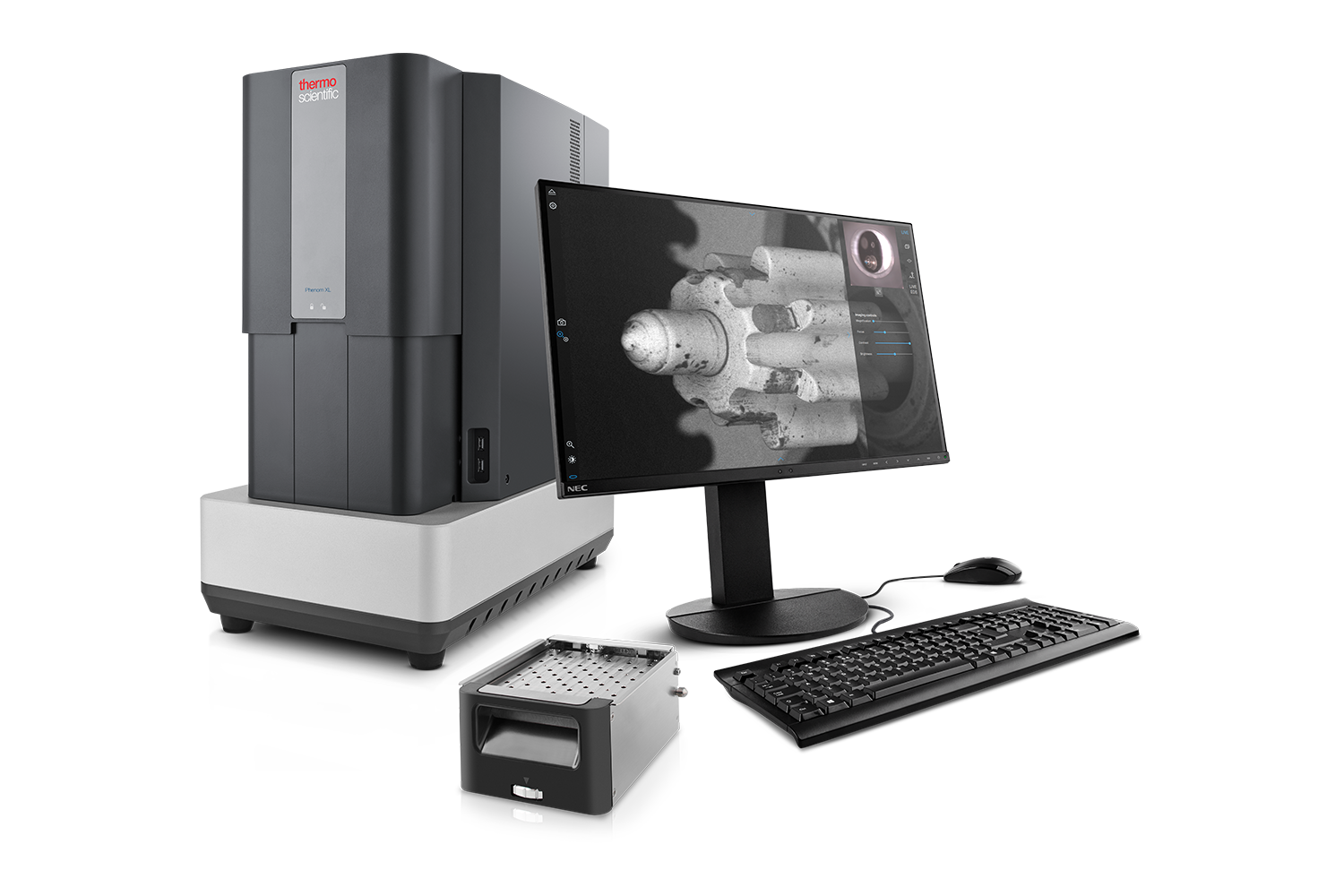

Phenom Scanning Electron Microscope

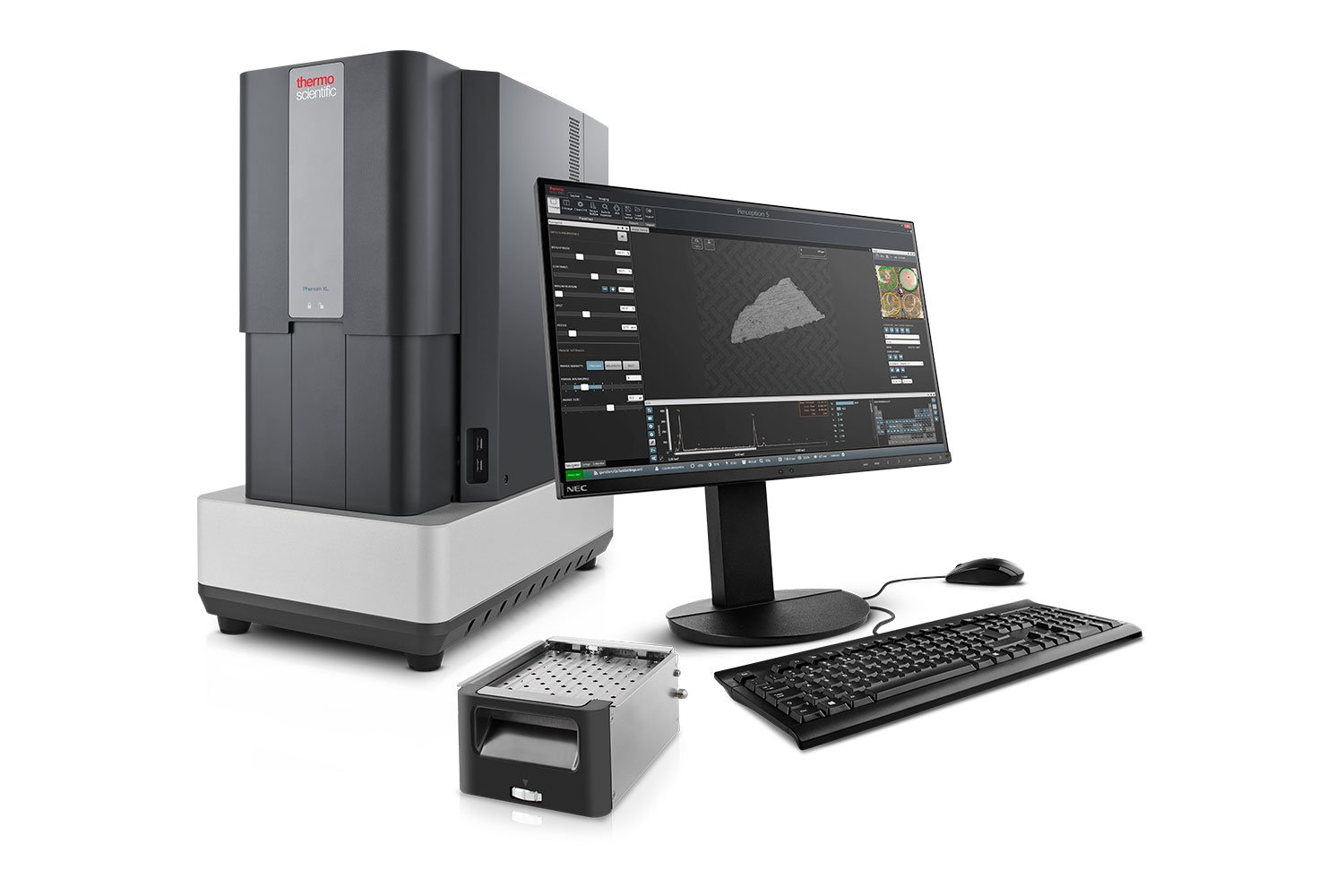

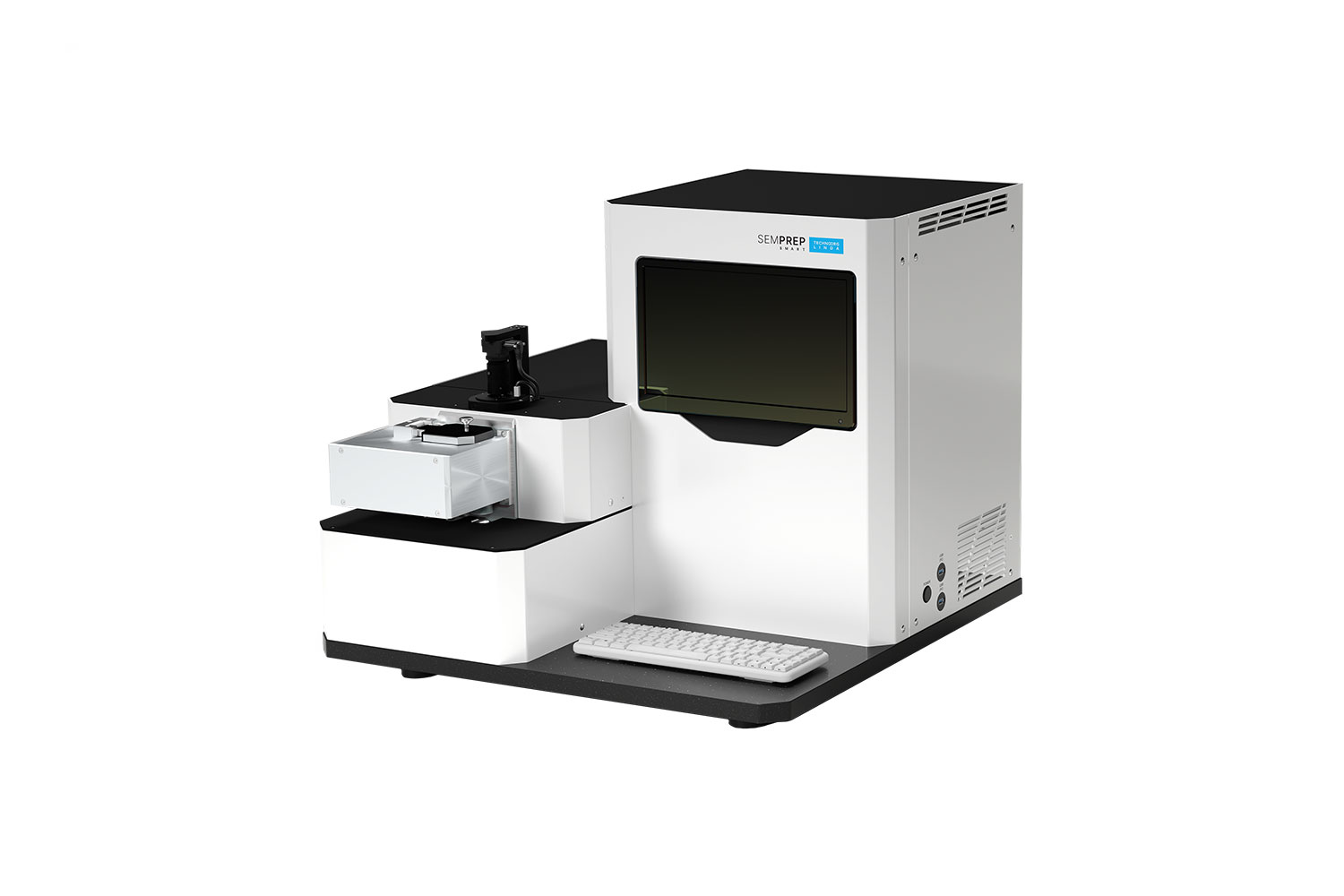

Phenom XL Desktop SEM

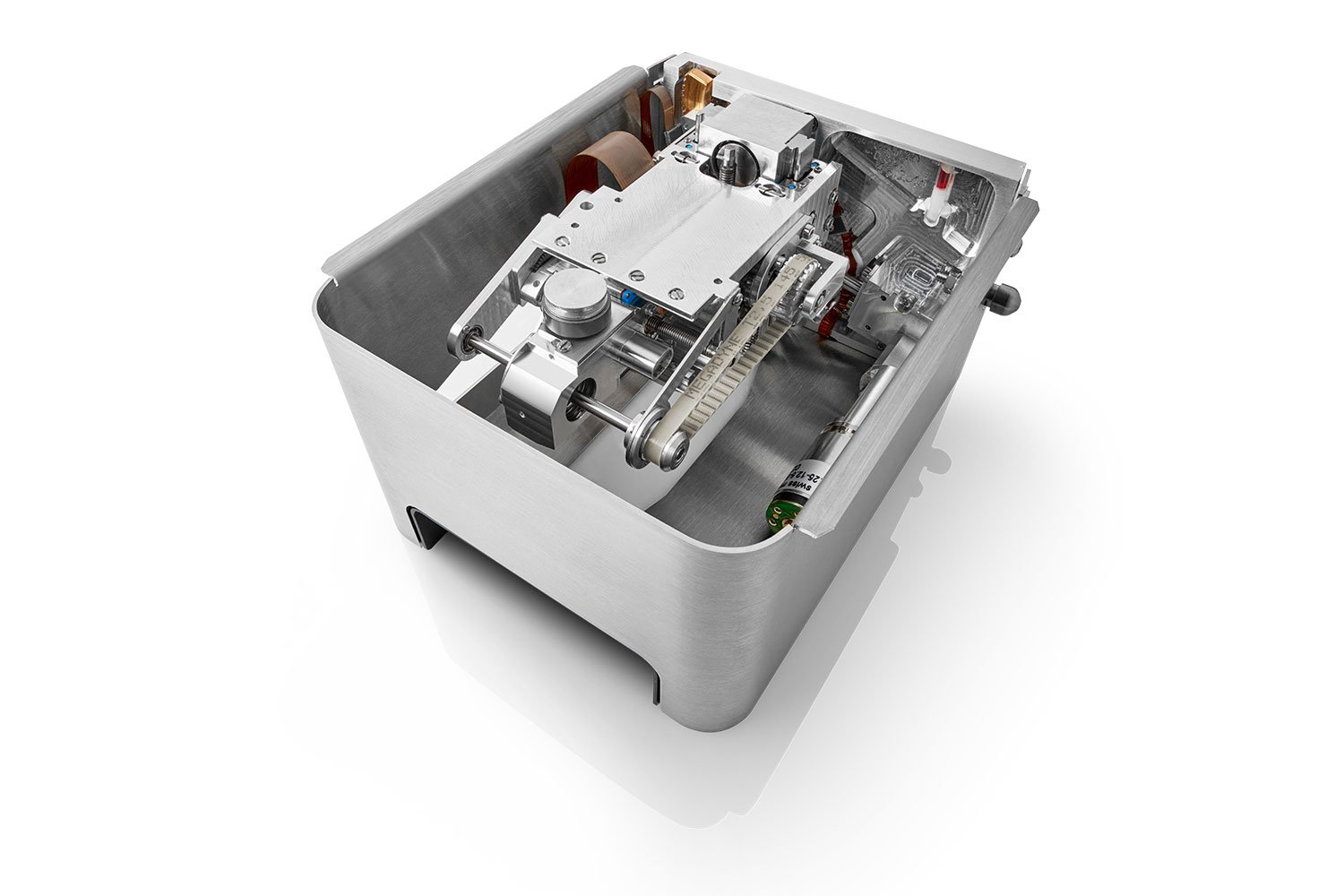

The Phenom XL is a powerful scanning electron microscope (SEM) that combines large sample capacity with an ultra-fast loading mechanism to maximize analysis throughput. It exceeds standard sample size limitations by supporting up to 36 half-inch SEM sample stubs on a 100 mm x 100 mm motorized stage, enabling efficient and versatile sample handling.

Largest Sample Stage

Load up to 36 half-inch SEM stubs in a wide analysis area up to 100 mm x 100 mm.

Automated Imaging & Analysis

Leverage pre-built or custom Python scripts to automate imaging. Integrated Phenom ProSuite for automated image analysis.

Specialized Sample Stages

Motorized eucentric tilting and rotating, tensile testing, vacuum transferring, and resin mounting.

Talk to an Instrumentation Specialist Today!

