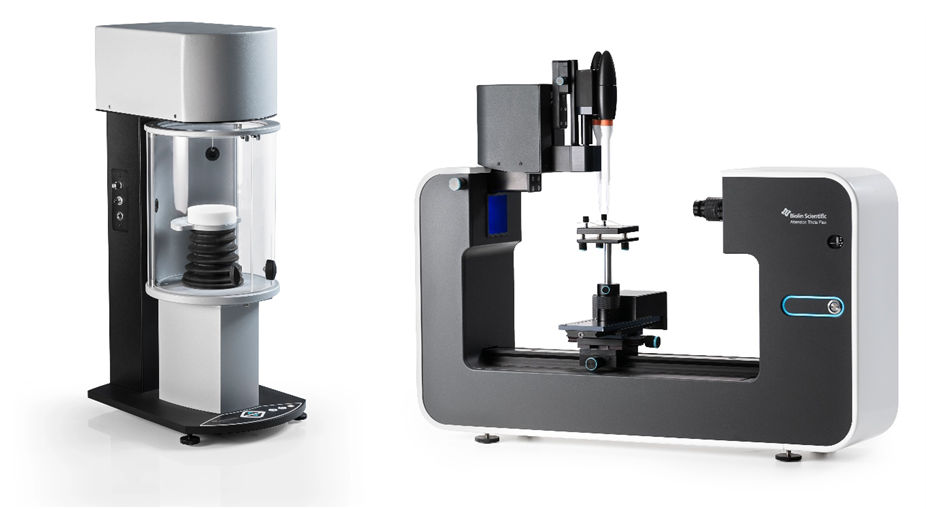

For powdered materials such as pharmaceuticals, dyes, proppants, and foods, wettability is an important parameter to characterize. As the powders are immersed into a liquid, fluid may wick into the interstitial spaces between powder particles through capillary forces. The wettability of the powder can be measured with a tensiometer and is related to properties such as bioavailability, color spreading, crush resistance, and mouthfeel. The sessile drop technique utilizes an optical tensiometer and is one option for measuring powder wettability. In this measurement, a drop of liquid is placed onto a surface and the contact angle is measured. Larger contact angle values (> 90°) indicate poor wettability and, smaller contact angle values (< 90°) indicate good wettability.

Contact angle goniometry of powders

For many powders, sample preparation is required prior to measuring with an optical tensiometer. A common preparation involves compressing the powder into a tablet using a press or other high-pressure device since surface features and roughness can result in large variations in measurements. As seen in Figure 1, a poorly prepared powder sample can make establishing a contact angle baseline difficult or even impossible. An instrument with a high-speed camera is preferable in case the powder is hydrophilic since the powder may wick the droplet quickly. Hydrophobic powders can sometimes be measured directly if they are spread evenly. A potential drawback of this approach is that the powder may creep up the side of the liquid droplet and the liquid may distort the powder surface it was meant to probe.

