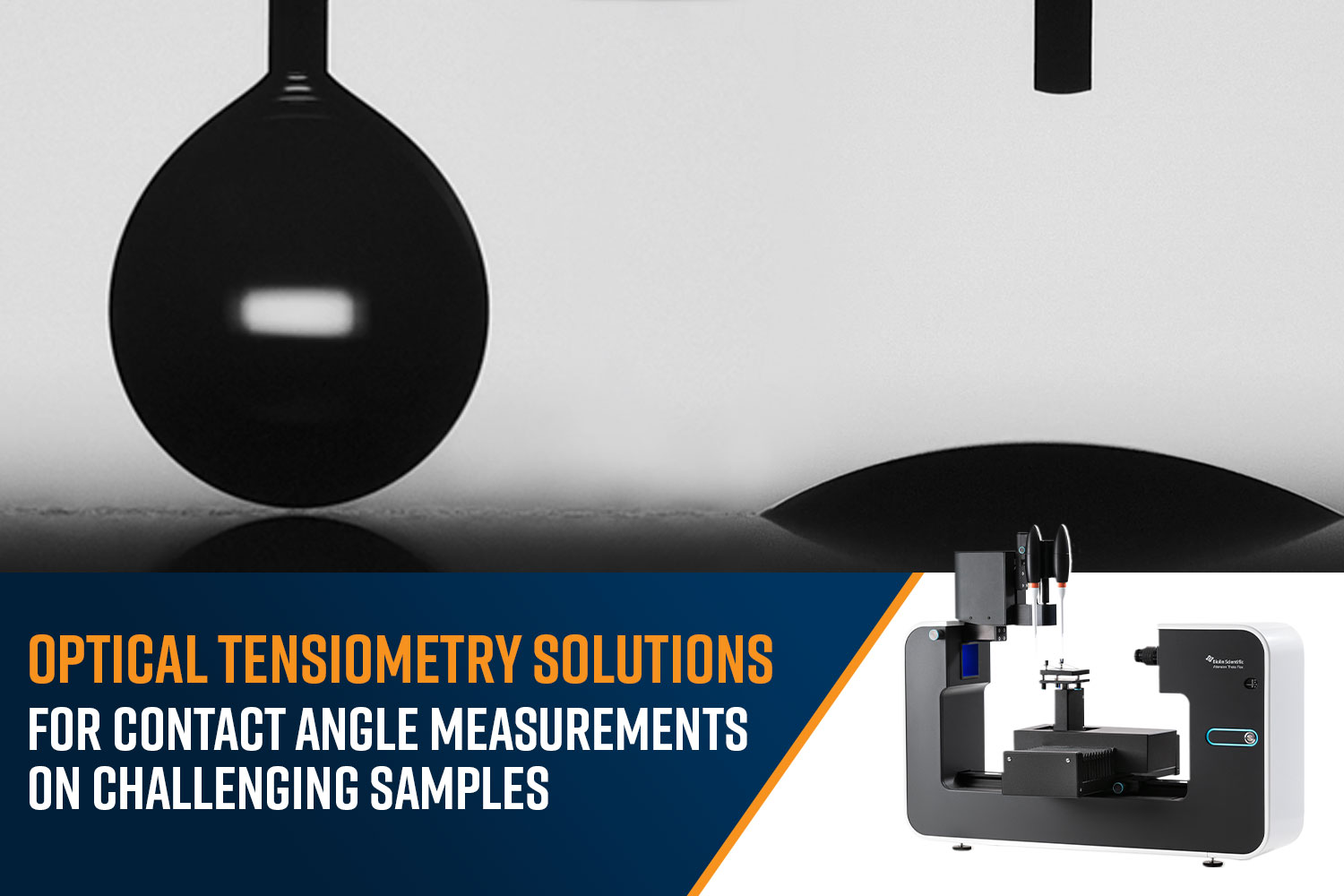

Why Measure Contact Angles?

Surface characterization plays a crucial role in various industries, from pharmaceuticals to electronics and beyond. Understanding how liquids interact with solid surfaces is essential for optimizing processes such as coating, adhesion, and wettability. Contact angle measurements can characterize the surface chemistry of a material and help to understand the wettability of the material surface with a liquid of interest. Contact angle measurement involves assessing the angle formed between a liquid droplet and a solid surface. This angle provides valuable insights into surface energy, wettability, and adhesion characteristics. For instance, a high contact angle indicates poor wetting, while a low angle suggests strong adhesion and spreading. Industries utilize contact angle data to enhance product performance, optimize manufacturing processes, and troubleshoot surface-related issues. From designing self-cleaning surfaces to formulating efficient coatings, the applications are diverse and impactful.

