Quartz Crystal Microbalance with Dissipation Monitoring

QSense™ QCM-D Instruments

Quartz Crystal Microbalance with Dissipation monitoring (QCM-D) is a highly sensitive, label-free analytical technique that tracks real time mass changes and viscoelastic properties of thin films on surfaces in a liquid environment.

QCM-D provides unique insights into molecular interactions, thin film behavior, and surface dynamics that are critical to fields including biotechnology, pharmaceuticals, energy, surface coatings, food science, medical devices, nanotechnology and advanced materials. QCM-D technology was developed in the 1990s and has been commercialized by Biolin Scientific Instruments, the pioneers and global leaders.

Unique Measurement Principle

Superior non-voltage readout of frequency and dissipation.

Most Sensitive QCM Instrument

Best Signal-to-Noise Ratio and baseline stability of any QCM system

Viscoelastic Modeling Software

Comprehensive data analysis software included

Modular and Customizable

Add-ons, include electrochemistry, ellipsometry, and high-temperature chambers

Download the QSense™ QCM-D Product Brochure:

Frequently Asked Questions (FAQ):

Quartz Crystal Microbalance with Dissipation monitoring (QCM‑D) is a highly sensitive, label‑free analytical technique that tracks real‑time mass changes and viscoelastic properties of thin films on surfaces. QCM-D monitors mass changes and viscoelastic properties by measuring both the frequency shift and the rate of oscillation decay of a driven quartz crystal. Mass uptake or loss causes a shift in resonant frequency proportional to the material’s mass. Dissipation or the rate of oscillation decay reveals the rigidity or softness of the adhered layer.

QCM-D Evaluates the following in a liquid environment:

- How much: <0.3 ng/cm2 mass sensitivity

- How fast: up to 300 data points per second

- What process: phase and conformational changes

- What structure: soft and rigid films

Adsorption and desorption on surfaces:

QCM-D is an ideal tool for studying adsorption and desorption processes on surfaces in real time and under relevant environmental conditions. As molecules adsorb onto the sensor surface, the increase in mass leads to a measurable decrease in frequency, while changes in dissipation reveal whether the adsorbed layer is rigid or viscoelastic. During desorption, the frequency increases as mass is removed, and shifts in dissipation indicate structural rearrangements or detachment dynamics. By analyzing both parameters simultaneously, QCM-D provides detailed insight into the kinetics, reversibility, and mechanical properties of surface interactions.

Molecular binding and release:

QCM-D enables real-time, label-free monitoring of molecular binding and release events on surfaces by detecting both mass changes and mechanical property variations. When a target molecule binds to a functionalized surface, the resulting increase in mass leads to a measurable frequency decrease, while dissipation changes indicate the rigidity or flexibility of the bound complex. During molecular release or dissociation, the frequency rises, and dissipation shifts reflect any conformational changes or structural relaxation. This dual-parameter analysis allows researchers to quantify binding kinetics, evaluate interaction strength, and characterize complex formation dynamics.

Conformational Changes:

QCM-D is highly effective for studying conformational changes in adsorbed biomolecules or soft films, as it simultaneously tracks mass and viscoelastic properties. While the overall mass on the surface may remain constant, changes in dissipation and frequency can indicate structural rearrangements, such as protein unfolding, polymer swelling, or hydration shifts. An increase in dissipation suggests the formation of a more flexible or extended conformation, whereas a decrease implies compaction or rigidification. By monitoring these subtle mechanical responses in real time, QCM-D provides valuable insights into the dynamic behavior of molecular assemblies and their functional states.

Material degradation:

QCM-D is well-suited for investigating material degradation by capturing both mass loss and changes in mechanical integrity over time. As degradation occurs, whether through dissolution, enzymatic activity, or chemical breakdown, the resonant frequency increases due to material loss from the sensor surface. Simultaneously, changes in dissipation reveal evolving viscoelastic properties, such as softening, fragmentation, or delamination of the material. This dual measurement capability allows researchers to quantify degradation rates and understand the mechanical evolution of coatings, films, or biomaterials under realistic conditions.

At the heart of QCM-D is a thin quartz crystal disc that oscillates at its resonant frequency when an alternating voltage is applied. The oscillation frequency is extremely stable and sensitive to surface changes. When molecules adsorb onto the surface of the crystal (coated with a sensing film), they increase the total mass on the surface. This added mass causes a decrease in the resonant frequency of the crystal. Similarly, when mass is removed from the surface, a associated increase in frequency is observed.

