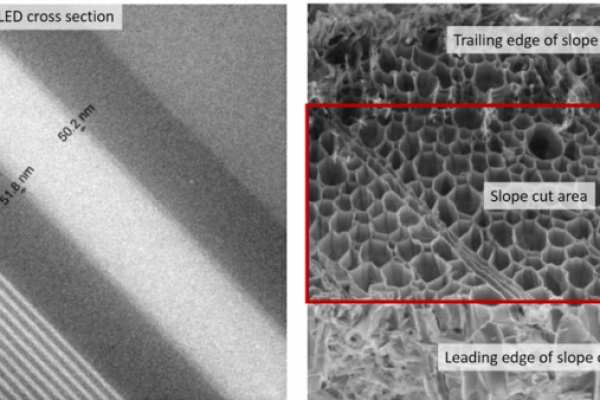

Sample preparation usually begins with mechanical grinding and polishing. During this process, the grinding and polishing creates a deformed or amorphous layer on the surface called the Beilby layer. This layer can disrupt scanning electron microscopy (SEM) measurements and blurs the diffraction pattern of the sample. Different ways to remove the amorphous layer are refining mechanical polishing, chemical etching, and electropolishing. These techniques are time consuming, material dependent, difficult processes, and sometimes unsuccessful. A promising technique that has been developed is ion polishing and milling. These techniques are less sensitive to the microstructure and chemical composition. By adjusting parameters such as the ion’s energy and angle of milling, users can control the milling rate and depth. The Ion Mill can be used to reveal features hidden under the amorphous layer and give researchers the ability to make precise measurements, EBSD measurements, and a view a true polishing of a cross section under the SEM.