Twin screw extruders are among the most versatile processing equipment used in polymer compounding, pharmaceutical hot-melt extrusion, food production, and advanced materials research. They provide the precision and flexibility needed for complex formulations. Twin screw extruders offer superior mixing, enhanced process control, and facile scalability making them indispensable in industries where performance and consistency are critical.

This article explores the basics of a twin screw extruder, common configurations, their applications across industries, and the benefits they deliver.

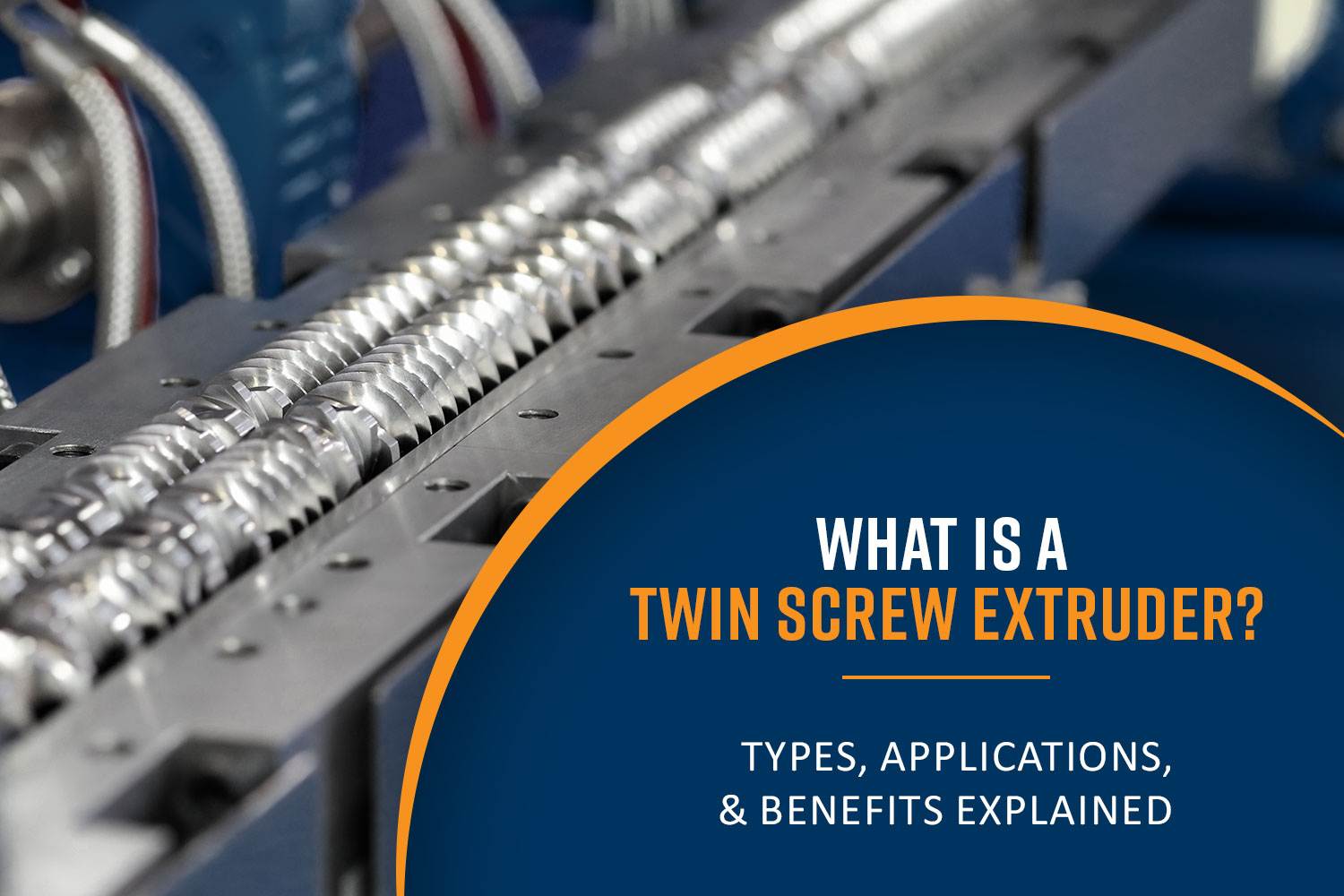

What is a Twin Screw Extruder?

