What is Particle Analysis?

Particle analysis is the measurement and characterization of particles in a sample. Particle analysis typically focuses on properties such as particle size and size distribution, shape and morphology, count, concentration, and composition. Particle analysis is used to ensure quality control, understand material properties, and optimize production processes.

Techniques for Particle Analysis:

Several different techniques are commonly used for particle analysis, each approaching from different angles to determine the size, shape, concentration, and composition of particles. The choice of techniques used depends on the size range of the particles, the medium in which the particles are suspended, and the information required. Some of the techniques include:

Mechanical Screening:

Particles are separated into size fractions by passing them through a stack of sieves with decreasing mesh sizes. Mechanical screening can be used to study particle size distribution (typically >40 µm) and mass fraction in each size range. This technique is simple and inexpensive and is suitable for bulk materials. It is commonly used for analyzing minerals, food ingredients, and powders. Mechanical screening has limited resolution and accuracy.

Sedimentation Techniques:

In this technique, particles are allowed to settle in a fluid under gravity or centrifugal force and their rate of sedimentation is used to calculate particle size based on Stoke’s law. Sedimentation techniques are used to analyze particle size distribution (submicron to 100 µm) in pigments, slurries, and emulsions. These techniques work well in opaque media and are accurate for dense or irregular particles.

Field-Flow Fractionation:

Particles are separated based on size or mass in a laminar flow channel under an applied field. Fractionation techniques can be used to measure the size, shape, and molecular weight of particles and for fractionation of polydisperse populations. These techniques are suitable for fragile or soft particles but involve complex instrumentation that requires calibration and method development.

Laser Diffraction (LD):

Laser diffraction measures the angular variation of light scattered by a group of particles when exposed to a laser beam. Laser diffraction is a fast method that can handle a wide range of sizes and is suitable for wet or dry samples. LD is commonly used to measure particle size distribution (typically 0.1 µm to 3 mm) in powders, emulsions, suspensions and sprays. The limitation of this technique is that it assumes that the particles are spherical and are therefore inaccurate for polydisperse or irregular-shaped particles.

Dynamic Light Scattering (DLS):

DLS analyzes the Brownian motion of particles in a liquid by measuring fluctuations in scattered light intensity. The diffusion coefficient is used to calculate the hydrodynamic diameter of the particle. DLS measures the particle size (1 nm – 1 µm) and the polydispersity index (PDI) and is commonly used in biotech, nanomedicine, and colloid science to analyze nanoparticles, liposomes and micelles. However, DLS assumes that the particles are spherical and hence can be less reliable for irregular shaped particles.

