When preparing samples for electron microscopy, the choice of method directly impacts the clarity and reliability of the images. Imperfections such as roughness, contamination, or surface damage can obscure fine details and lead to misinterpreted data.

Ion beam polishing, also known as ion beam milling, is an advanced sample preparation method that uses a directed stream of ions to precisely remove material from a sample’s surface. Unlike conventional mechanical polishing, ion beam polishing minimizes artifacts and delivers the ultra-smooth, defect-free surfaces that are necessary for high-resolution imaging.

For scanning electron microscopy (SEM), this is typically used to create cross sections that maintain the sample’s true structural and morphological features. For transmission electron microscopy (TEM), ion beam polishing can be used to prepare electron-transparent samples.

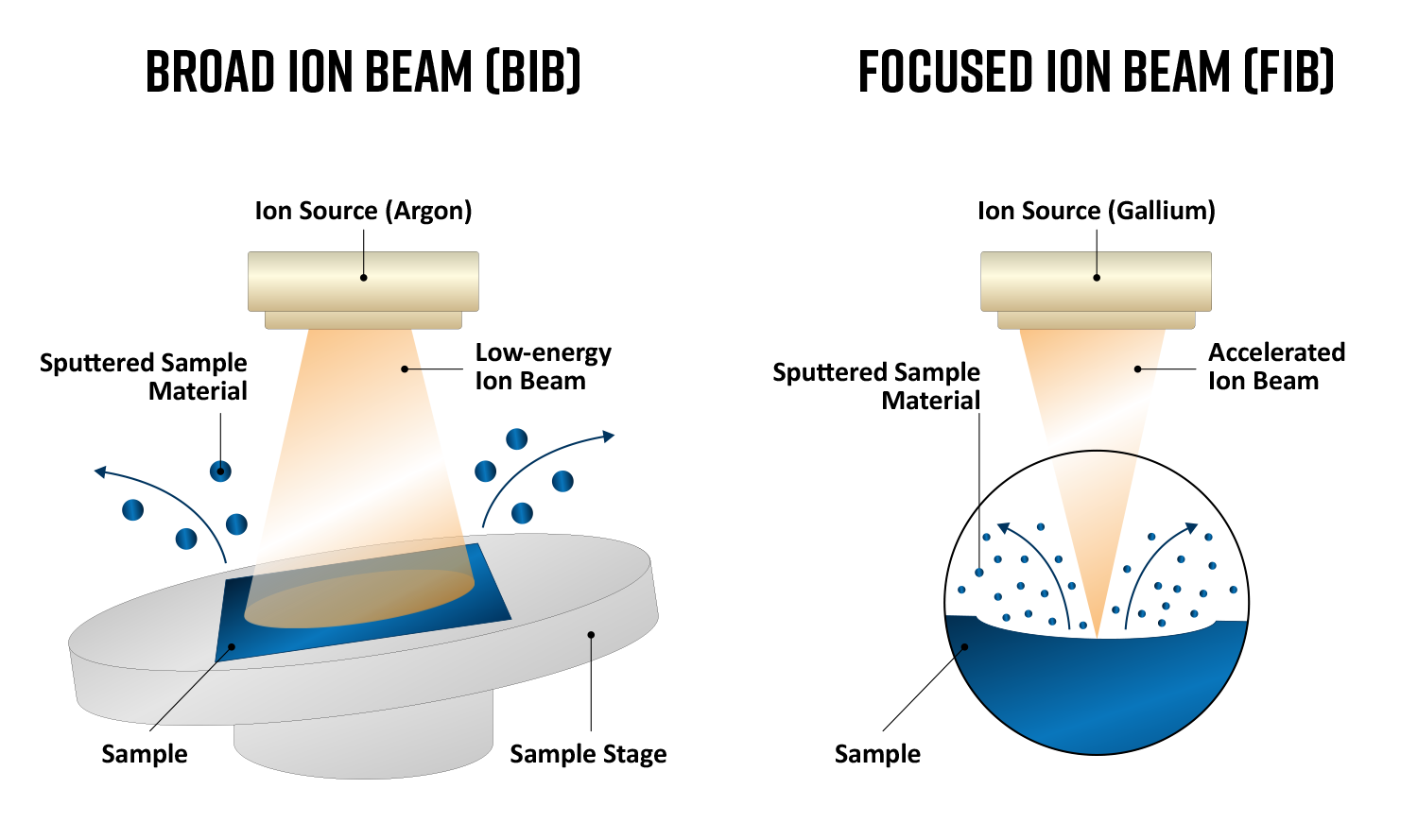

There are two primary methods of ion beam polishing: broad ion beam (BIB) polishing and focused ion beam (FIB) polishing. Both rely on accelerated ions to thin and polish materials, but they differ significantly in beam geometry, precision, throughput, and ideal applications (Figure 1). Choosing the right technique requires understanding the strengths, limitations, and best use cases of each technique.

What Is Broad Ion Beam (BIB) Polishing?

Broad ion beam polishing uses a broad-area, low-energy ion beam, typically composed of argon ions, to mill the surface of a sample. This creates a smooth, uniform surface on the millimeter scale. Due to the low energy nature of the ion beam, sample damage is minimized.1

Strengths of BIB Polishing

Large-area coverage:

BIB polishing produces flat, uniform surfaces over millimeter-scale regions, making it highly effective for preparing samples for SEM or EBSD analysis.

