Improving Enhanced Oil Recovery (EOR) with the Attension Theta Flex High Pressure Chamber Measurements

As oil demand continues to rise, many oil reservoirs are no longer capable of producing oil by traditional primary and secondary extraction methods. To extract these oils, enhanced oil recovery (EOR) techniques that aim to improve oil mobility through lowering oil viscosity, lowering interfacial tension, and reducing wettability of oil on reservoir surfaces, are needed. Understanding how EOR approaches alter interfacial tension and wettability is important, and these properties are heavily dependent on temperature and pressure, it is crucial to have the ability to measure these properties at temperatures and pressures relevant to reservoir conditions.

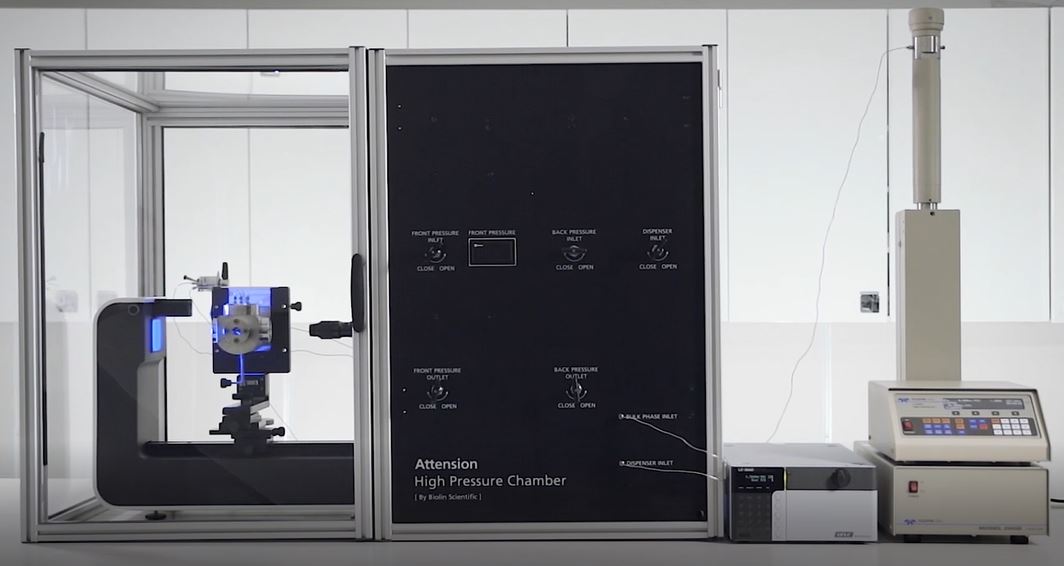

With the Attension Theta Flex High Pressure Chamber, contact angle and interfacial tension measurements are made easy and intuitive right in the lab. With market-leading sample sizes, automatic pressurization capability, unique chamber design, easy sample loading and cleaning, the Attension® Theta Flex High Pressure will advance your EOR research.

Meeting the Global Oil Demand with EOR Research

By 2040, OPEC predicts global oil demand will increase by 15% to 111.7 million barrels of oil per day (OPEC World Oil Outlook 2018). However, as many oil reservoirs are no longer capable of producing oil through traditional primary and secondary extraction methods, a significant portion of this increase in demand will need to be met by employing enhanced oil recovery (EOR) techniques. The oil remaining after primary and secondary extraction methods is challenging to recover due to its high viscosity and low mobility [Speight JG. Enhanced recovery methods for heavy oil and tar sands. Houston (Texas): Gulf Publishing Company; 2009.].

Furthermore, a considerable amount of oil reserves are locked in oil sands, i.e. bitumen. In Canadian oil sands alone, it is estimated that the ultimate oil in place is approximately 2500 billion barrels, 2400 of which are only accessible through specialized EOR methods currently in development [Huc AY. Heavy crude oils: from geology to upgrading: an overview. Paris

(France): Editions Technip; 2011.]

EOR Research Strategies and the Oil and Gas Industry’s Challenges

A primary strategy for EOR is to improve oil mobility through lowing the oil viscosity and its interfacial tension with EOR fluids. Generally, these EOR techniques fall into either thermal, gas, or chemical injection methods as described in more detail below. Lowering the viscosity and interfacial tension reduces detrimental phenomena such as viscous fingering, where less viscous EOR fluids penetrate the oil with poor displacement efficiency and improve dewetting of the oil from solid surfaces in the reservoir.