Best Selling Desktop SEM Empowered with Large Sample Stage

The Phenom XL G2 desktop SEM features the largest sample stage of any desktop SEM and delivers intuitive, automated solutions that reduce manual repetitive tasks. The large chamber enables innovative solutions such as motorized eucentric sample tilting, in situ tensile testing, and electrical feedthrough capabilities. Dry-room and argon compatibile models are available for placing the SEM in inert environments and protecting sensitive samples.

The Phenom XL comes equipped with PyPhenom, a comprehensive Python library that provides users the flexibility to script customizable and automated workflows. It enables the design of personalized GUIs, EDS analysis procedures, and more, enhancing control and efficiency in imaging operations.

Phenom XL Desktop SEM

Product Features

Cerium Hexaboride Crystal Electron Source

Cerium hexaboride (CeB6) crystals, used as thermionic electron sources, deliver superior image quality with sharper resolution and enhanced contrast. These robust electron sources are more durable than traditional tungsten filaments, lasting over 30 times longer. Unlike tungsten filaments, these sources are not susceptible to catastrophic failures and degrades gradually. This enables the users to schedule replacement of the source as part of routine maintenance.

Proven Ease-of-Use Operation

Live SEM images, an optical overview, clean menus, and straightforward controls culminate into an accessible and intuitive, friendly user experience.

Flexible Integration & Minimal Footprint

Phenom Desktop SEMs are designed to deliver the capabilities of larger SEMs in a more compact and versatile form. Their streamlined design allows them to fit seamlessly into any workspace, whether on a surface or tabletop. With built-in vibrational stability, the Phenom offers a highly durable and robust SEM solution suitable for a wide range of applications.