Contact Angle Measurements

Typically, contact angle measurements are done by placing a small drop of liquid on the material surface and recording the droplet image with a camera. With modern optical tensiometers, also known as contact angle goniometers, this measurement is quick and simple for a variety of different materials. However, measuring contact angles accurately, especially on challenging or unconventional samples, has long been a hurdle. These samples may include porous materials, rough surfaces, powders, or even biological tissues. Conventional goniometers struggle to provide accurate measurements on such substrates due to factors like irregular topography, surface heterogeneity, or rapid droplet absorption. This article looks at two types of materials, porous and powder materials, that are challenging to measure with contact angle and ways the contact angle can be measured.

Porous Materials

The wettability of porous materials is important for several applications, such as inkjet printing or membrane separation. However, characterizing the wettability of these materials with contact angle measurements presents a unique challenge. For many porous materials, the liquid drop applied to the surface is actively absorbed by the material over time, resulting in a reduction in drop volume as well as contact angle during the measurement. Because no equilibrium is reached between the drop and the surface, determining the contact angle for these materials is difficult.

Different strategies can be used to characterize the wettability of porous materials with contact angle. The contact angle of porous substrates is often examined as a function of time rather than a single value. Looking at the contact angle development over time can give insight into the absorption kinetics of the material and allow comparison of the absorption rate between different substrates. If a single contact angle value is needed for the material, the initial contact angle directly after drop application can be used. This initial value is the first measured contact angle after the drop has stopped any oscillation. Some research has also suggested reporting the percentage of absorbed drop volume along with the contact angle value, e.g. 20% of initial drop volume absorbed, for more accurate comparison between samples.1 Whether looking at the initial contact angle or the contact angle over time, a higher camera frame rate than what is used for a standard non-absorbing substrate is often needed. Many porous materials will rapidly absorb the drop, sometimes in a matter of seconds, and too low of a frame rate will miss important information.

As an alternative to the standard sessile drop measurement, contact angle of porous material can also be measured with the captive bubble method. In the captive bubble method, the sample is inverted and wetted from below from an adjoined liquid. A hooked needle filled with air is placed below the sample, and a bubble of air is dispensed onto the sample surface. The contact angle of the air bubble is then analyzed similarly to a standard sessile drop experiment. The liquid contact angle can be determined by subtracting the measured contact angle from 180°. While the captive bubble method requires a more involved sample setup than the standard sessile drop measurement, it can ultimately be easier for some porous materials. Because the sample is already wetted by the liquid in the captive bubble measurement, the drop applied to the surface does not absorb into the sample and can be more easily analyzed.

Powder Materials

Powder wettability is significant in many applications such as pharmaceutical drugs, coatings, and food science. However, powder wettability can be challenging to characterize with a standard static contact angle measurement. Powders often have a surface roughness that can affect the measured contact angle as well as a porous structure that promotes absorption of the drop into the substrate. The sessile drop method is one of the most common optical tensiometry methods for measuring powder wettability.

Sessile drop measurements with powders are like sessile drop measurements with standard substrates. However, since a drop cannot be easily placed on the unaltered powder, the powder first requires some sample preparation. If the powder is compressible, the powder can be compressed into a tablet by applying high pressure. A hydraulic pellet press like those used to make KBr pellets for IR spectroscopy is suitable for making a powder tablet. Alternatively, a thin layer of loose powder can be spread across another substrate (with the help of an adhesive like double-sided tape if needed). Once the powder sample is prepared, the sessile drop can be placed directly on the sample and the contact angle can be measured.

However, contact angle measurements on some hydrophilic powders can be challenging due to their tendency to absorb the liquid drop over time. Additionally, powder samples tend to have a surface roughness that can affect the contact angle, although this effect can be accounted for by measuring the surface roughness and performing a roughness correction. The type of sample preparation used on the powder sample may also affect the contact angle. There is some evidence that the surface properties of certain powder samples can be altered by compression.2 Although compression can be avoided by using a thin powder layer on another substrate, careful preparation is still required to form a complete uniform coverage over the supporting substrate. Any exposed substrate in contact with the liquid drop could affect the measured contact angle.

The best method for powder wettability is dependent on the wetting properties of the powder and the application.

References

- Krainer, S., and Hirn, U. Contact angle measurement on porous substrates: Effect of liquid absorption and drop size. Colloids and Surfaces A: Physiochemical and Engineering Aspects 2021 619 https://doi.org/10.1016/j.colsurfa.2021.126503 ↩︎

- Alghunaim, A., Kirdponpattara, S., and Newby, B. Techniques for determining contact angle and wettability of powders. Powder Technology 2016 287 https://doi.org/10.1016/j.powtec.2015.10.002 ↩︎