Scanning Electron Microscopy (SEM) is a versatile tool in geology used in high-resolution imaging and chemical analysis of rocks, minerals, and microfossils. SEM provides detailed images of mineral morphology and surface textures, which are essential for identifying minerals and understanding their growth patterns. Studying the deformation features using an SEM helps reconstruct the geological history of rocks. SEM reveals clay mineral morphology that are crucial for evaluating reservoir quality in petroleum geology or aquifer studies. In paleontology and microfossil analysis, SEM is often used to examine the surface features of microfossils and biomineralized structures. Precise mineral classification can be achieved when combining Energy-Dispersive X-ray Spectroscopy (EDS) with SEM.

Desktop SEM:

Desktop SEMs offer a compact, cost-effective alternative to traditional floor-standing models, making high-resolution imaging and elemental analysis more accessible to geologists. A few of the benefits of using a desktop SEM include,

Robust Feature Set

Desktop SEMs can obtain detailed images of surface morphology and features at nanometer scales. Mineral textures, grain boundaries, and fractures can all be easily teased out of samples. Energy Dispersive X-ray Spectroscopy (EDS) detectors are available in most desktop SEMs, which are critical for mineral identification. Low-vacuum settings are common in desktop units that enable imaging on uncoated nonconductive samples.

Compact Design and Portability

Unlike floor-standing SEMs that require dedicated space and specialized infrastructure, desktop SEMs are designed to fit on standard laboratory benches. Their compact size allows for easy integration into existing lab environments without the need for significant modifications.

Cost-Effective

Desktop SEMs generally have a lower initial purchase price and reduced operational costs compared to their larger counterparts. This affordability enables smaller institutions and laboratories with limited budgets to access advanced imaging capabilities.

Ease of Use

Modern desktop SEMs are designed with user-friendly interfaces and often include automated features, reducing the learning curve for new users. This accessibility allows researchers and technicians to operate the equipment with minimal specialized training.

Rapid Sample Analysis

The simplified vacuum systems and reduced chamber sizes in desktop SEMs lead to faster pump-down times, enabling quicker sample turnaround. This efficiency is particularly beneficial in high-throughput environments where time is critical.

Reduced Maintenance Requirements

With fewer complex components and a more straightforward design, desktop SEMs typically require less maintenance and experience less downtime, ensuring consistent performance and reliability.

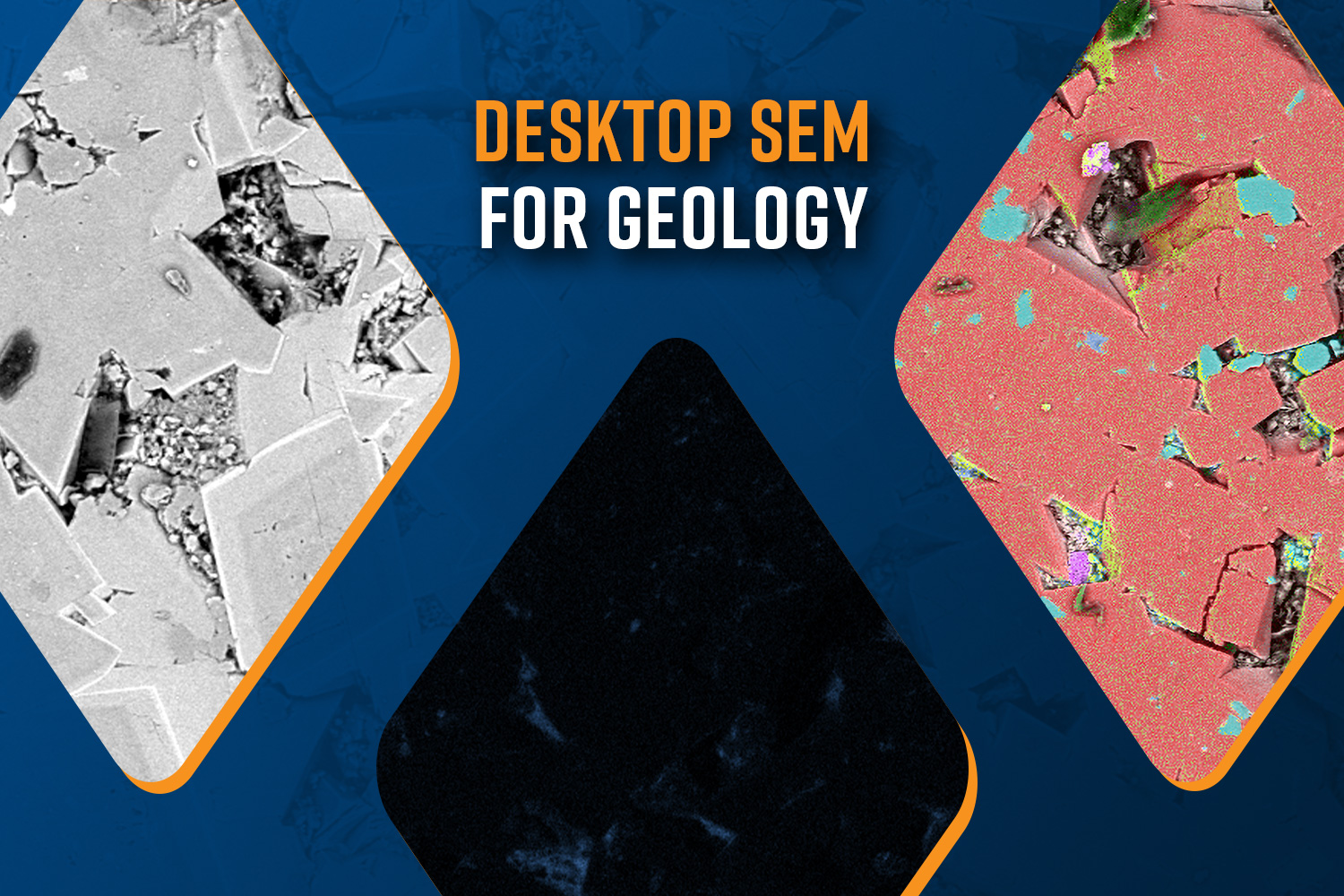

Desktop SEM in Geology

Most common geologic sample types can easily be imaged and chemically analyzed on desktop SEMs, like the Phenom. Due to the high-resolution imaging capabilities, micron and nanometer sized features can be imaged on most systems. Also, with the addition of an EDS (Energy Dispersive X-Ray Spectroscopy) detector users can get fast insights into the elemental composition of their geologic samples. Knowing when to use some of the common tools that most desktop SEMs offer as well as some advanced imaging and sample preparation techniques can greatly aid in highlighting important geologic information (such as crystal size, grain boundaries, inclusions, etc.).