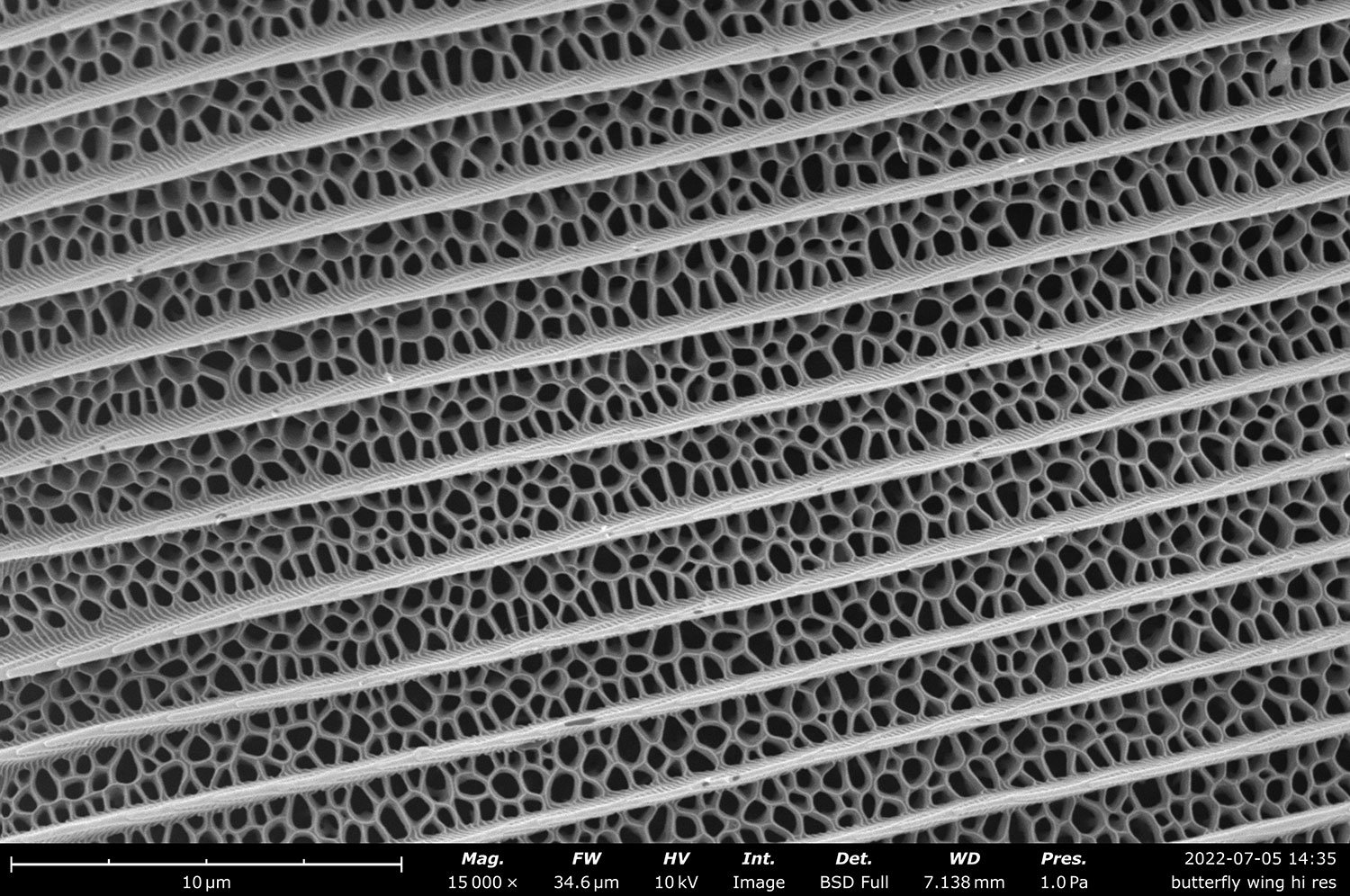

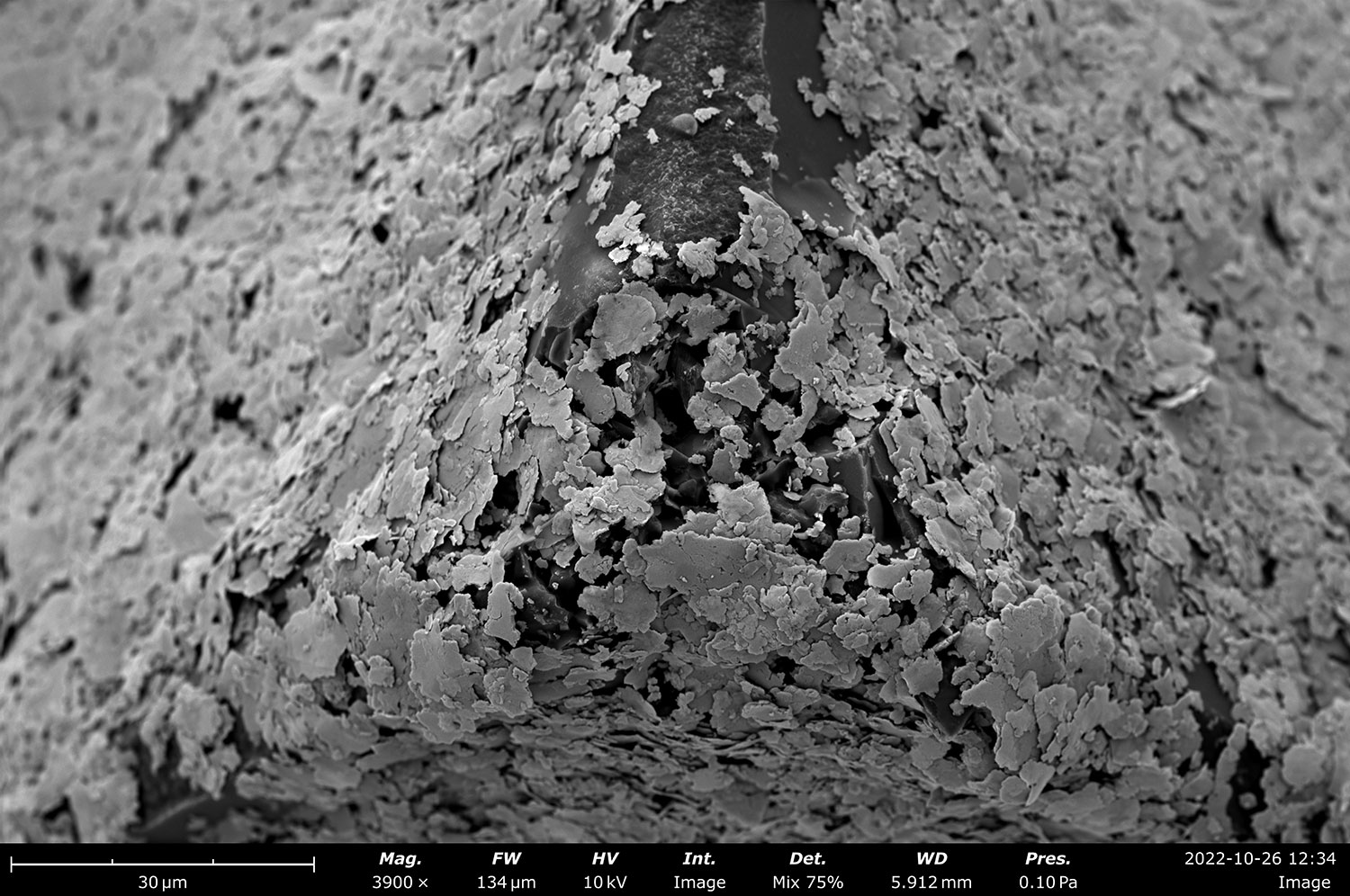

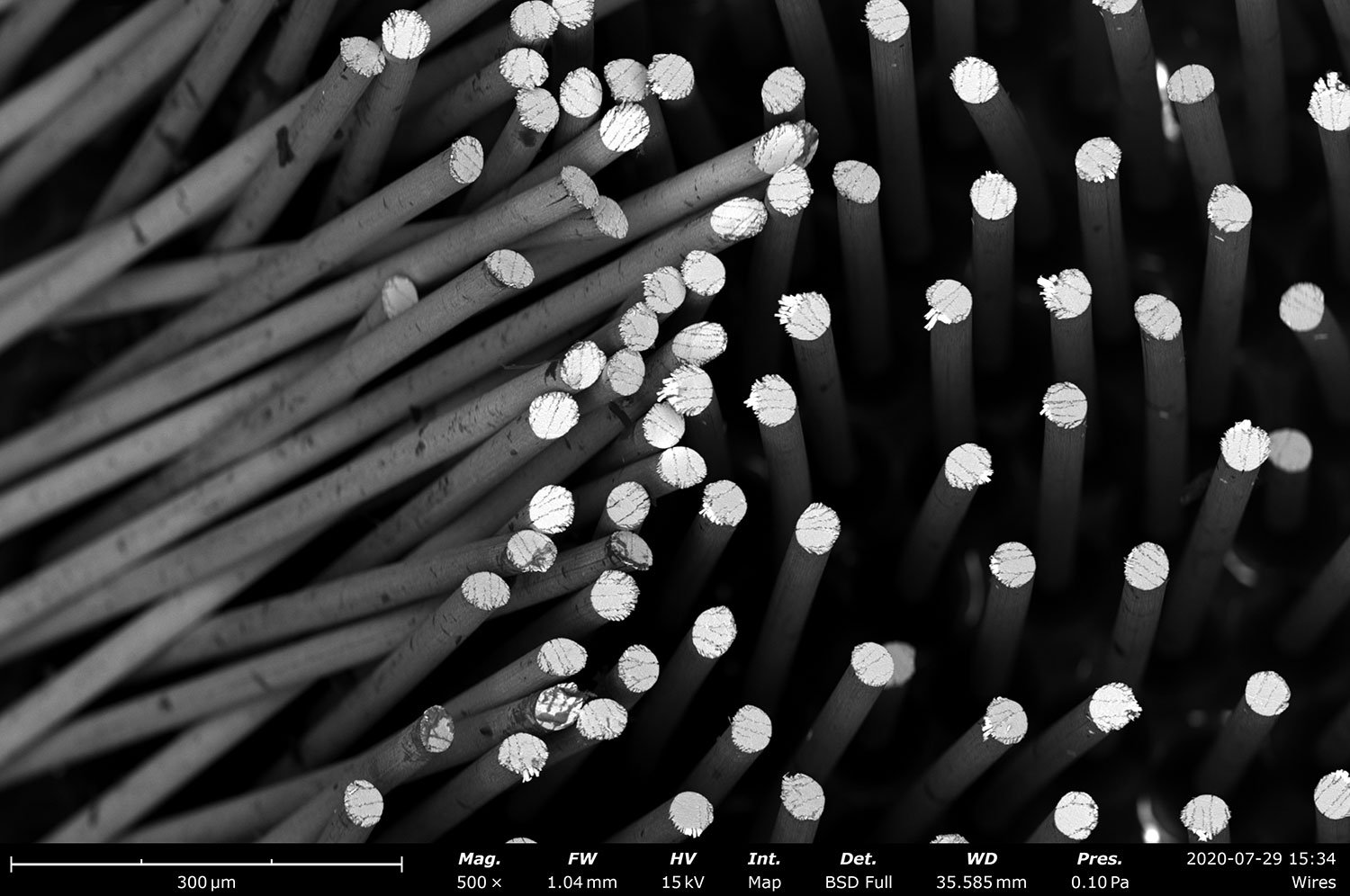

Four-Segment Backscattered Electron Detector (BSD)

The four-segmented backscattered electron detector (BSD) delivers sharp compositional contrast between light and heavy elements. Included as a standard feature in every Phenom system, it also offers topographic modes for qualitative visualization of surface roughness, enhancing surface detail and material differentiation.