In addition to frequency, QCM-D measures dissipation (D), the rate at which the oscillation decays once the driving voltage is switched off. This reveals the mechanical properties of the film. Low dissipation numbers indicate a rigid layer while high dissipation numbers correspond to soft, viscoelastic or loosely bound layers.

By measuring both parameters, frequency (f) and dissipation (D), QCM-D can distinguish between mass changes due to rigid adsorption and structural changes due to softness or hydration.

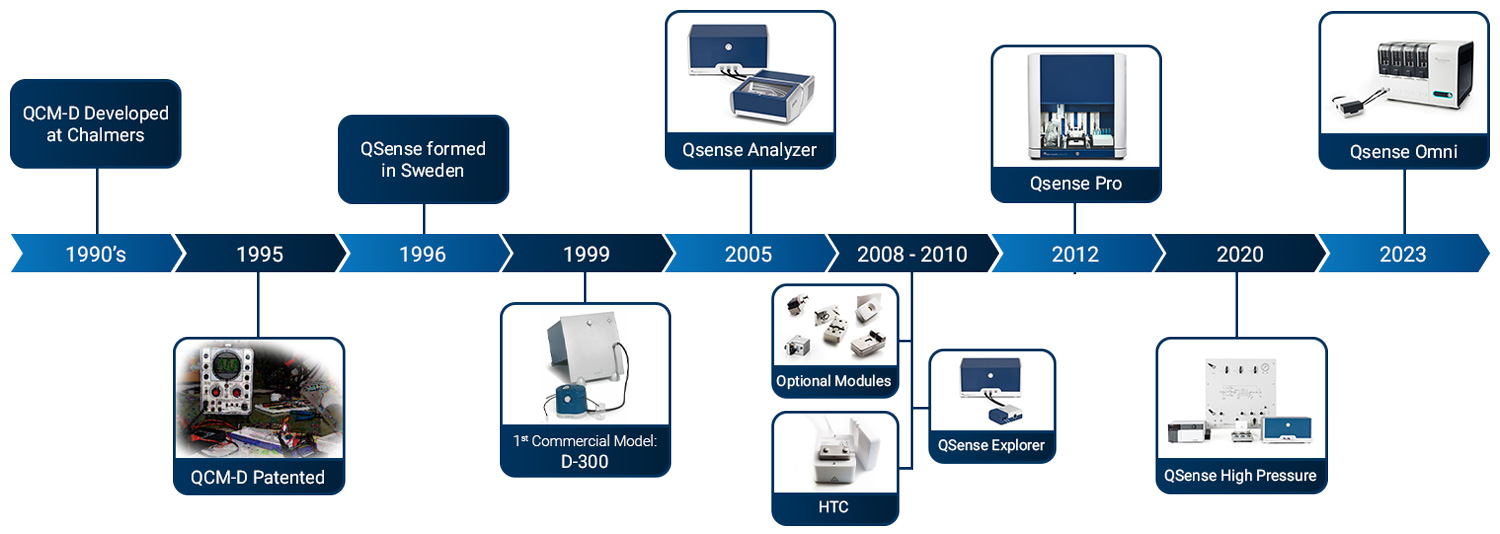

QCM-D was developed in the 1990s in Professor Bengt Kasemo’s lab at Chalmers University for liquid-phase adsorption studies. In 1996, the QSense company was formed in Sweden to commercialize the QCM-D technology. The first QSense-branded instrument, the D 300, was released in 1999. QSense Analyzer (E4), the first four-channel QCM-D system, was introduced in 2005, followed by the QSense Explorer (E1) and optional modules, which joined the QSense family between 2008 and 2010. The fully automated, eight-channel QSense Pro was developed in 2012. As the QSense user-base continued to grow, there was also increasing demand for expanded QCM-D capabilities, leading to the release of the QSense High Pressure system in 2020, enabling a wider range of experimental conditions. Finally, in 2023, the QSense Omni systems were introduced, setting a new gold-standard in QCM-D technology.

Over 5000 publications available!

QSense QCM-D Publication Finder

Search the Publications Database

Over the years, several Modules have been developed to extend functionality and collect additional data beyond just frequency and dissipation. From ellipsometry to electrochemistry, these optional modules allow simultaneous use of the QCM-D liquid-flow cells with complementary techniques.

