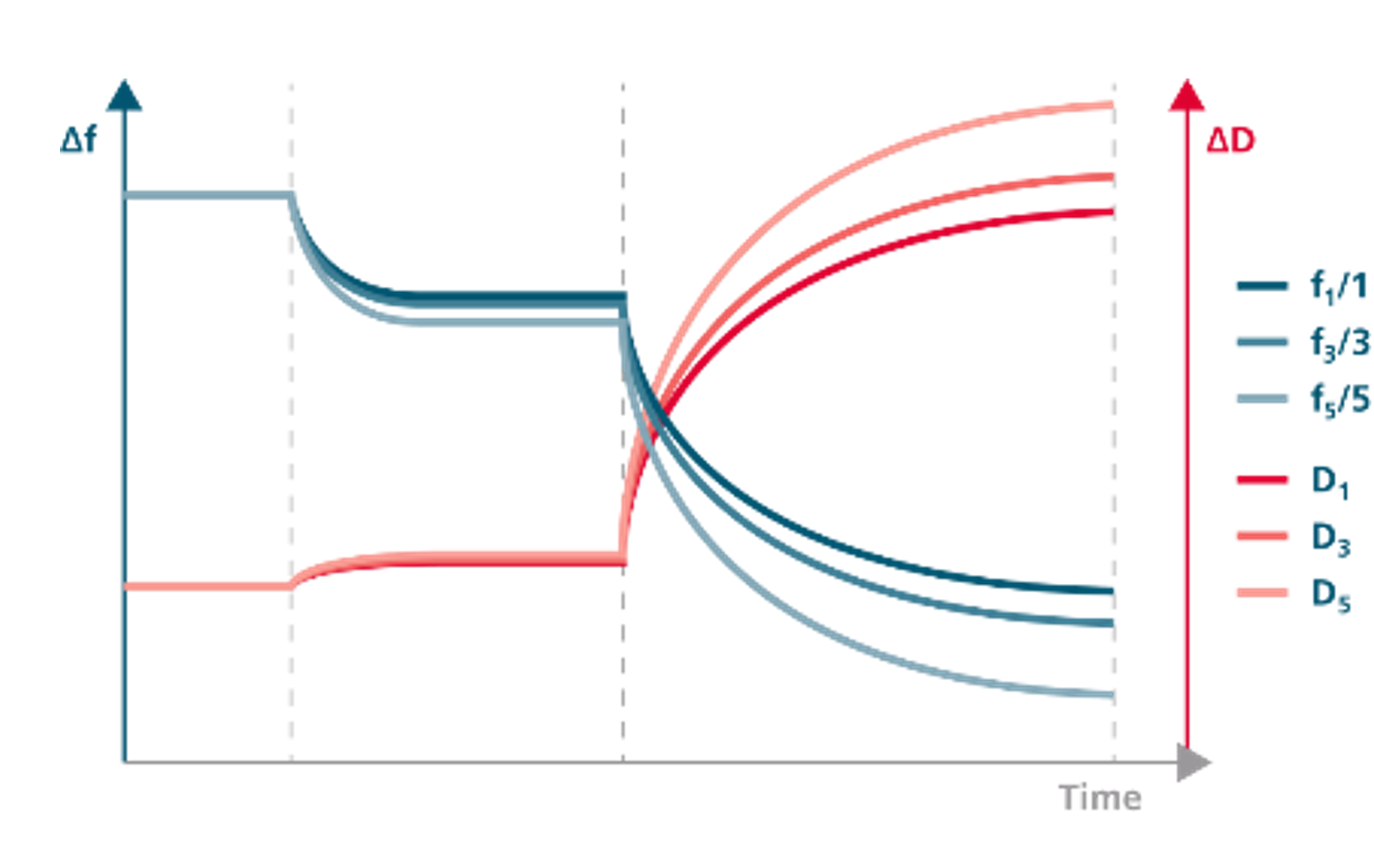

Quartz crystal microbalance with dissipation monitoring (QCM-D) instruments are powerful tools for real-time, label-free analysis of molecular interactions on a surface in a liquid environment. QCM-D systems can quantify nanoscale mass changes and viscoelastic properties of thin films on the surface in adsorption or desorption studies.1,2 If you are curious about adding QCM-D to your lab, you might be wondering: what factors influence the instrument’s data quality and price?

In this blog, we will review 10 key variables that impact the capabilities and cost of a QCM-D system, from measurement method to service and support.

1. Measurement Method

The two main types of QCM-D measurement methods are the ring down method (sometimes called the “ping principle”) and impedance-based method. The costs and performance vary greatly between the two methods. The ring down systems is typically more expensive than their impedance-based counterparts. However, the impedance-based methods often suffer from performance limitations and signal instabilities.