Force based powder contact angle using the Washburn method

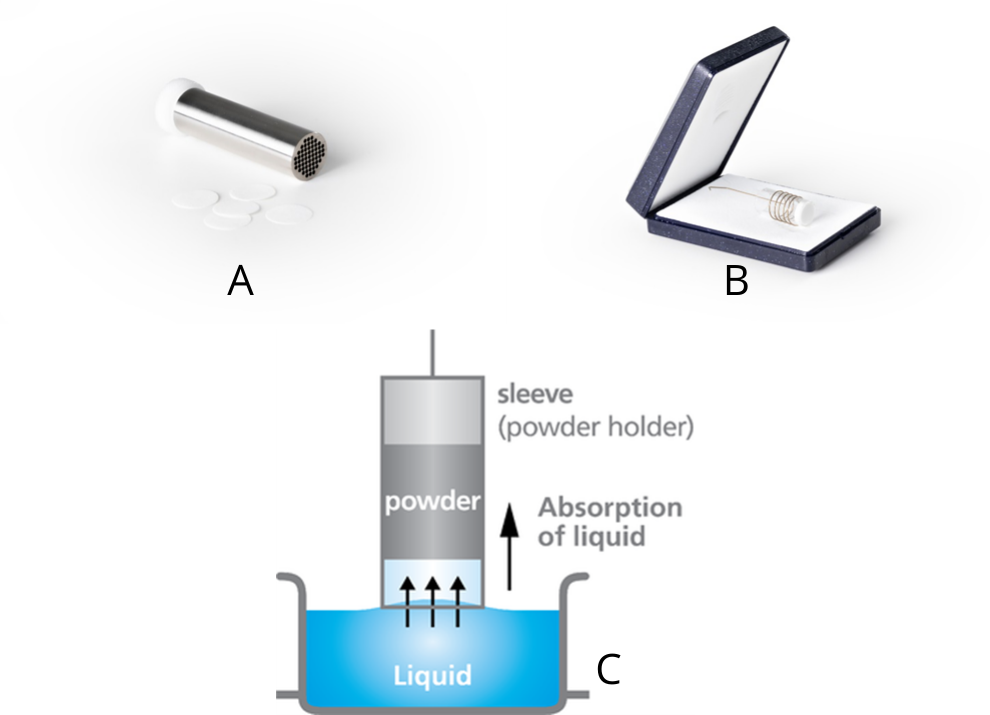

A second option for measuring powder wettability is to use a force tensiometer. With this instrument, the powder is packed into a spring-loaded vessel that has holes at the bottom. Filter paper is placed into the bottom of the vessel to ensure that powder does not fall out of the holes. A glass vessel with a porous sintered bottom can also be used with smaller powder volumes. The vessel is then hung onto the sample hook of the force tensiometer and dipped into the liquid. The tensiometer measures mass changes over time as liquid wicks into the powder.