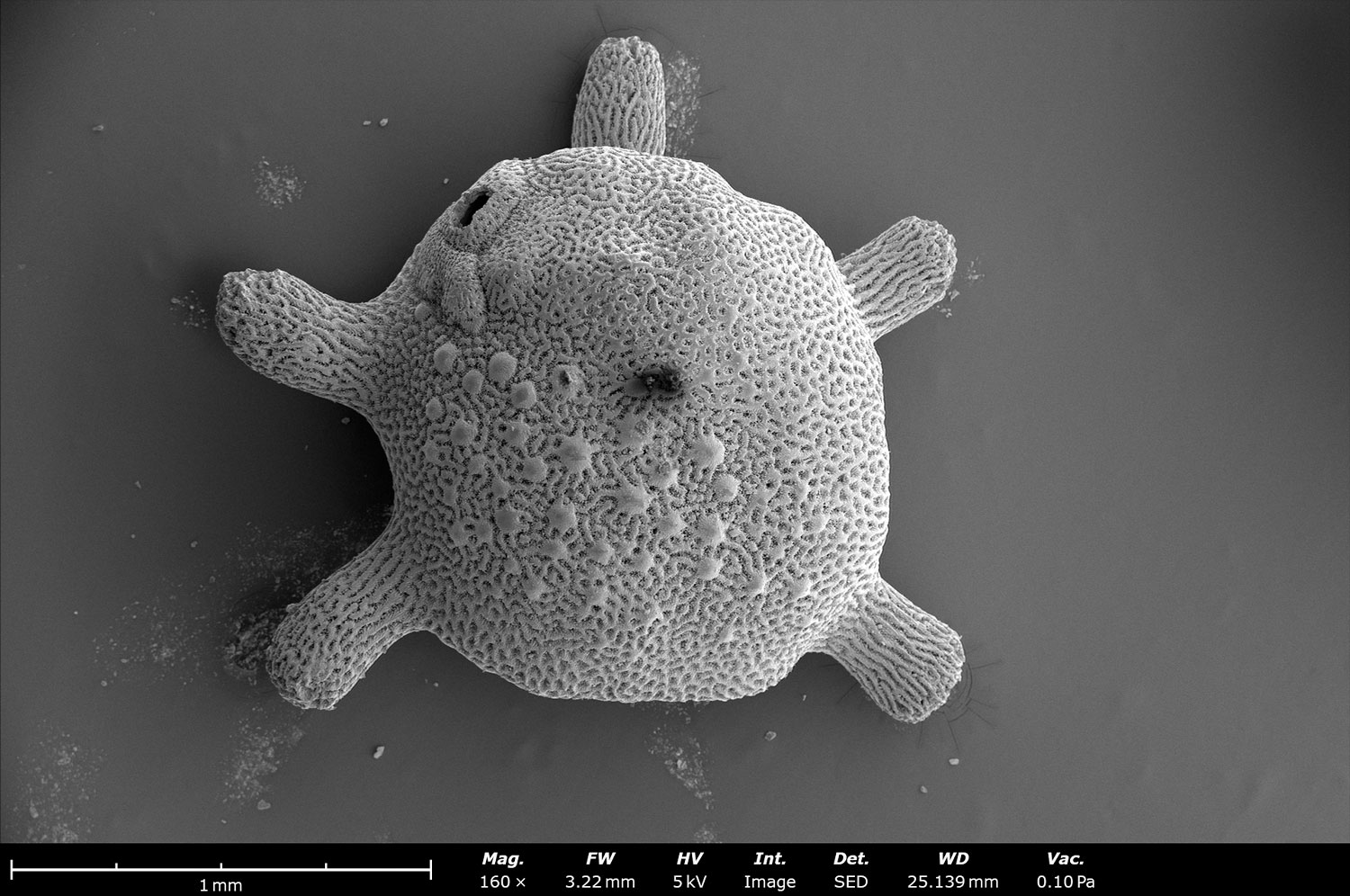

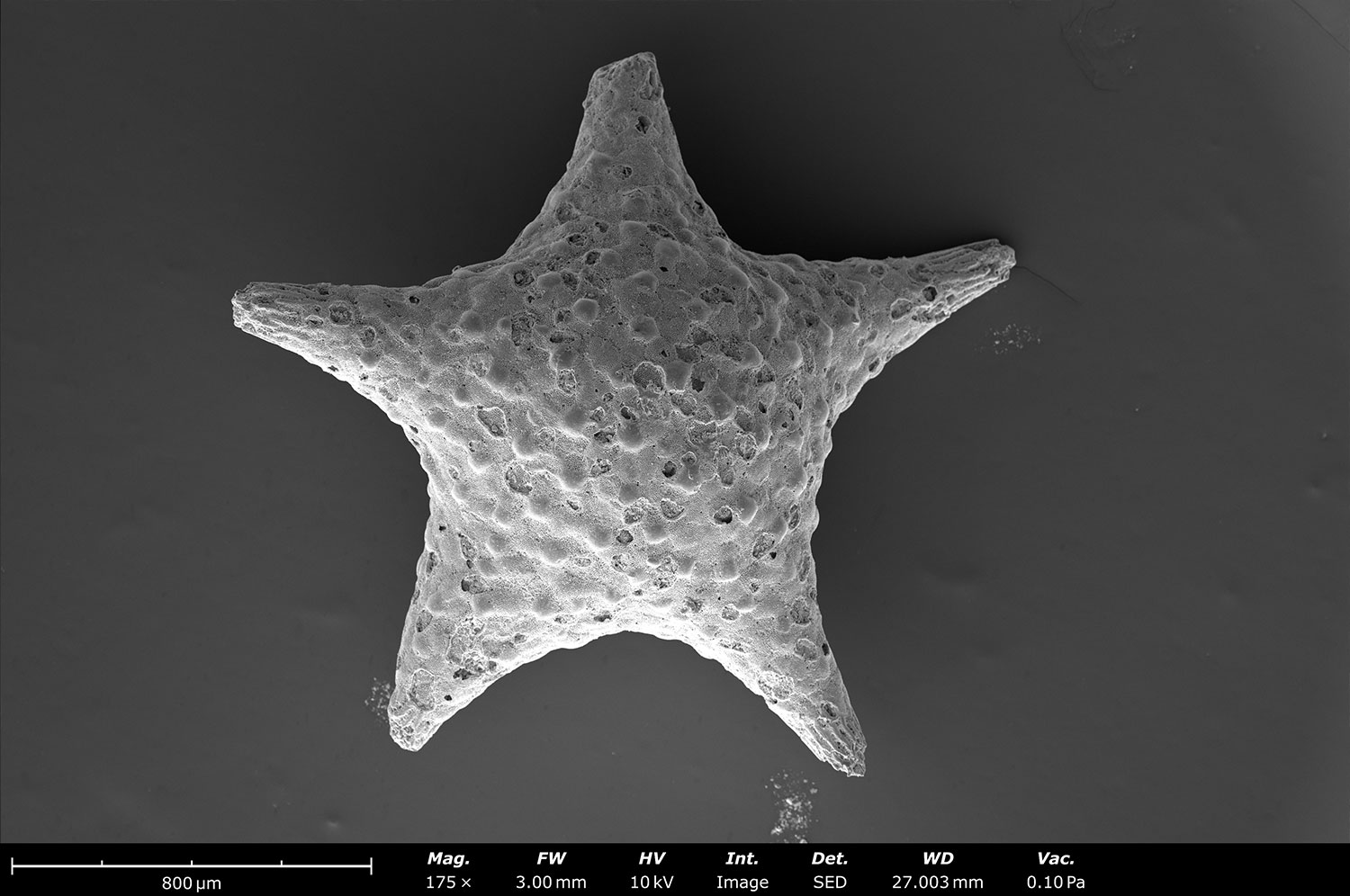

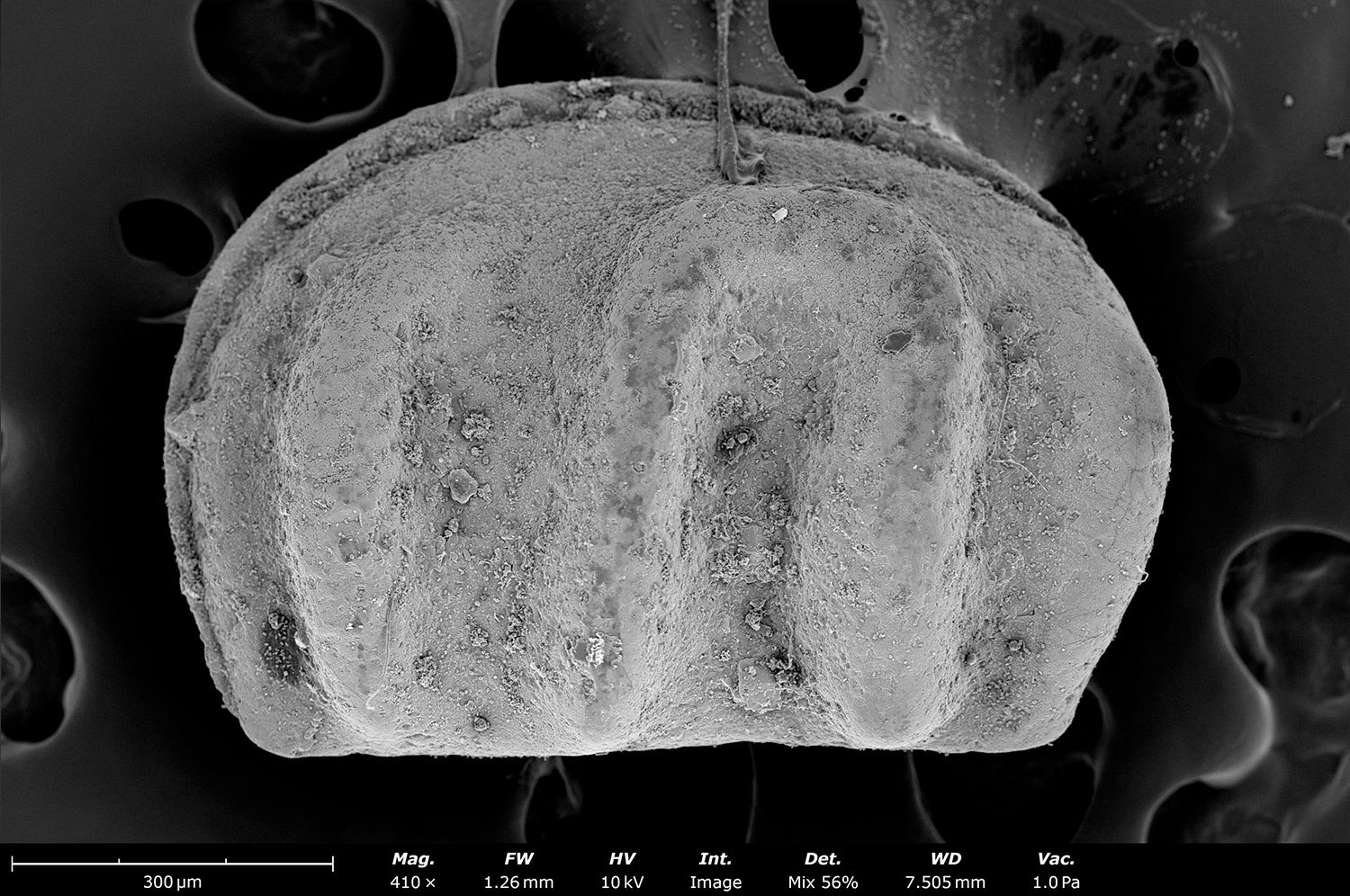

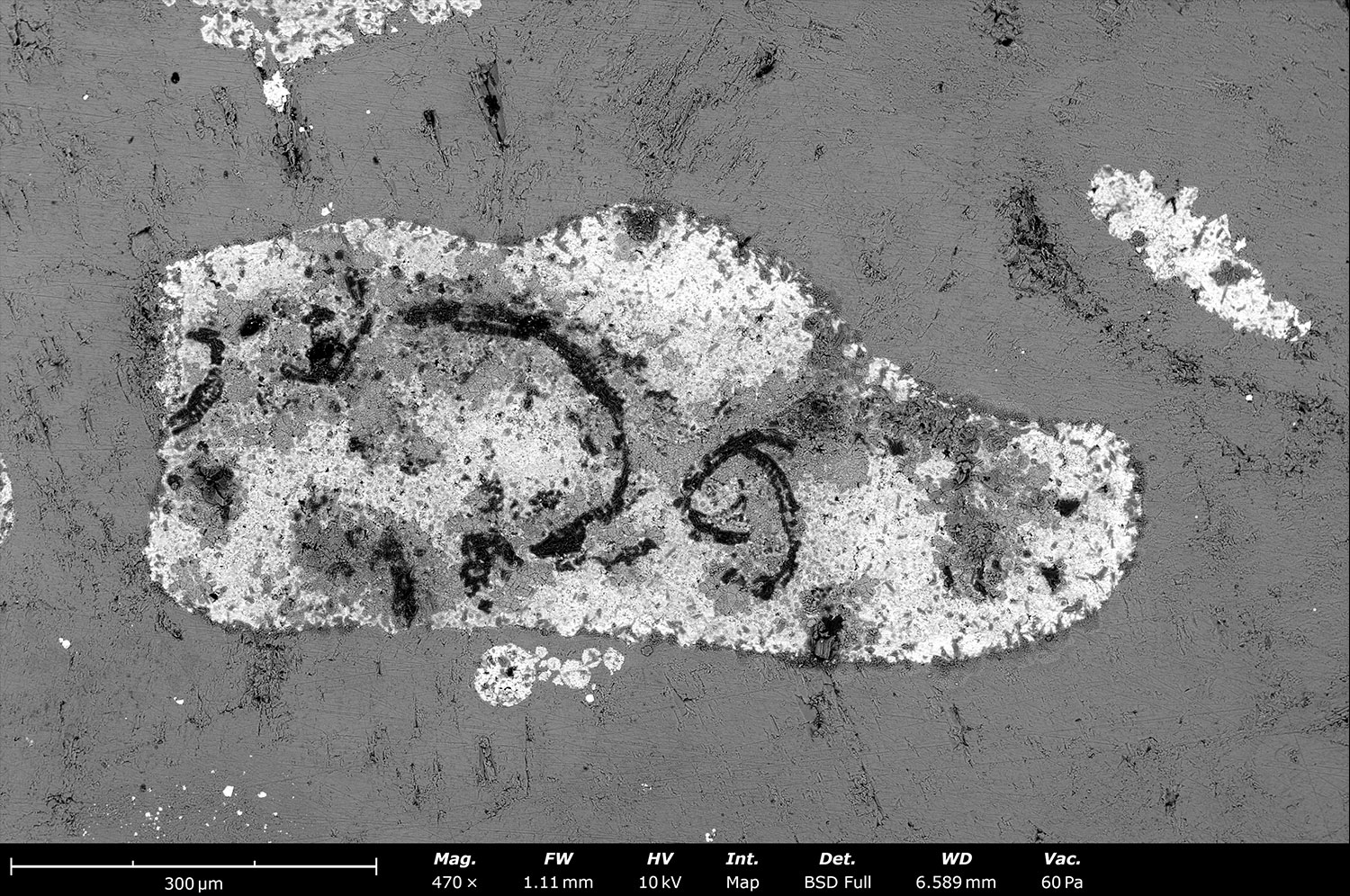

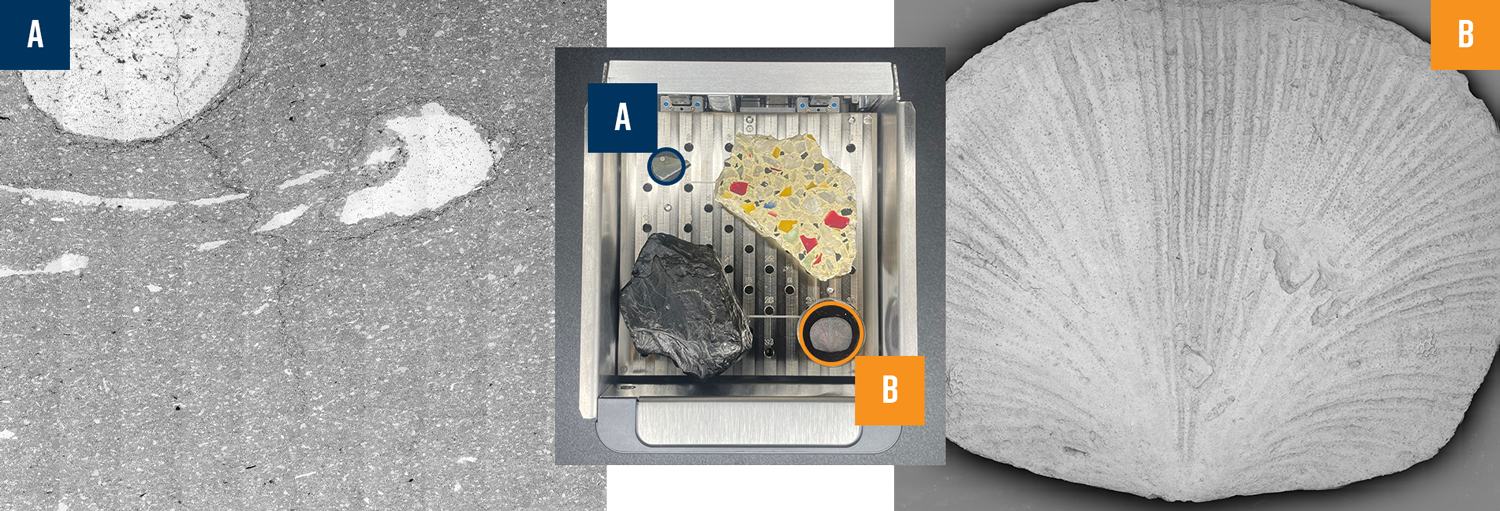

Microfossils and High-Resolution Imaging

Fossil material is ideal for imaging on desktop SEMs. The high-resolution capabilities allow for high quality images of micron to nanometer sized features. Figure 1 showcases a variety of microfossils imaged using Phenom desktop SEMs. Most microfossils benefit from a light coating of gold, platinum or another conducting material to mitigate charging. However, if there is a concern of covering up small areas of interest (such as pores), leaving samples uncoated and using low vacuum mode can also reduce charge buildup.

