Empowering Battery Research & Development

Battery Research Solutions:

Considering the widespread use of batteries in daily-use devices, such as smartphones, laptops, and electric vehicles, the impacts of battery research are extremely far-reaching. Innovations in battery technology have the potential to increase energy and power density, reduce charge times, extend battery lifetimes, reduce environmental effects, and improve safety worldwide.

Nanoscience Instruments provides advanced and reliable solutions for your battery research needs:

Consistent, reproducible polymer compounding

Electrospun battery materials

Failure analysis and quality control

Optimization of slurry surface tension

Preparing artifact-free cross-section samples

High-resolution imaging to characterize battery materials

Elemental composition analysis for development of novel materials

Automated particle analysis

Solid Electrolyte Interphase (SEI) analysis

In-situ monitoring of complex electrodes

Electrolyte uptake analysis

Empowering Battery Research & Development

Our Solutions

SEMPREP SMART

SEMPREP SMART is an automated broad ion milling system featuring two ion sources, low-energy and high-energy. This enables the SEMPREP SMART to have the widest range and highest precision of ion mills on the market. For certain samples, this also eliminates the need for cooling, since they can be milled more gently. Regardless of sample type, the SEMPREP SMART is a great choice for high-quality imaging preparation.

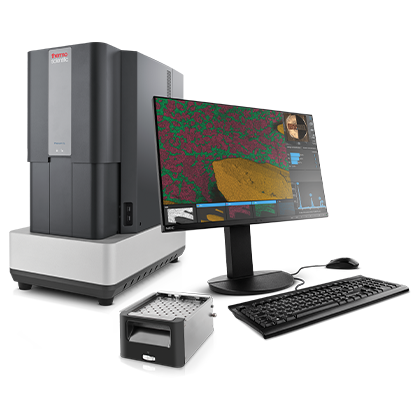

Phenom SEM

The Phenom line of desktop SEMs hosts the most powerful and reliable electron sources on the market, enabling higher resolutions and magnifications while also reducing maintenance costs. Operators can be trained in a matter of hours, if not minutes, and time-to-image can be as short as 30 seconds. Multiple Phenom models with varying capabilities and sample stages are available to match your analysis needs.

QSense

Founded by the original developers of the QCM-D technique, QSense is uniquely equipped to provide top-tier instrumentation to their users. Their technology is more sensitive and easier to use than any QCM instrument on the market, lending value to even the most sensitive and complex experiments. Data analysis can be completed with the accompanying QSoft software.

Xplore

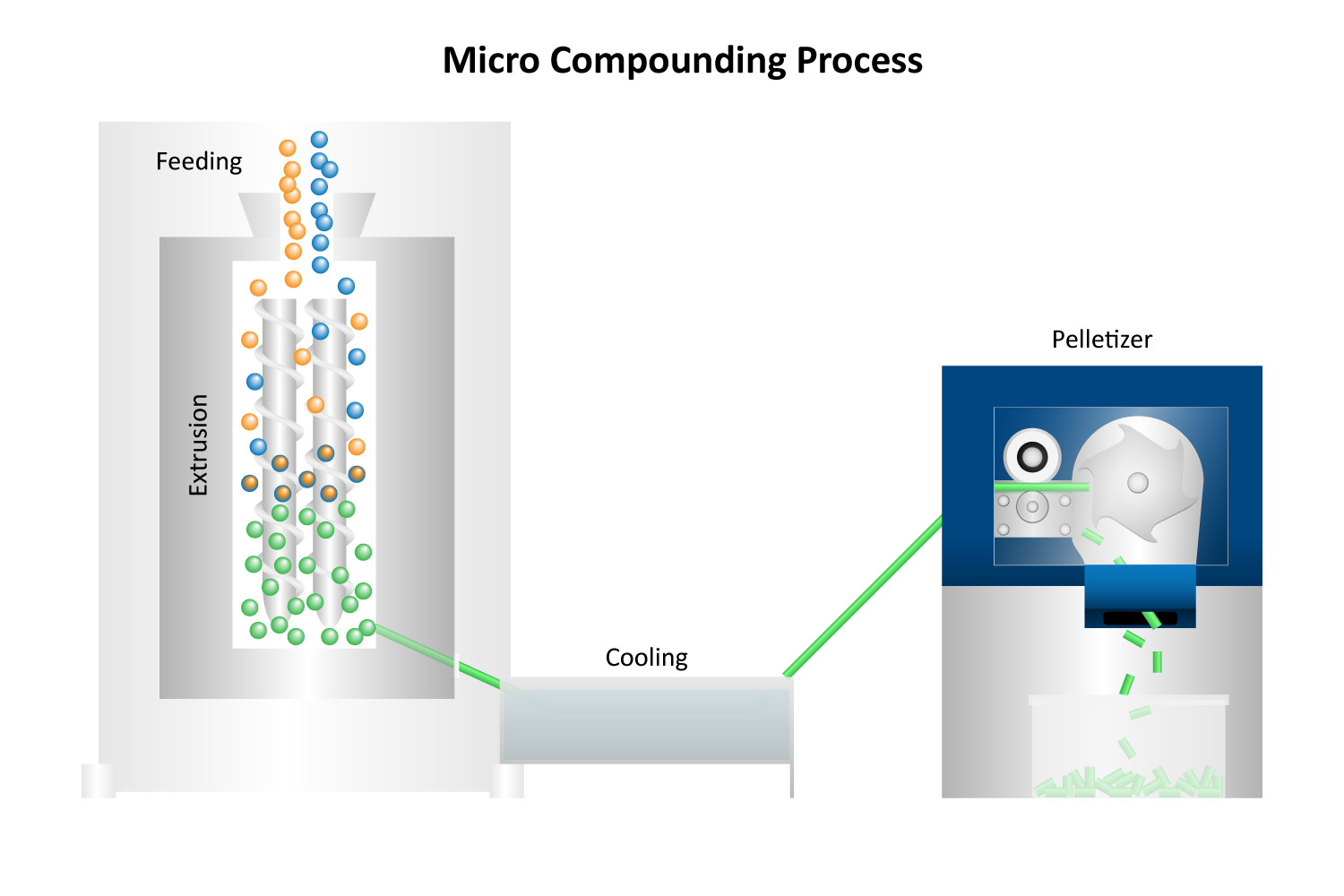

Micro-compounders and shaping instruments from Xplore offer a wide range of size capacities, separated heating zones, and quick sample and screw exchanges to support quick and efficient polymer research. Additionally, they are designed for use in fume hoods, and considering the hazardous materials often used in batteries, this is especially important. These instruments are exceptional when scaling up polymer material research.

Attension

The Attension Theta and Attension Sigma are lines of optical and force tensiometers, respectively. In addition to class-leading hardware and all-inclusive software, the Attension instruments are fully modular, with various plug-and-play accessories available for complex experimentation. The robust instrument design and option to use chemically resistant pipette tips enables use inside of a glovebox and measurements with harsh chemicals.

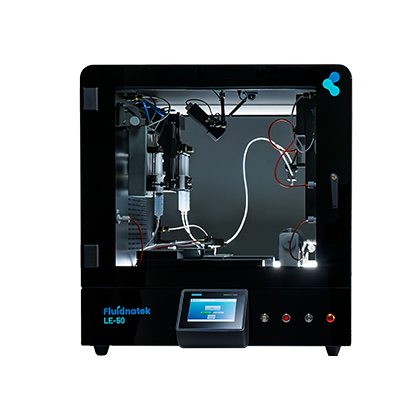

Fluidnatek

From benchtop systems to fully automated, industrial-size manufacturing, the Fluidnatek and Spinbox electrospinning systems offer flexibility and scalability for every application. Their focus on environmental control leads to consistency, precision, and efficiency throughout nanofiber production. This is particularly valuable in research applications, where reproducibility is critical for verifying observations and trends.

Battery Research Solutions

Producing Battery Materials

Consistent, reproducible polymer compounding

There are hundreds of variables that affect battery performance, from electrode composition to separator properties and more. Rapid prototyping is ideal for exploring new battery formulae, but full-scale production facilities are not typically well-suited for quick material changeovers. Instead, micro-compounders offer a solution to iterative development, allowing researchers to mix and test small batches of electrode slurry or other polymer composite materials. Uniform distribution of lithium salts or nanofillers within polymer matrices to generate solid polymer electrolytes for next-generation batteries can be achieved using micro-compounders.

Once the small-batch formula has been optimized, scaling to full-size systems is relatively simple, as the micro-compounder’s twin screw system offers consistent viscosity modeling with scale-up factors to inform large batch extrusion.

