Contact angle measurement is essential for characterizing the wettability and surface energy of materials, providing critical insights into how liquids interact with solid surfaces. This is vital for applications ranging from coatings, adhesives, and packaging to biomedical devices and semiconductors. Contact angle measurements help quantify hydrophobicity or hydrophilicity, assess surface treatments, optimize adhesion, and predict liquid spreading or droplet behavior.1 By understanding these interactions, researchers and engineers can design surfaces with controlled wetting properties, improve product performance, and ensure reliability in real-world applications.

Water is the most common probe liquid in contact angle analysis. However, using alternative liquids can provide deeper insights into surface properties. Varying the liquid varies the interaction with the surface, enabling comprehensive characterization of surface energy (polar and dispersive components), detection of chemical heterogeneity or localized surface variations, better understanding of dynamic wetting, adhesion, and spreading behaviors, and insights relevant to real-world applications (oils, solvents, biofluids). By strategically selecting probe liquids for contact angle analysis, researchers can obtain a more complete and application-relevant picture of surface wettability and material performance.

Common Probe Liquids for Contact Angle Analysis |

|||

|---|---|---|---|

| Liquid | Surface Tension (mN/m, 25°C) | Polarity | Typical Applications / Insights |

| Water | 72.8 | Highly polar | Standard wetting studies; hydrophilicity assessment. |

| Glycerol | 64.0 | Polar, viscous | High-viscosity liquids; mimics biofluids; dynamic wetting studies and spreading. |

| Formamide | 58.0 | Polar | Intermediate polarity; polar contribution to surface energy; protein or polymer wettability. |

| Diiodomethane (CH₂I₂) | 50.8 | Nonpolar | Measures dispersive surface energy component; oleophobicity and oil–surface interactions. |

| Propylene Glycol | 36.0 | Polar, viscous | Mimics pharmaceutical liquids or biofluids; dynamic wetting and hysteresis analysis |

| Oil emulsions / mineral oil | 30–35 | Nonpolar | Industrial coatings, packaging, and lubrication studies; real-world wetting behavior |

| Toluene | 28.4 | Nonpolar | Surface wettability with organic solvents; adhesion and coating performance |

| Hexadecane | 27.5 | Nonpolar | Hydrophobic/oleophobic surface characterization; dispersive energy assessment |

| Ethanol | 22.3 | Polar | Low surface tension; studies spreading, hydrophobicity, or solvent effects on coatings |

| n-Hexane | 18.4 | Nonpolar | Extreme low surface tension; evaluates superhydrophobic or oleophobic surfaces |

While choosing a probe liquid, characteristics of the dispenser must also be taken into consideration. Strong acids or organic solvents, for example, can react with or dissolve certain dispenser tips. Liquids with low surface tension can draw up the side of certain dispenser tips, preventing accurate dispensing of droplets.2 Choosing chemically compatible dispenser materials is fundamental to accurate contact angle measurements. The ideal system minimizes chemical reactions, avoids swelling or leaching, resists adsorption, and withstands cleaning procedures. Materials like PTFE (polytetrafluoroethylene), glass, PEEK (polyetheretherketone), and stainless steel each offer unique strengths depending on the chemical environment.

Key Factors to Consider When Selecting a Dispenser for Contact Angle Measurements

Chemical Resistance of Dispenser Material

Ensuring chemical compatibility between the dispensing tip and the measurement liquid is key for ensuring accurate results and undamaged equipment. Common chemically resistant materials include PTFE, which is resistant to most organic solvents, acids, bases, and aggressive chemicals, PEEK, a high-performance plastic with broad resistance to many solvents, acids, bases and good thermal stability, stainless steel and borosilicate glass. But not all materials are universally compatible: for example, PEEK has limitations with strongly oxidizing acids (e.g., nitric or sulfuric acids), halogenated acids, or some aggressive organics. PTFE or PFA tips should be used to dispense harsh acids and organics, such as sulfuric acid and THF.