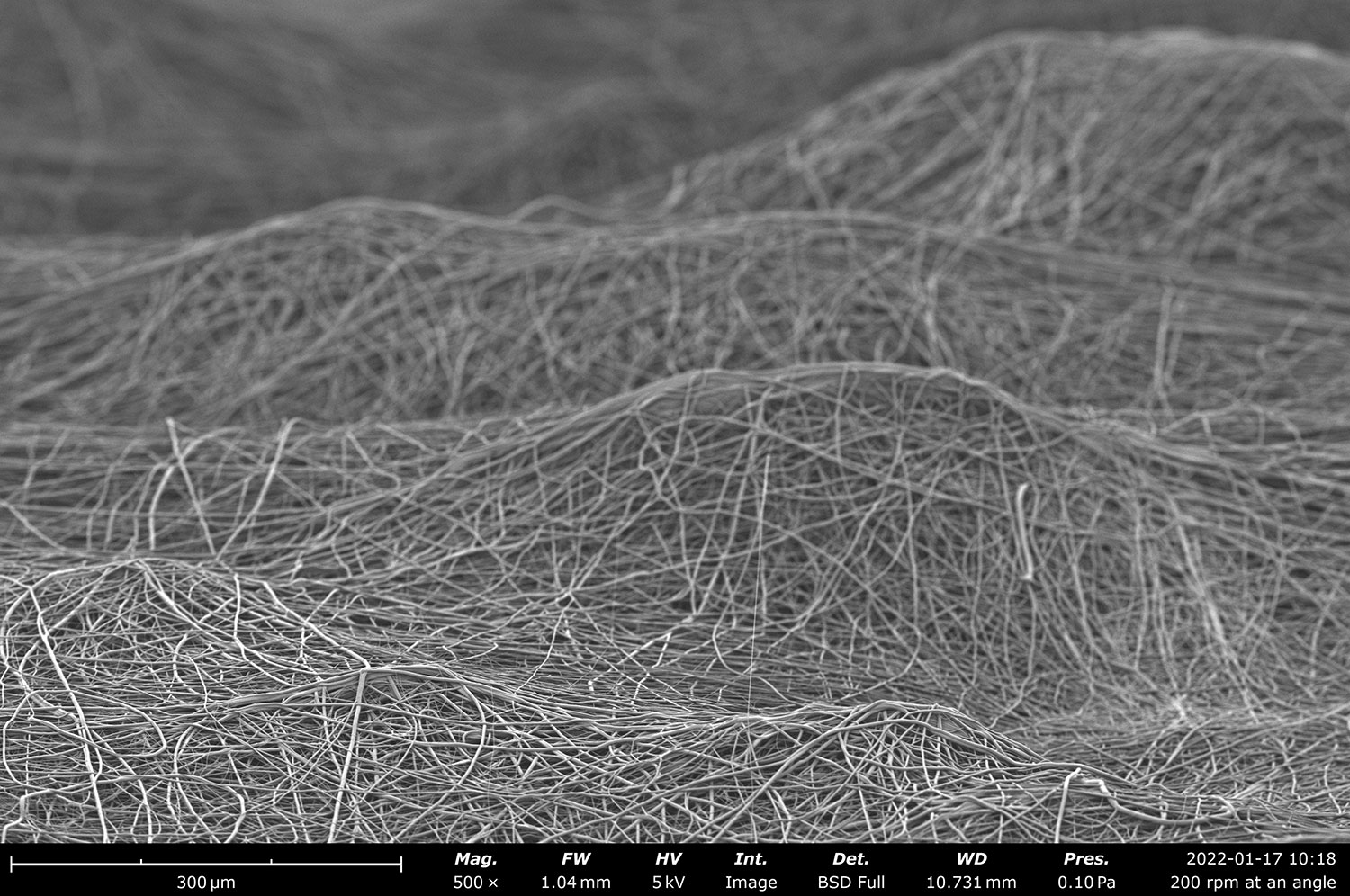

Secondary Electron Detector (SED)

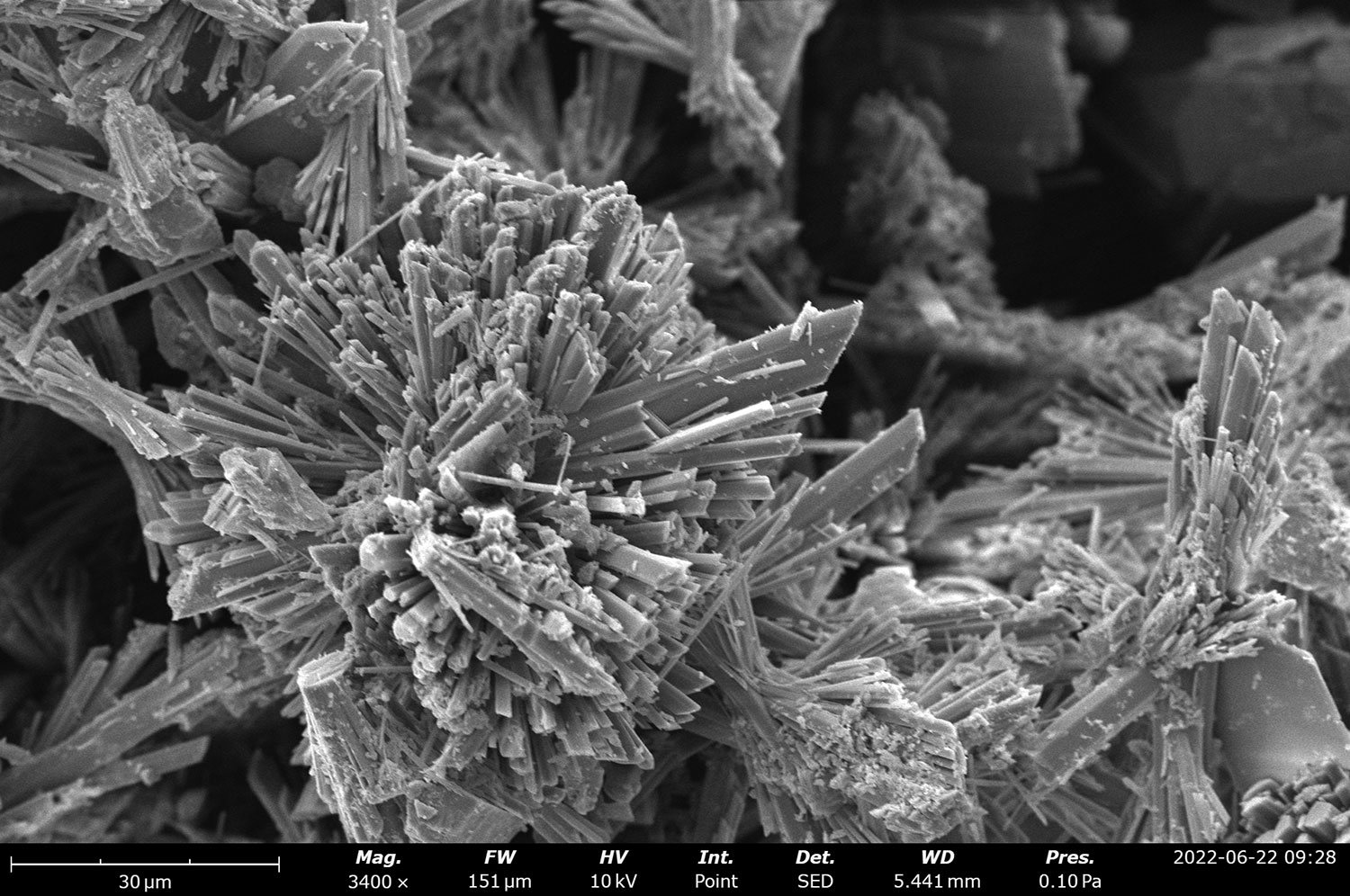

Secondary Electron Detectors (SED) are perfect for high-resolution, surface-sensitive SEM imaging, providing detailed topographical information through secondary electron emissions. This allows for crisp visualization of fine surface features. With an SED, Phenom users can also activate a mixed mode, combining both SED and BSD signals at a customizable ratio for comprehensive imaging analysis.

Energy Dispersive X-ray Spectroscopy Detector (EDS)

Energy Dispersive X-Ray Spectroscopy (EDS) detectors are fully integrated into Phenom SEMs, enabling efficient quantitative surface chemistry analysis. EDS provides rapid and precise results across multiple analysis modes, including regions, points, and lines, making it a versatile tool for a wide range of applications.