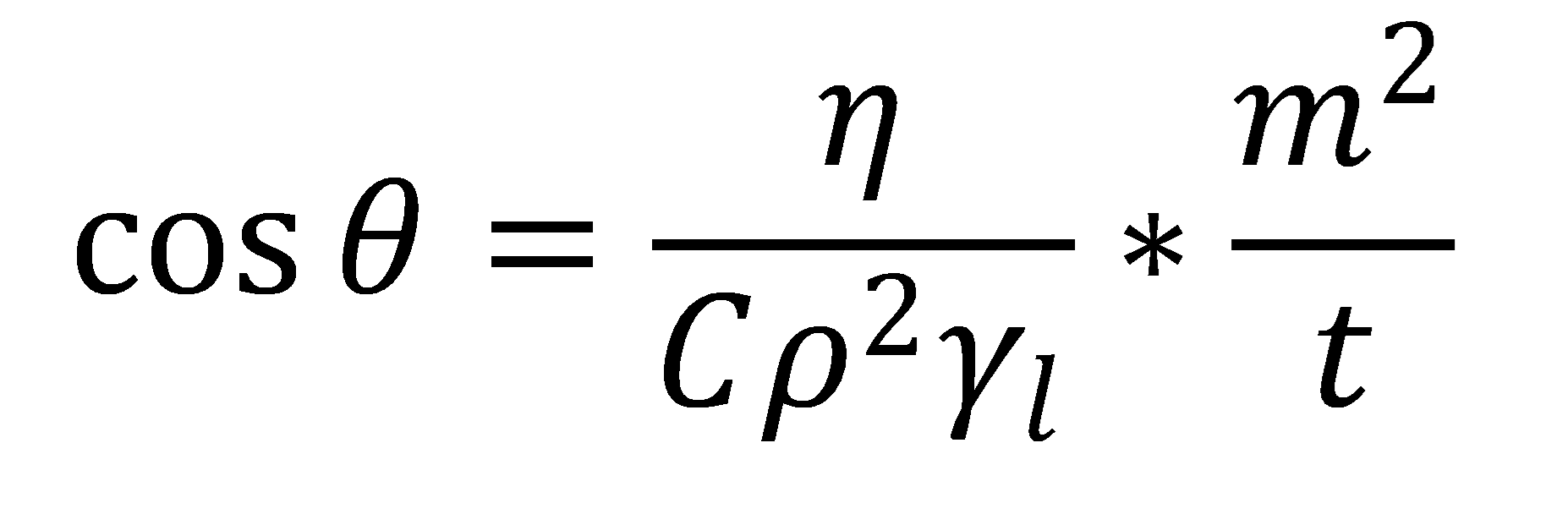

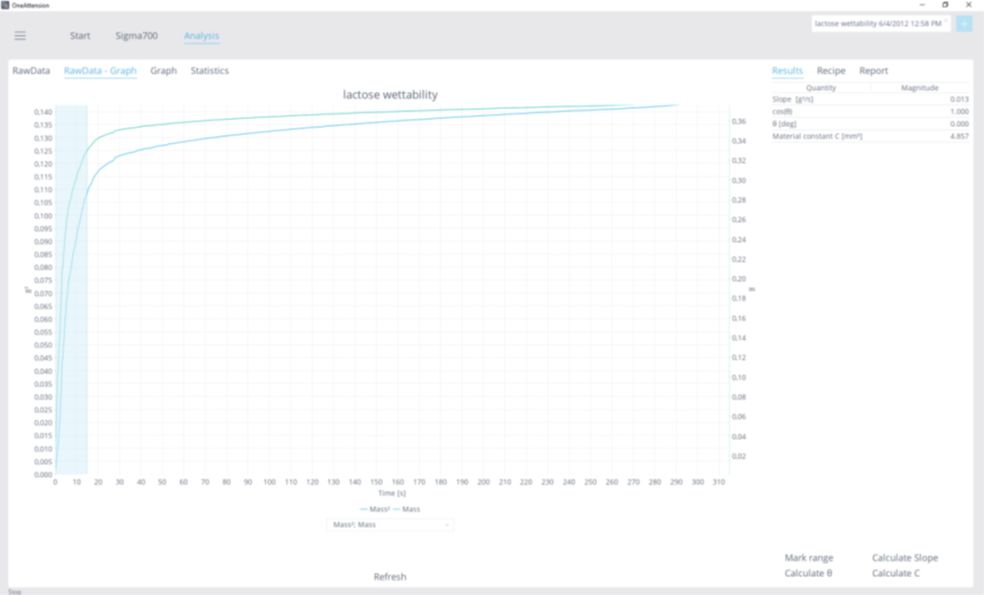

The contact angle can be measured by the Washburn equation,

where C is material constant, ρ is density of the liquid, η is viscosity of the liquid, γl is surface tension of the liquid, and m2/t is the slope of the absorption curve. Using the OneAttension software, simple point-and-click operations allow the user to measure these relevant parameters.

To determine the contact angle of a powder, measurements in two liquids are typically performed. First, the material constant C must be calculated. A low surface tension liquid (usually hexane) is used since these liquids will completely wet most materials and a contact angle of 0 can be assumed. Hence, C is the only unknown in the Washburn equation and can be directly calculated. The second measurement uses the liquid of interest and the calculated C value can be used to determine the contact angle. In cases where an unknown liquid is used, the surface tension must be measured first.

For best results and reproducibility, the liquids used during measurements should be as pure as possible. Changes in purity will affect the surface tension of the liquid and can cause errors in the measurement. Additionally, the packing, mass, and grain size of the powders should also be controlled. The same mass of sample should be used for each measurement, and if the vessel is agitated to improve packing, this should also be done the same way each time. The Washburn approach may not work for water contact angles if the powder is too hydrophobic because the liquid will simply not wick into the pores.

Surface free energy of powders

It is possible to measure the surface free energy (SFE) of a powder in much the same way as on a flat planar surface. After using the Washburn method to obtain contact angles with at least two probe liquids having polar and dispersive components (water and diiodomethane are most common) one can use the OneAttension software to automatically calculate the SFE using the desired method.