Electrospun battery materials

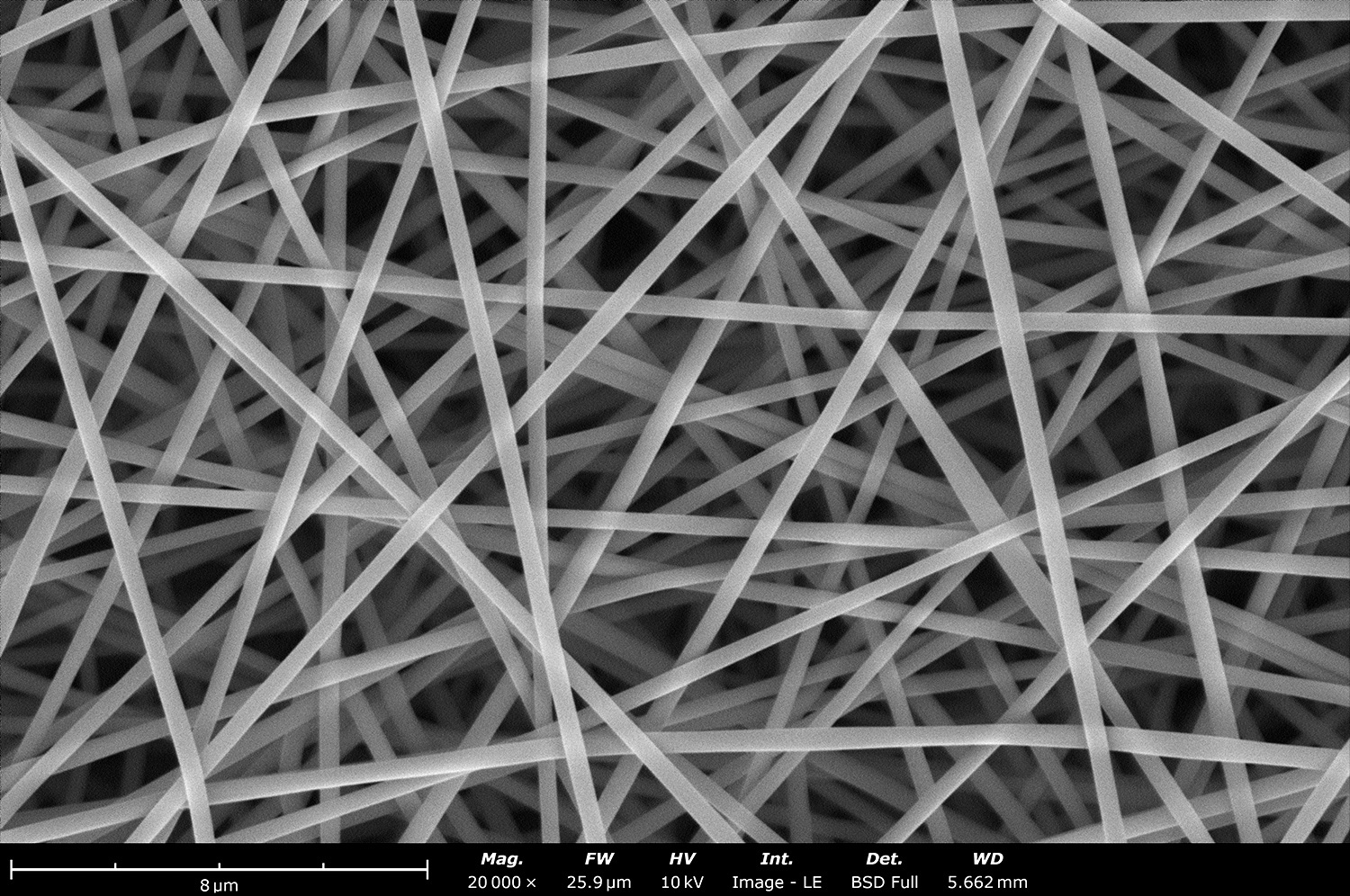

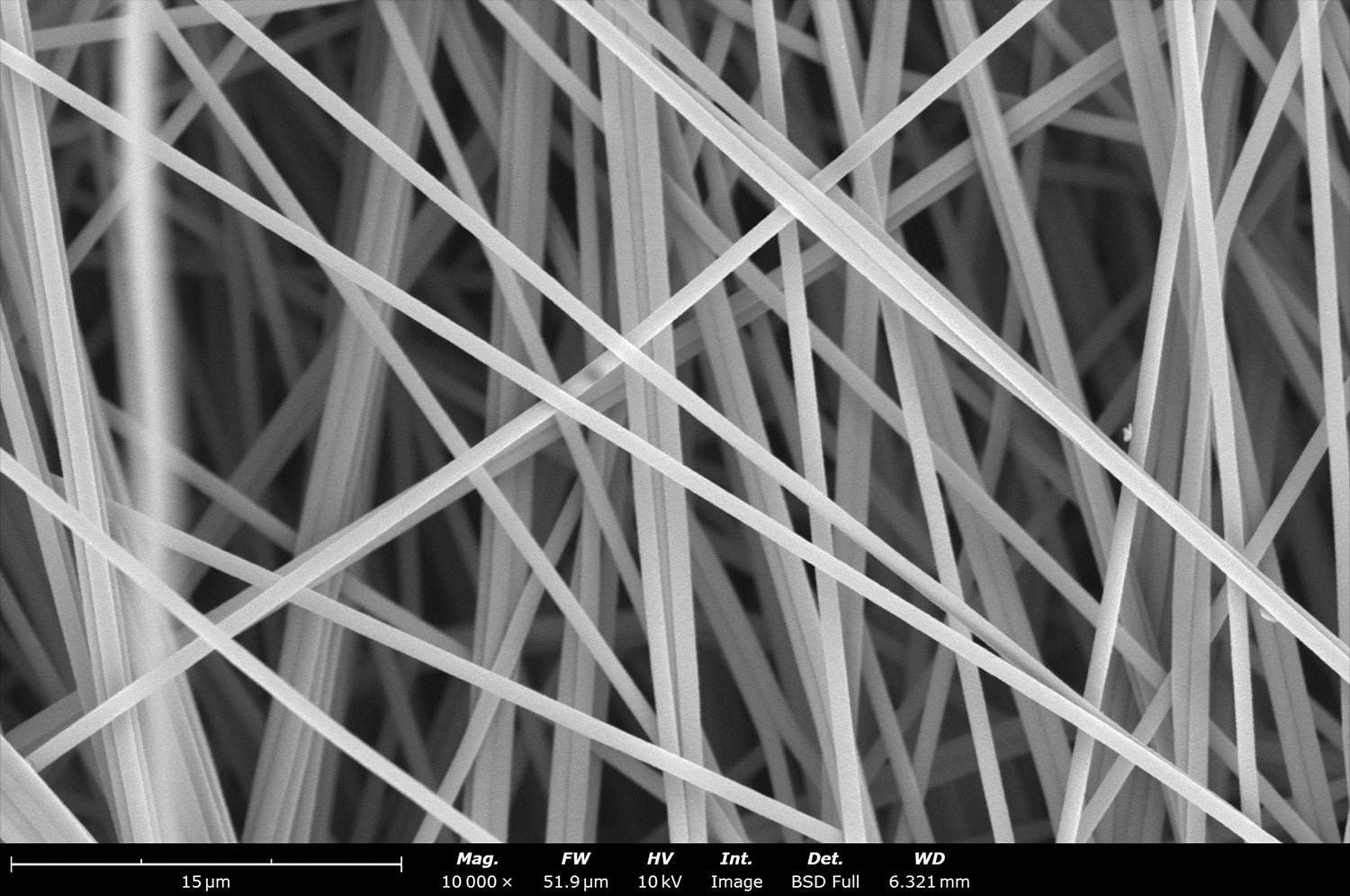

Standard polypropylene or polyolefin-based separator membranes are limited by the amount of mechanical strain and volume change they can experience before battery performance is compromised. Developing separators with improved properties and unique materials requires novel techniques.

Electrospinning is a process where a high voltage is applied to specially designed polymer solutions, which spins the solution(s) into fibers with diameters in the nanometers. This gives the resulting nanofiber mats structural and chemical properties that are valuable for battery research applications. Specifically, carbon nanofiber separators have been shown to improve shorten diffusion pathways, increasing electrical conductivity. The fibers’ high porosity also helps to dampen mechanical strain, increase thermal stability, and improve electrolyte accessibility. Electrospinning can also be done directly onto electrode surfaces, improving surface area adhesion.

For solid-state battery applications, composite solid electrolytes can be electrospun, reducing the risk of leakage, flammability, and lithium dendrite growth associated with liquid electrolytes. Polymer-ceramic composites can also be spun into electrolyte material, balancing the strong interfacial contact from polymers with the high Li-ion conductivity from ceramics.

