Scanning Electron Microscopy for Additive Manufacturing

The Additive Manufacturing (3D Printing) market is rapidly growing and expected to nearly triple within the next six years, surpassing 23 billion dollars in 2026 from 8 billion dollars in 2018. The increasing developments in technologies and materials used in additive manufacturing are creating opportunities, innovations, and excitement across the industry.

Please join our applications scientist, Zachary Gray, PhD, for a webinar on the Phenom Desktop SEM to learn how it can help facilitate research and contain material costs in the additive industry.

The Phenom XL Desktop SEM has been developed for ease of use for evaluating and characterizing both the raw material (powder) and finished (printed) product for the Additive Manufacturing Industry. Featuring the largest sample stage available on a desktop platform with automation enabling fast and easy data acquisition.

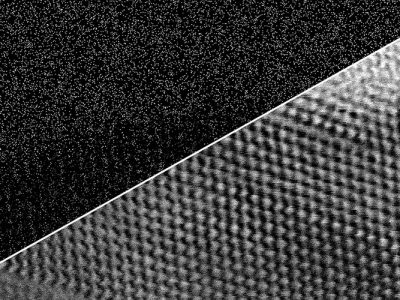

The Phenom platform with ParticleMetric and/or ParticleX software is designed to quantify powder morphologies and their size distribution in an automated fashion. An appropriate size distribution with minimal defects (agglomerates) is required for a good print which avoids defects and pores in the finished product. The high-resolution nature of the SEM technique simultaneously allows one to investigate the microstructure and chemistry of the finished product.