Biolin QCM-D Instruments

QSense™ Modules

The QSense QCM-D systems come equipped with standard flow modules, which enables a wide variety of aqueous and gas-phase experiments. Many other specialized modules are available to support experiments that require the use of additional technologies in combination with QCM-D or involve extreme temperature and/or pressure conditions. These plug-and-play modules offer expanded capabilities such as electrochemical impedance spectroscopy (EIS), ellipsometry, fluorescence or optical microscopy, and more.

Talk to an Instrumentation Specialist Today!

QSense Teflon™ Flow Module

The PTFE Flow Module is suitable for flow or stagnant measurements where the reagents or molecules are sensitive to interactions with titanium. The Teflon™ flow module is similar to the QSense standard Flow Module but the titanium flow part is exchanged for Teflon™-like (PTFE).

The parts exposed to liquid in a Teflon Flow Module are the flow chamber of the module made of Teflon and O-ring made of Viton. More chemically resistant options are available upon request. QSense Teflon Flow Module is useful for samples that contain harsh chemicals that may etch titanium, or samples that may interact with titanium and aggregate on the titanium in the standard flow module.

| Specifications | ||

|---|---|---|

| Compatibility | Compatible with all QSense sensors, QSense Explorer, Analyzer, Pro (via an add-on Explorer chamber), and Omni (via an add-on Orbit chamber) | |

| Internal volume | 100 μl (above the sensor) | |

| Type of measurements | Flow or stagnant liquid or gas measurements | |

| Maximum temperature | 110 °C | |

| Materials exposed to liquid | Viton® (standard O-ring) or Kalrez® (high resistance O-ring), PTFE (flow path) | |

| Cleaning | All parts may be disassembled for separate cleaning, except the module base contacting the chamber platform | |

QSense Electrochemistry Window Module

The QSense Window Electrochemistry Module is designed to combine Quartz Crystal Microbalance with Dissipation Monitoring and Electrochemical measurements (EQCM-D) with microscopy. The module can also be used to perform light sensitive EC experiments combined QCM-D. The window, made from a 1 mm thick quartz or sapphire glass microscopy slide allows optical access to the sensor surface that also acts as working electrode (WE). A platinum ring sputtered on glass window acts as a counter electrode (CE) The reference electrode (RE) is placed in the outlet flow path.

| Specifications | ||

|---|---|---|

| Compatibility | Compatible with all QSense sensors, QSense Explorer, Analyzer, Pro (via an add-on Explorer chamber), and Omni (via an add-on Orbit chamber) | |

| Internal volume | 100 μl (above the sensor) | |

| Type of measurements | Flow or stagnant liquid measurements | |

| Glass | 1 mm thick Sapphire | |

| Window dimensions | 16.6 mm x 7.2 mm | |

| Materials exposed to liquid | Titanium (flow path), Sapphire (glass), platinum (counter electrode), Viton® (standard O-ring) or Kalrez® (high resistance O-rings) and Polyurethane-based polymer (reference electrode) | |

| Maximum temperature | 40 °C | |

| Working distance | 3.3 mm | |

| Bench to objective distance | 35 mm | |

| Cleaning | All parts may be disassembled for separate cleaning, except the module base contacting the chamber platform | |

QSense Ellipsometry Module

The QSense ellipsometry module enables simultaneous QCM-D flow experiments and ellipsometric measurements on the same substrate. The complementing measurements allow for greater insight into the hydration properties of the surface and molecules being measured.

The ellipsometry module is used in the Explorer or Orbit chamber which can be mounted on the stage of the ellipsometer (not included) due to their compact design.

| Specifications | ||

|---|---|---|

| Compatibility | QSX 301 (gold) and QSX 335 (SiO2 with thick titanium adhesion layer). Other QSense sensors can be used but may be difficult to optically characterize. Compatible QSense Explorer, Analyzer, Pro (via an add-on Explorer chamber), and Omni (via an add-on Orbit chamber) | |

| Optical sensor characterization | Each sensor may not provide the same optical response. It is recommendable to individually measure the optical properties of each sensor. An example of characterization is available in a separate technical note. | |

| Internal cell volume | Above sensor ~100 µl | |

| Type of measurements | Flow or stationary liquid measurements | |

| Maximum temperature | 80 °C | |

| Materials exposed to liquid | Viton® (standard O-rings and sealing gasket) or Kalrez® (high resistance O-rings and sealing gasket), PTFE (tubing connector), titanium (flow channel), 1/4 Wave fused silica (optical glass window) | |

| Cleaning | All parts may be disassembled for separate cleaning, except the module base contacting the chamber platform | |

QSense Humidity Module

Compatible with all QSense systems, the humidity module enables QCM-D measurements in a humidity controlled enviroment. The sensor surface of this module is separated from the liquid flow by a GORE™ membrane, creating an air-filled compartment over the sensor. Flowing saturated salt solutions over the membrane will generate a specific and controlled relative humidity in the volume above the sensor surface.