Battery Research Solutions

Characterizing Battery Materials

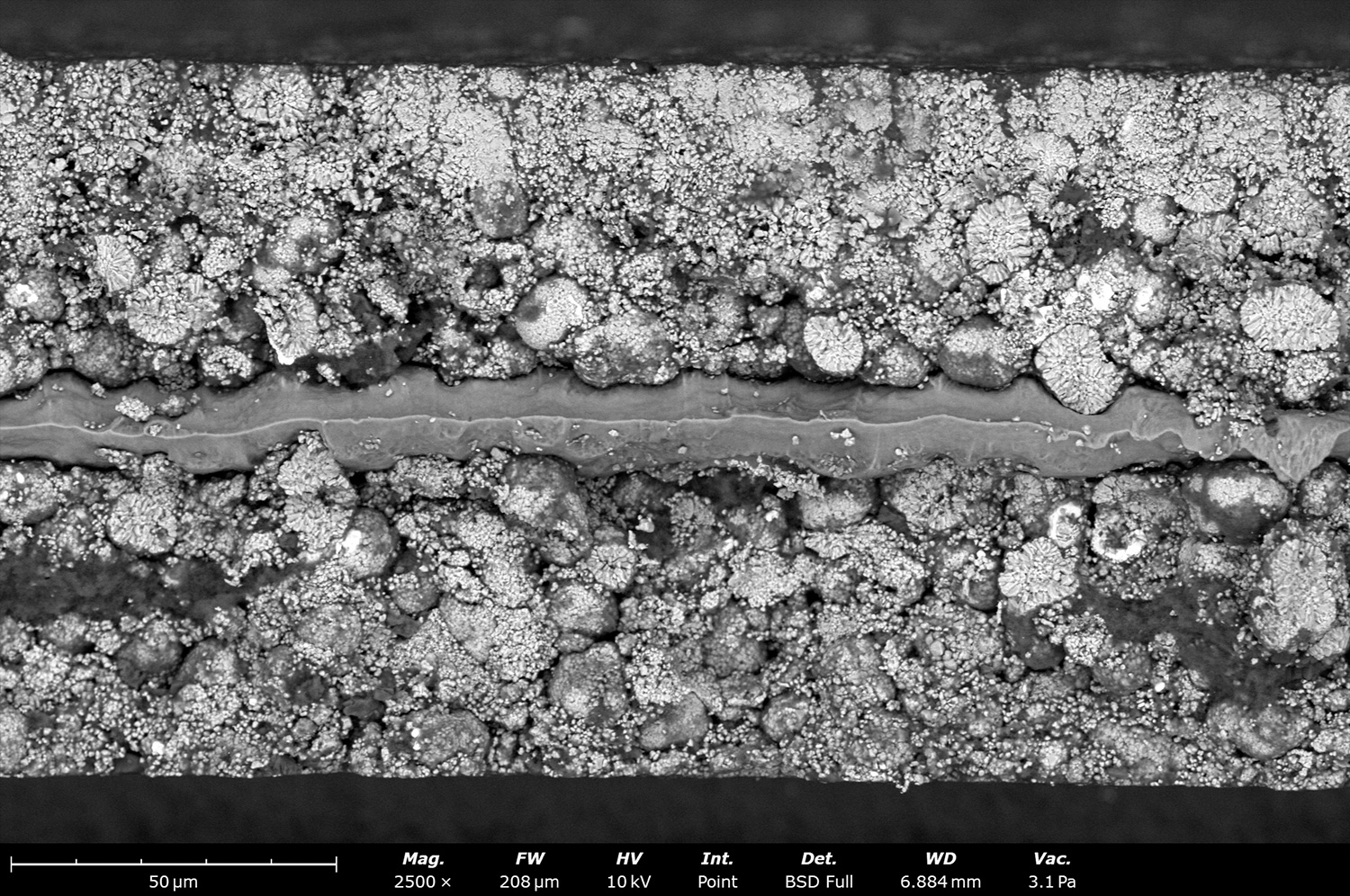

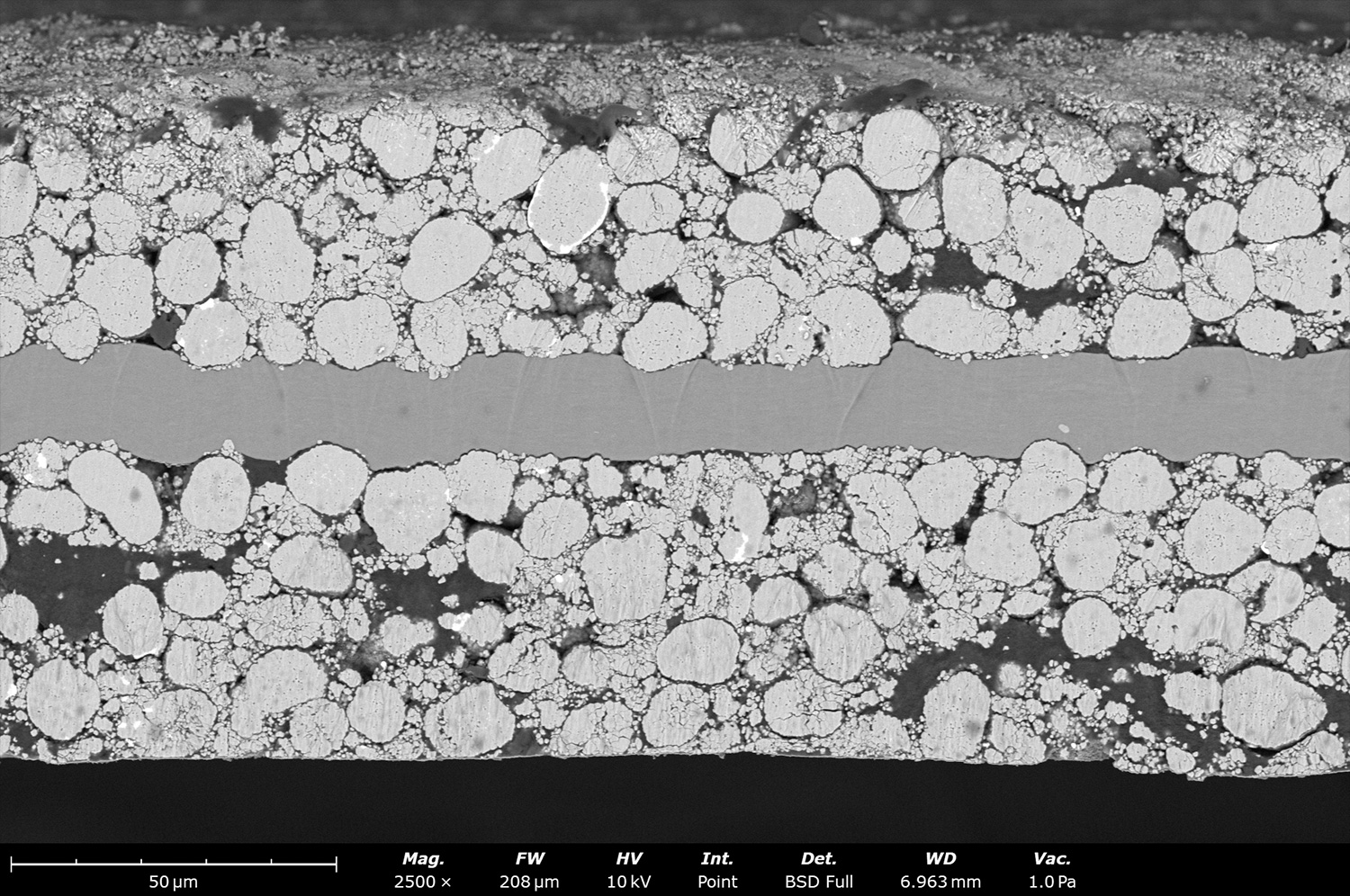

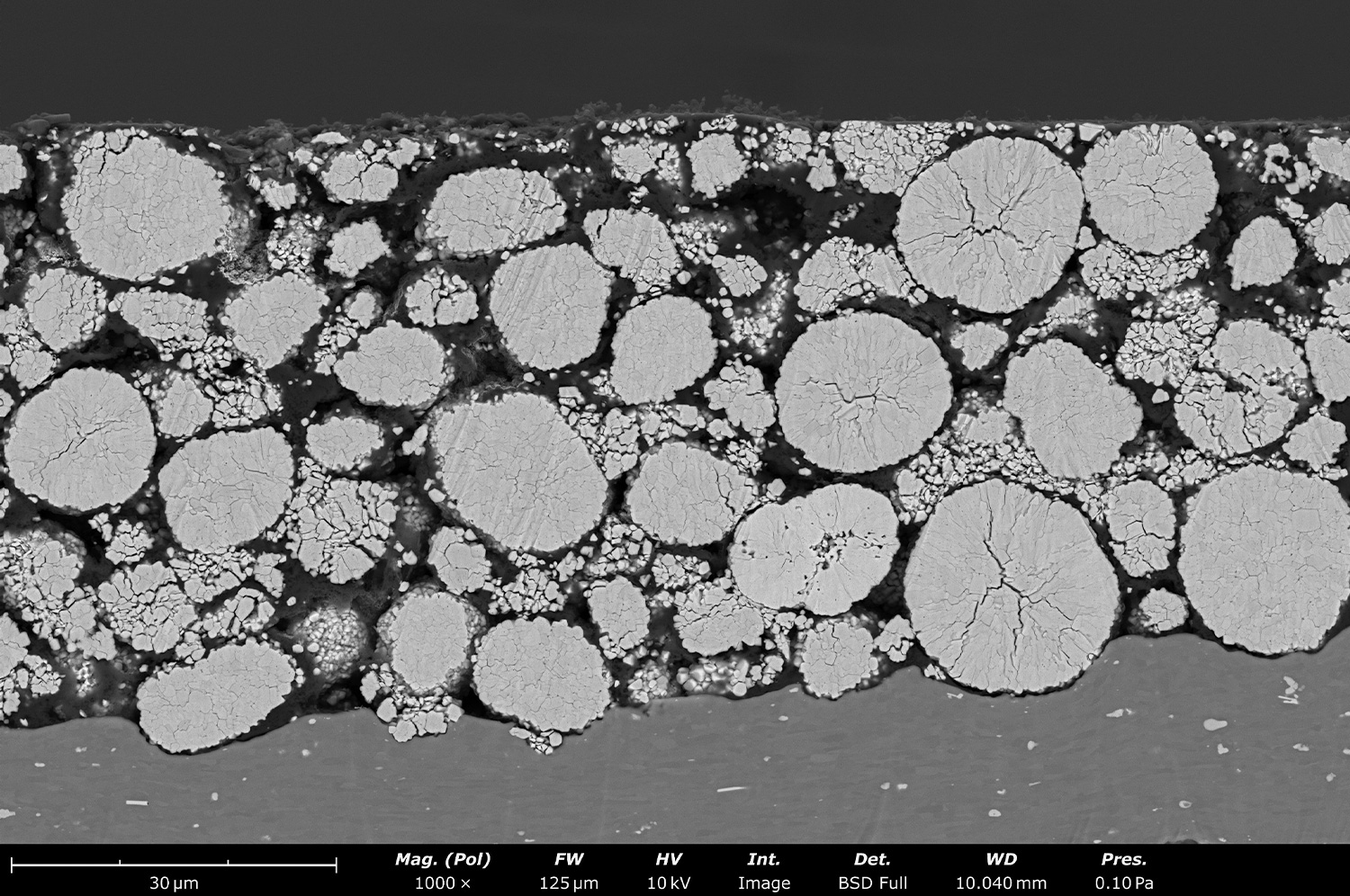

Preparing artifact free cross-section samples

Since batteries contain several interfaces of thin films, powders, and organic separators, they require a high-quality surface finish to reveal grain structures and precise layer thicknesses. As batteries grow more complex in design, the surface artifacts from mechanical polishing will be increasingly detrimental for imaging and accurate analysis. Instead, ion milling uses a beam of ions to eject layers of material from a sample’s surface, enabling artifact-free cross-sections suitable for scanning electron microscopy (SEM) analysis.

To learn more, see our latest webinar on the topic:

High-resolution imaging to characterize battery materials

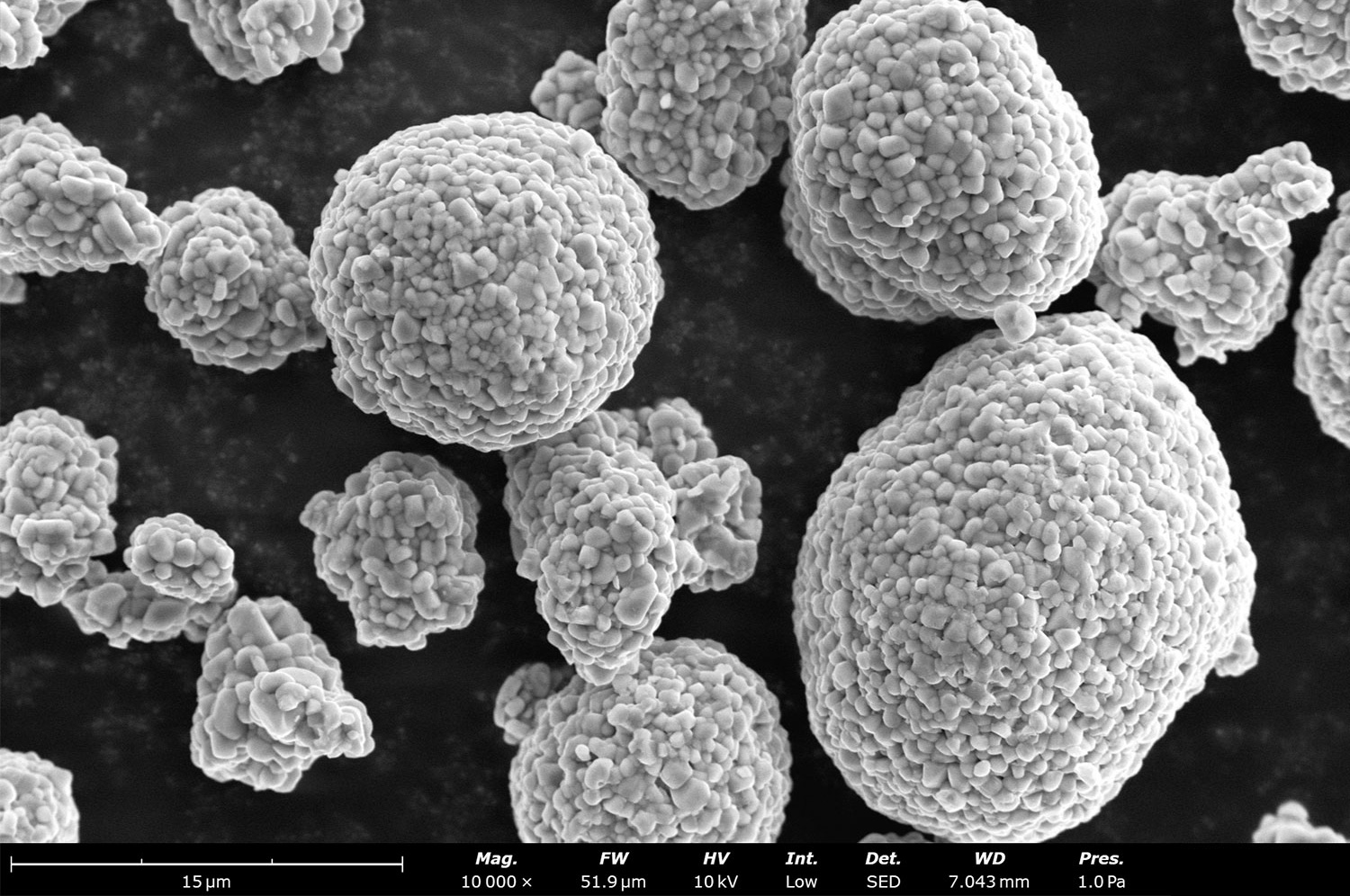

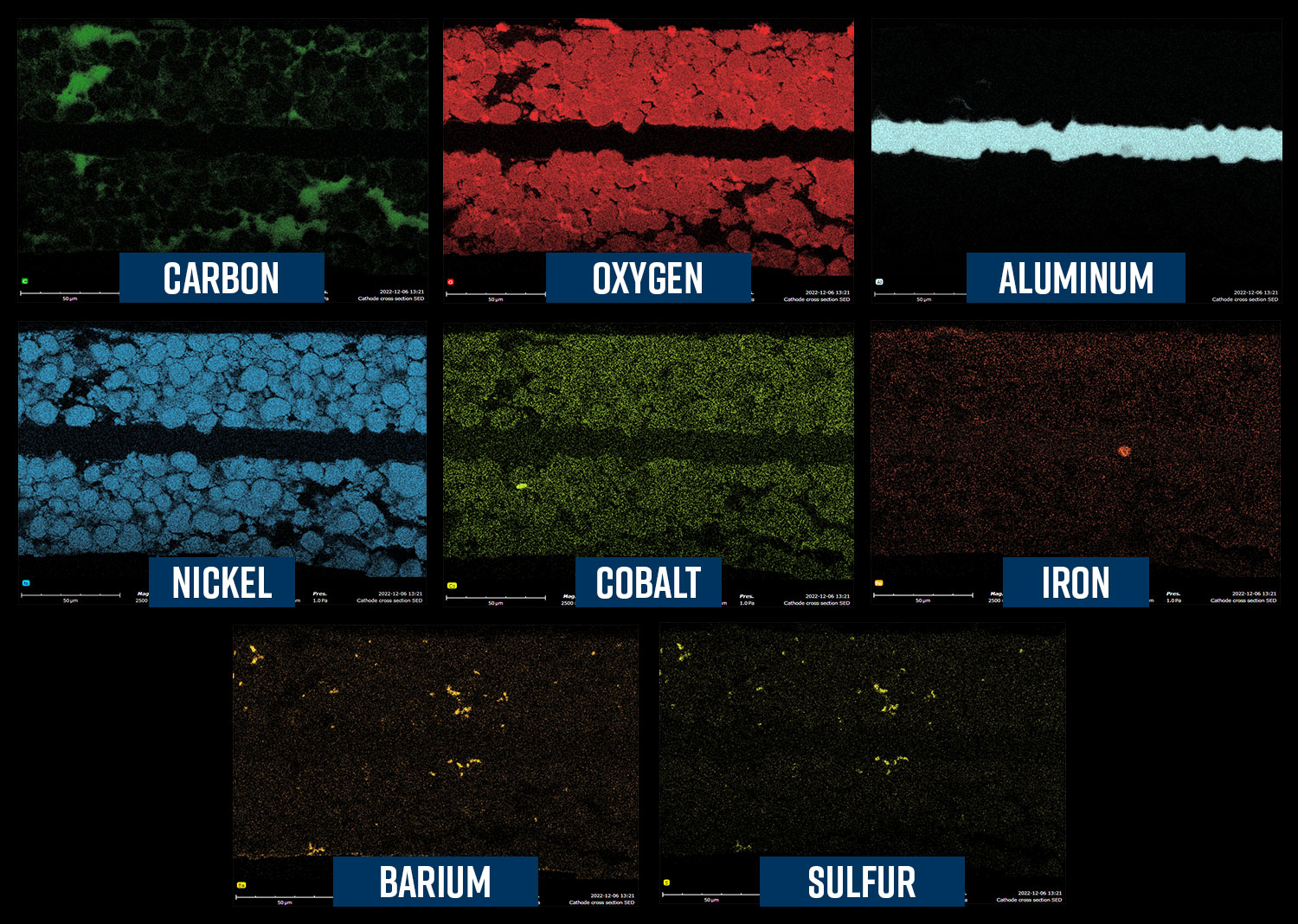

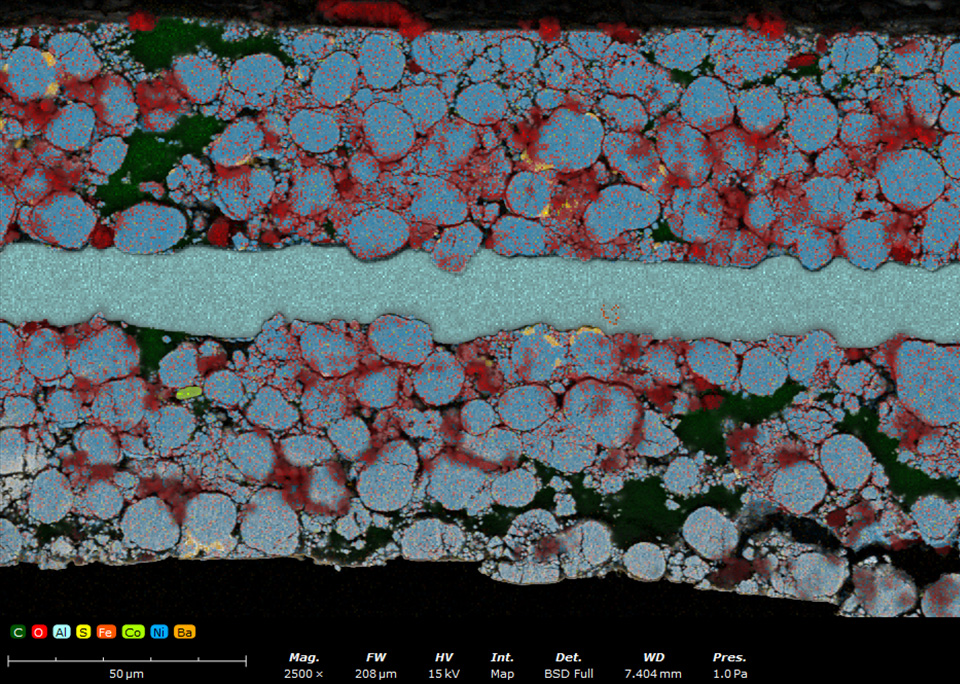

Images with high resolutions and high magnifications are required for a complete understanding of a material’s microstructure, from morphology to elemental composition. In battery applications, where materials have multiple microstructural phases of interest, this level of precise imaging is especially important. SEM is an imaging technique that utilizes a focused electron beam and a series of detectors to formulate high-resolution images of a sample. The backscattered electron detector (BSD) can highlight differences in atomic weights across the sample, while the secondary electron detector (SED) is perfect for surface characterization.

Elemental composition analysis for development of novel materials

Developing new formulae for anodes, cathodes, and separators requires precise electrochemical elemental mixtures. As such, any particle contaminants or deformed phase boundaries could have a direct impact on battery performance, damping the advantages that the material would otherwise provide. While these features may not be evident in BSD or SED images, SEM microscopes equipped with energy-dispersive X-ray spectroscopy (EDS) detectors are capable of complete, nondestructive elemental analysis, enabling precise detection of the presence and locale of elemental phases.

