How can Optical Tensiometry Characterize Coatings?

Coatings are used to modify the properties of the substrate that they cover and are ubiquitous in our everyday lives. They can have functional, protective, and/or aesthetic purposes. One everyday example of a coating is the touchscreen on a smartphone. The coatings on these screens repel oils, which allows a finger to glide easily on the surface. The coatings also provide some protection to the underlying glass and makes the phone look glossy and attractive.

To perform effectively, coatings must be well-adhered to their substrate. This requires good wettability between the coating and the substrate. Characterization of the coating surface itself is equally important, as the coating surface should have the intended adhesive or repellent properties. Critical aspects of the coating adhesion and performance can be readily measured using optical tensiometry. This article focuses on five techniques that allow for development and characterization of coatings – static contact angle, advancing/receding contact angle, tilting angle, surface free energy, and 3D topography for roughness corrected contact angles. While this article will not discuss the theory or practice of each measurement in detail, it will describe the significance of each of these measurements with regards to coating adhesion and performance. Links are provided to our technique pages to allow the reader to learn more about the details of each specific technique.

How to determine how well a coating adheres: contact angle measurements

A fundamental way to determine how well a coating will adhere to its substrate is through contact angle measurements. Static contact angle measurements are performed by placing a drop of liquid onto a surface and measuring the angle that the edge of the drop makes with the surface. This angle represents an equilibrium state between the solid, liquid, and vapor surface tensions. Lower contact angles (values approaching 0°) usually indicate better adhesion, and this in turn usually means better coating performance and durability. One can also use contact angle to measure the performance of the coating itself. For example, if one develops a water-repellent (hydrophobic) coating, a high contact angle (> 90°) for a drop of water on the coating would be desirable.

Figure 1: Examples of a droplet on a hydrophobic (left) and hydrophillic (right) surface

Another important use of contact angle measurements is to determine the cleanliness of a surface. Because liquid drops are highly sensitive to the chemical properties of the surface, any changes in the surface chemistry from dirt, debris, oxides, or other contamination can be measured. This is especially important for coatings since applying a coating onto a dirty surface may cause it to fail prematurely. For example, if spots of dust are present on a piece of wood before you paint it, the loosely bound dust may serve as a weak point for the paint adhesion. This could eventually lead to delamination and peeling. Contamination may manifest itself through large variations from spot checks across the surface or differences between the left and right contact angle. Because of this surfaces usually require cleaning treatments prior to the coating application. For contact angle characterization it is routine to wash surfaces with water, or solvents (such as ethanol), followed by drying with an inert gas.

Advancing and Receding Contact Angle

A variation of the contact angle measurement, called the advancing and receding contact angle, or dynamic contact angle, can be used to obtain information about the heterogeneity of the surface. In this measurement, instead of placing a single, static drop on the sample surface, a needle is placed in the drop and the volume is slowing increased. As this occurs, the baseline where the drop contacts the surface also steadily increases until it reaches a maximum value. The receding contact angle is measured by withdrawing liquid from the drop, and as its volume decreases the baseline also decreases until a constant value is reached. The difference between the advancing and receding contact angle is called the contact angle hysteresis and is indicative of variations in the surface chemistry and roughness. Characterization of non-adhesive superhydrophobic surfaces (water contact angle > 150°), requires measuring advancing and receding contact angles since surfaces with high static contact angle are not necessarily non-adhesive.

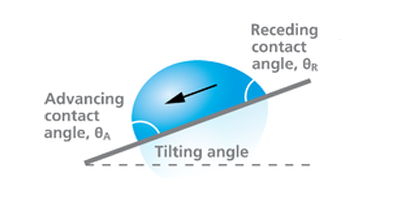

Figure 2: Example of an advancing (left) and receding (right) contact angle measurement. Picture courtesy of Biolin Scientific.

Tilting Contact Angle

Tilting contact angle is a method for determining under what conditions a drop begins to roll off its substrate. The test is performed by either placing the instrument on a tilting cradle and rotating the entire instrument or by using a tilting stage to rotate the sample. As the droplet tilts, the effect of gravity causes it to distort its shape and eventually roll off the sample. The leading edge of the drop is called the advancing contact angle, and the trailing edge is called the receding contact angle.

Figure 3: Schematic of a tilting contact angle measurement. Image courtesy of Biolin Scientific.

