Batteries are a decisive element of modern mobile power consumption. While batteries have already been integrated irrevocably into smaller devices such as smartphones or portable computers, rechargeable batteries are increasingly used to propel larger energy consumers like cars and trucks as we shift our reliance away from energy resources based on fossil fuels. With goals like 50% of all new vehicle sales being electric by 2030 in the US, the demand for batteries will keep increasing.

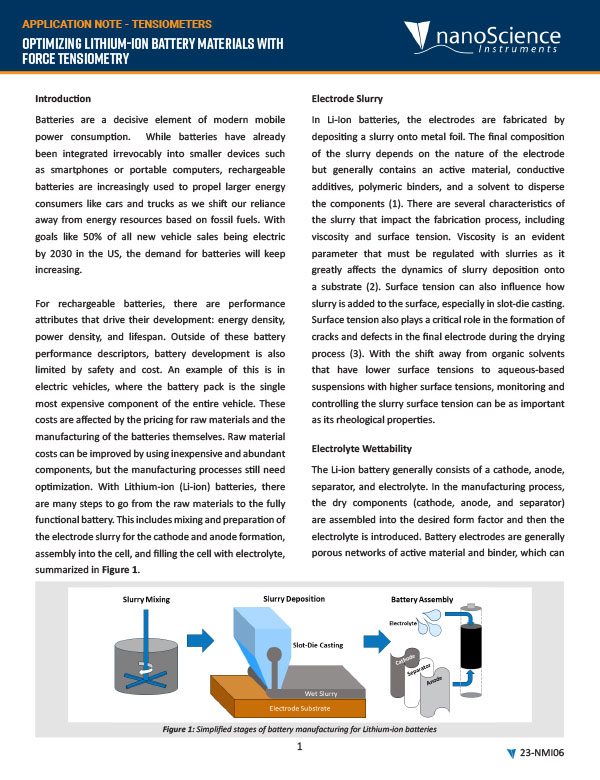

For rechargeable batteries, there are performance attributes that drive their development: energy density, power density, and lifespan. Outside of these battery performance descriptors, battery development is also limited by safety and cost. An example of this is in electric vehicles, where the battery pack is the single most expensive component of the entire vehicle. These costs are affected by the pricing for raw materials and the manufacturing of the batteries themselves. Raw material costs can be improved by using inexpensive and abundant components, but the manufacturing processes still need optimization. With Lithium-ion (Li-ion) batteries, there are many steps to go from the raw materials to the fully functional battery. This includes mixing and preparation of the electrode slurry for the cathode and anode formation, assembly into the cell, and filling the cell with electrolyte, summarized in Figure 1.