The ring down method offers superior analytical performance by enabling better kinetic resolution, with the ability to capture more than 300 data points per second. This high temporal resolution allows the system to track fast reaction dynamics with precision. Additionally, ring down instruments support signal averaging, which enhances the signal-to-noise ratio and makes it possible to detect smaller mass changes.

Another critical advantage of the ring down approach is its ability to eliminate stray capacitances that commonly affect impedance measurements. By removing this source of interference, ring down systems provide more stable signals with significantly less drift.

The ring down method eliminates stray capacitances that are present in impedance-based measurements, leading to less drift and more stable signals.

2. Baseline Signal Stability

A key performance factor in any QCM-D system is the detection of the smallest reproducible signal change. This sensitivity is directly determined by the stability of the baseline signal, which is the drift in frequency and dissipation observed over time. The lower the drift, the more stable the baseline, and with greater stability, the system can reliably detect smaller mass changes.

3. Number of Measurement Channels

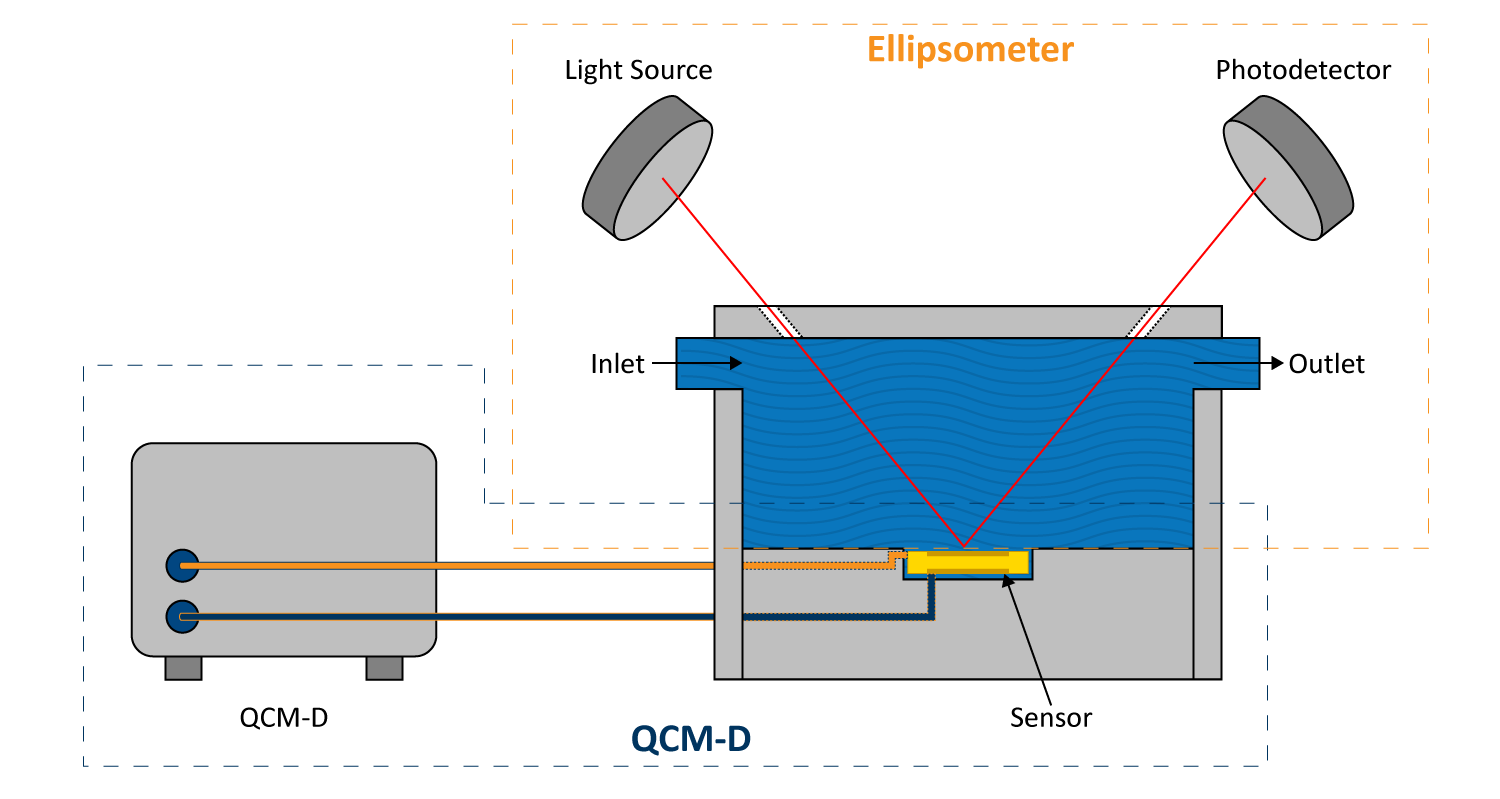

QCM-D systems are available in configurations ranging from single-channel to multi-channel setups with up to eight channels. While multi-channel instruments are typically more expensive, they offer the advantage of simultaneous measurements, significantly increasing experimental throughput. Single-channel systems, on the other hand, provide greater flexibility for integration with complementary techniques such as optical microscopy, ellipsometry, or electrochemistry. In these cases, the simplicity of a single channel often makes coupling with other instruments more practical, whereas multi-channel configurations can introduce additional complexity.