While these are the same terms used as the needle-in method described previously, it should be noted that the values from the two measurements will not necessarily be the same since the results for the tilting angle are dependent on the drop volume1. For adhesion measurements, the two techniques can be used in a complementary fashion. For example, consider a coating for a car windshield. For best visibility, raindrops should roll down the windshield and not stick to the surface, so the coating should be hydrophobic and non-adhesive to water. However, not every windshield is installed at the same angle. Sports cars may have a shallower windshield angle relative to the roof while family cars or buses may have a steeper angle. Needle-in advancing, receding and hysteresis measurements would provide basic information that the coating fulfills the hydrophobic and non-adhesive requirements, while the tilting angle would confirm that a certain sized drop does indeed roll off the coating at a specified angle.

Surface Free Energy

Surface free energy (SFE) is another technique that allows us to determine the chemical properties of our solid, and consequently what types of liquids wet a solid. It characterizes the different intermolecular forces in a surface, such as its polar, dispersive, hydrogen bonding, and acid-base forces, among others. At a high level, surfaces with large SFE values tend to be easily wetted by a range of liquids and are usually hydrophilic. Examples of such materials include metals and ceramics. On the other hand, low SFE surfaces are not easily wetted and include materials like plastics and Teflon.

By using at least two different liquids with known surface tensions, the SFE can be determined. Commonly used liquids include water, di-iodomethane, and ethylene glycol. Depending on the method used to calculate the SFE, information about the polar, dispersive, acid, and base components can be measured. To maximize adhesion between a liquid and its surface, one would want to closely match the values of the polar and dispersive components of the liquid and substrate. There are some instances, such as with inkjet printing, where SFE optimization between the liquid and substrate is preferred instead. Printing on highly adhesive surfaces may cause unrecognizable splotches, whereas poorly adhesive surfaces may lead to beading and smearing of printed droplets2. Surface treatments such as plasma or flame annealing are commonly used to increase the SFE of a material.

Roughness Corrected Contact Angle using 3D Topography

Surface roughness is often not accounted for in contact angle measurements but can have a large effect on the results. Robert Wenzel established in 1936 that roughness amplifies the wettability of a surface. In other words, surfaces with a low contact angle will have an even lower contact angle when roughened, and vice versa. Wenzel developed an equation that allows one to correct for the effects of roughness to determine the contact angle of a perfectly flat surface, called the roughness-corrected contact angle (RCCA). The first commercial device to enable this measurement is the Attension Theta Flex with Topography, which utilizes a fringe projection phase-shifting method to first measure the 2D and 3D roughness of a surface. A calibrated XYZ sample stage then moves the characterized spot to the liquid dispenser, where a contact angle measurement can be performed on the exact spot where roughness was measured.