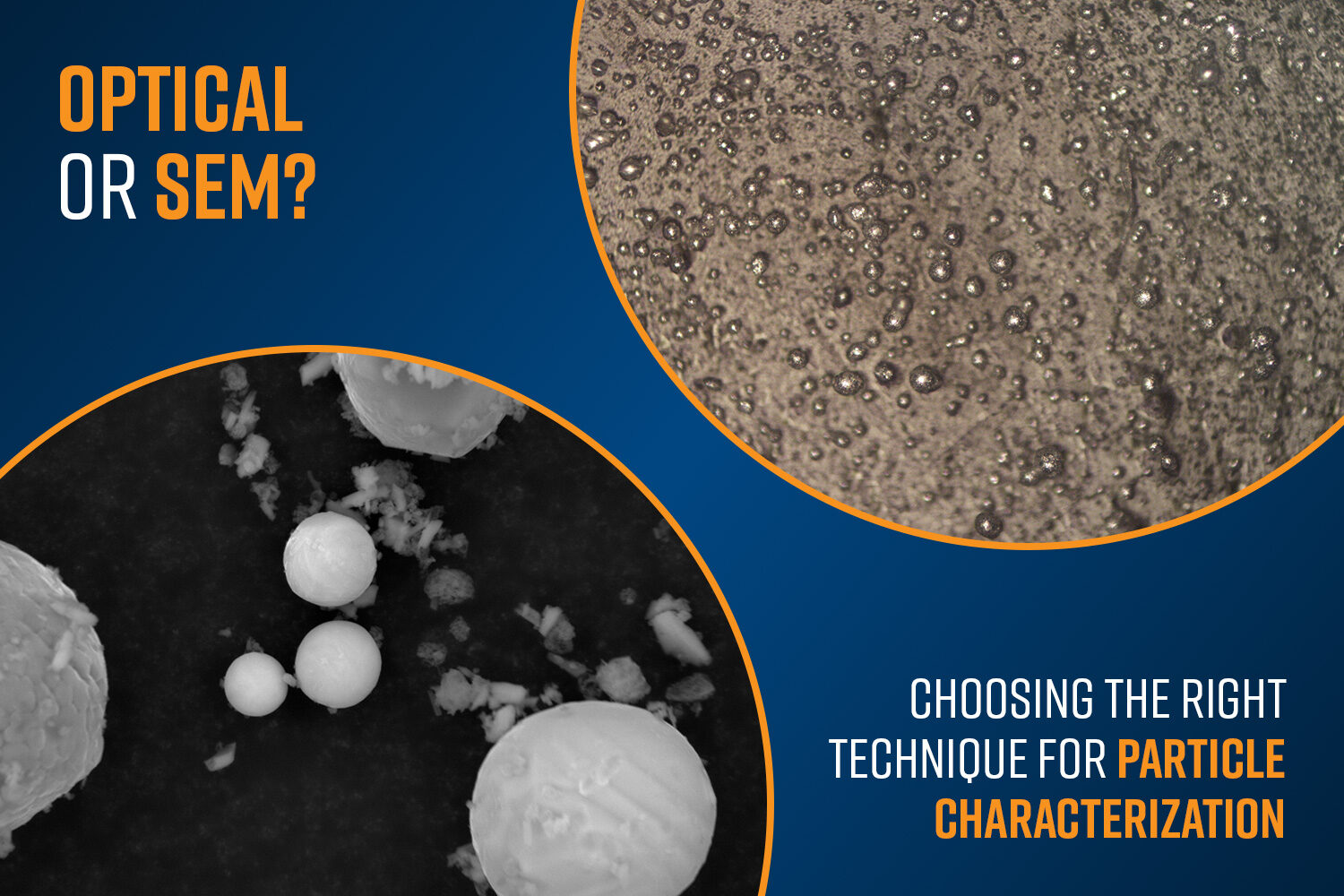

Image Analysis:

Particles are directly imaged using optical or electron microscopy (SEM or TEM), and specialized software is used to quantify their size, shape, and morphology. Since the particles are directly visualized by these techniques, they are ideal for analyzing complex or irregular particles and are commonly used in materials science, geology, and failure analysis. However, these techniques are slow, time consuming, and have relatively low throughput.

Spectroscopic Methods:

Spectroscopic methods like Energy-Dispersive X-ray Spectroscopy (EDS) or Raman spectroscopy coupled with SEM or TEM techniques can be used to analyze elemental or molecular composition of particles. These techniques provide both morphology and composition information and are ideal for contaminant analysis, failure analysis, and composite materials analysis. The drawback with these techniques is that they require vacuum-compatible samples and are qualitative or semi-quantitative in most cases.

Applications for Particle Analysis:

Particle analysis is essential across a wide array of industries, providing insights into material behavior, product performance, and regulatory compliance. Some of the key sectors where particle analysis plays a critical role include:

Pharmaceuticals & Biotech:

Particle size plays a critical role in drug formulation since it directly affects dissolution rate, absorption, and bioavailability of active pharmaceutical ingredients (APIs). Smaller particles tend to dissolve faster, which can improve drug efficacy. In the case of inhalable drugs, particle size is critical for pulmonary delivery wherein the particles must be 1 – 5 µm to reach the lungs efficiently. Ensuring uniform particle distribution prevents sedimentation or aggregation of injectables and suspensions. In nanoparticle-based drug delivery systems (e.g., liposomes, polymeric nanoparticles), precise size and shape control are essential for targeting and cellular uptake. Detecting foreign material/particulate present in drug formulation and identifying their potential source is an emerging need and requires information about both the size and composition of the particles.