QCM-D experiments rely on piezoelectric quartz crystal sensors, also sometimes referred to as resonators. In addition to standard gold surfaces, we also offer dozens of surface coatings to mimic your model system. From functionalized surfaces to food soils, several sensors are available as standard items on our webstore. Other surface coatings can be customized by the Sensor development team at Biolin Scientific.

Drug container interaction

Drug discovery & stability

Drug delivery systems

Optimization of flavor & nutrition

Safety & storage

Antifouling & Processing

Cleaning evaluation

Etching & corrosion

Surfactant performance

CMP protocol optimization

Photoresist optimization

ALD characterization

Battery Electrode/Electrolyte Development

SEI characterization

Enhanced oil recovery

Scale & foulant remediation

Bitumen-surface interaction

Biocompatibility studies

Biomolecule-surface interactions

Biofilms

Develop filtration membranes

Water purification (e.g. PFAS)

Desalination

Biomolecular interaction

LNP characterization

Cell-surface interaction

See available product options

QSense™ QCM-D Product Options

The quartz crystal microbalances from Biolin Scientific have earned trust in labs all over the world. With more than 100 sensor coatings available, QSense has enabled the analysis of interfaces, thin-films, and molecular interactions. Through long-term development and experience, the advanced measurement techniques of these instruments have earned a reputation of precision in several industries.

QSense Omni is the most sensitive and automated QCM-D, with the best signal-to-noise ratio of any available QCM or QCM-D system. The Omni combines award-winning design with cutting-edge technology to deliver high-quality data, faster experiments, and simpler workflows.

QSense Pro is the most advanced QCM instrument on the market with full automation and high-throughput enabling enhanced efficiency and reproducibility. You can easily program your measurements in the software and the high precision flow-control ensures effective sample use.

QSense Analyzer produces high-quality data from up to four channels running experiments and measuring in parallel. The smart design with four removable flow modules makes it easy to set up new experiments. QSense Analyzer will quickly become a workhorse in your lab.

QSense Explorer is a versatile instrument with the flexibility to fit any application. Thanks to its modular design, it enables you to extend your measurement conditions with various modules and combine experiments with several other technologies.

QSense Initiator focuses on the fundamental functions and qualities of QCM-D analysis. It produces data with superior accuracy, has a robust design, and enables a wide range of experimental conditions to suit your basic research needs.

See available accessories

QSense™ QCM-D accessories

The QSense QCM-D systems come equipped with standard flow modules, which enables a wide variety of aqueous and gas-phase experiments. Many other specialized modules are available to support experiments that require the use of additional technologies.

The QSense High Temperature Chamber enables QCM-D measurements across a temperature range of 4 °C to 150 °C. The chamber is compatible with QSense Analyzer and Explorer systems and fully integrated with QSoft401 software for real-time data acquisition.

Applications

QSense™ QCM-D Applications

QSense has a wide range of applications in a range of disciplines.

- Pharmaceutical R&D

- Biotechnology & Medical Devices

- Cleaning & Detergents

- Batteries & Energy Storage

- Electronics & Semiconductors

- Food Science

- Polymers

Knowledgebase

QSense™ QCM-D Knowledgebase

Webinar

Predicting Solution Behavior: Insights into the Developability of Biologics

Monoclonal antibodies (mAbs) are widely used in the pharmaceutical and biotechnology indus…

Blog

How Much Does a QCM-D System Cost?

What is Quartz Crystal Microbalance with Dissipation Monitoring (QCM-D) and What Does it M…

White Paper

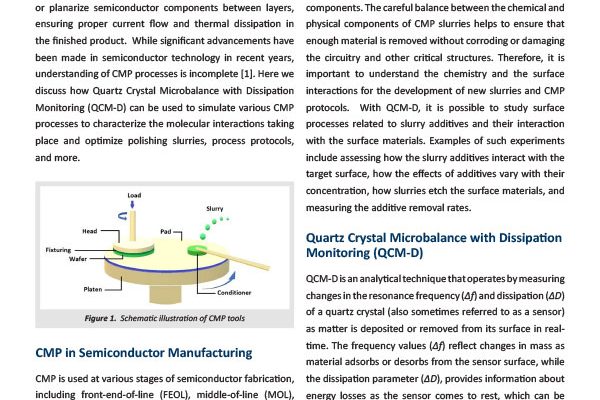

Optimizing Chemical Mechanical Planarization (CMP) Processes with QCM-D

Chemical mechanical planarization (CMP), also called chemical-mechanical polishing, is a c…

Over 5000 publications available!

QSense QCM-D Publication Finder