4. Automation Capabilities

Fully automated QCM-D systems for unattended measurements and sample handling typically cost more than manual systems, but they save time and reduce errors in routine workflows. Depending on the level of automation, the cost differs greatly. Examples of automated features that add to the cost of a QCM-D instrument may include automatic cleaning, sample delivery, systemic readiness/baseline stability tests, sensor quality checks, and more.

5. Temperature and Flow Control Options

Precise control of experimental conditions, such as temperature ramps, flow rates, or humidity, adds to system complexity and cost. Sensor oscillation, and therefore the resulting data signal, can be significantly influenced by temperature fluctuations and flow turbulences, so good temperature and flow control is crucial for reliable data. Higher-cost QCM-D systems typically have temperature control systems built into their hardware, ensuring that samples and reaction chambers remain at the same temperature throughout the experiment. In lower cost QCM-D systems, temperature control is typically an external accessory that requires circulating water baths, hot plates, or other devices for heating and/or cooling.

6. Liquid Handling and Sample Environment

QCM-D systems that include integrated liquid handling modules, compatibility with harsh solvents, or flow chambers designed for specific sample types, including biological materials like antibodies and cells, can increase the overall system price. QCM-D systems that use tubing connected to an external pump to flow liquid samples through the experiment chamber are generally priced lower. These systems will require more manual interventions that can introduce errors, contamination, or variability.

7. Software and Data Analysis Tools

Advanced software for data acquisition and modeling of viscoelastic films, multilayer adsorption, or coupled analyses with other techniques adds value, but also increases cost. The real-time data acquired at multiple harmonics can be visualized in different ways, which can change the complexity of the overall user experience. Also, having the option to apply multiple modeling approaches broadens the range of potential applications. Lower cost QCM-D instruments usually do not include advanced software, so data must be processed externally and manually. Higher cost QCM-D instruments are more likely to be compatible with data analysis and/or automation software, increasing throughput and accuracy of results. These features are also important contributors to ease-of-use, reducing the training time needed for new operators.

8. Accessory Modules and Customization

Optional modules can expand QCM-D capabilities and raise the overall price, depending on your application needs. These external modules allow users to collect simultaneous data alongside frequency and dissipation changes, including optical or fluorescence microscopy images, ellipsometry data, electrochemical measurements, and more. Entry-level QCM-D instruments are not typically compatible with these external modules, but mid-range and high-end instruments are. External modules are ideal for more precise control over the experimental environment, a greater range of measurable parameters, and improved customization / specialization of QCM-D instruments.

9. Sensor Range

The range of available sensor surface coatings is an important consideration when choosing a QCM-D system, since the sensor surface is the heart of the technique. Most manufacturers supply basic surfaces like gold (Au) and silica (SiO2), however more advanced systems often offer a wider range of sensor surfaces that significantly expand the potential applications of the system. Top suppliers like Biolin Scientific offer ~100 different commercially available sensor coatings with the flexibility to make custom coatings on demand.

10. Service, Support, and Training

The level of support included, such as installation, application training, and service contracts, can vary greatly between suppliers and will almost certainly impact the total cost of ownership. When choosing between suppliers of QCM-D instruments, it is important to understand the level of support in terms of both maintenance, service and application support. Correctly interpreting data from QCM-D instruments is complex, and depending on the situation, might require support from experts with years of experience using the system. Support of this nature will likely add to the total cost of the instrument over time, but the assistance provided by application scientists can have significant effects on the success of your experiment.

Summary:

Hardware, software, and service options are all factors that influence both the cost and capability of a QCM-D system. More advanced features enable improving overall data quality and empower a greater variety of applications, but they also raise the barrier of entry. Different combinations of options have resulted in a spread of available QCM-D instruments, including entry-level, mid-range, and high-end options . Choosing the right one for your lab requires balancing cost with the specifications needed to best accomplish your measurement goals.

References:

- Liu, G.; Zhang, G. Basic Principles of QCM-D. Springer briefs in molecular science 2013, 1–8. https://doi.org/10.1007/978-3-642-39790-5_1. ↩︎

- Chen, Q.; Xu, S.; Liu, Q.; Masliyah, J. H.; Xu, Z. QCM-D Study of Nanoparticle Interactions. Advances of Colloid and Interface Studies 2016, 233 (223), 94–114. https://doi.org/10.1016/j.cis.2015.10.004. ↩︎