Automated particle analysis

Performing statistics on SEM-EDS images can lead to critical information regarding particle morphology, including size distribution of primary particles and locations of cracked or fine particles. However, manual operation of this method is tedious and can lead to difficulties when reproducing results. For ease-of-use, reproducibility, and improved throughput, particle analysis can be automated with software, generating full pass/fail reports with just a few clicks from the operator. Technical cleanliness and powder purity can also be assessed particle-by-particle to verify adherence to industry and company standards.

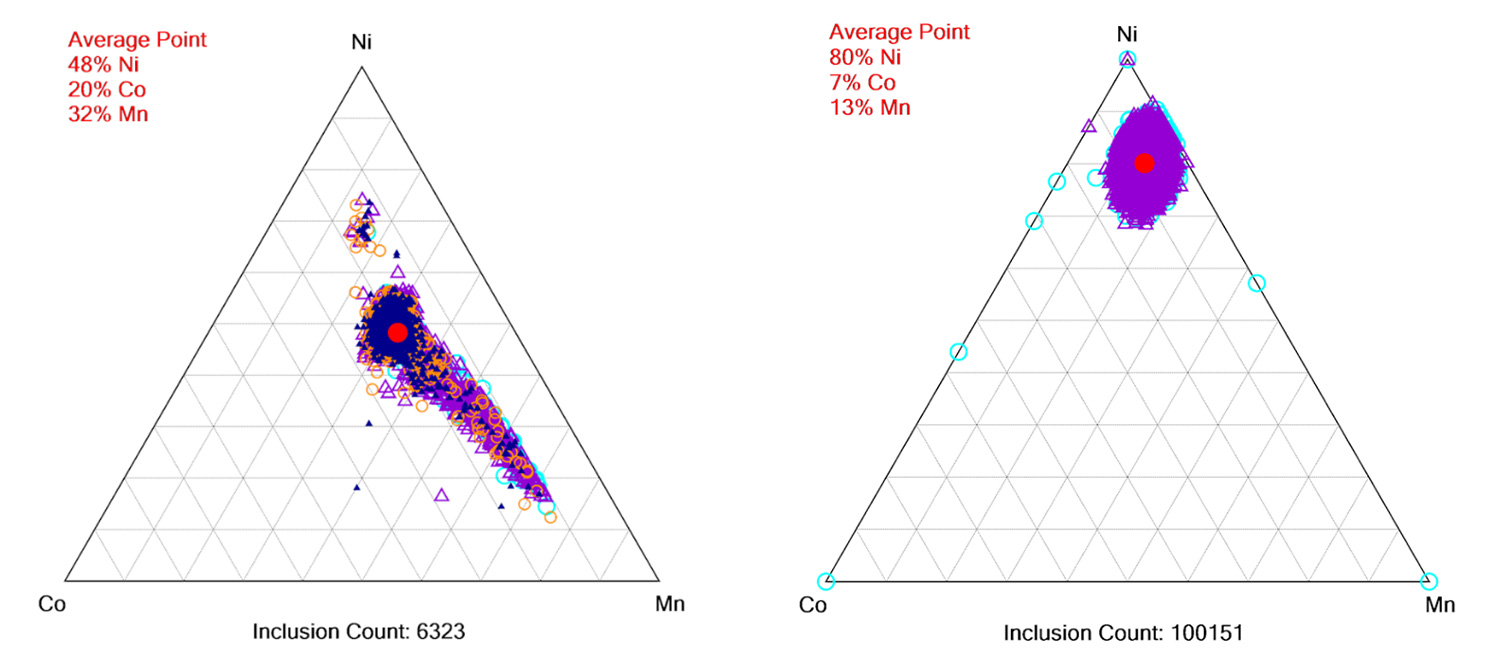

Figure 6. Running ParticleX for automated particle analysis

ParticleX, a software package for the Phenom XL desktop SEM, can automatically compile results into ternary diagrams showing the distribution of size and composition across a sample. In this analysis of over 6,300 NCM-523 particles, the average composition matches closely to the expected ratio of each element. The ternary diagram, however, shows a 20% fluctuation in cobalt composition, and a much larger fluctuation in the Ni/Mn ratio. Furthermore, the diagram shows that this fluctuation is more prevalent in the larger particles. This level of detail can only be obtained through particle-by-particle characterization.