Typical applications include vapor uptake and release by the film coated on sensor surface, swelling and shrinking of the polymer films in humid environment and stability of film under certain relative humidity.

| Specifications | ||

|---|---|---|

| Compatibility | Compatible with all QSense sensors, QSense Explorer, Analyzer, Pro (via an add-on Explorer chamber), and Omni (via an add-on Orbit chamber) | |

| Internal volume | Air pocket: 100 mm3 between the sensor and the membrane Liquid flow system: 120 μl from inlet to outlet (above membrane) | |

| Type of measurements | Vapor sorption / desorption | |

| Maximum temperature | 70 °C | |

| Materials exposed to liquid | Viton® (O-ring and sealing gasket), titanium (flow path), GORE-membrane | |

| Cleaning | All parts may be disassembled for separate cleaning, except the module base contacting the chamber platform. Do not use surfactants to clean the membrane, only pure water. | |

QSense Electrochemistry Module

The QSense Electrochemistry Module allows for simultaneous Quartz Crystal Microbalance with Dissipation Monitoring and Electrochemical measurements (EQCM-D) or QCM-D and Electrochemical Impedance Spectroscopy (EIS) measurements (Technology note). The design enables flow measurements and withstands the harsh conditions necessary for some electrochemistry applications.

| Specifications | ||

|---|---|---|

| Compatibility | Compatible with all QSense sensors, QSense Explorer, Analyzer, Pro (via an add-on Explorer chamber), and Omni (via an add-on Orbit chamber) | |

| Internal cell volume | Total ~125 μl Flow channel ~25 μl, above sensor ~100 μl |

|

| Type of measurements | Flow or stationary liquid measurements | |

| Maximum temperature | 40 °C | |

| Materials exposed to liquid | Teflon® (tubing and flow channels), Platinum (counter electrode), Viton® (standard O-rings) or Kalrez® (high resistance O-rings), Polyurethane-based polymer (reference electrode) | |

| Cleaning | All parts may be disassembled for separate cleaning, except the module base contacting the chamber platform | |

QSense Window Module

Compatible with all QSense systems, this optional flow cell module allows for optical access to the sensor surface through sapphire window for studying the light induced reactions and fluorescence detection. When combined with the compactly designed QSense Explorer chamber platform, which fits most upright and fluorescence microscope stages, optical microscopy of the sensor surface is possible.

| Specifications | ||

|---|---|---|

| Compatibility | Compatible with all QSense sensors, QSense Explorer, Analyzer, Pro (via an add-on Explorer chamber), and Omni (via an add-on Orbit chamber) | |

| Internal volume | 100 μl (above the sensor) | |

| Type of measurements | Flow or stagnant liquid measurements | |

| Maximum temperature | 80 °C | |

| Glass | 1 mm thick Sapphire | |

| Window dimensions | 16.6 mm x 7.2 mm | |

| Materials exposed to liquid | Viton® (standard O-ring) or Kalrez® (high resistance O-ring), titanium (flow path) and Sapphire (glass) | |

| Working distance | 3.3 mm | |

| Bench to objective distance | 33 mm | |

| Cleaning | All parts may be disassembled for separate cleaning, except the module base contacting the chamber platform | |

QSense Flow Module

This standard QSense Flow Module is included with the Explorer (one module) and Analyzer (four modules) instruments. The standard flow modules offer high flexibility in terms of chemical compatibility (aqueous and non aqueous), flow conditions (static and flow), temperature, and gas phase measurements at atmospheric pressure. The brilliant design of the flow module ensures a homogenous flow profile leading to even sample exposure, reduced risk of trapping air bubbles, and excellent thermal stability.

The parts of a standard flow module that are exposed to the fluid are the body of the module made of titanium, and the O-rings and sealing gaskets made of Viton. More chemically resistant materials are available upon request.

