Scanning Electron Microscopes (SEMs) are indispensable tools for analyzing surface morphology, materials composition, and microstructural details at high resolution. They are used extensively across research institutions, manufacturing lines, forensic labs, environmental monitoring stations, and more. However, conventional floor-model SEMs come with significant infrastructure requirements, such as dedicated space, environmental conditioning, and auxiliary systems, that often limit where and how they can be deployed. Desktop SEMs offer many of the same features as floor-model systems in a compact design that can be accommodated virtually in any lab space.

Limitations of Traditional Floor-Model SEMs

Full-size SEMs are typically large, heavy, and complex. Operating one often demands a dedicated technician as well as a custom-built room outfitted with vibration isolation, upgraded electrical systems (typically requiring 240 V power), temperature and humidity regulation, and frequently, a bulky water chiller. These systems also must be professionally installed, calibrated, and maintained, adding to the logistical overhead. Relocating a floor model is a nontrivial task as it typically involves disassembly, freight elevators, and service engineers. This makes them impractical for dynamic or space-constrained environments such as shared research labs, classrooms, mobile units, or cleanrooms.

Desktop SEMs: A Compact Alternative

Phenom tabletop SEMs are engineered to eliminate these barriers. Designed to fit on a standard lab bench or even an office desk, these systems can be installed in virtually any lab environment without requiring modifications. Unlike traditional systems, they operate on a standard 110 V outlet and do not require specialized cooling, room renovations, or environmental controls.

Minimal Footprint and Infrastructure Requirements:

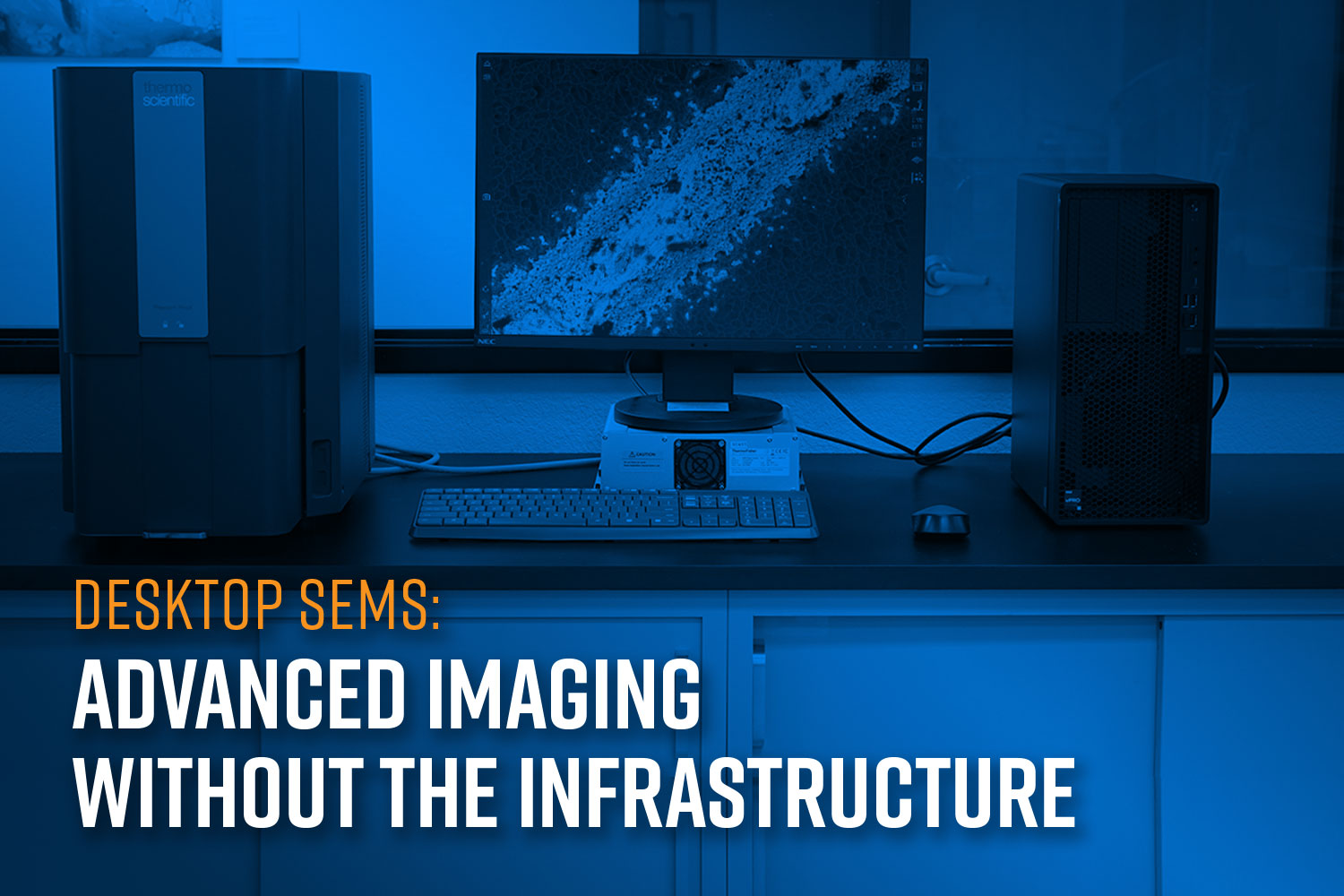

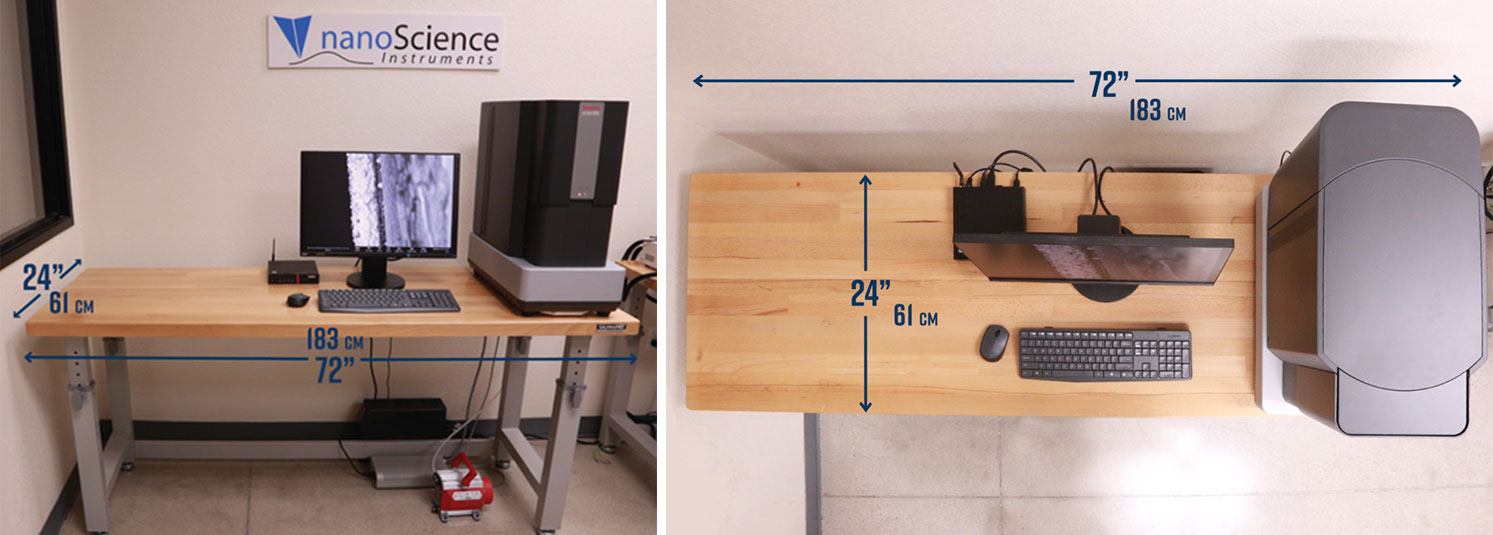

While traditional SEMs may sprawl across multiple rooms to accommodate chillers, pumps, and computer systems, a Phenom tabletop SEM fits neatly on less than half of a standard 72-inch bench, as seen in Figure 1. For a standard set up, essential components like the pre-vacuum pump and power supply are housed below the bench, keeping the workspace clean and organized. This streamlined footprint opens possibilities for integration into environments where floor space is at a premium.

Versatile Applications Across Diverse Environments:

The compact nature of tabletop SEMs extends their utility across a wide range of specialized applications. Desktop SEMs can be placed on a standard lab bench in any laboratory, allowing users to quickly transition from sample production to analysis. They are small enough to fit in cleanrooms without disturbing airflow or requiring floor plan redesign. They can even be placed inside or near gloveboxes for analysis of air or moisture-sensitive materials such as those in the development of batteries and catalysts. Desktop SEMs allow for imaging directly on the production floor thereby enabling faster feedback loops in manufacturing & QA.