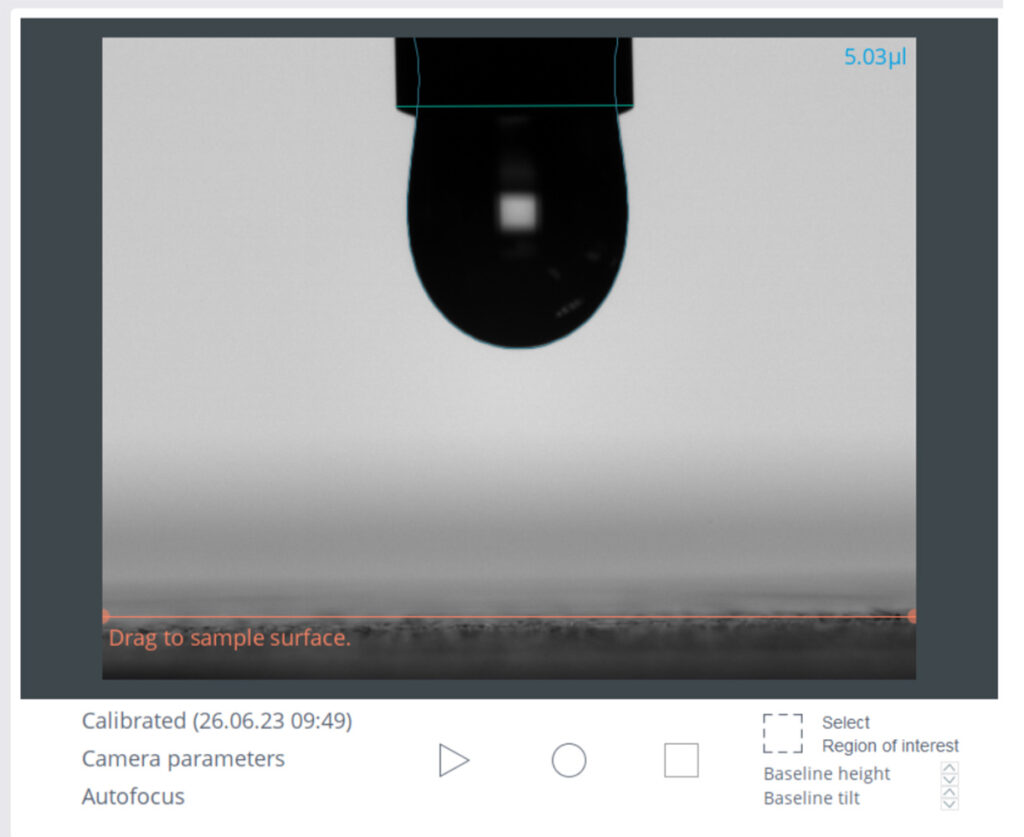

Surface Tension of Probe Liquid

The surface tension of the probe liquid plays a direct role in how droplets form, detach, and interact with the internal surfaces of the dispenser. Higher surface tension liquids such as water or glycerol tend to bead strongly and resist flowing, which enables consistent dispensing with most materials. Typically, polypropylene or stainless steel are used, as they are abundantly sourced and disposable versions exist to prevent cross-contamination.

Low surface tension liquids, such as alcohols, hydrocarbons, and organic solvents, spread more easily and can draw up the sides of dispensing tip materials like polypropylene or stainless steel. In addition, low-tension liquids detach more readily, so the dispenser tip geometry and material must control droplet size and prevent uncontrolled dripping. Specifically, liquids with surface tensions lower than 30 mN/m need to be dispensed from a PTFE or PFA tip.

