High Resolution Electron Back Scatter Diffraction (EBSD) and Scanning Electron Microscope (SEM) Surface/Cross Section Sample Preparation

In Electron Back Scatter Diffraction (EBSD) studies, surface quality is a key issue. Diffraction patterns are formed within a few tens of nanometers of the sample surface. A crystalline, damage-free and oxide-free surface is needed in order to get good quality EBSD patterns to visualize small-scale variability in grain- and/or crystallographic orientation. Argon broad beam ion milling treatment using Technoorg’s SEMPrep2 system provides proper sample surface for EBSD investigation. In some cases, only 10 minutes of ion milling treatment provides samples that yield excellent EBSD results.

Other sample preparation methods induce the diffuseness of the diffraction patterns reducing its quality as well as the following problems, for example:

- Mechanical grinding and polishing create an amorphous layer of 1 nm to 100 nm thickness on the surface, called the Beilby layer.

- Diamond polishing can deform the grains on the surface.

- Collodial silica polishing, a commonly suggested method, is time-consuming and can result in embedded residual polishing material in the surface grains.

- Electro-polishing, is complex process with variable results.

Ion Mill Sample Preparation for EBSD Maps

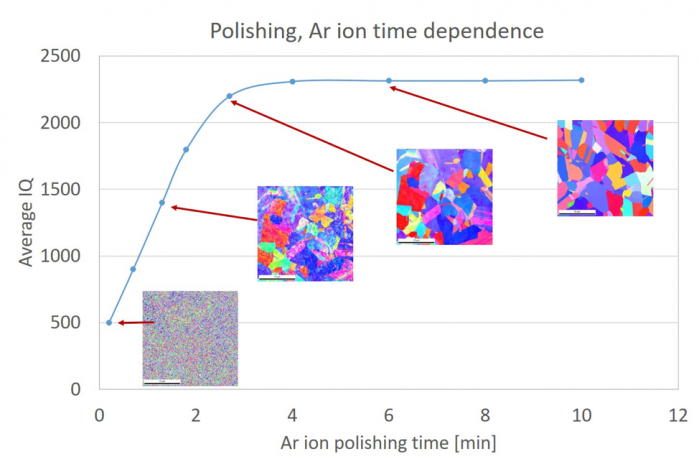

Ion milling with an Argon (Ar+) ion gun overcomes all of the difficulties mentioned above, giving the surface finish needed for high-resolution EBSD Maps. The samples can be prepared for the surface or cross-section analysis using various modules available on the SEMPrep2 system. The sample preparation involves milling of a sample using high energy Ar+ ion gun. The sample is simultaneously rotated and oscillated during the process removing any artifacts related to grain boundaries. The subsequent cleaning with a low energy Ar+ ion gun leads to a surface ready for EBSD measurements. The EBSD map quality improves significantly as can be seen in the Ar+ ion time dependence curve.

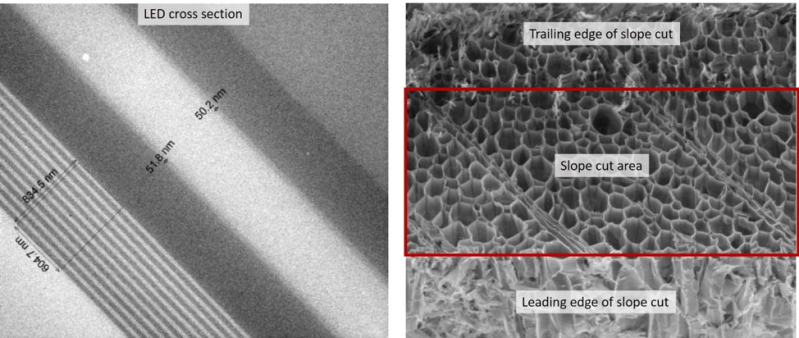

In applications such as electronics, semiconductors, and biological materials, the cross-section of the sample is of interest and value to understanding production processes. SEMPrep produces a high-quality cut surface that makes EBSD studies possible on a-symmetrical cut surfaces. In a mechanically pre-prepared sample, the integrity of the sample is maintained by marking the sample with a screen and milling the sample from an angle to expose the cross-section.

The SEMPrep2 comes with load lock mechanic for faster sample transfer along with several head types including flat head for larger samples, standard for thicker samples and hollow type for metallurgical mounted samples. The vacuum is maintained in the working chamber continuously, protecting the ion source from contamination. Temperature sensitive samples can be prepared with Peltier cooling or Nitrogen cooling stages.

References: Z. Dankhazi et al, EBSD sample preparation: high energy Ar ion milling