Developing new polymer materials often involves a difficult transition from concept to a testable prototype. During this early phase, researchers typically conduct multiple iterations, refining formulations, adjusting processing parameters, and evaluating material compatibility.1 Relying on large-scale production equipment for these exploratory steps can be inefficient and time-consuming. Conventional twin-screw extruders, for instance, require substantial material quantities, involve lengthy setup times, and are impractical for rapid screening of numerous formulation variations.

Batch micro-compounding offers an efficient and scalable alternative. Modern benchtop systems replicate the processing conditions of industrial compounders while using only a few grams of material. This capability allows laboratories to explore new polymer formulations, optimize processing parameters, and investigate material performance efficiently, minimizing waste and accelerating research and development.

This article explores the principles, advantages, and practical considerations of batch micro-compounding, highlighting why it has become a cornerstone in modern polymer formulation and composite research.

What is Batch Micro-Compounding?

Batch micro-compounding, also known as lab-scale micro-compounding, is the process of compounding polymers, fillers, and additives in small quantities, typically ranging from a few grams to tens of grams. Unlike conventional lab mixers, micro-compounders provide precise control over shear, temperature, and mixing patterns, closely mimicking industrial extrusion conditions.

By enabling small-batch processing under precisely controlled conditions, micro-compounders provide researchers with a powerful and efficient platform for polymer development and optimization. Their design bridges the gap between benchtop experimentation and industrial-scale production.

Why Lab-Scale Micro-Compounding Matters

Micro-compounding streamlines polymer R&D by combining material efficiency, experimental flexibility, and process reliability, helping researchers move from concept to commercial-scale production with lower cost, less risk, greater speed and precision.

Minimize material usage & reduce costs:

Micro compounders require only a few grams of material per batch, which is especially valuable when working with polymers that are expensive or difficult to synthesize, rare additives, or nanofillers such as carbon nanotubes or graphene. This low material demand allows researchers to experiment freely without the financial or logistical constraints of large-scale trials. The result is a more sustainable and cost-effective approach to early-stage research, minimizing both waste and production costs.

Conduct rapid iterations of formulations to optimize performance:

The small batch size and fast processing time make micro compounders ideal for iterative testing. Researchers can quickly adjust formulation parameters and observe the resulting effects on mechanical, thermal, or rheological properties. This capability accelerates the optimization cycle, enabling faster identification of promising material compositions for further development.

Achieve reproducible results that translate effectively to larger-scale manufacturing:

Micro compounders are designed to replicate the shear and mixing conditions of industrial extruders, supported by measuring and controlling rheological parameters. This ensures that the results obtained at the laboratory scale are directly comparable to those expected in full-scale production.

Xplore Micro Compounders

The lab-scale micro-compounders from Xplore are engineered to deliver precision, efficiency, and flexibility in small-scale polymer processing. Designed specifically for research and development, these systems allow accurate replication of industrial compounding conditions using only a fraction of the material required by traditional equipment.

Small batch size:

Xplore micro-compounders require only 2–40 mL of raw material, making them highly valuable for applications involving rare, high-cost, or newly synthesized polymers. This capability is particularly beneficial when working with experimental materials or additives available only in limited laboratory-scale quantities, allowing researchers to perform meaningful tests without excessive material consumption or waste. This small batch size further supports quicker formulation work given faster temperature control as well as easier cleaning and filling.

