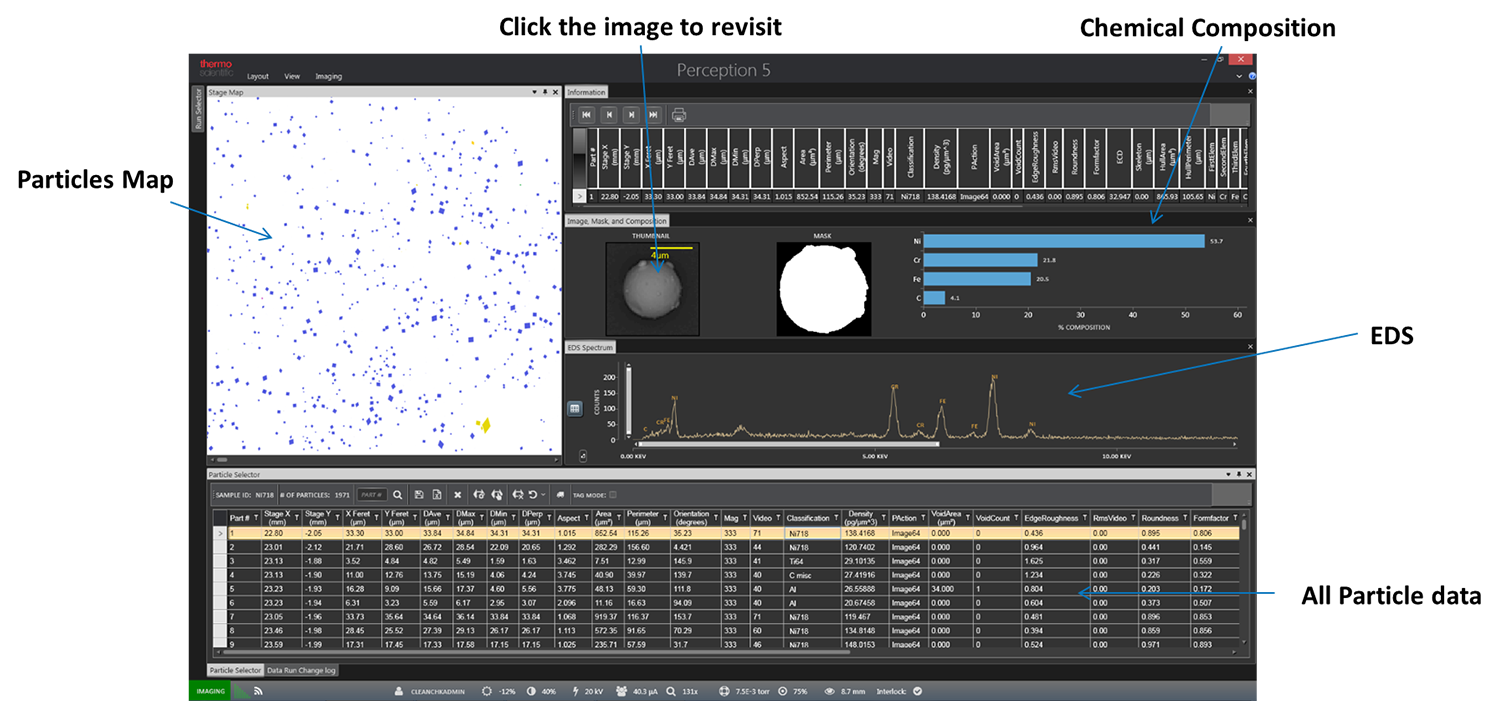

One of the primary advantages of SEM automation is its ability to remove user bias in data collection and analysis. Human operators can inadvertently introduce bias into their observations and data interpretation, particularly when using complex instruments such as SEMs. An automated SEM workflow ensures that data collection is standardized and that data analyses follow a well-defined set of operations, leading to more reliable results. In quality control applications, various types of features (e.g., particles, fibers, inclusions, etc) can be automatically detected, and measured, and their composition analyzed using automated SEM and energy dispersive X-ray spectroscopy (EDS) analysis. By ensuring unbiased analyses are performed consistently across different samples, the influence of human subjectivity on sample size and dimensional measurements is eliminated which allows for batch-to-batch variations to be accurately assessed.

2. Mitigating User Fatigue:

Repetitive tasks within SEM operations, such as imaging large sets of samples or conducting thorough measurements, can lead to operator fatigue and degrade the quality of results. SEM automation systems can work continuously through tedious and detailed routines, ensuring that tasks are carried out consistently. For example, in forensic science, where SEM and EDS are employed to analyze a vast number of samples for trace evidence like gunshot residue, automation minimizes the risk of errors stemming from human fatigue during investigations.

3. Standardizing Testing and Analysis:

Standardization of SEM and EDS data collection and analysis is critical in manufacturing environments where maintaining the safety of the finished product is of primary concern. Monitoring cleanliness during fabrication and handling, detecting impurities in material formulations, and monitoring quality on the microscopic scale require different types of measurements and classification rules to be applied to large datasets acquired by SEM instruments. With the proper automation workflow in place, organizations can remain compliant with a variety of internationally recognized standards while ensuring their industrial processes meet safety and quality benchmarks. In the automotive industry, automated SEM and EDS can be leveraged for conducting technical cleanliness evaluations that are compliant with ISO 16232 (international standard) and VDA-19 (European standard).

4. Maximizing Operational Efficiency:

By reducing user bias, mitigating user fatigue, and standardizing testing and analysis, SEM automation ultimately maximizes operational efficiency. With the capability to perform SEM and EDS workflows completely unattended, aside from loading the sample and initiating each run, automation frees up human resources for more strategic and creative roles and opens up the possibility of reducing personnel-related costs. In the pharmaceutical field, where SEM is used for drug formulation analysis, automated SEM allows scientists to obtain data on statistically relevant sample sizes of pharmaceutical ingredients (e.g., powders) much faster than if they were to rely on manual approaches. By expediting the time-to-results, more time can be spent on innovating drug formulations and accelerating the development process.

The Perception user interface, part of ParticleX automation software for the Phenom XL Desktop SEM, enables users to create fully automated SEM/EDS workflows. Learn more by watching the webinar on demand.

Automation solutions such as ParticleX and the Python Programming Interface (PPI), on Phenom Desktop SEM instruments, are proving to be a game-changer for tackling repetitive microscopy tasks required in industrial environments. ParticleX makes it simple to collect and analyze particle data with the Phenom XL and is the premier solution for implementing high-throughput, unattended operation on a 24/7 basis. There are several ready-to-use packages available and custom protocols can be easily designed or modified with flexible automation features. Easily set criteria for pass or fail, feature categorization, and create visual reports, all in a user-friendly interface. PPI is compatible with all Phenom Desktop SEM models and provides capability-expanding features through access to PyPhenom, a Python-based programming library. Scripting in PPI offers Phenom users the absolute freedom to create SEM workflows tailored to their needs that achieve faster, more accurate data collection and analysis.

Conclusion

SEM automation is reshaping industries by providing effective solutions to the challenges posed by repetitive tasks. By minimizing user bias, combating user fatigue, enabling standardized testing, and optimizing operational efficiency, SEM automation tools provide significant cost savings to a variety of customers. Organizations that implement this technology are gaining a competitive edge by enhancing precision, increasing productivity, and empowering their workforce to focus on higher-value activities. As SEM automation continues to advance, companies that embrace these solutions will be better positioned to thrive in an increasingly automated world and drive innovation in their respective fields.