Ideal for TEM thinning:

BIB polishing enables high-resolution imaging of microstructures by producing electron-transparent regions without mechanical artifacts.

Damage-free preparation:

Since BIB systems use wide, low-energy ion beams, they minimize amorphization, implantation, and redeposition of material. The instrument allows the sample to oscillate during the mill to prevent curtaining artifacts, which is especially valuable when preparing sensitive materials such as ceramics, composites, polymers, or biologics.

Space requirements:

BIB mills can typically be installed on a typical laboratory bench.

Ease of use:

BIB systems are relatively simple, and multiple users within a laboratory space can be easily trained as operators.

Limitations of BIB Polishing

Slow material removal:

BIB is not efficient for bulk thinning, requiring long milling times compared to mechanical grinding.

Limited precision:

While BIB systems can perform with micron-scale accuracy, they cannot target specific features of interest on the nanoscale.

Specialization:

While less complex than FIB, BIB systems are still not as widely available as traditional polishing methods.

| Feature | Broad Ion Beam (BIB) | Focused Ion Beam (FIB) |

| Beam Geometry | Wide,low-energy beam | Narrow,high-energy focused beam |

| Surface Area | Millimeter-scale,large-area polishing | Nanometer–micrometer-scale,site-specific |

| Precision | Low | High(nanometer-scale) |

| Surface Damage | Minimal | Potential gallium implantation and amorphization |

| Throughput | Efficient for broad areas | Inefficient for large areas |

| System Complexity | Moderate | High; of tendual-beam SEM/FIB |

| Typical Use | EBSD prep, TEM thinning, cross-sections | TEM lamella prep, nanofabrication, 3D analysis |

What is Focused Ion Beam (FIB) Polishing?

Focused ion beam polishing utilizes a narrow, high-energy ion beam, commonly composed of liquid gallium, that can be directed with nanoscale precision.2 Unlike BIB, FIB systems allow researchers to target specific regions of interest, making them crucial for nanofabrication and site-specific TEM lamella preparation.

Strengths of FIB Polishing

Unmatched precision:

FIB ion beams have extremely high spatial resolution, enabling targeting of grain boundaries, inclusions, cracks, or defect regions with nanometer accuracy.

High sputtering rate for small areas:

FIB systems have a high sputtering rate compared to BIB and can remove material quickly within smaller areas.

Dual-beam capability:

Many FIB systems are coupled with SEM, allowing real-time imaging during milling. This enables researchers to visualize structures and adjust milling paths with real-time feedback.

Versatility

Beyond polishing, FIB can be used for circuit editing and milling. Also, by sequentially milling and imaging, FIB enables tomography and 3D visualization of microstructures.

Targeted sample extraction:

FIB enables preparation of TEM lamellae from exact microstructural locations, which is critical for failure analysis and semiconductor research.

Limitations of FIB Polishing

Ion damage risk:

High-energy gallium ions can implant into the surface, cause amorphization, or introduce curtaining artifacts. Additional low energy “clean-up” steps are often needed when preparing a sample with FIB.

Low throughput for large areas:

FIB is inefficient for polishing millimeter-scale surfaces. Nanoscale features are ideal targets.

High cost and complexity:

These systems require skilled operators and typically accrue higher maintenance costs.

Which Technique Should You Choose?

BIB and FIB polishing are complementary techniques. Many advanced laboratories use them in tandem to maximize the quality and range of their electron microscopy analyses. Having access to both instruments enables flexibility; BIB excels at preparing large, smooth surfaces, while FIB offers unmatched site-specific precision. For laboratories with limited budgets, however, choosing between BIB and FIB can be challenging.

BIB polishing is valued for its ability to produce large, damage-free surfaces with relative ease. One example is metallographic surface preparation for electron backscatter diffraction (EBSD) analysis. While FIB can achieve similar results, it is typically more time-consuming and costly. In contrast, BIB polishing can be performed in the same laboratory as mechanical polishing equipment and delivers high-quality results quickly. Other BIB applications include thinning samples for TEM, producing cross sections, and preparing delicate materials.

FIB polishing is primarily known for its nanoscale precision. This is particularly valuable for applications that require site-specific milling, such as TEM lamella preparation, where electron-transparent sections are cut from the bulk material to analyze crystal structures, interfaces, and defects at atomic resolution. FIB is also critical for more specialized applications, such as subtractive processing for TEM and irradiation of materials for defect engineering.

Summary

Broad ion beam and focused ion beam polishing are complementary techniques for electron microscopy sample preparation. BIB excels at preparing broad, smooth surfaces efficiently and cost-effectively, which is ideal for routine SEM and EBSD work. On the other hand, FIB is essential for high-precision, site-specific tasks such as TEM lamella preparation and defect analysis. For laboratories with access to both, dual usage provides the most complete solution, but for labs with limited resources, it is best to consider the specific strengths and limitations of each technique.

References

- Hanke, L. D.; Schenk, K. H.; Scholz, D. R. Broad beam ion milling for microstructure characterization. Materials Performance and Characterization 2016, 5 (5), 767–779. https://doi.org/10.1520/mpc20160049. ↩︎

- Sezen, M. Focused Ion beams (FIB) — novel methodologies and recent applications for multidisciplinary sciences. In InTech eBooks; 2016. https://doi.org/10.5772/61634. ↩︎