Ideal for liquid-based experiments for monitoring mass and viscoelastic changes of surfaces.

| Specifications | ||

|---|---|---|

| Compatibility | Compatible with all QSense sensors, QSense Explorer, Analyzer, Pro (via an add-on Explorer chamber), and Omni (via an add-on Orbit chamber) | |

| Internal volume | Total ~140 μl Flow channel ~100 μl, above sensor ~40 μl |

|

| Type of measurements | Flow or stagnant liquid or gas measurements | |

| Maximum temperature | 150 °C (if “H” inscripted) | |

| Materials exposed to liquid | Viton® (standard O-rings and sealing gasket) or Kalrez® (high resistance O-rings and sealing gasket) and titanium (flow path) | |

| Cleaning | All parts may be disassembled for separate cleaning, except the module base contacting the chamber platform | |

| Specifications | ||

|---|---|---|

| Compatibility | Compatible with all QSense sensors, QSense Explorer, Analyzer, Pro (via an add-on Explorer chamber), and Omni (via an add-on Orbit chamber) | |

| Maximum pressure | No limit | |

| Type of measurements | Gas measurements in vacuum and high pressure chambers | |

| Maximum temperature | 250 °C | |

| Materials exposed to gas | Stainless steel (holder and ring), Macor (holder), aluminum (holder) and Kapton (cable | |

| Dimensions | Height: 5 mm; Width: 24 mm; Depth: 32 mm | |

| Length of cables | Electronics unit to vacuum/high pressure chamber: 80 cm. Vacuum/high pressure chamber to ALD holder: 1 m | |

| Other: | ||

| Customer installation/adaption required. | ||

| Delivered with 2 cables: one to connect the ALD holder to the inside of the vacuum or high pressure chamber and one to connect the chamber to the QCM-D electronics unit. | ||

| Screw holes to enable mounting in vacuum/high pressure chamber. | ||

QSense Open Module

The open module is an optional module compatible with all Q-Sense systems. It is designed for low volume (10 – 300 µl) samples. The Open Module allows direct access to the sensor surface where minimal amount of samples can be directly pipetted to cover the sensor surface. A Teflon lid is included to avoid evaporation of samples and to improve measurement stability.

Ideal for evaporation studies, deposition from low volume samples, and external triggered reactions.

| Specifications | ||

|---|---|---|

| Compatibility | Compatible with all QSense sensors, QSense Explorer, Analyzer, Pro (via an add-on Explorer chamber), and Omni (via an add-on Orbit chamber) | |

| Internal volume | Application dependent due to wetting of the surface, typical range is 10-300 μl | |

| Type of measurements | Stagnant liquid measurements | |

| Maximum temperature | 110 °C | |

| Materials exposed to liquid | Viton® (O-ring), PTFE (module) | |

| Cleaning | All parts may be disassembled for separate cleaning, except the module base contacting the chamber platform | |

QSense™ Modules

Product Knowledgebase

Using QSense QCM-D to Assess & Optimize Cleaning Efficiency

Analyze cleaning process dynamics, surface etching, and surface residual! In this webinar…

Evaluating Alternative Techniques for Real-Time Monitoring of Molecular Interactions at Surfaces

Understanding molecular interactions at surfaces is essential for advancing fields such as…

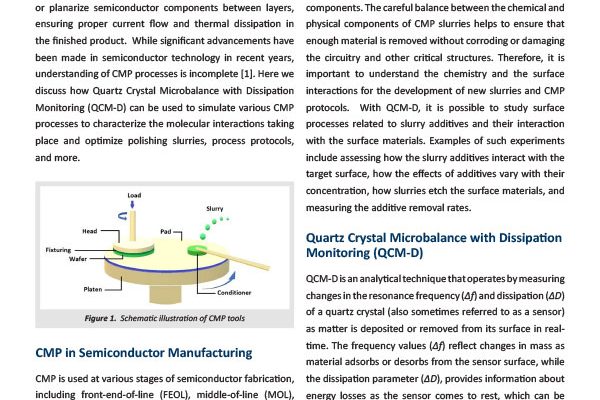

Optimizing Chemical Mechanical Planarization (CMP) Processes with QCM-D

Chemical mechanical planarization (CMP), also called chemical-mechanical polishing, is a c…

QSense QCM-D Publication Finder

Over 5000 publications available!