Additionally, the fluid properties are heavily dependent on pressure and temperature. Thus, having a firm understanding of the in situ interfacial tensions and wetting properties of EOR fluids and the targeted oil is crucial when evaluating and developing EOR methods. This means having the ability to measure these properties at pressures and temperatures mimicking reservoir conditions is imperative. With the Theta Flex High Pressure Chamber, these measurements, including contact angles and interfacial tensions using optical tensiometry, are made easy and accessible to scientists in the laboratory. When it comes to oil recovery, one of the biggest challenges is determining the most effective method of extraction from carbonate reservoirs and waterflooded carbonates.

The gas and oil industry work with engineers to better understand and solve these challenges of enhanced oil recovery (EOR) and ultimately increase the yield to maximize efficiency. When 50% to 60% of the world’s oil is retained in carbonate reservoirs, working with scientists on extraction methods and enhanced oil recovery seems like a top priority. Before extraction methods can be put to practice several questions arise:

- Will the oil extraction method damage the equipment used in enhanced oil recovery?

- How do you determine the most effective method of extracting oil?

- Which oil extraction will increase the yield the most?

- Is there a technique that will provide valuable data on oil recovery to determine the best method for enhanced oil recovery?

- Will the reservoir conditions influence the yield of oil extraction when put into practice?

- These are very important questions or challenges engineers and oil companies encounter when assessing carbonate rich reservoirs.

- To determine the most effective method for enhanced oil recovery, knowing each method and how it impacts the equipment is important.

Three Methods of EOR: Gas, Chemical and Thermal Enhanced Oil Recovery

The gas and oil industry are familiar with these methods and determining the most effective method for the reservoir they are working with is part of that challenge. Each one of these methods come with their own challenges.

Gas Enhanced Oil Recovery

CO2 Gas injection, aka miscible gas injection, is the most widely used EOR method in a carbonate reservoir. This method of EOR is utilized in both mature and waterflooded carbonates. When practiced, the injected CO2 dissolves in formation water producing carbonic acid that reacts with the reservoir rock and mixes of the oil. One challenge with CO2 flooding is that the lower viscosity of the CO2 causes mobility issues and instability in the displacement front. These challenges can lead the low volumetric sweep efficiencies as oil at the low permeability parts of the reservoirs are not contacted by CO2.

Thermal Enhanced Oil Recovery

Thermal recovery, aka steam injection, is a technique were the wettability of the carbonate reservoir is altered to lower the viscosity of the oil. When the wettability is altered at elevated temperatures it increases the solubility of adsorbed materials from the surface. This in turn decreases the interfacial tension between the water and oil making thermal EOR methods common in carbonate reservoirs. This fractured nature of carbonate reservoirs can lead to uneven sweeping resulting in low recovery factors.

Chemical Enhanced Oil Recovery

Chemical recovery methods utilize different types of polymer, surfactants, and low salinity water injections. Chemicals are injected into the reservoir to improve the mobility ratio, reduce the interfacial tension (IFT) and/or alter the wettability of the rock. By adding the polymer and/or surfactants to the waterflood the sweeping efficiency increases the viscosity and decreases the mobility of the flood water. Studies show that polymer flooding is the only proven chemical method for carbonate reservoirs and different types of surfactant injections have been known to improve oil recovery in a carbonate formation. Research is being conducted to study the surfactant nanoparticles or nanofluids because at low concentrations these particles penetrate the smallest pores thus increasing the effectiveness of oil recovery.

Low-salinity, aka brine or smart water injection, is another actively investigated method for enhanced oil recovery. Brine composition can have a positive impact on oil recovery in carbonate reservoirs. Engineers are studying the effectiveness of this EOR as this method is not entirely understood and currently under investigation.

With these three EOR methods in practice, the oil and gas industry are faced with challenging questions with their billion-dollar equipment in mind.

The Solution to the Oil & Gas Challenges: Attension® Theta Flex High-Pressure Chamber: Modeling Tool that Does All Three EOR Methods

Oil and gas companies must assess each method’s efficiency in extracting oil from carbonate rich reservoirs with the risk of damaging their equipment when these methods are put into practice.

To determine the most effective method of EOR for their reservoir no longer has to be a mystery with billion-dollar equipment at stake. Utilizing the Attension® Theta Flex High Pressure Chamber is a scientific instrument that can model the reservoir conditions testing these three EOR methods before putting them into practice.