Portability and Flexibility in Use:

One of the most compelling advantages of tabletop SEMs is their mobility. Lightweight and compact, a Phenom SEM can be easily carried by two people and transported. This makes it ideal for facilities such as temporary research setups, educational settings, remote geological or environmental sites, where flexibility is key. Because these systems are self-contained and not hardwired into the infrastructure, they can be moved without requiring expert technical support.

No Trade-off in Performance

Phenom tabletop SEMs are designed not only for convenience and flexibility but also for robust analytical performance. Despite their smaller size and minimal infrastructure requirements, these systems are engineered to deliver results that meet the demands of research-grade and industrial applications alike.

High-Resolution Imaging:

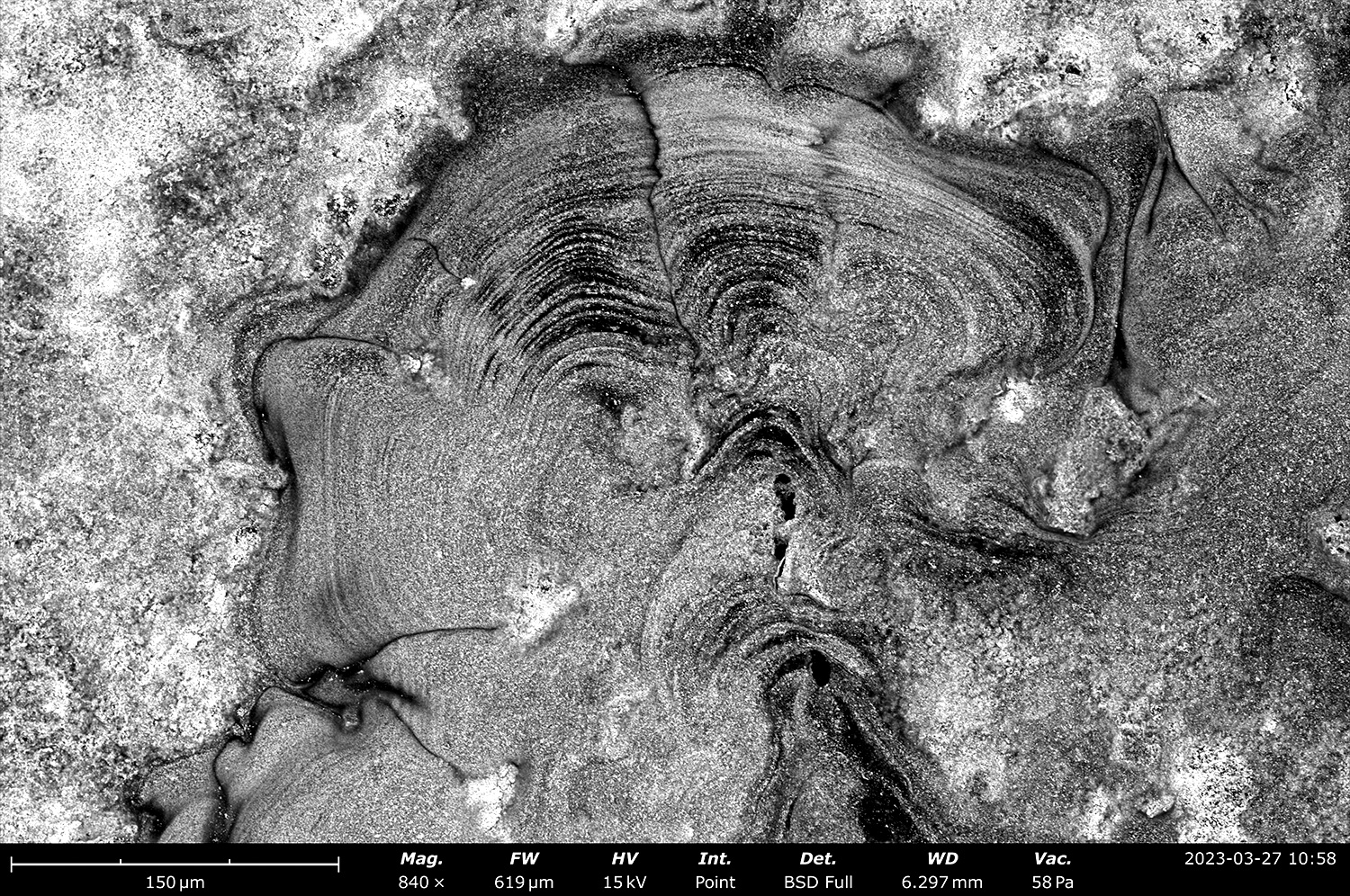

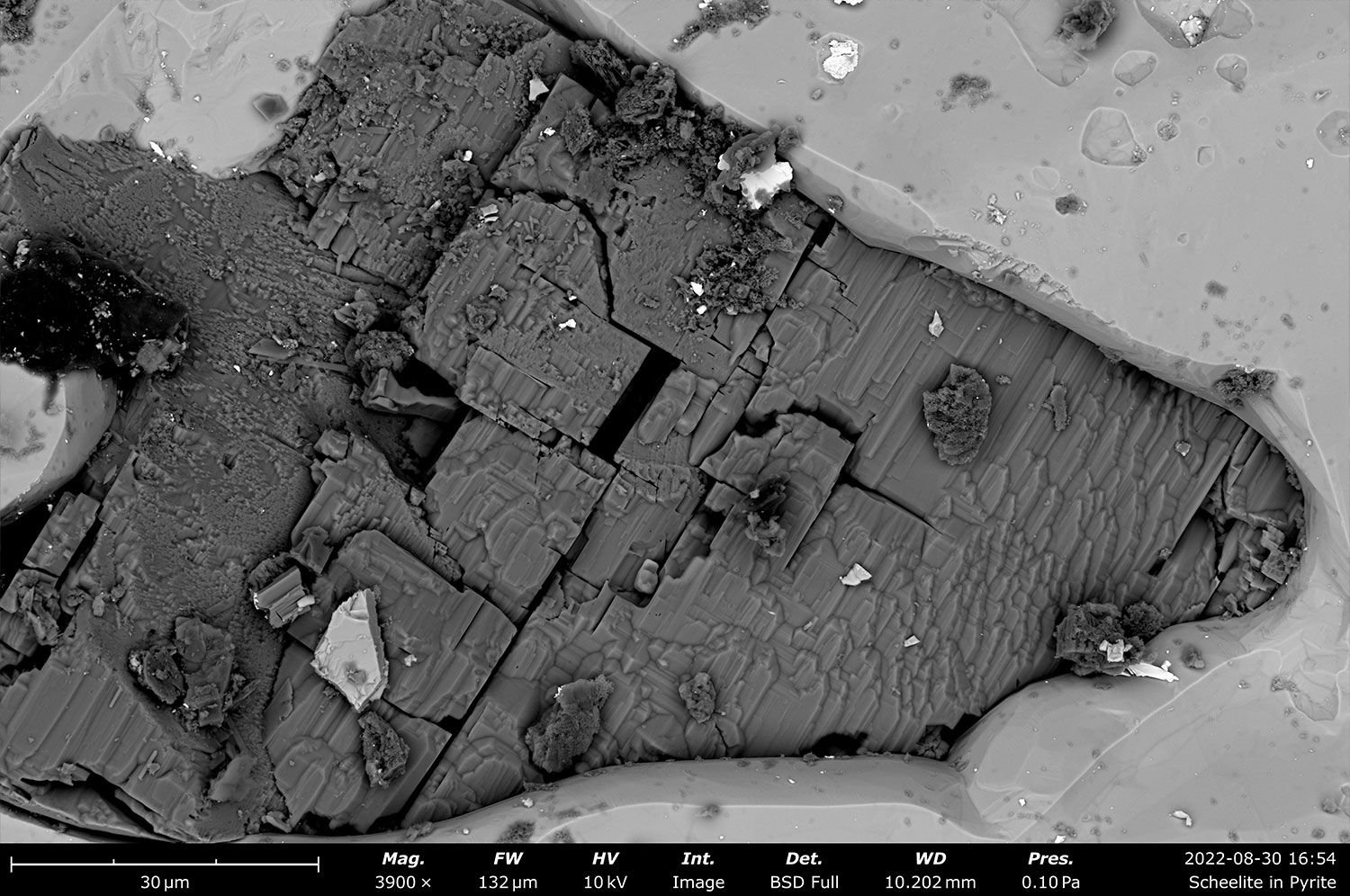

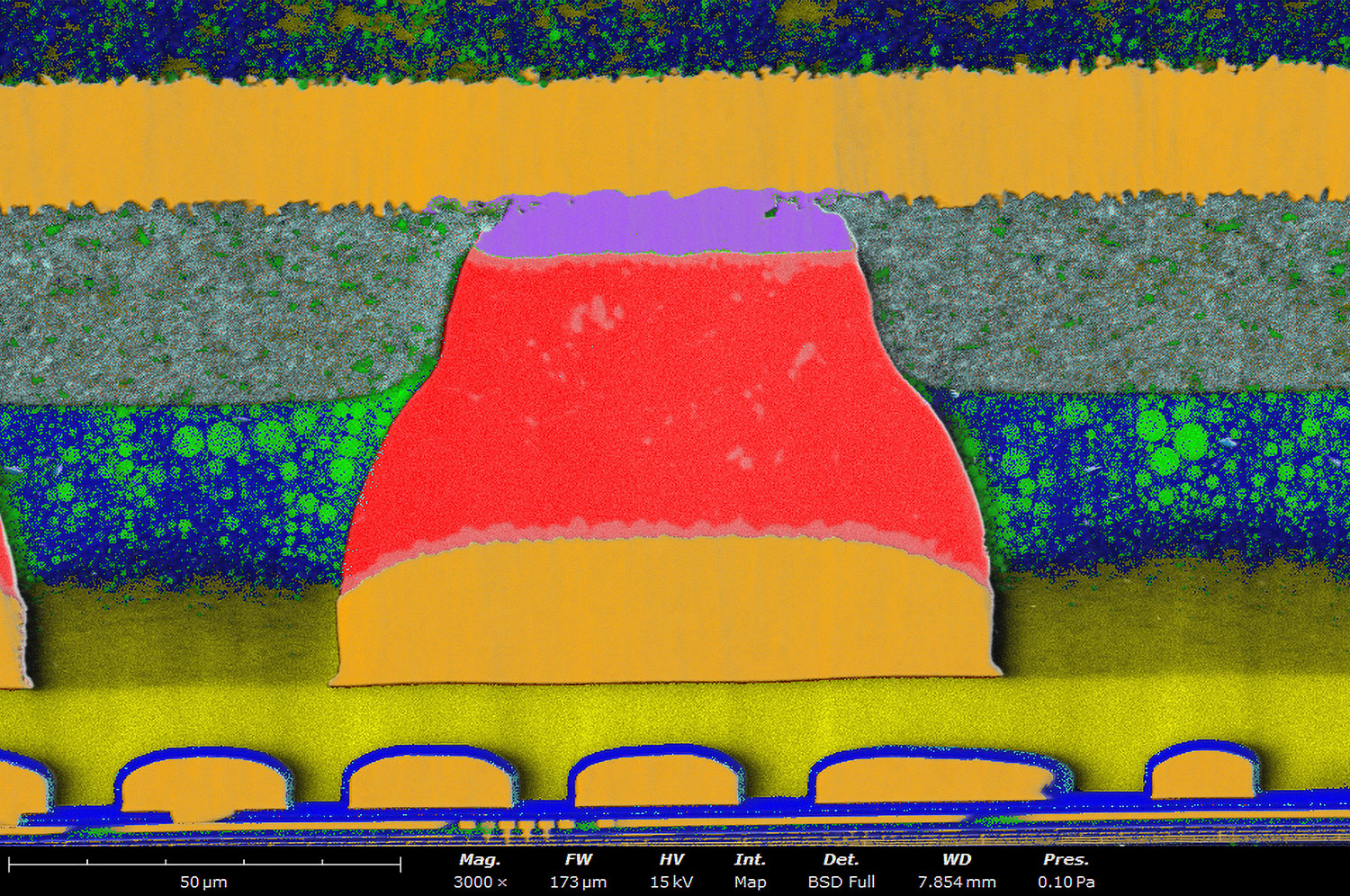

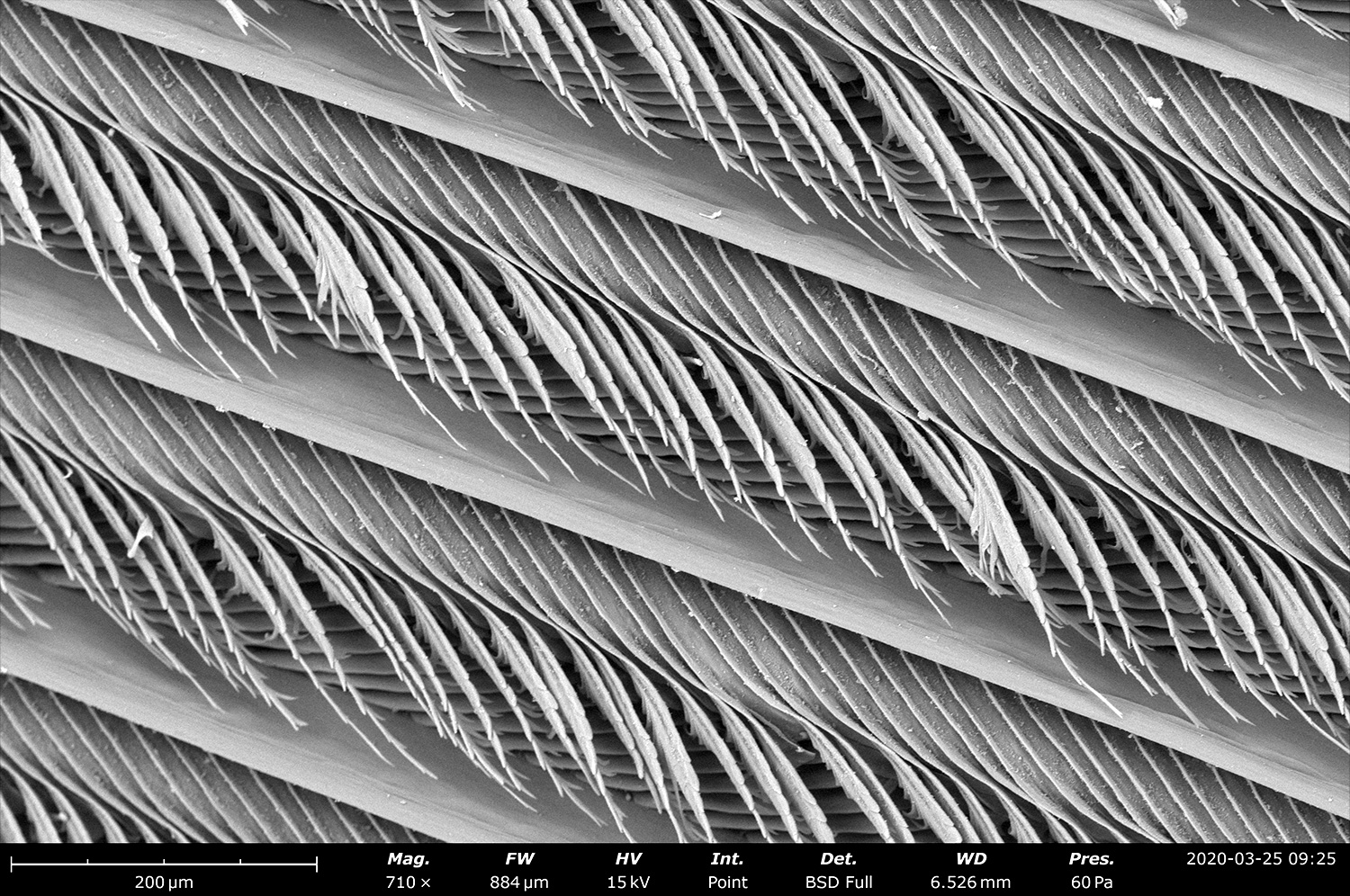

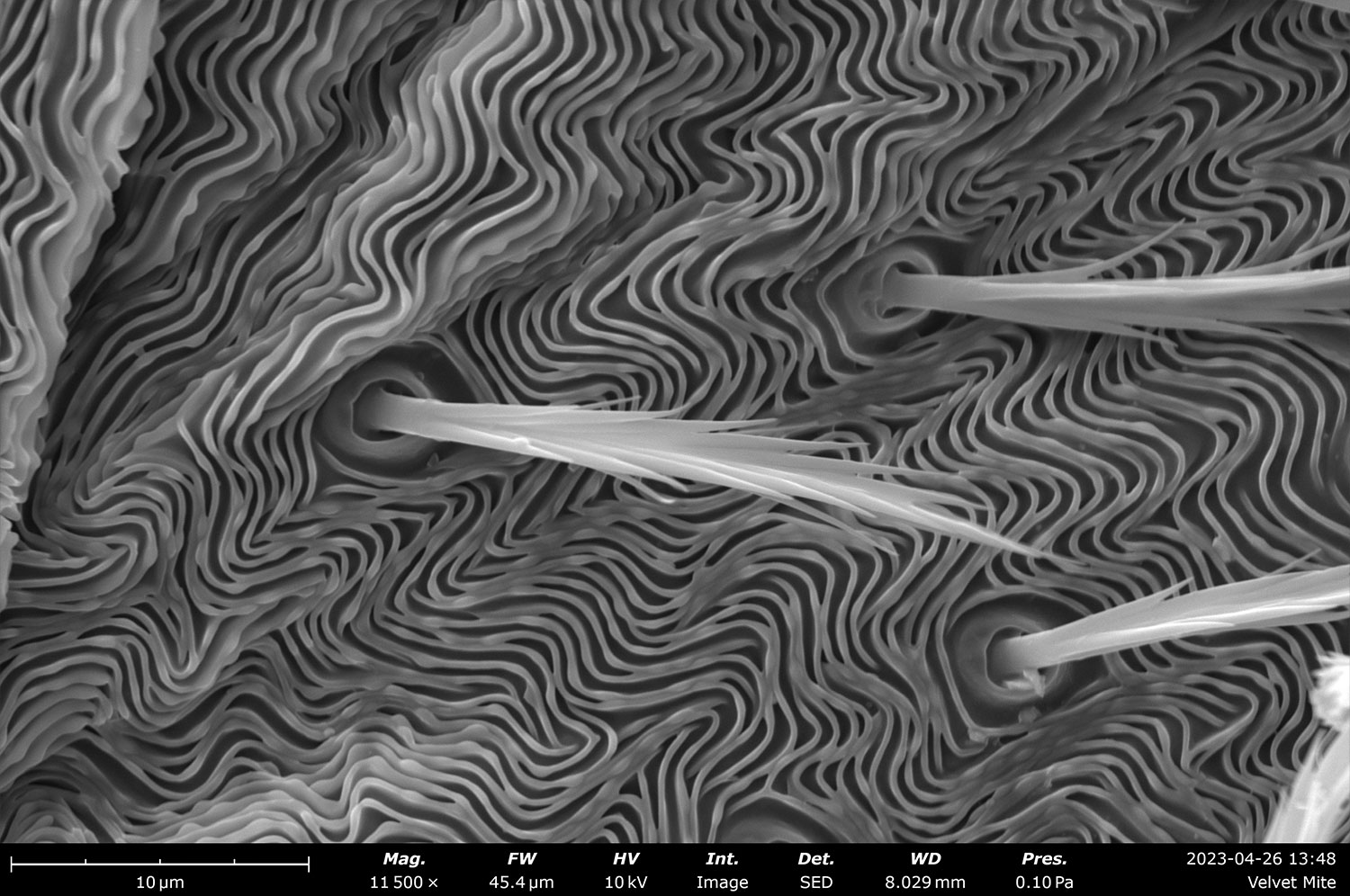

Phenom SEMs can achieve resolutions down to 2 nm, depending on the model. This makes them suitable for resolving fine surface structures, thin films, nanoparticles, biological tissues, fibers, and microfabricated devices. Phenom Desktop SEMs include both the secondary electron (SE) and backscattered electron (BSE) detection for surface topology and compositional contrast. The Phenom Pharos can also come equipped with a STEM detector to perform transmission imaging at sub 1 nm resolution. Proprietary electron optics and advanced detector technologies ensure sharp, low-noise imaging across a wide range of accelerating voltages and working distances (Figure 2).