A twin-screw extruder uses two rotating screws inside a barrel to continuously mix, convey, and process materials.1 Depending on the screw configuration, the extruder can provide high shear mixing, gentle compounding, or efficient material transport. Unlike single screw extruders, which mainly melt and convey material, twin screw extruders are engineered for mixing and compounding complex formulations including incorporating fillers, additives, and multiple components with high precision.

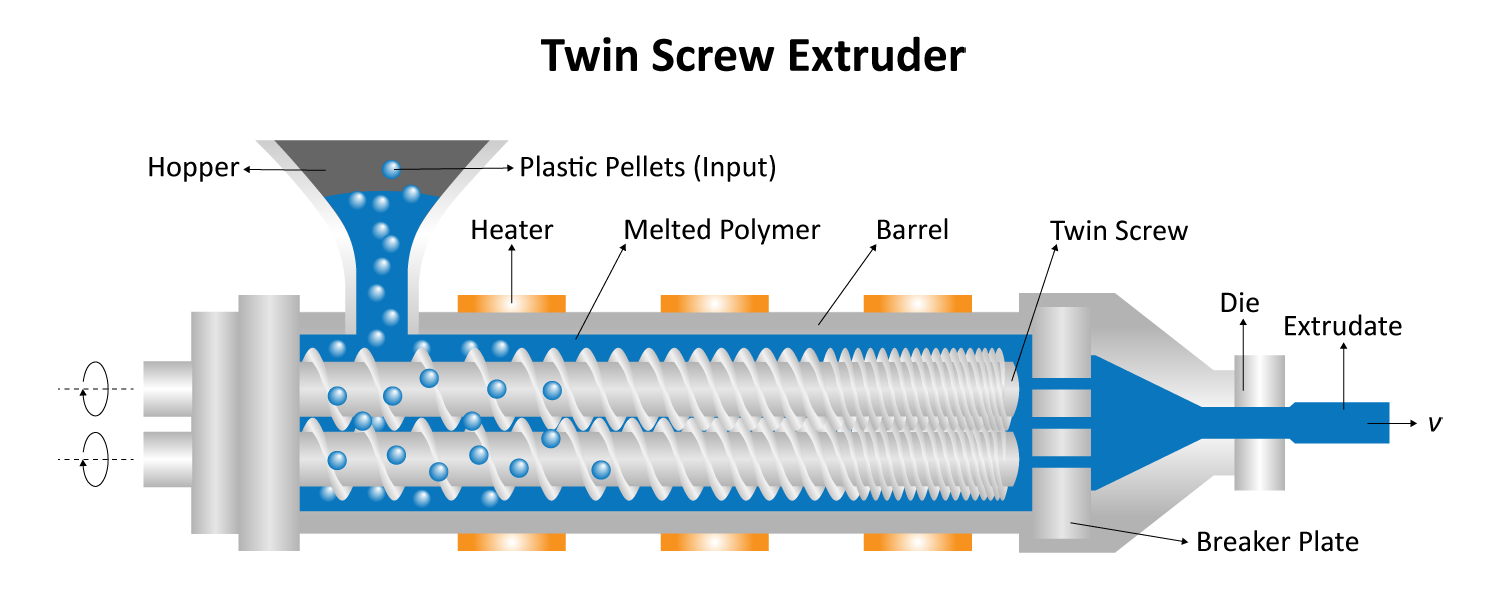

A twin-screw extruder consists of the feeding system, barrel, screws, drive, heating/cooling, venting, die, controls, and downstream equipment (Figure 1). The feeding system usually consists of a hopper where the raw materials are introduced to a feed throat that guides the material from the hopper into the screws. In certain cases, side feeders, injectors, or syringes are used to introduce additional components in many phases including solids, liquids, or powders to controlled points along the barrel. Some examples of these additives includes fillers and fibers. The barrel is a cylindrical housing that encloses the screws and is usually made of a hard material to resist wear and corrosion, even when exposed to abrasive or corrosive materials. Heating and cooling elements are an essential part of the barrel design that maintains precise temperature control. Circulating water or oil is occasionally used to prevent overheating in the barrel. The heart of the twin screw extruder is a pair of intermeshing screws that can be configured for ideal conveying, kneading, or mixing. The screw shape, diameter, pitch, and residence time define throughput and mixing capability. The drive system, consisting of the motor and gearbox provide the power to rotate the screws. The gearbox synchronizes screw rotation and regulates motor speed to optimize torque.