The Attension® Theta Flex High Pressure Chamber is a tensiometer designed to measure wettability and interfacial tension at high pressures and high temperatures with the ability to model each EOR to determine the best method for their reservoir. With the harsh conditions of an oil reservoir in mind, the instrument is designed to ensure ease of use and offer a wide variety of measurement with efficiency and safety in mind. This state-of-the-art instrumentation can model reservoir conditions and make crucial interfacial measurements between EOR fluid, oil and rock samples to optimize EOR methods.

High-Quality Chamber with Unique Piston Design

The instrument consists of high-quality parts that ensure the ease of use, functionality, and safety of the system. The chamber itself is made from corrosion resistant stainless steel and three windows for easy viewing of the experiment.

The Attension® Theta Flex High Pressure Chamber’s unique piston design allows you to increase the chamber pressure without adding additional bulk liquid or affecting the bulk concentration. This enables accurate and convenient studies using surfactants and brines. Additionally, the piston design means corrosive solutions such as brines are restricted to the measurement chamber itself, and the pumps, valves and other instrument components are not in danger of corrosion.

Automated Pumping Options

The Attension® Theta Flex High Pressure can be used with automated pumps for both chamber pressurization and droplet dispensing. This enables easy control over chamber pressure with the touch of a button. With a single droplet, a full range of pressures can be efficiently set with the automated pumps to study the effects of pressure on interfacial tension and contact angles.

Temperature and Pressure Control for Reservoir Modeling Conditions

The temperature control of the chamber has two options, resistor heating and Peltier heating and cooling. Resistor heating enables software-controlled temperature range from ambient to 200 °C whereas the Peltier element combined with a water bath enables temperature control down to 1°C .

Easy Using and Cleaning

The entire chamber can be disassembled and reassembled easily within minutes making cleaning or maintenance of the chamber convenient. The smart sample port enables direct introduction of a sample with a syringe, reduces the total sample volume, and allows direct cleaning of the sample line without needing to pass cleaning solutions through a pump.

Safety Mechanisms with the Operator in Mind

The Attension® Theta Flex High Pressure keeps its user well protected with multiple safety mechanisms with two overpressure valves that automatically release any excess pressure through the release lines. Overheating prevention with both an overheating switch that will cut the heating power if the temperature exceeds the maximum temperature limit and OneAttension software that will refuse to overheat the chamber.

Other Features of the Attension® Theta Flex High Pressure Chamber:

- Special Sample Port for easy introduction and cleaning.

- Rock material wettability to increase oil reservoir yield.

- Efficiency of CO2 in flooding EOR by measuring the minimum miscibility pressure (MMP) of CO2.

- Analyze drilling fluid composition and effectiveness and EOR oil displacement with supercritical fluids (SCF).

Measurements of the Attension® Theta Flex High Pressure Chamber: Determining Oil Recovery Yield with Quality Data

Example Measurements: The Effect of Pressure, Temperature, and Surfactants on Interfacial Tension

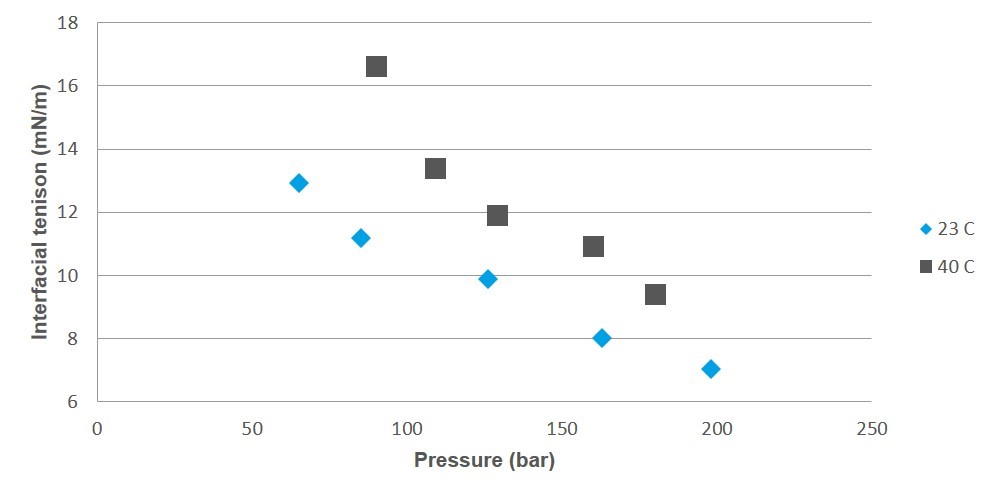

Both temperature and pressure can have a significant impact on interfacial tension. In this example, interfacial tension between a brine droplet with surfactant (3.5 % NaCl, 0.01% Tergitol) and supercritical CO2 is measured versus pressure for two temperatures in Fig. 1. As pressure increases, more CO2 becomes dissolved in the aqueous droplet which causes a reduction in interfacial tension.