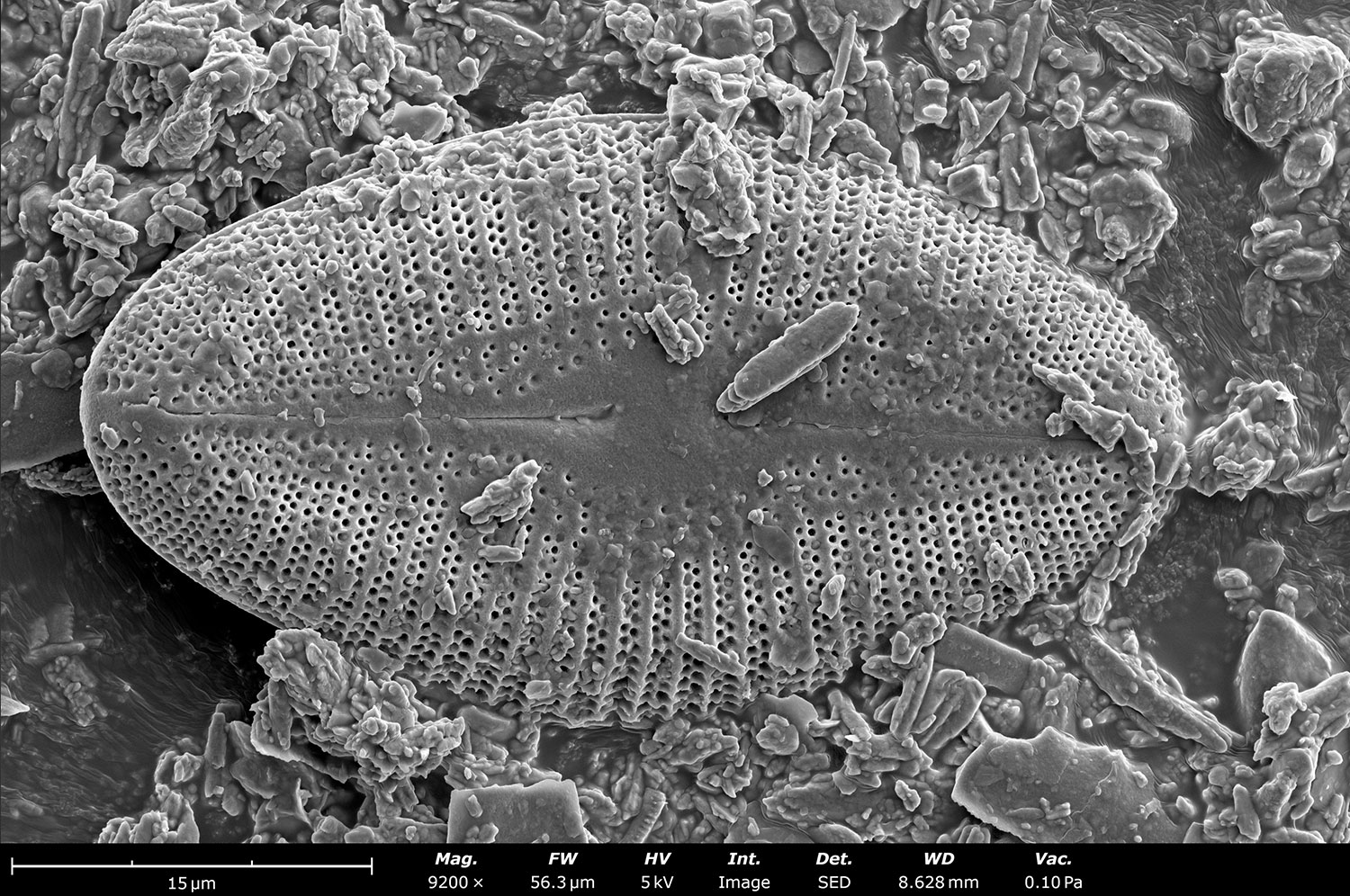

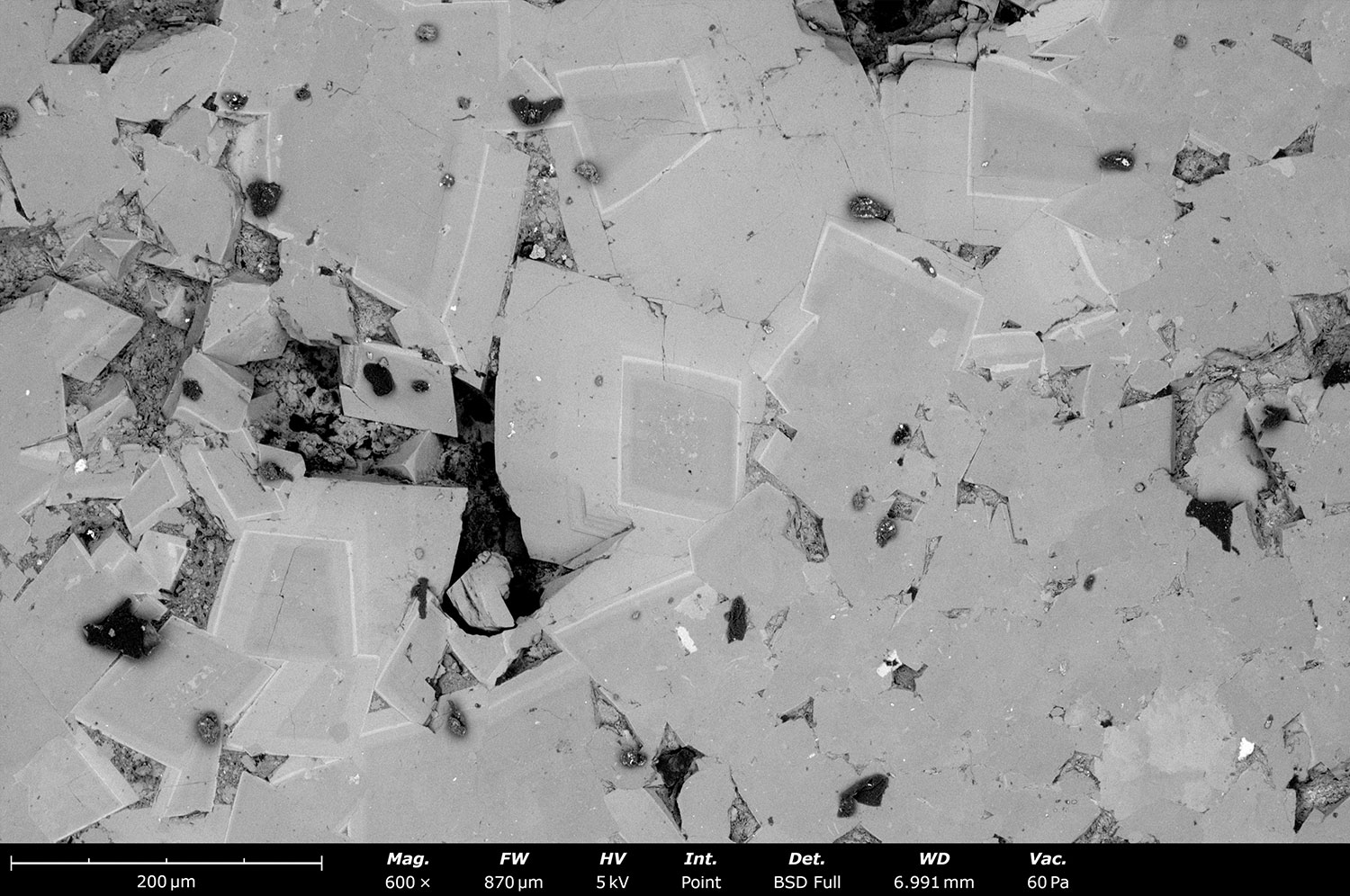

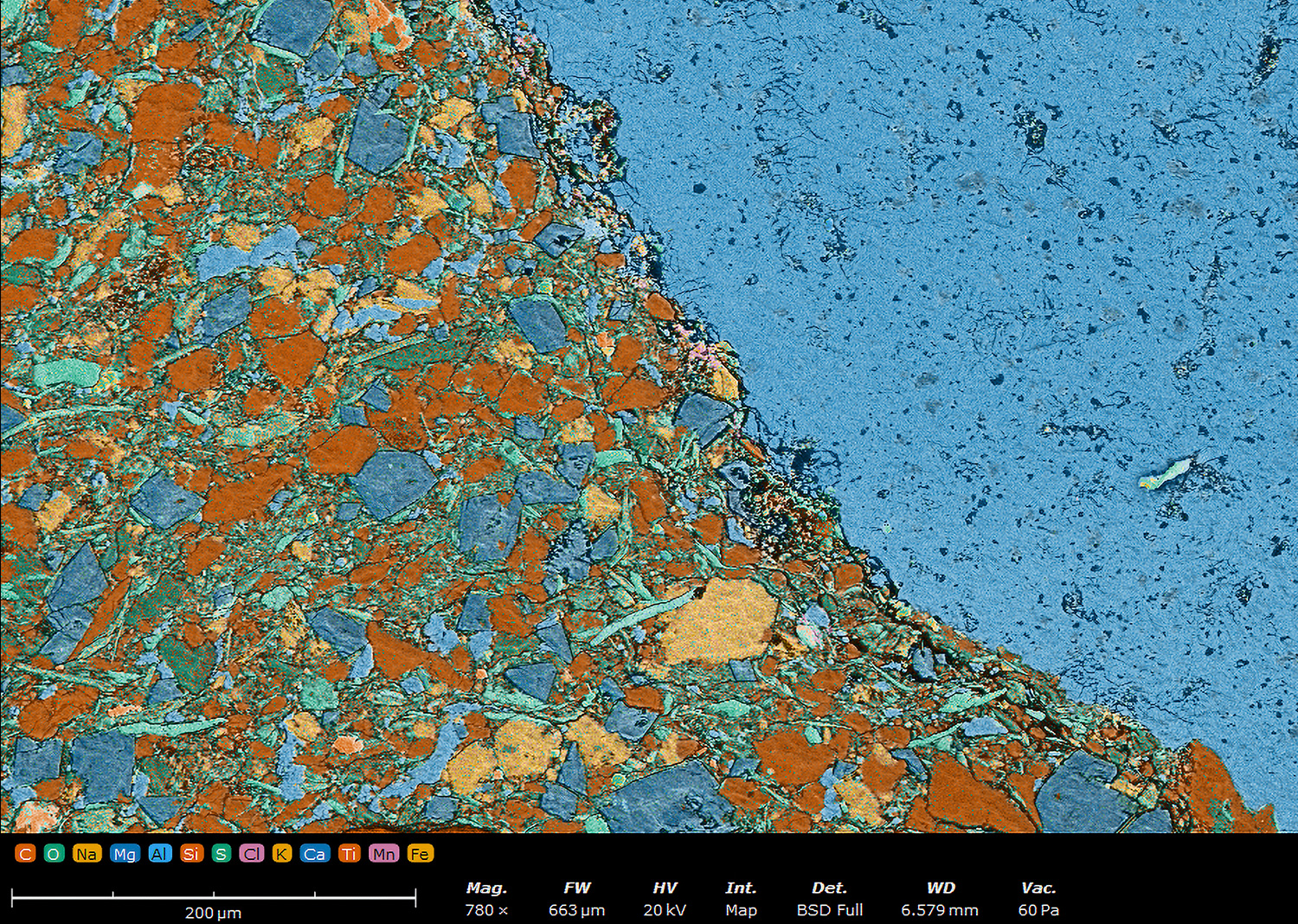

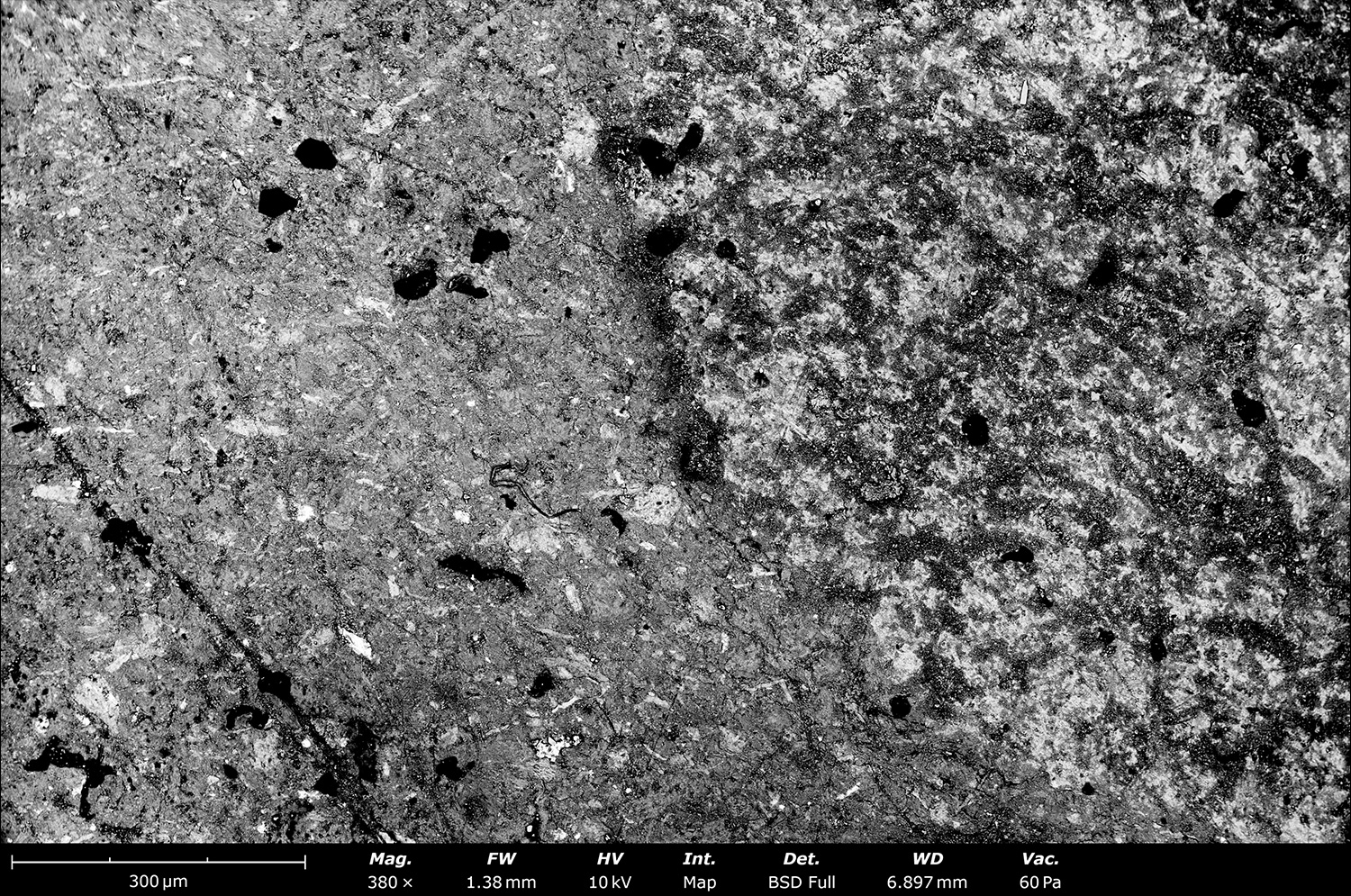

Thin Sections and Variable Pressure

Thin sections are one of the most common types of samples that geologist’s image. Since these samples are generally non-conductive, electrons collect on the surface of the material with no easy pathway to escape. The buildup of electrons results in “charging”, that can negatively impact image quality and EDS results. Low vacuum mode on desktop SEMs is one of the most effective ways to mitigate charging effects. In low vacuum mode, air molecules are introduced into the imaging chamber where they are ionized and neutralize the charged surface of the sample. Figure 2 shows images collected from a thin section in low vacuum mode. Without low vacuum capabilities, images of this quality would be challenging and nearly impossible to obtain.