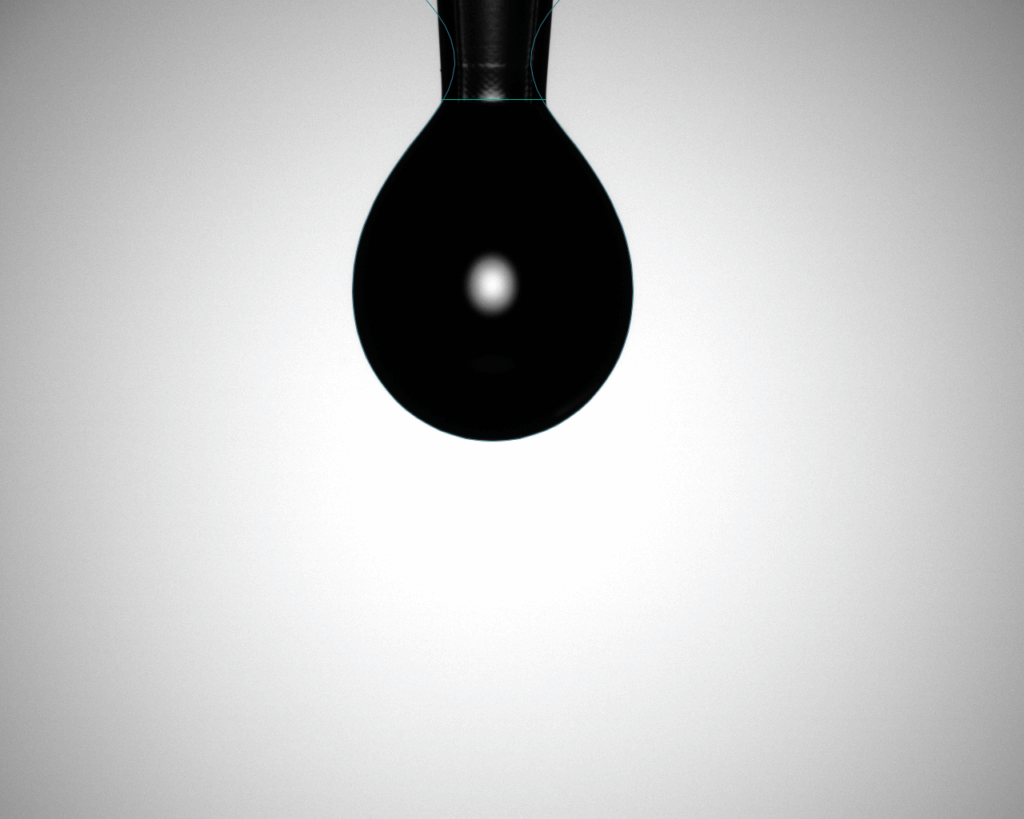

Density of the Probe Liquid

The density of the probe liquid influences both the mechanical demands placed on the dispenser and the stability of droplet formation, making it an important factor when selecting appropriate materials and components. Higher density liquids, such as glycerol, and formamide, exert greater hydrostatic pressure within the syringe or tubing. As a result, the dispenser materials must maintain structural rigidity and dimensional stability to prevent deformation, leakage, or drift in delivered volume.

Conversely, low density liquids impose less mechanical stress but often flow more readily, which can exaggerate issues such as dripping or rapid detachment at the needle tip. In these cases, the dispenser material must ensure controlled droplet formation through consistent inner-surface smoothness and compatibility with the fluid’s wetting behavior.

For example, diiodomethane is often used as a non-polar probe liquid in surface free energy (SFE) calculations, and while its surface tension is high enough to support larger drops and higher contact angles, its density caps the maximum drop volume that can be held by the tip.

Viscosity of Probe Liquid

The viscosity of the probe liquid directly influences how easily it can be drawn, metered, and dispensed, making it a critical consideration when selecting a suitable dispenser. High viscosity liquids, such as glycerol, propylene glycol, or silicone oils, generate greater flow resistance and require dispensers built with materials and geometries that maintain smooth, controlled movement under higher mechanical loads. These applications typically benefit from low gauge or wide orifice geometries.

On the other hand, low viscosity liquids flow rapidly, spread easily, and can leak or drip if the internal tolerances of the dispenser are not tight enough. For these fluids, the priority shifts toward precise sealing, smooth internal surfaces, and chemically resistant materials to prevent swelling or poor fit, which could lead to unstable droplet formation. For lower viscosity liquids like mineral oil that are typically accompanied by low surface tensions, PTFE or PFA tips are ideal for droplet formation.

Selection Guide for Dispensing Tips |

||||||

|---|---|---|---|---|---|---|

| Fluid type | PTFE / PFA tip | Stainless steel needle | Polypropylene tip | Polypropylene tip with wide orifice | Parylene coated tip | |