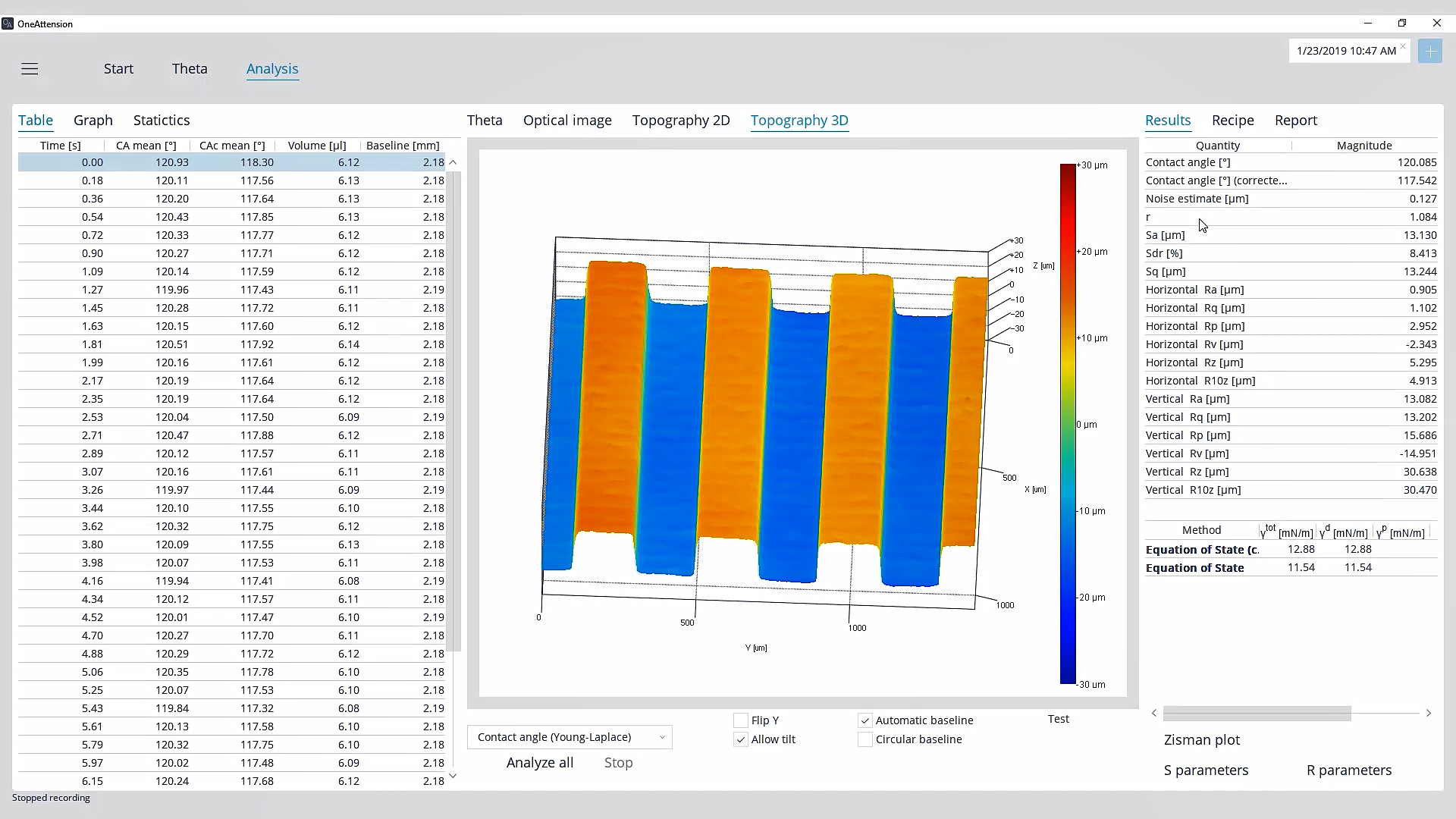

Figure 4: An output from a simultaneous contact angle and 3D topography measurement from the OneAttension software.

Examples of benefits from measuring the RCCA using the Theta Flex with Topography include:

- Separating the effect of roughness from the surface chemistry of a contact angle measurement confirms that pre-processing steps like grit-blasting, plasma treatment, or sanding produce the expected roughness and contact angle changes.

- Accurate measurement of Young-Laplace contact angles on real world samples that have texture and roughness eliminates the need to make perfectly flat coatings to properly characterize the contact angle.

- Roughness correction enables more accurate SFE measurements to determine the polar and dispersive properties of a surface.

Conclusion

Overall, optical tensiometry is an indispensable tool for measuring coating adhesion and performance. The different measurements that can be performed as well as their relevance to adhesion is listed in the table below.

| Technique | Use to Measure |

|---|---|

| Static Contact Angle | Cleanliness, Wettability |

| Advancing and Receding Contact Angle | Adhesion, Heterogeneity |

| Surface Free Energy | Chemical Interactions Between Liquids and Surfaces |

| Tilting Angle | Adhesion Under Specific Conditions |

| Roughness-Corrected Contact Angle | Contact Angle Independent of Roughness Features |

The Attension Theta Flex is a versatile, modular optical tensiometer that can perform all the above measurements with high sensitivity and reproducibility. To learn more about the features of the Attension Theta Flex and how it can be used for adhesion, please view our on-demand webinar.

- [1] Pierce, E.; Carmona, F. J.; Amirfazli, A. Understanding of Sliding and Contact Angle Results in Tilted Plate Experiments. Colloids Surf. Physicochem. Eng. Asp. 2008, 323 (1–3), 73–82.

- [2] Matavž, A.; Bobnar, V.; Malič, B. Tailoring Ink–Substrate Interactions via Thin Polymeric Layers for High-Resolution Printing. Langmuir 2017, 33 (43), 11893–11900.