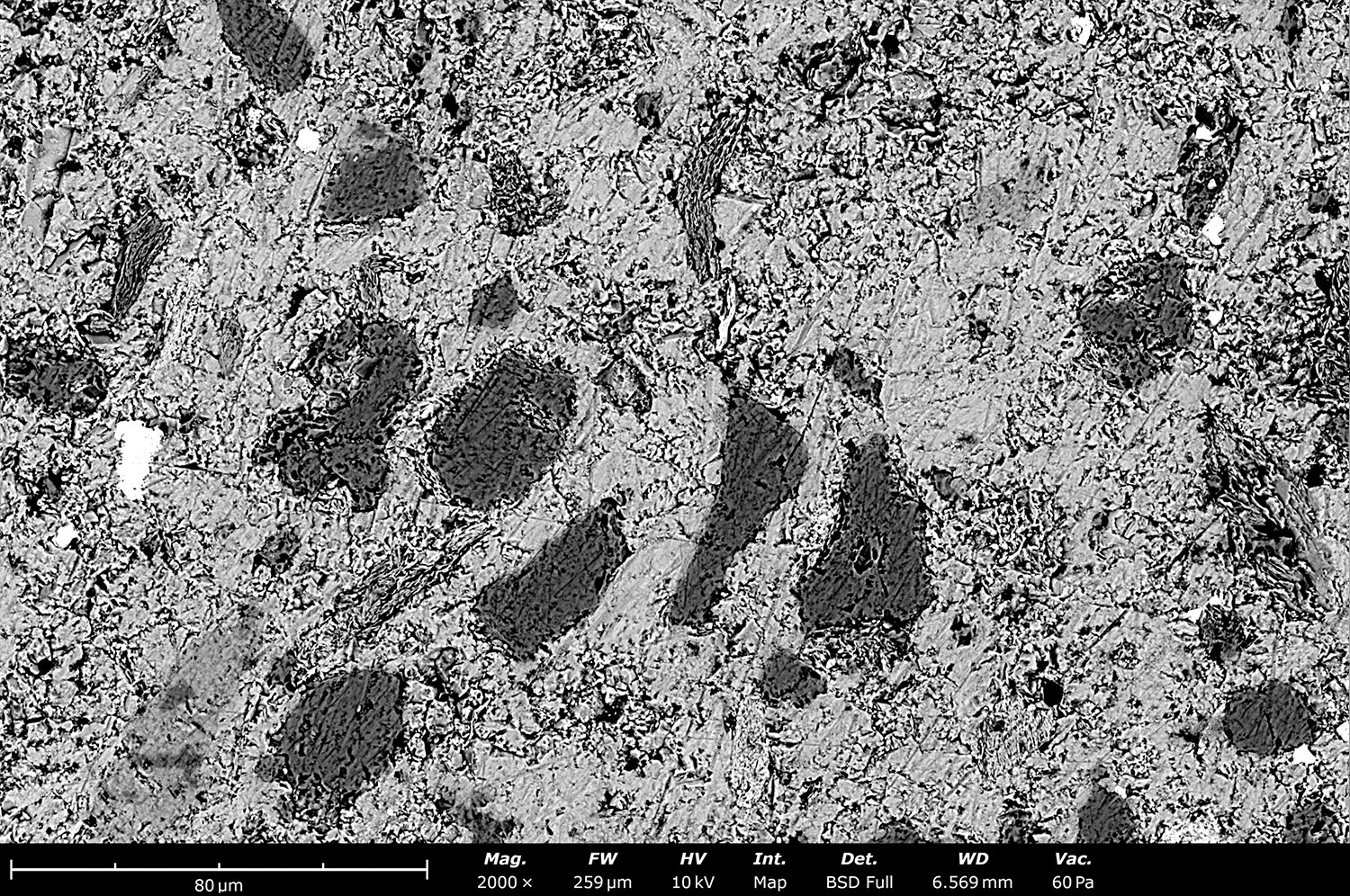

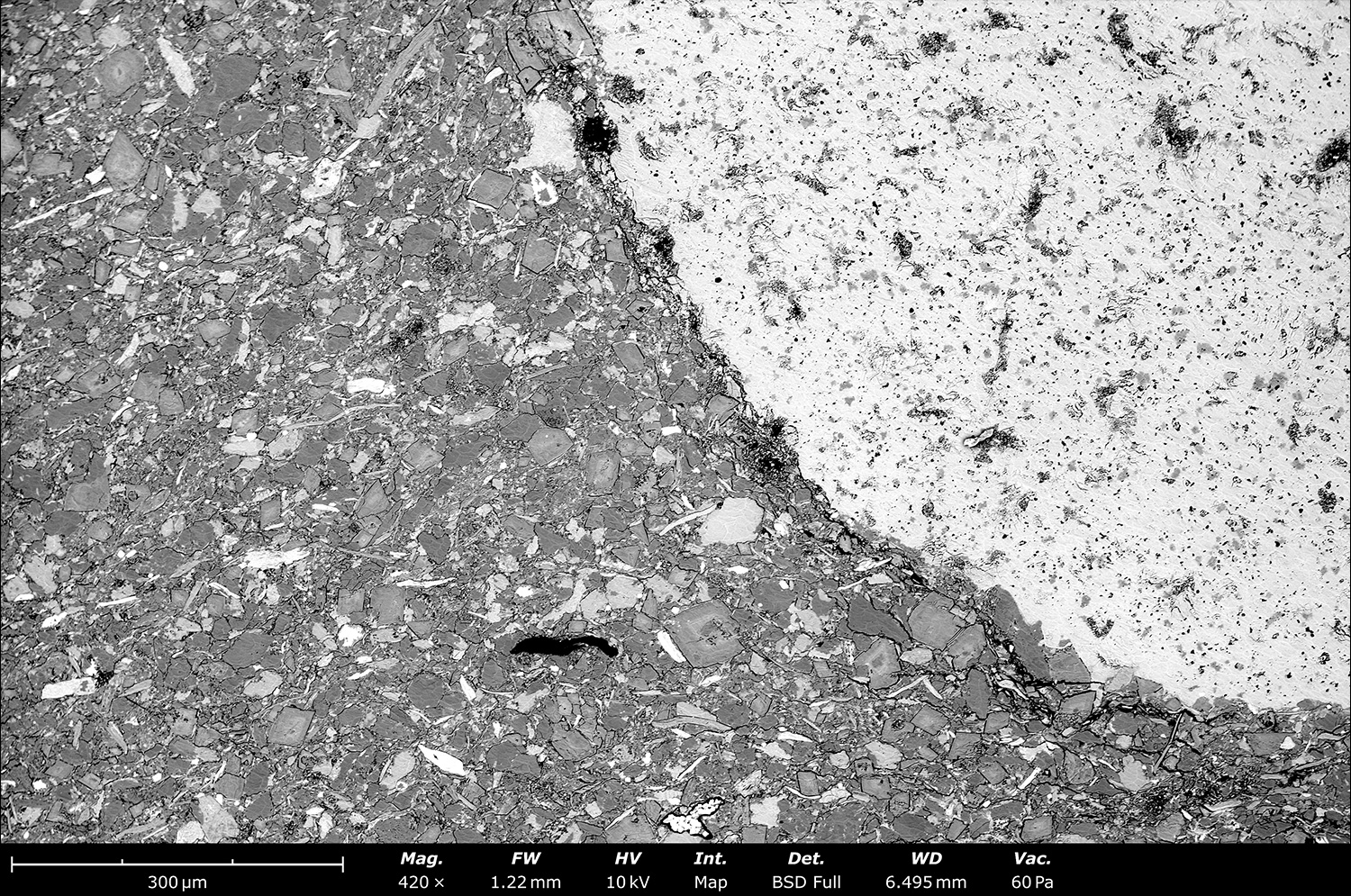

Bulk Rock Samples and Image Stitching

Although the desktop SEM’s have a compact footprint, they can analyze bulk rock samples. Phenom XL has a large sample holder with an analysis area of 100 mm x 100 mm. Phenom XL can be used to easily image and analyze unpolished or rough-cut rock chips, drill core fragments, or even whole hand samples. With built-in, advanced image stitching tools, large areas and even entire samples can be imaged with SEM. With this technique, individual tiles are automatically imaged and collected by software. These tiles are then subsequentially stitched together to produce a single image of the entire sample. Figure 3 showcases two stitch images generated on Phenom XL as well as the large sample holder, which is ideal for bulk rock analysis. The combination of the large sample holder and image stitching makes Phenom XL the perfect instrument for geologists.