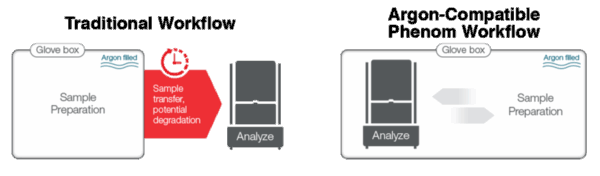

Argon-Compatible Model Available

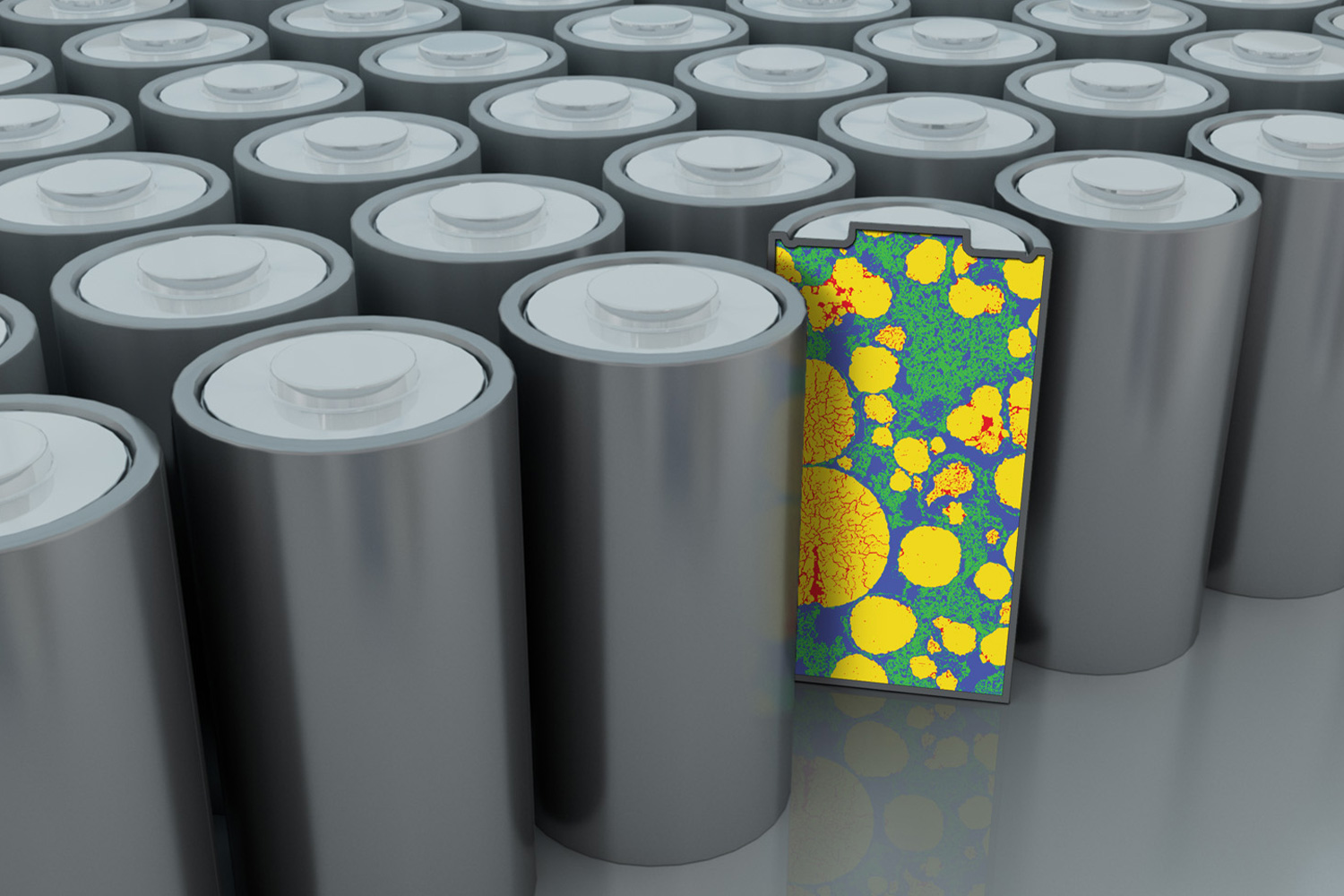

The newest variation of the Phenom XL G2 desktop scanning electron microscope (SEM) was designed to be used in argon-filled gloveboxes to study materials that require non-reactive environmental conditions to prevent sample degradation. The compact footprint, easy workflow, and automation capabilities of the system enable the completion of a full SEM workflow inside a glovebox while maintaining conditions that minimize the risk of sample degradation.

From sample preparation and imaging to performing elemental analysis (EDS), users can maintain sample integrity and complete experiments faster without sacrificing performance.

Phenom XL Desktop SEM

Accessories

Eucentric Stage

The only eucentric tilt stage available on a desktop SEM, featuring six motorized axes that offer precise control over height, tilt, and rotation, all while maintaining perfect focus on the sample.

Tensile Testing Stage

Examine material properties in the SEM under forces of up to 1 kN, with the software plotting the force vs. displacement curve.

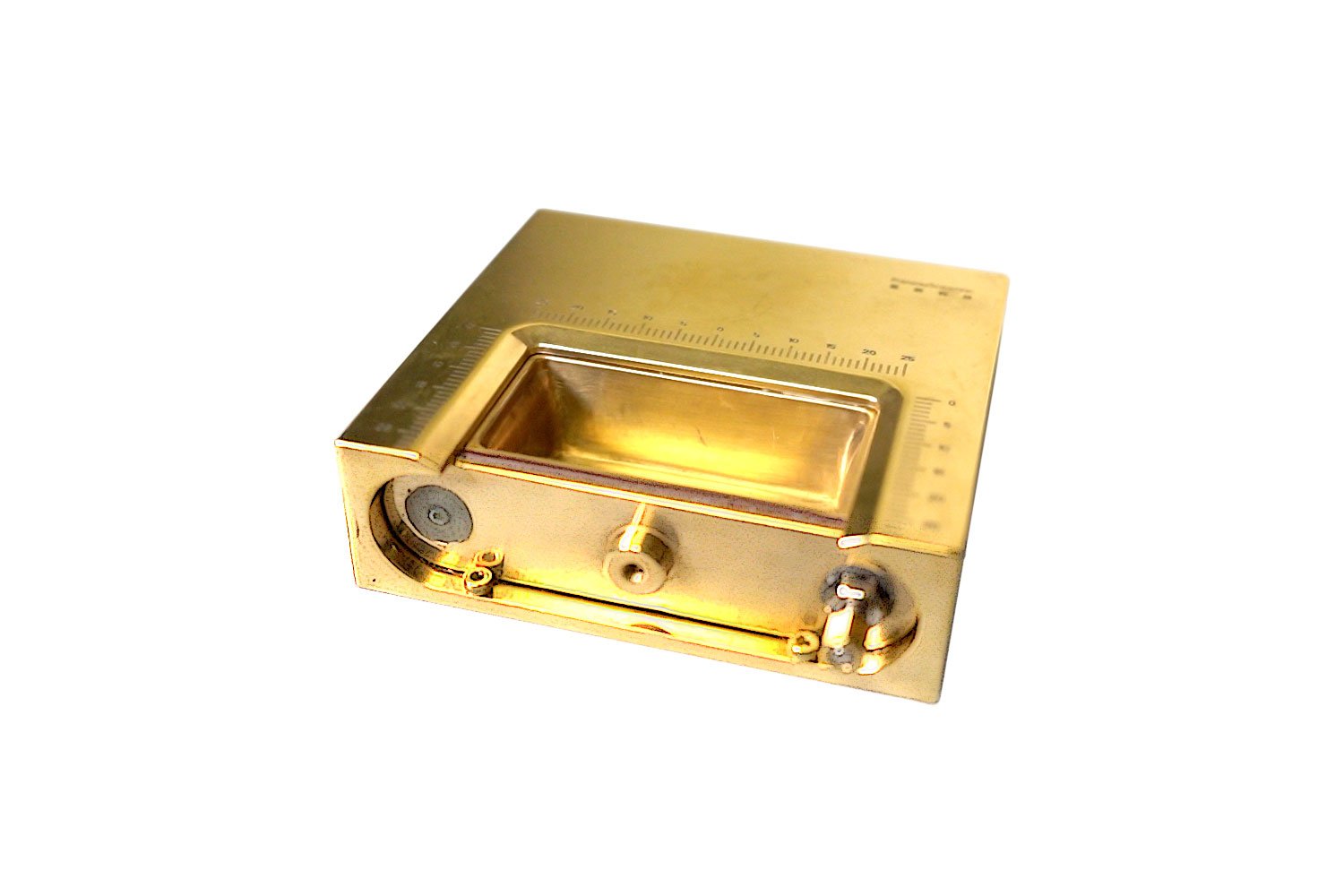

Resin Mount & Metallurgical Stage Inserts

Ensure a uniform working distance across multiple polished samples, which is especially beneficial for accurate quantitative EDS analysis.

Filter Stage Inserts

Secure delicate filter and membrane samples firmly without the need for carbon tape, ensuring accurate SEM imaging and EDS analysis.

Vacuum Transfer Box

Prepare sensitive samples in a glove box and transfer them in an enclosed transfer box to maintain an inert atmosphere during the transition to the SEM.

Phenom XL Desktop SEM

Software

Python-Based Automation (PPI & PPA)

Expand the capabilities of your Phenom Desktop SEM with PyPhenom, a Python-based library for custom programming. Create your own workflows to control microscope hardware and automate data analysis (PPI) or have us develop a tailored automated workflow for you (PPA).