Materials Science & Advanced Manufacturing:

Particle size and shape influence powder flowability, compaction, and sintering behavior in additive manufacturing and can play a major role in layer uniformity and part strength. In batteries and energy storage devices, their performance is highly dependent on the particle size and morphology of anode and cathode materials. Understanding the possible contaminants is critical for batteries to prevent premature failures or thermal runaways. And in catalyst development, particle size impacts surface area and reactivity, both essential for consistent catalytic performance.

Environmental Monitoring & Clean Technologies:

Characterization of particulate matter in both air and water is critical for environmental monitoring. Fine particles in the air can penetrate the respiratory system and pose health risks. Particulate contaminants in drinking water and wastewater can be hazardous to humans and livestock. Microplastic detection and quantification in marine and freshwater systems is necessary to understand pollution and its ecological impact.

Automotive & Aerospace:

Particle analysis is vital to ensure that nanoparticle dispersions remain stable and do not clog filters or damage components in lubricants and fuel additives. Monitoring particles from wear processes in mechanical components is necessary to avoid catastrophic failures in systems. Particulate transfer during the manufacturing process can lead to catastrophic failures. Monitoring parts cleanliness will maintain proper internal and external supply chain integrity.

Electronics & Semiconductors:

In the electronics and semiconductor industry, particle characterizations help optimize deposition techniques for thin film coatings. Particle size uniformity in conductive and dielectric pastes is critical for consistent electrical performance. In chemical mechanical planarization, the size and uniformity of the abrasive particles ensures uniform material removal without damaging wafer surfaces.

Cosmetics & Personal Care:

Particle size of emulsified droplets in cosmetics and personal care products impacts skin absorption, texture, and ability to spread. In products like foundations, sunscreens, and powders, particle size affects color uniformity and UV protection.

Food & Beverage Industry:

Particle size in food products affects the texture and influences consumer perception of creaminess, smoothness, and richness. Particle morphology also affects the flow properties and solubility of powders. Particle dispersion and size uniformity in emulsions influence the stability of many products, including salad dressings, dairy beverages, and nutritional supplements.

Conclusion

Particle analysis reinforces innovation and quality control across dozens of fields. From ensuring drug safety and environmental compliance to enhancing battery materials and food textures, particle size and morphology measurements help scientists and engineers understand and control complex systems.

Each particle analysis technique has distinct strengths and limitations, making it important to select the appropriate method based on the particle size range, sample type, desired measurement parameters, and application. Often, multiple techniques are used in combination to gain a comprehensive understanding of particle characteristics.

As analytical technologies continue to evolve, their applications expand into emerging domains like nanomedicine, environmental microanalytics, and advanced manufacturing. The proper use of particle analysis techniques enables precise control over products and processes in both research and industry.

References

- Nijhu, R. S.; Khatun, A.; Hossen, Md. F. A comprehensive review of particle size analysis techniques. International Journal of Pharmaceutical Research and Development 2024, 6 (1), 01–05. https://doi.org/10.33545/26646862.2024.v6.i1a.37.

- Ainurofiq, A.; Suryanto, A. A.; Beltiartono, B. S.; Merdekawati, N. A.; Ardiyani, N. P.; Farohma, Q. Y. C.; Budiman, A.; Wardhana, Y. W.; Nugraha, Y. P. Literature review: The role of particle size distribution in drug delivery. Multidisciplinary Reviews 2025, 8 (9), 2025269. https://doi.org/10.31893/multirev.2025269.

- Mariano, S.; Tacconi, S.; Fidaleo, M.; Rossi, M.; Dini, L. Micro and Nanoplastics identification: classic methods and innovative detection techniques. Frontiers in Toxicology 2021, 3. https://doi.org/10.3389/ftox.2021.636640.