The twin screw extruder often includes venting and degassing zones. Atmospheric vents remove entrapped air and volatile gases while vacuum vents extract moisture, solvents, or low-molecular-weight compounds. A computerized control system monitors and adjusts the process parameters, controls temperature zones, screw speed, torque, pressure, and feed rates. This ensures reproducibility and compliance with regulatory standards. The die assembly shapes the molten homogenized extrudate as it exits the barrel and is customized to form the desired product shape including rods, films, tubes, mono-, and multi-filaments.

Types of Twin Screw Extruders

Twin screw extruders are categorized based on screw rotation direction (co-rotating or counter-rotating), geometry (parallel or conical), and application design.

Co-Rotating:

Co-rotating means that both screws rotate in the same direction, delivering outstanding dispersive and distributive mixing. This makes co-rotating extruders the preferred choice for demanding mixing and compounding applications such as polymer compounding, nanocomposites, pharmaceutical hot-melt extrusion, food texturization, and bio-based polymer processing.

Counter-Rotating:

In counter-rotating twin screw extruders, the screws turn in opposite directions. This generates strong conveying forces while applying lower shear between the screw flights, making them especially well-suited for processing shear-sensitive materials. Counter-rotating designs are widely preferred for shaping operations, including PVC compounding, pipe and profile extrusion, cable coatings, and both rigid and flexible sheet production.

Parallel Screw Extruders

With parallel screw extruders, the screws maintain a constant diameter along their length, making them ideal for compounding, research, and high-throughput applications. In contrast, conical screw extruders feature screws that taper toward one end, providing enhanced feeding capability that is well-suited for high-viscosity or bulkier materials. Many conical systems will feature a recirculation chamber to allow a simulation of different L/D ratios

Benefits of Twin Screw Extruders

Superior Mixing and Broad Material Compatibility:

Twin screw extruders are highly versatile, making them suitable for processing polymers, pharmaceuticals, food products, and biomaterials. They are capable of both large-scale production and specialized low-volume runs, while efficiently handling complex, multi-component formulations to ensure consistent dispersion and uniform product quality across batches.

Flexibility and Modularity:

Twin screw extruders can be tailored to diverse applications through modular design. Barrel sections may be equipped with feeders, venting ports, or liquid injection points, while screw elements can be arranged for conveying, kneading, or intensive mixing. Independent temperature zones along the barrel, combined with adjustable screw speed and torque, provide precise process control. This flexibility allows rapid adaptation when working with new materials or formulations.

High Throughput and Process Efficiency:

Twin screw extruders operate in a continuous mode, minimizing downtime and delivering greater energy efficiency compared to batch mixing. Twin screw micro compounders further enhance efficiency by reducing material waste through precise mixing and lowering R&D costs with small-batch trials. This capability accelerates innovation by enabling faster iteration cycles and more effective material development.

Xplore Micro compounders:

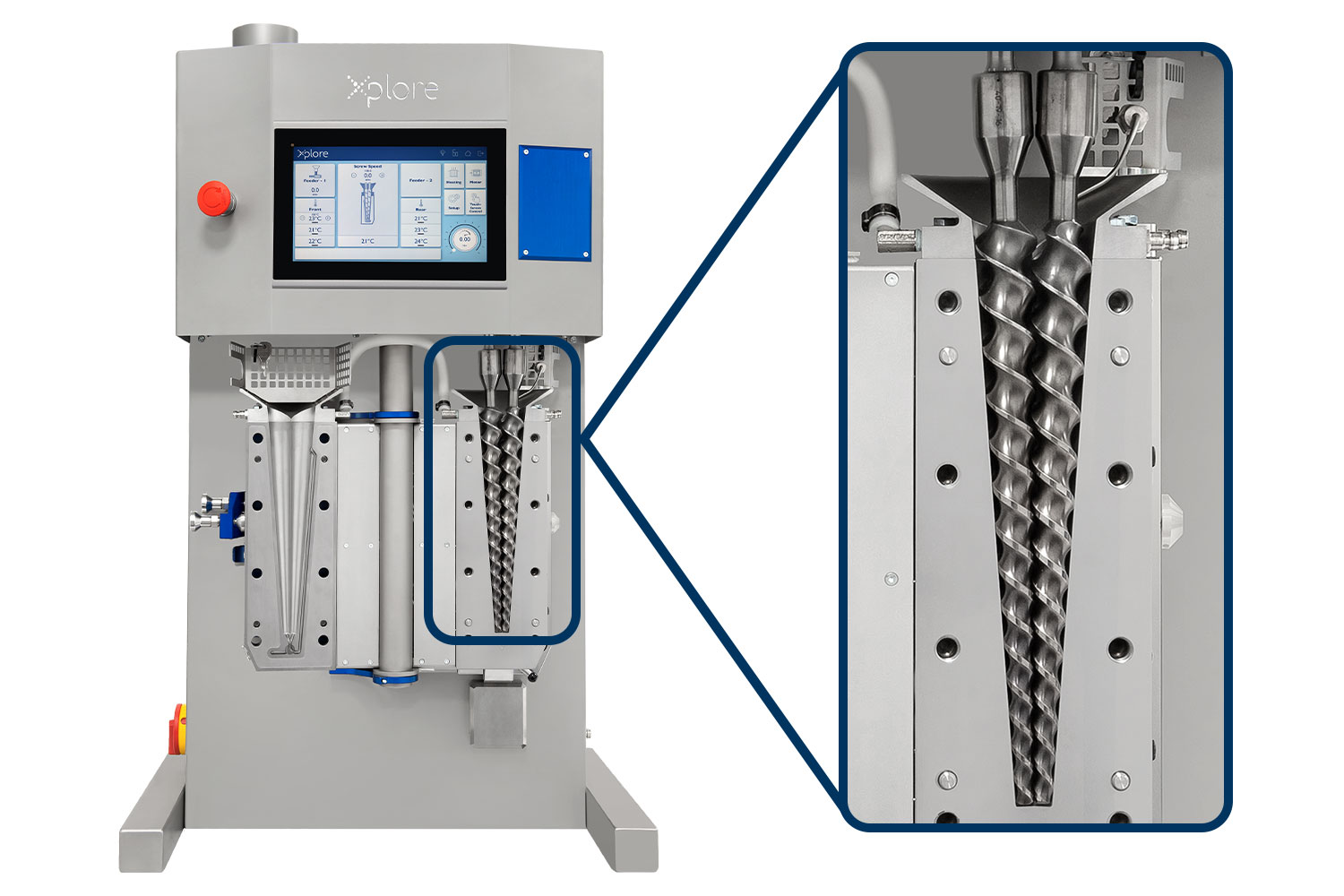

Xplore micro compounders bring the versatility of twin screw extrusion to the laboratory scale, allowing researchers to test new formulations with just a few grams of material (Figure 2). The Xplore micro compounders are conical screw extruders and can be configured either with co-rotating or counter rotating screws to handle all material types. They offer modular screw and barrel configurations, precise temperature control, and excellent mixing efficiency. By minimizing waste and enabling rapid iteration, Xplore micro compounders serve as the perfect bridge between small-batch R&D and larger-scale production, making them an invaluable tool for innovation in polymer design and compound development.

Applications of Twin Screw Extruders

Twin screw extruders are central to industries where precise mixing, scalability, and efficiency are essential. They are commonly used in polymer compounding for blending polymers with fillers, additives, and stabilizers to produce engineering plastics, high-performance composites and biodegradable polymers.2 In Pharmaceuticals, Hot-Melt Extrusion (HME) enhances solubility and bioavailability of poorly soluble drugs. It produces solid dispersions and controlled-release formulations.3 Twin screw extruders are used in continuous manufacturing and provides consistent product quality with tightly controlled residence time and temperature.

Conclusion

Twin screw extruders are advanced processing tools that provide unmatched control, flexibility, and scalability. Whether used in polymer engineering, pharmaceutical production, food technology, or material science, they deliver consistent results and enable innovation. By understanding the types of twin screw extruders, their applications across industries, and the benefits they offer, manufacturers and researchers can select the right configuration to optimize efficiency, product quality, and development speed.

References

- Dhaval, M.; Sharma, S.; Dudhat, K.; Chavda, J. Twin-Screw Extruder in Pharmaceutical Industry: History, Working Principle, Applications, and Marketed Products: an In-depth Review. Journal of Pharmaceutical Innovation 2020, 17 (2), 294–318. https://doi.org/10.1007/s12247-020-09520-7. ↩︎

- Lewandowski, A.; Wilczyński, K. Modeling of twin screw extrusion of polymeric materials. Polymers 2022, 14 (2), 274. https://doi.org/10.3390/polym14020274. ↩︎

- Patil, H.; Vemula, S. K.; Narala, S.; Lakkala, P.; Munnangi, S. R.; Narala, N.; Jara, M. O.; Williams, R. O.; Terefe, H.; Repka, M. A. Hot-Melt Extrusion: from Theory to Application in Pharmaceutical Formulation—Where Are We Now? AAPS PharmSciTech 2024, 25 (2). https://doi.org/10.1208/s12249-024-02749-2. ↩︎