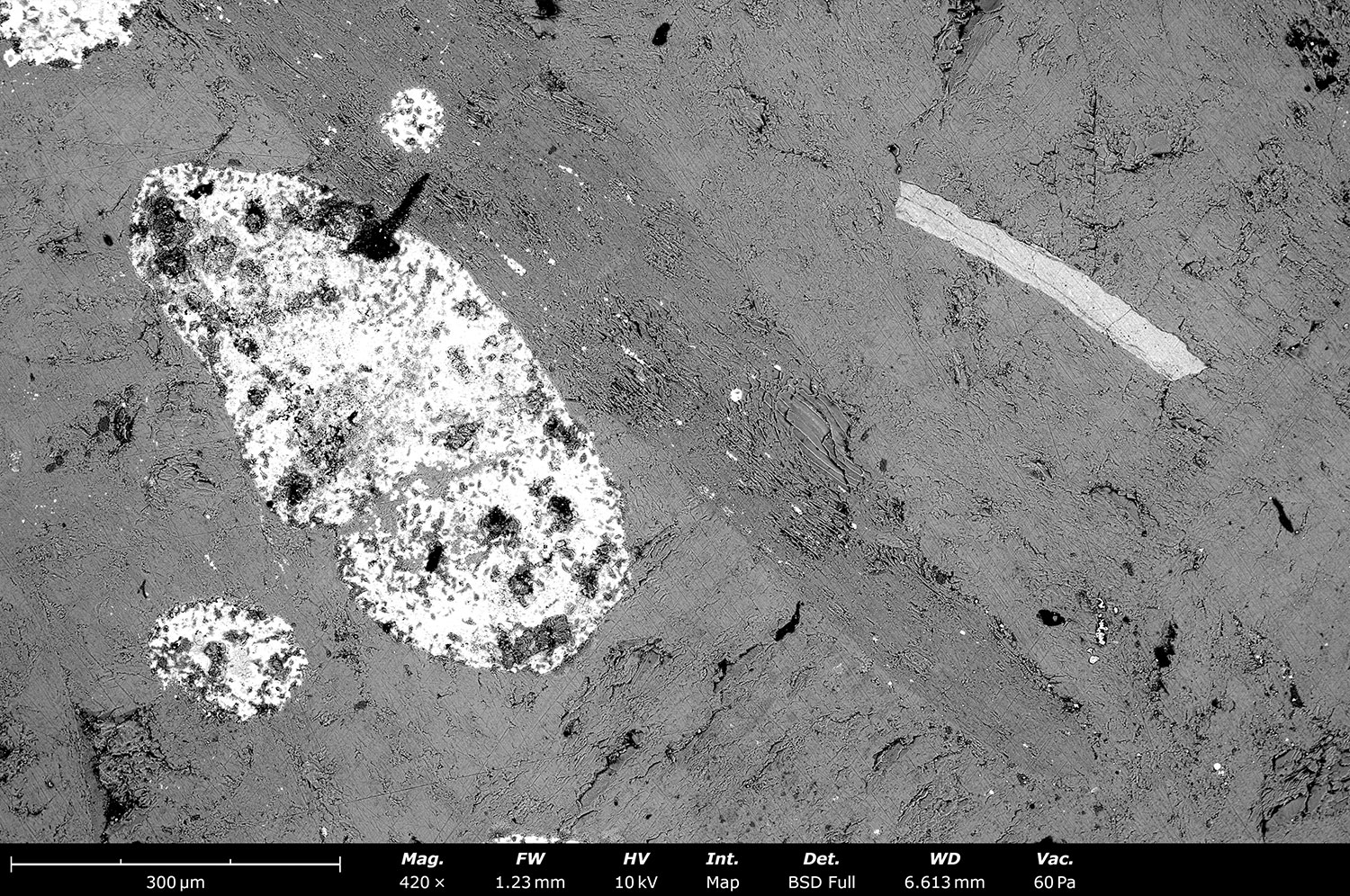

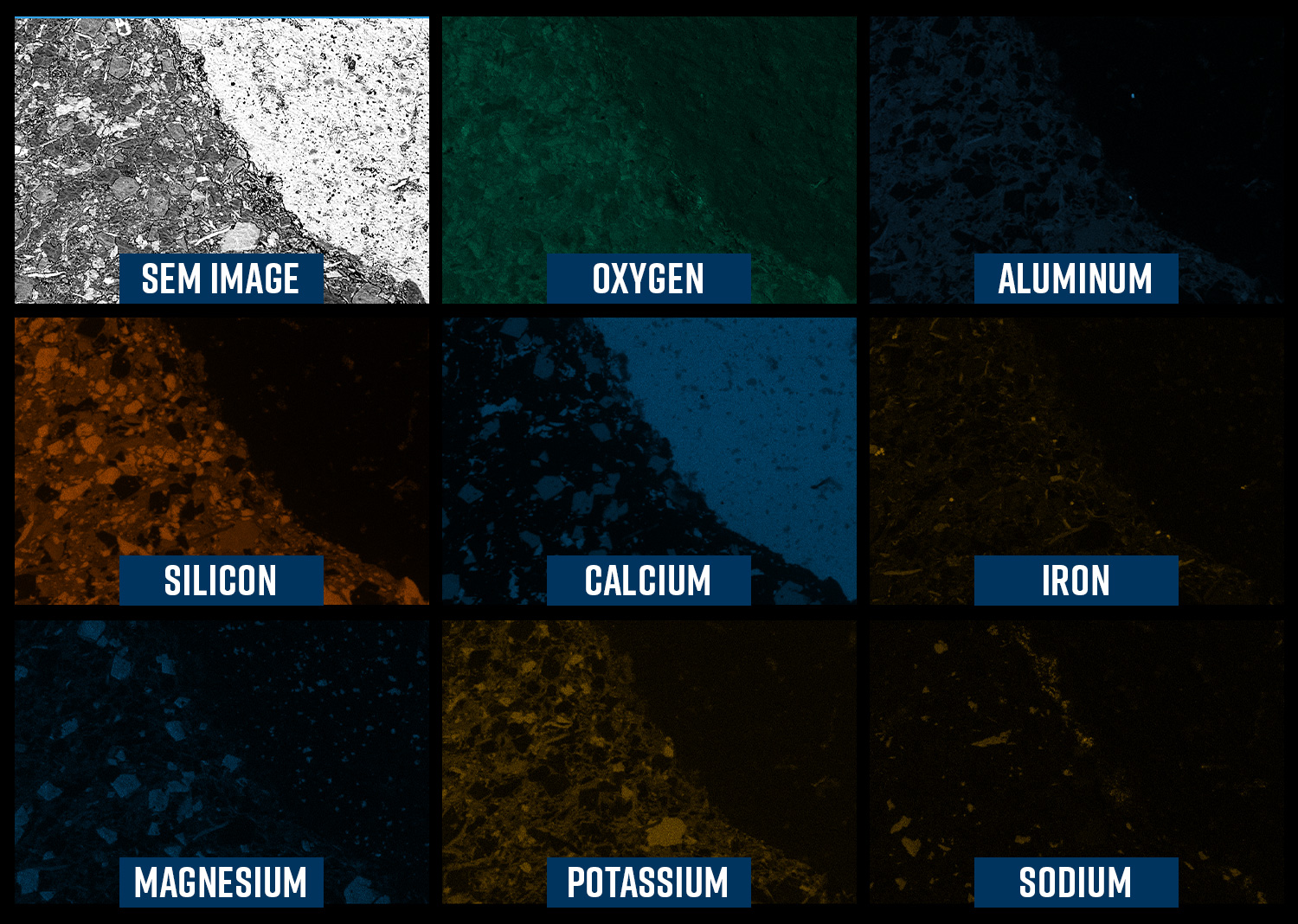

Mineralogy and EDS

EDS mapping coupled with SEM is incredibly valuable for mineral identification. EDS maps can provide insight into elemental composition and spatial distribution of minerals in a sample. EDS detectors collect characteristic X-rays that are emitted from the sample after interacting with the electron beam. Each element has a unique X-ray signature which is automatically identified by software. While mapping, the electron beam scans a selected area, and a color-coded map is generated which shows where specific elements are located. This can help distinguish different minerals in a complex matrix. Figure 4 demonstrates this technique on a fossiliferous limestone sample. Note the crinoid ossicle composed of a large, single crystal of calcite is clearly identified in the map based on the abundance of calcium.