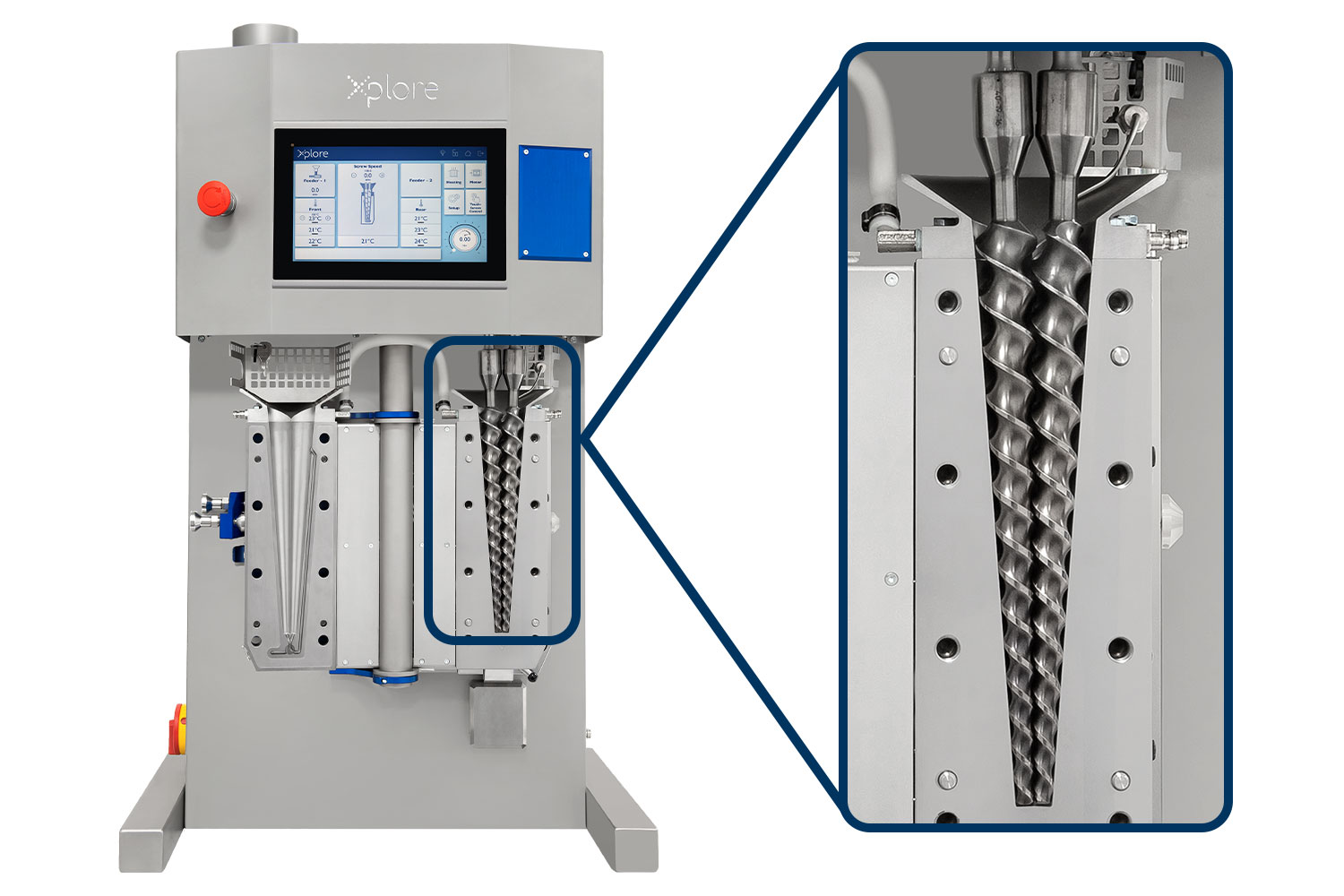

Twin-screw mixing:

The systems feature fully intermeshing twin screws that create a dynamic and continuous mixing environment.2 Material is constantly transferred between the screws, generating strong shear forces and achieving both distributive and dispersive mixing. This mechanism ensures uniform dispersion of fillers, additives, and nanoparticles while minimizing dead zones within the barrel, as shown in Figure 1. The self-wiping screw design further enhances performance, each screw cleans the other’s surface, preventing buildup, reducing the risk of thermal degradation, and simplifying cleaning. Thanks to the continuous forward pumping action, even highly viscous polymers and heavily filled formulations, can be processed efficiently.

Conical barrel design:

The conical screw barrel design facilitates smooth material feeding and compresses the molten polymer into a smaller volume, promoting stable flow and consistent pressure. This geometry minimizes pressure fluctuations in the recirculation channel, leading to steady processing conditions and improved mixing uniformity throughout the batch.

Tunable residence time:

During batch micro-compounding, the molten polymer continuously circulates through the recirculation channel, ensuring thorough mixing and dispersion. With the valve closed, the system mimics an extruder with an infinitely long length-to-diameter (L/D) ratio—providing extended residence time under controlled shear and temperature conditions. When the valve is opened, the defined residence time ends, and the material is directed toward the die for extrusion. This precise control over residence time allows researchers to fine-tune processing parameters for optimal results.

Easy feeding system:

Materials, powders, pellets, or liquids, can be easily introduced through a top gravity feed. The simple loading mechanism accommodates various material forms and eliminates the need for complex feeding accessories. This flexibility allows for quick material changes and efficient experimentation with different formulations, supporting a wide range of research applications.

Conclusion

Batch micro-compounding empowers polymer scientists and engineers to achieve realistic, reproducible, and scalable formulations using minimal material.3 Compared to conventional lab mixers, micro-compounders provide uniform shear, precise temperature control, and efficient small-batch processing. This technology not only reduces cost and development time but also improves the predictive value of R&D experiments, bridging the gap between lab-scale experimentation and industrial production.

For researchers working with polymers, composites, or nanomaterials, adopting batch micro-compounding can significantly enhance efficiency, accuracy, and success of formulation development.

References

- Silviya, E. K.; Varma, S.; Unnikrishnan, G.; Thomas, S. Compounding and mixing of polymers. In Elsevier eBooks; 2009; pp 71–105. https://doi.org/10.1533/9781845696429.1.71. ↩︎

- Martin, C. Twin Screw Extruders as Continuous Mixers for Thermal Processing: a Technical and Historical Perspective. AAPS PharmSciTech 2016, 17 (1), 3–19. https://doi.org/10.1208/s12249-016-0485-3. ↩︎

- Sakai, T.; Thommes, M. Investigation into mixing capability and solid dispersion preparation using the DSM Xplore Pharma Micro Extruder. Journal of Pharmacy and Pharmacology 2013, 66 (2), 218–231. https://doi.org/10.1111/jphp.12085. ↩︎