Battery Research Solutions

Characterizing Battery Components

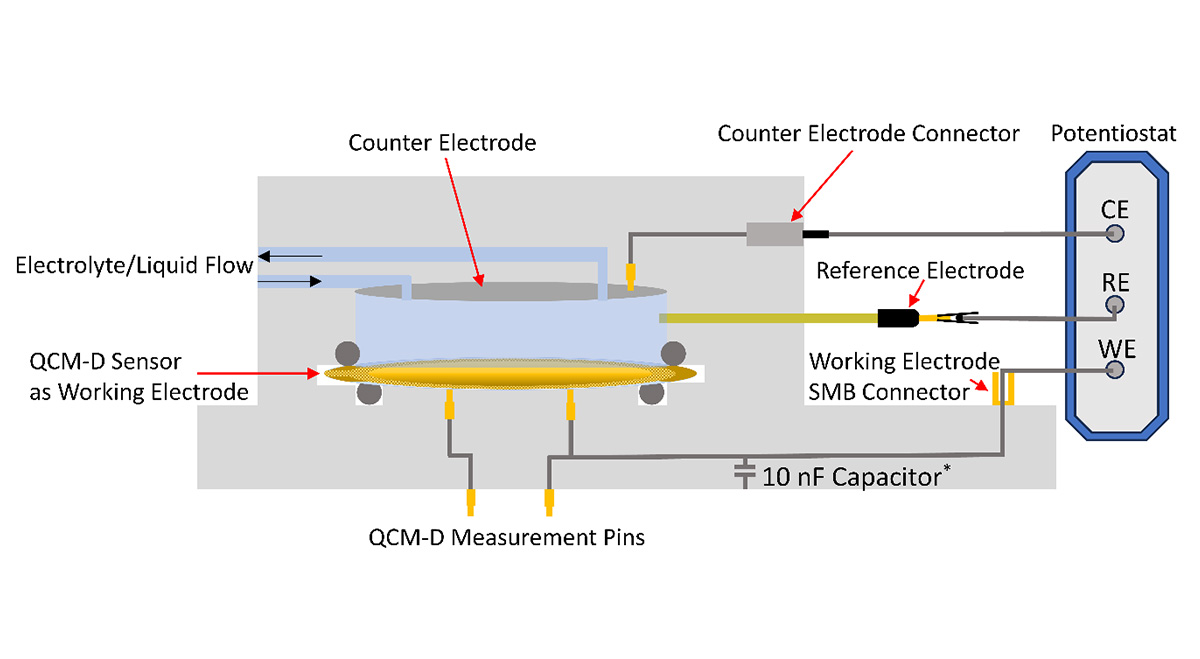

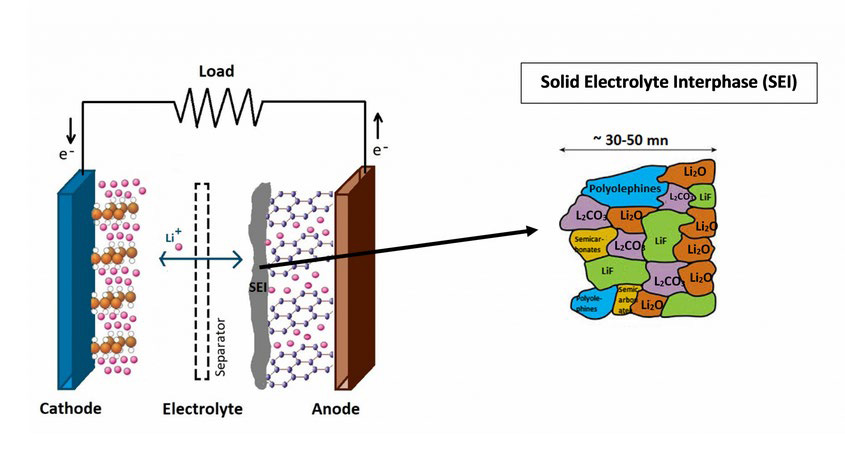

Solid Electrolyte Interphase (SEI) analysis

The solid electrolyte interphase (SEI) is a layer of salt degradation and solvent reduction materials that grow at the electrode/electrolyte interface. While SEI is fundamental to successful charge and discharge cycles, changes in the thickness or structure of the SEI can result in a decrease of storage capacity and an increase in cell resistance. Therefore, monitoring this boundary and its behavior over time is crucial for quantifying and improving battery health. Since in-situ conditions are also ideal for SEI analysis, QCM-D is a unique and powerful technique for this application. Quartz crystal microbalance with dissipation (QCM-D) is a highly sensitive surface analysis technique that monitors the oscillation properties of a quartz sensor during nanoscale surface interactions in real time. Changes in oscillation frequency and energy dissipation, linked to the mass and mechanical properties of the surface layer, enable in-situ tracking of:

- Dynamic buildup of the SEI

- Structural and mechanical changes in the SEI

- Influence of the electrolyte

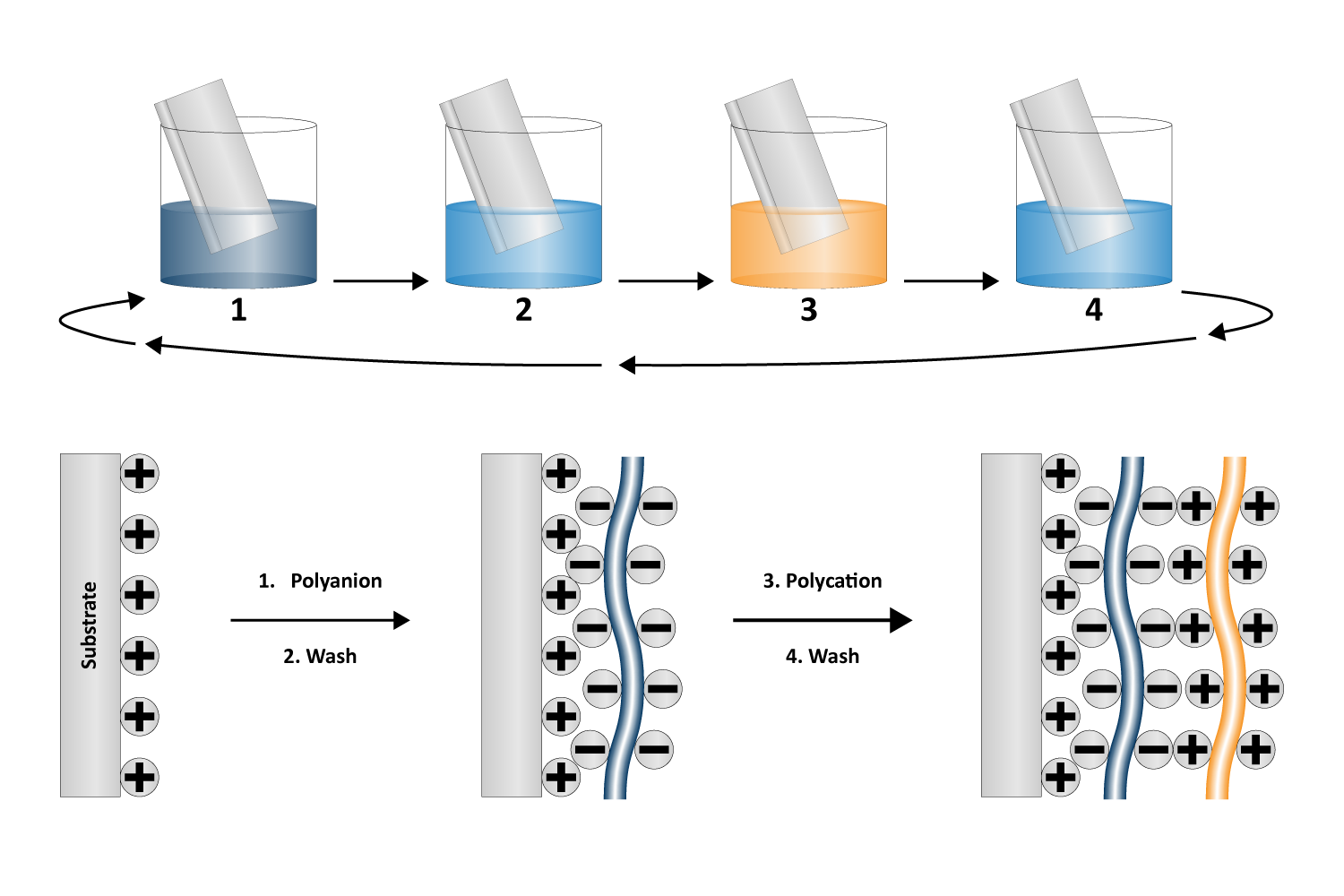

In-situ monitoring of complex electrodes

Exploring new materials for anodes, cathodes, and electrolytes is fundamental for the future of battery technology, as the material properties often determine key parameters such as charge/recharge time. However, materials with dynamic viscoelastic properties can be difficult to measure through traditional methods, since these materials require real-time analysis under dynamic environmental conditions. QCM-D instruments provide a solution to this; composite materials, polymer-containing electrodes, porous electrodes, and layer-by-layer assemblies can all be analyzed with this technique. Developing a better understanding of these materials with QCM-D is a critical step towards creating batteries with unique and powerful capabilities.