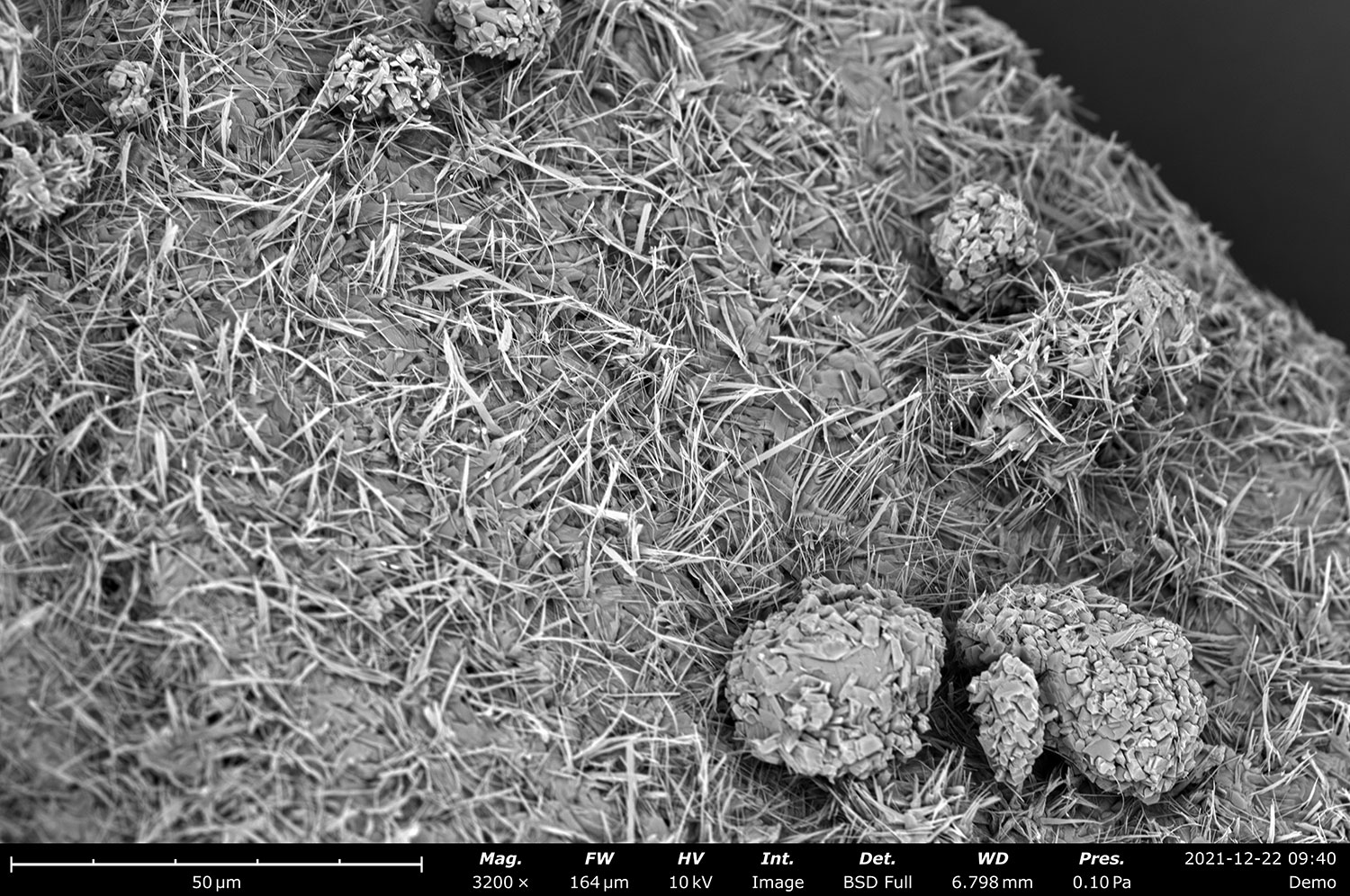

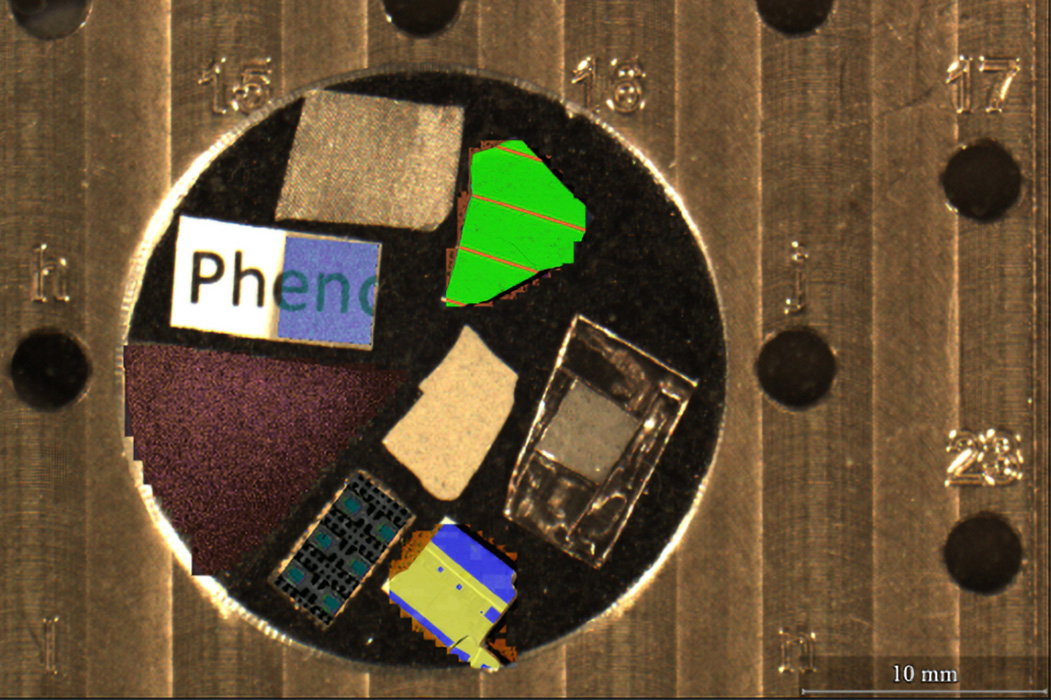

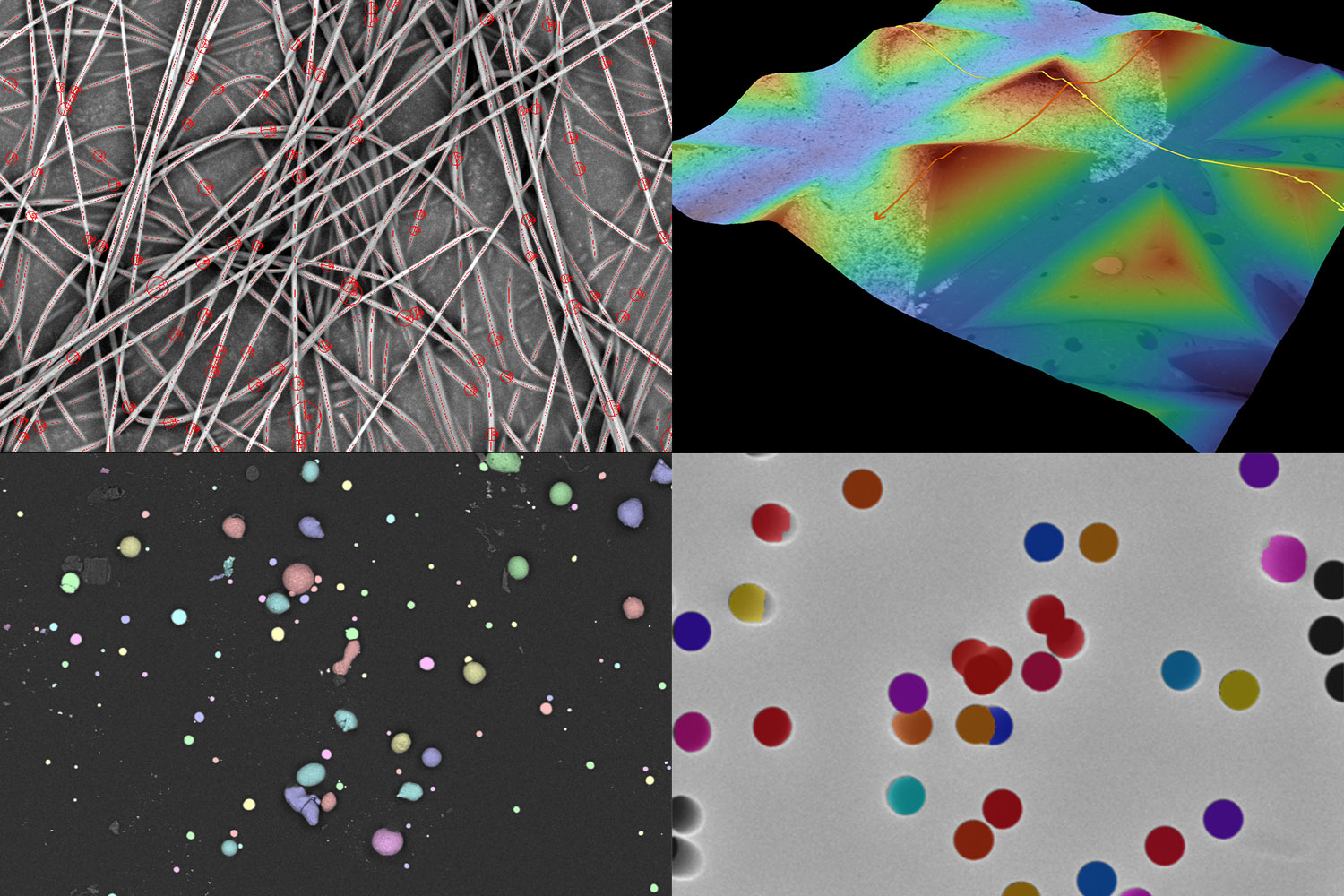

Phenom Prosuite Software

ProSuite Software, developed specifically for Phenom SEMs, enhances data throughput and eliminates user bias from manual measurements, ensuring more accurate and reliable results. It can extract actionable data on the size and shape of features in SEM images.

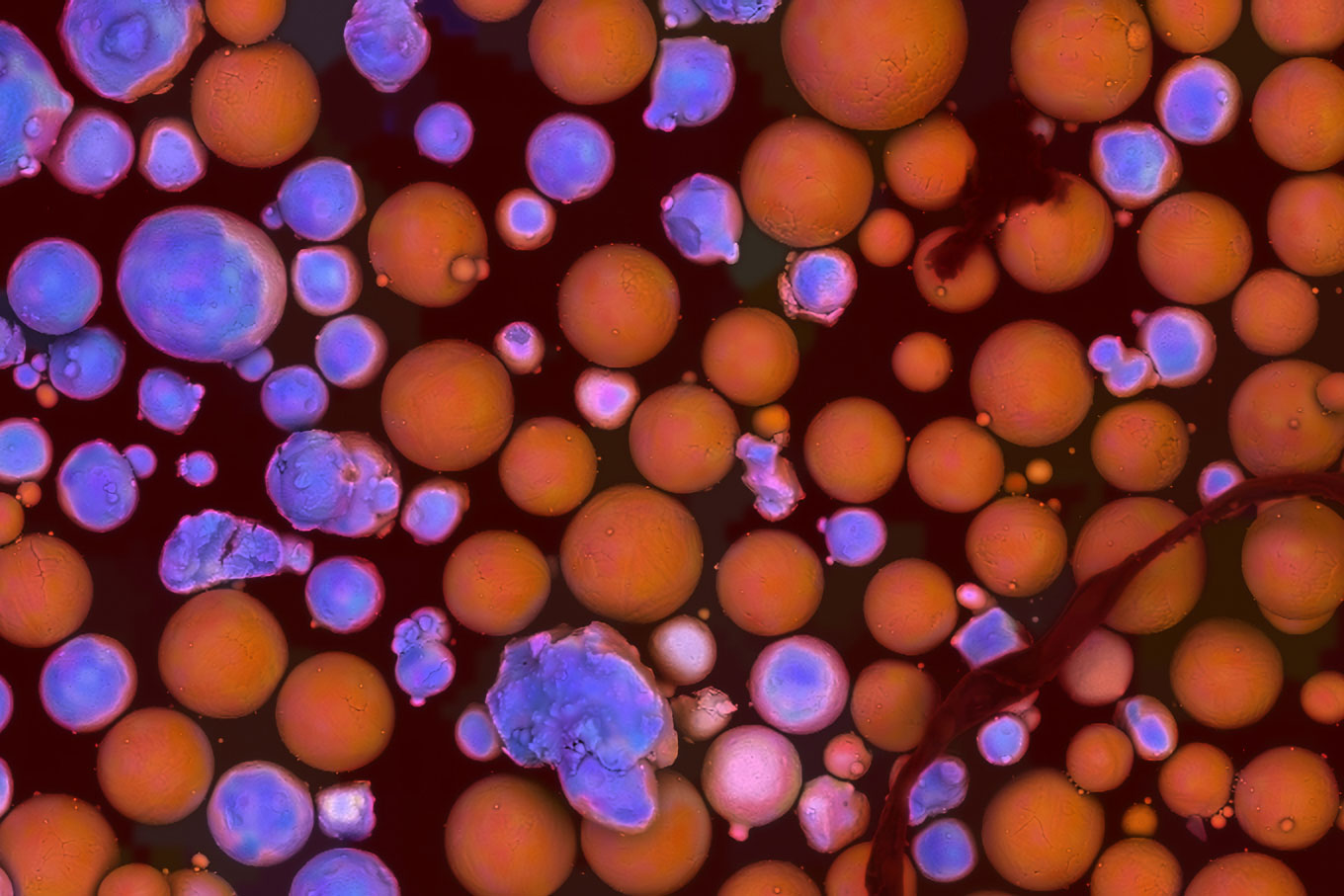

ParticleX: Automated SEM/EDS for Particle Analysis

ParticleX is an advanced software package that enables automated data collection, particle analysis, and report generation for Phenom SEM/EDS systems. Ideal for manufacturing environments, it integrates sophisticated algorithms, autonomous workflows, and comprehensive documentation into a single, industry-leading solution.

MAPS

Avizo Trueput

ChemiSEM / ChemiPhase

Streamline elemental and phase analysis with integrated data collection and advanced analysis capabilities. ChemiSEM provides real-time elemental mapping during live imaging and ChemiPhase transforms EDS maps into color-coded phase maps.