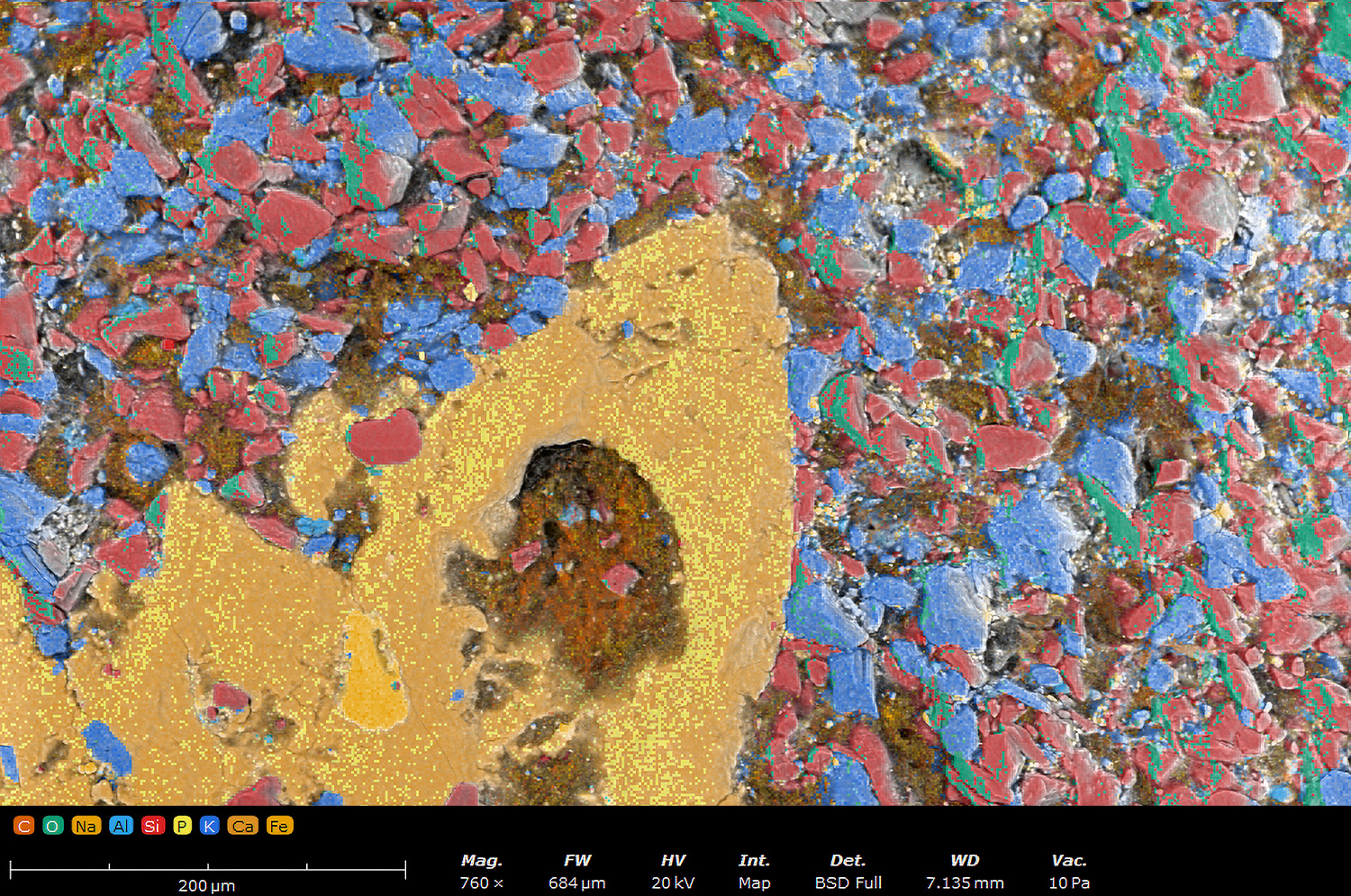

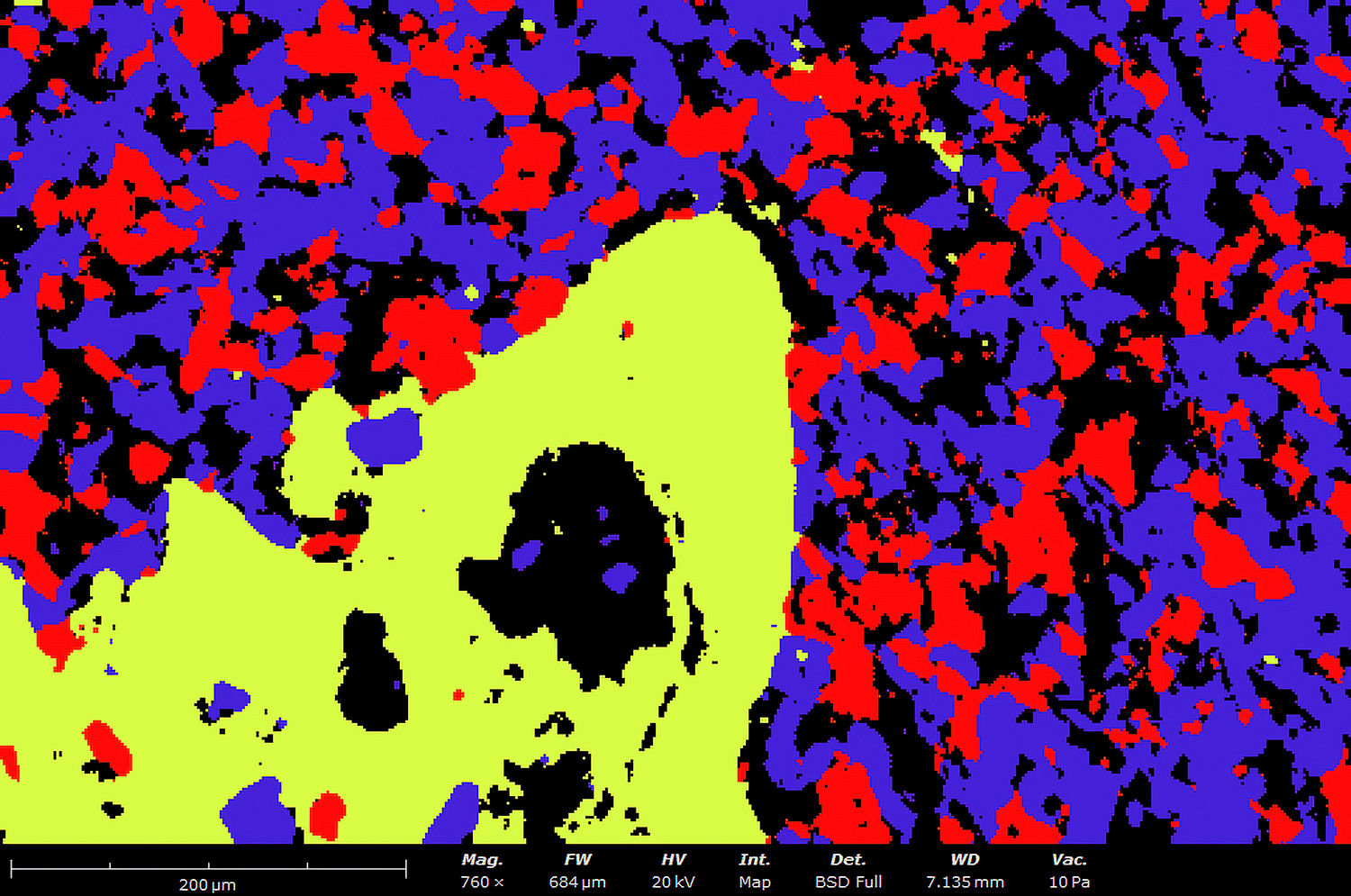

Phase Mapping of Minerals

EDS maps can be quickly converted into phase maps, in a Phenom desktop SEM, which can help distinguish minerals even better. The number of different material phases is calculated in the sample by using principal component analysis (PCA) to simplify the analytical dataset and highlight hidden trends. PCA reduces the complexity of the data by transforming it into principal components, which represent the most significant variations within the dataset. In phase mapping, the EDS analysis generates spectral data for each pixel in the image. The software then calculates the chemical phases by grouping pixels with similar spectra, regardless of their exact individual quantification results. This approach ensures that pixels with comparable spectral characteristics are combined into distinct phases. The result is a map where each phase is represented by a unique color, making it much easier to interpret the material’s composition as shown in Figure 5. Figure 5A shows an EDS map of a sandstone sample that contains 9 elements. Most of these elements occur across several mineral phases in various amounts. Pinpointing the location of an individual mineral based off these results is difficult. Figure 5B shows the phase map of the same sample. Multivariate statistical analysis was used to combine pixels with similar spectra into one phase. This helps unambiguously identify the major and minor components in the sample and clearly display mineral phases.

Mineral Grains and Ion Milling

Polishing is a commonly used sample preparation technique for SEM imaging of geologic samples. Even a basic mechanical polish can reveal grain structure and features that may not be visible on an unpolished rock surface. However, basic mechanical polishing can result in scratches and pits on the surface of the sample as well as an amorphous surface layer known as the Beilby layer. These side effects of mechanical polishing negatively impact both image quality and EDS results. Broad ion beam (BIB) milling is the ideal solution for polishing a geologic sample on a microscopic level. This technique works by using a broad beam of argon ions to bombard and sputter material off the sample surface with the goal of creating a clean, flat surface to perform high quality analysis. Figure 6 clearly shows how ion milling can dramatically improve surface quality of a limestone sample and even reveal mineral grains previous hidden beneath the surface. With ion mills, such as the SEMPREP Smart, geologists can easily and with limited effort create stunning surface polishes which are ideal for SEM imaging.

Summary

SEM is a versatile tool in geology, offering detailed imaging and elemental analysis at the microscale. It enhances our understanding of mineralogy, rock textures, sedimentary processes, paleobiology, and ore genesis. Desktop SEMs provide a practical solution for laboratories seeking high-quality imaging and analysis without the constraints associated with larger SEM systems. Their compact size, affordability, user-friendly operation, and versatility make them an attractive option for analyzing geological samples.