To learn more, see our latest webinar on the topic:

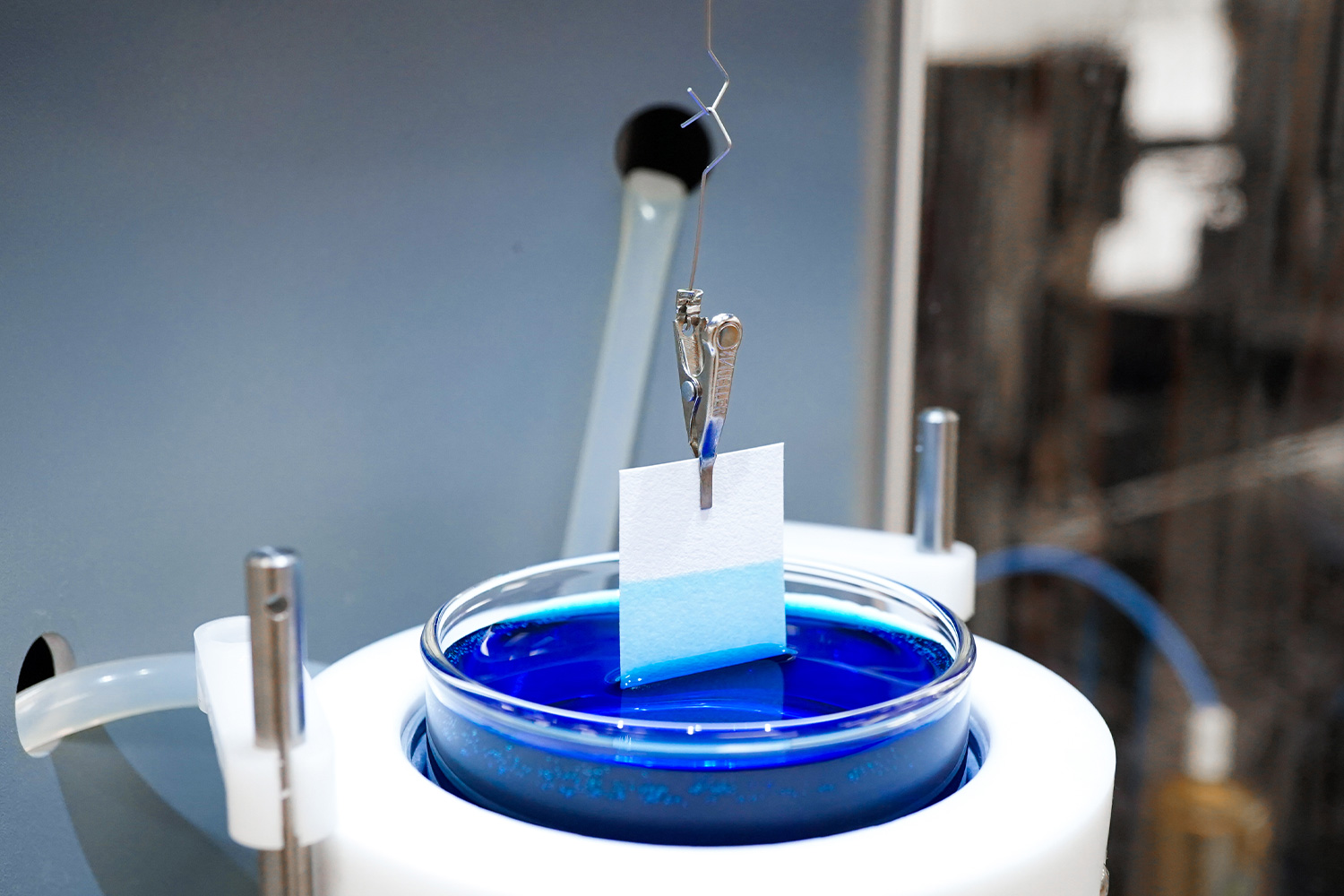

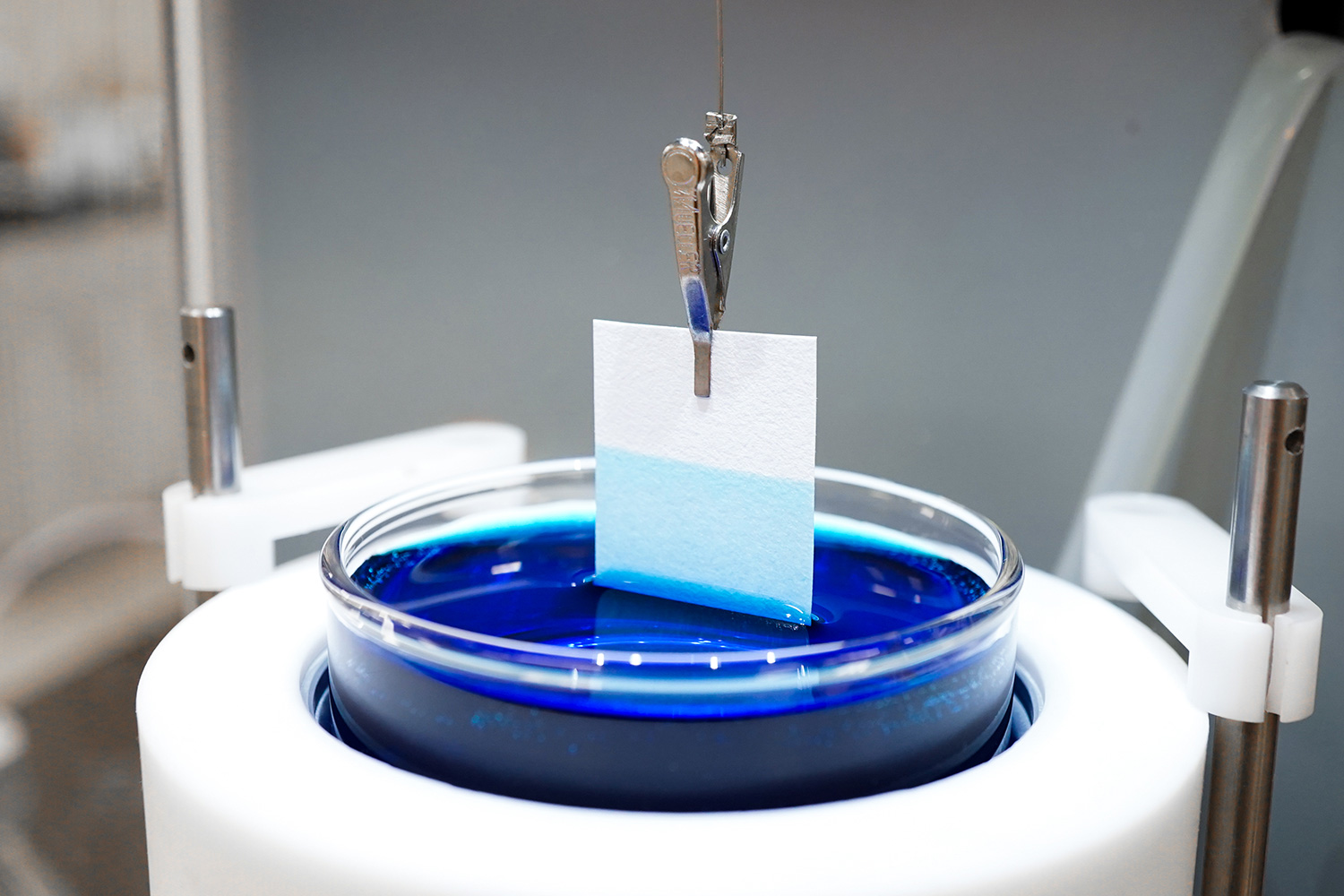

Electrolyte uptake analysis

Since separators and electrodes must be fully wet with electrolyte solution for ideal ionic transport, analyzing and optimizing the rate of electrolyte absorption could lead to improvements in not only battery manufacturing time, but also performance and safety. Therefore, proper wettability characterization is critical for future innovations. Tensiometers are instruments that characterize the surface and interfacial forces/tensions of solids and liquids; force-based instruments utilize sensitive balances to directly measure these forces, while optical tensiometers use digital cameras and drop-shape fitting software to quantify these properties. Optical tensiometers are especially helpful for quantifying liquid contact angles and the impact of surface roughness, which contributes to electrode wettability. Force tensiometers can accurately measure liquid mass/volume uptake into porous materials, lending valuable insight into wettability of battery components.