Phenom XL Desktop SEM

SEM Sample Preparation

Sputter Coaters

Minimize electric charging and enhance SEM image quality with uniform gold and platinum coatings.

Ion Mills

Prepare artifact-free samples for high quality cross-sectional analysis. Especially useful for EBSD and failure analysis.

Nebula Particle Disperser

The Nebula is designed to assist in dispersing powder samples, facilitating their preparation for SEM analysis.

Phenom XL Desktop SEM

Product Knowledgebase

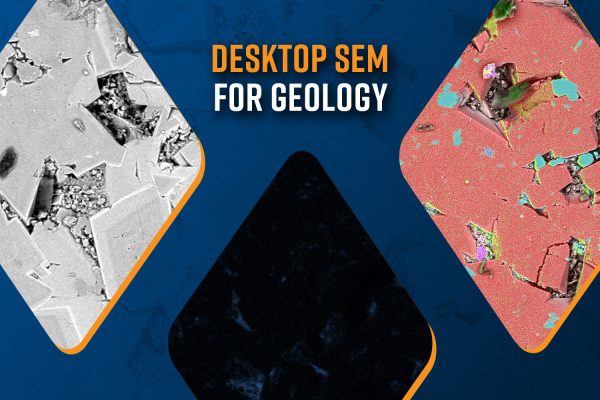

Applications for Desktop SEM in Geology

Scanning Electron Microscopy (SEM) has become a vital tool in geology, offering high-resol…

Desktop Scanning Electron Microscopy in Geology

Scanning Electron Microscopy (SEM) is a versatile tool in geology used in high-resolution…

Automated SEM/EDS Monitoring of Steel Inclusions for Compliance with ASTM Standards

In modern steel manufacturing, non-metallic inclusions represent a critical quality concer…