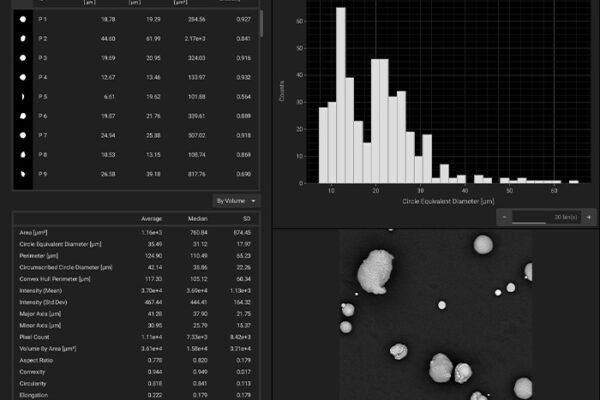

Battery manufacturers face increasing demands for higher throughput, reproducible quality control, and reduced time-to-market. Traditional manual analysis of electrode materials under the scanning electron microscope (SEM) is often labor-intensive, inconsistent, and difficult to scale. Thermo Scientific’s Avizo Trueput software, when combined with Phenom Desktop SEMs, provides an automated solution for high-throughput, standardized inspections. Avizo Trueput coupled with Phenom desktop SEMS enables operators of any skill level to acquire SEM images, apply automated feature detection, and generate consistent pass/fail metrics for critical parameters such as particle size (primary and secondary), morphology, cracks, coating uniformity and more.

To broaden the capabilities of these automated analyses, high-quality sample preparation is essential. The SEMPREP SMART broad-beam ion mill provides clean, artifact-free cross sections of battery electrodes and other heterogeneous materials. The ion milled cross sections expose particle interfaces, binder distribution, and porosity without mechanical smearing or polishing-induced damage. Ion milling also ensures that Avizo Trueput’s automated feature detection can run with greater accuracy and repeatability, in turn improving comparability across batches.

This webinar will demonstrate how integrating Avizo Trueput with Phenom Desktop SEMs (supported by precise sample preparation using the SEMPREP SMART ion mill) can be a powerful QA/QC solution for battery materials analysis. This solution delivers fast workflows, reproducible results, and greater confidence in data-driven decision-making in both research and production environments.