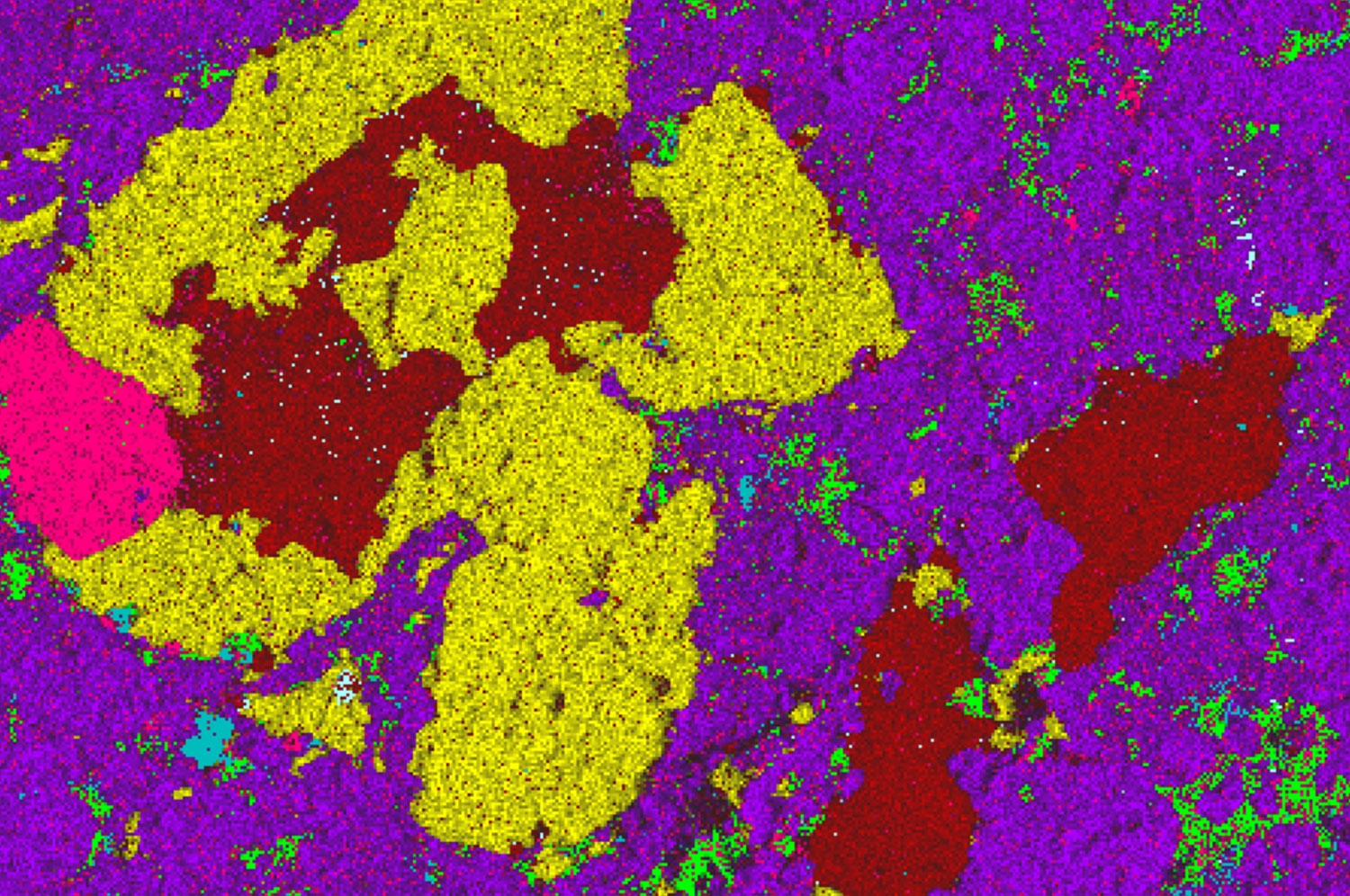

Elemental Analysis with Integrated EDS:

A fully integrated Energy-Dispersive X-ray Spectroscopy (EDS) detector for rapid and intuitive elemental analysis is also available as an option in the Phenom SEM (Figure 2b and 2d). This feature allows users to identify, map, and quantify elemental composition directly within the same interface used for imaging. A user-friendly software with intuitive workflows for non-expert users and real-time spectral overlays on SEM images are among the key highlights of the Phenom SEM.

Automation and Workflow Efficiency:

Phenom systems are designed for speed and ease-of-use. Features that support rapid and repeatable workflows include fast start times (~ 30 sec), automated image optimization (focus, contrast, brightness) and batch imaging and analysis for high-throughput situations. Phenoms can also be controlled through python scripting, allowing for endless possibilities in automation.

Advanced Sample Handling and Imaging Conditions:

Phenom SEMs accommodate a broad range of sample types through flexible sample stages and imaging conditions. Motorized stage options for automated multi-point inspection and imaging are available. Phenom XL includes a large sample chamber able to attend samples up to 100 mm diameter. The charge reduction or low vacuum capabilities of the Phenoms enable imaging of non-conductive samples, such as biological or polymeric specimens, that tend to charge under the electron beam. The seamless and fast transition to low vacuum mode allows Phenom users to quickly combat charge build up and dramatically improve images of non-conductive samples.

Conclusion

Phenom tabletop SEMs redefine what’s possible in electron microscopy by removing the traditional constraints of space, infrastructure, and mobility. For labs that value flexibility, efficiency, and ease of use, without sacrificing image quality or analytical capabilities, the compact form factor offers a compelling solution.

Phenom SEMs demonstrate that high-performance scanning electron microscopy doesn’t have to come with a large footprint or steep learning curve. With nanometer-scale resolution, integrated elemental analysis, broad sample compatibility, and workflow-accelerating features, these systems are well suited for both routine inspection and sophisticated research applications.

Whether in materials science, life sciences, industrial QA/QC, or education, Phenom makes high-performance SEM accessible where it was previously impractical and delivers the performance expected from a research-grade SEM, packaged in a system designed for the modern lab.