| Water, diluted acid, alkali solutions | ||||||

| Diiodomethane with density > 3 g/cm³ | ||||||

| Low surface tension liquids (< 30 mN/m) | ||||||

| High surface tension liquids (≥ 30 mN/m) | ||||||

| Low viscosity liquids (<1 mPa.s) | ||||||

| High viscosity liquids | * | |||||

| Strong acids (pH of 0-1) | ||||||

| Strong alkali (pH of 12-14) | ||||||

| Harsh organics (e.g. THF) | ||||||

Attension Theta Optical Tensiometers

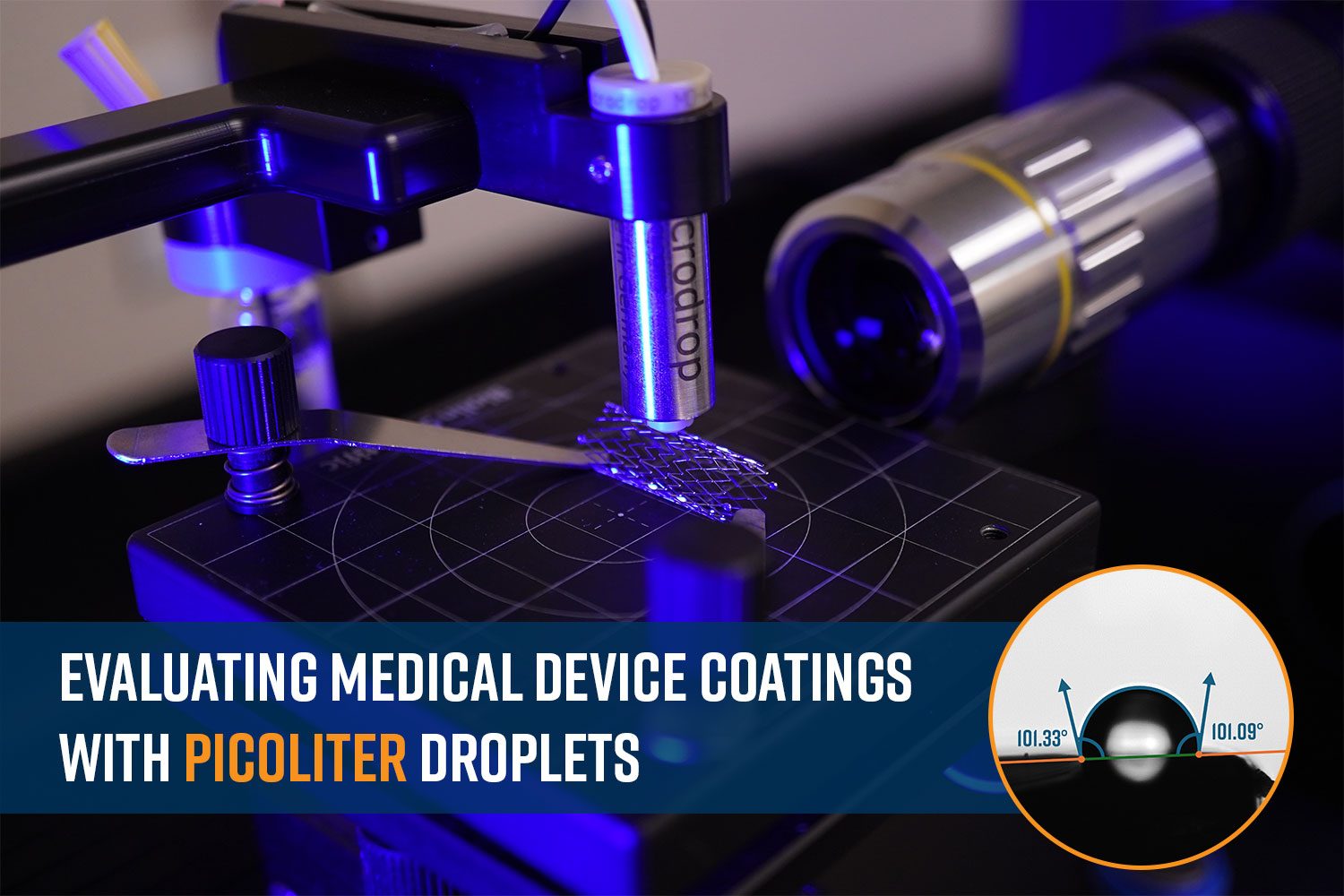

The Attension Theta series of optical tensiometers are versatile instruments designed for R&D and quality control applications, enabling precise measurement of contact angles and characterization of surface and interfacial properties. These tensiometers support a full range of automated measurements, making them highly adaptable for research, industrial, and QC laboratories.

Attension Theta optical tensiometers utilize automated disposable tip dispensers to deliver probe liquids with high accuracy and precision. A broad selection of disposable tips, constructed from different materials, is available to ensure compatibility with various probe liquids, optimizing droplet formation and reliable contact angle measurement.

Conclusion

The properties of the probe liquid, surface tension, density, viscosity, and chemical composition play a critical role in determining the appropriate dispenser materials for optical tensiometry and contact angle measurements. Selecting materials that are chemically compatible, mechanically stable, and tailored to the liquid’s physical behavior ensures precise droplet formation, reproducible measurements, and long-term instrument reliability. By carefully matching dispenser materials to the characteristics of the probe liquid, researchers and engineers can achieve accurate surface characterization, optimize wetting studies, and maintain consistency across a wide range of applications in coatings, biomedical devices, packaging, and materials science.

References

- Cwikel, D.; Zhao, Q.; Liu, C.; Su, X.; Marmur, A. Comparing Contact Angle Measurements and Surface Tension Assessments of Solid Surfaces. Langmuir 2010, 26 (19), 15289–15294. https://doi.org/10.1021/la1020252. ↩︎

- (COX, R. G. Inertial and Viscous Effects on Dynamic Contact Angles. Journal of Fluid Mechanics 1998, 357, 249–278. https://doi.org/10.1017/s0022112097008112. ↩︎