Battery Research Solutions

Manufacturing Batteries

Failure analysis and quality control

Monitoring morphological features of interest, such as the sphericity of anode particles or lithium dendrite growth, can give researchers critical insights into battery health and quality. Microscopic or nanoscopic cracks could lead to conductivity voids inside the battery; these defects are only detectable with powerful microscopy techniques. SEM technology unlocks the ability to identify crystalline defects in electrodes and analyze pore distribution in separators. Desktop SEMs, with their higher throughput and ease-of-use, are ideal for determining any systemic sources of contamination or defects.

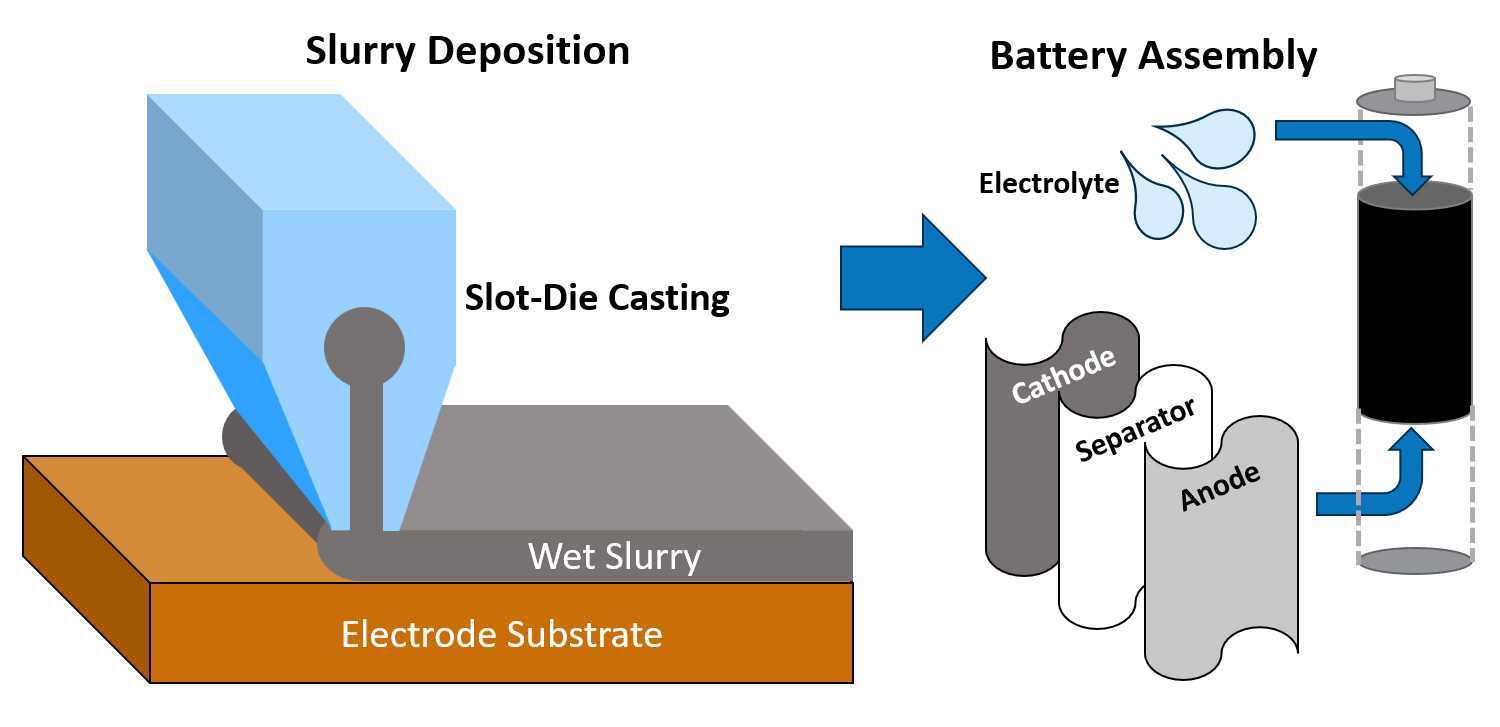

Optimization of slurry surface tension

Across the manufacturing process, slurry surface tension is related to processing time, shaping methods, and likelihood for defects. Carefully controlling this quality can open the door to new battery production methods. For example, electrode slurry extrusion via slot die coater can be both difficult to scale up and incapable of producing intricate microstructural designs. Syringe deposition 3D printing is one solution to these problems, but the properties of the electrode slurry must be redesigned to optimize it for thin-line extrusion. This is easier to accomplish when surface tension, adhesion force, and other parameters can be precisely quantified with a tensiometer.

Battery Research Solutions

References:

Vilkman, M.; Pechancová, V.; Mousavi, S.; Mosallaei, M.; Paul, D.; Obrezkov, F. Extrusion Coating as a Tool for Sustainable Solid-State Battery Manufacturing; 2024.

Ding, W.; Ru, C.; Xu, L. Recent Progress in Electrospun Nanofiber Separators for Advanced Lithium-Ion Batteries. Journal of Energy Storage 2024, 102, 114200.

Weng, W.; Kurihara, R.; Wang, J.; Shiratori, S. Electrospun Carbon Nanofiber-Based Composites for Lithium-Ion Batteries: Structure Optimization towards High Performance. Composites Communications 2019, 15, 135–148.

Mondal, A. N.; Wycisk, R.; Waugh, J.; Pintauro, P. N. Electrospun Si and Si/c Fiber Anodes for Li-Ion Batteries. Batteries 2023, 9 (12), 569.

Zheng, G.; Zeng, Z.; Chen, Y.; Wang, X.; Sun, D.; Cui, C. Versatile Electrospinning Technology on Solid-State Electrolytes for Energy Storage: A Brief Review. Journal of Energy Storage 2024, 86, 111285.

Li, B.; Pei, M.; Qu, Y.; Su, C.; Zhang, J.; Jin, X.; Wang, L.; Jian, X.; Hu, F. Electrospun Core–Shell Carbon Nanofibers as Free-Standing Anode Materials for Sodium-Ion Batteries. ACS Applied Nano Materials 2024, 7 (9), 10760–10769.

Kraytsberg, A.; Yair Ein-Eli. Conveying Advanced Li-Ion Battery Materials into Practice the Impact of Electrode Slurry Preparation Skills. Advanced Energy Materials 2016, 6 (21), 1600655–1600655.

Wu, M.-S.; Liao, T.-L.; Wang, Y.-Y.; Wan, C.-C. Assessment of the Wettability of Porous Electrodes for Lithium-Ion Batteries. Journal of Applied Electrochemistry 2004, 34 (8), 797–805.

Reynolds, C. D.; Alsofi, G.; Yang, J.; Simmons, M. J. H.; Kendrick, E. Design of Slurries for 3D Printing of Sodium-Ion Battery Electrodes. Journal of Manufacturing Processes 2024, 110, 161–172.

Ji, Y.; Yin, Z.-W.; Yang, Z.; Deng, Y.-P.; Chen, H.; Lin, C.; Yang, L.; Yang, K.; Zhang, M.; Xiao, Q.; Li, J.-T.; Chen, Z.; Sun, S.-G.; Pan, F. From Bulk to Interface: Electrochemical Phenomena and Mechanism Studies in Batteries Via Electrochemical Quartz Crystal Microbalance. Chemical Society Reviews 2021, 50 (19), 10743–10763.

Wang, Z.; Ouyang, L.; Li, H.; Lars Wågberg; Mahiar Max Hamedi. Layer‐By‐Layer Assembly of Strong Thin Films with High Lithium-Ion Conductance for Batteries and Beyond. Small 2021, 17 (32).

Cora, S.; Ahmad, S.; Sa, N. In Situ Probing of Mass Exchange at the Solid Electrolyte Interphase in Aqueous and Nonaqueous Zn Electrolytes with EQCM-D. ACS Applied Materials & Interfaces 2021, 13 (8), 10131–10140.