The effect of temperature on the interfacial tension is complicated due to the presence of surfactants. Generally, for pure systems without surfactants, increasing temperature weakens the cohesive intermolecular forces, causing the interfacial tension to decrease. However, elevated temperature also tends to reduce the effectiveness of surfactants, causing a relative increase in interfacial tension. This is what we observe in Fig. 1. The increase in temperature from 23 to 40 °C causes the interfacial tension to increase, particularly at lower pressures. The complex relationship between pressure, temperature, and additives like surfactants demonstrates the need to perform these measurements at conditions relevant to the oil reservoir.

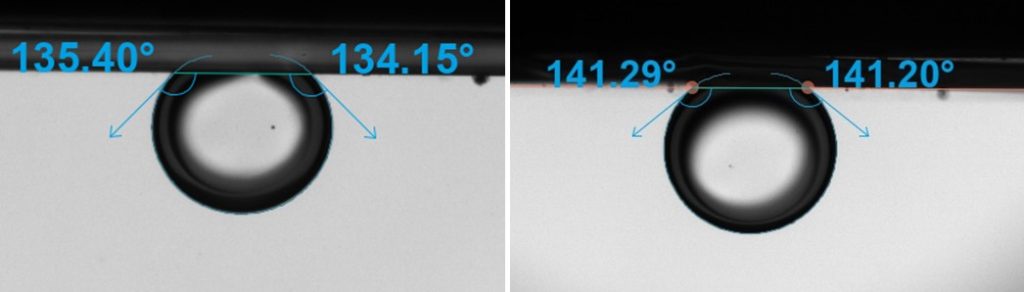

The Effect of CO2 on Contact Angles

At elevated pressures relevant to oil reservoirs, injected CO2 can dissolve readily into EOR fluids and favorably impact interfacial tensions. As interfacial tension is directly related to contact angles, the addition of CO2 can reduce oil wettability on reservoir surfaces. In Fig. 2, this is demonstrated by measurements of contact angles between a dodecane drop on a quartz substrate and surrounding brine. The surrounding liquid is 3.5% NaCl with either no dissolved CO2 (left in Fig. 2) or with dissolved CO2 (right in Fig. 2). The addition of CO2 impacts the interfacial tension and as a result increases the oil contact angle with the quartz, a situation that would be more favorable to increased oil recovery.

References

- Laurén, Susanna. “3 Examples of How to Utilize High Pressure Tensiometer.” Surface Science Blog, blog.biolinscientific.com/3-examples-of-how-to-utilize-high-pressure-tensiometer.

- “Attension Theta Flex High Pressure Chamber.” Nanoscience Instruments, www.nanoscience.com/products/optical_tensiometers/theta-high-pressure-chamber/.

- X. Li, E. Boek, G. C. Maitland, and J.P. M. Trusler, “Interfacial tension of (Brines + CO2): (0.864 NaCl + 0.136 KCl) at temperatures between (298 and 448) K, pressures between (2 and 50) MPa, and total molalities of (1 to 5) mol*kg-1”, Journal of Chemical Engineering & Data, 57 (2012) 1078.

- B. Bharatwaj, L. Wu and S. R. P. da Rocha, “Biocompatible, lactide-based surfactants for the CO2 – water interface: High-pressure contact angle goniometry, tensiometry, and emulsion formation”, Langmuir 23 (2007) 12071.

- C. Chalbaud, M. Robin, J.-M. Lombard, H. Bertin and P. Egermann, “Brine/ CO2 interfacial properties and effects on CO2 storage in deep saline aquifers”, Oil & Gas Science and Technology – Rev. IFP, 65 (2010) 541.

- Ameri, N. Shojai Kaveh, E.S.J. Rudolph, K-H. Wolf, R. Farajzadeh and J. Bruining, “Investigation on interfacial interactions among crude oil – brine – sandstone rock – CO2 by contact angle measurements”, Energy & Fuels 27 (2013) 1015.