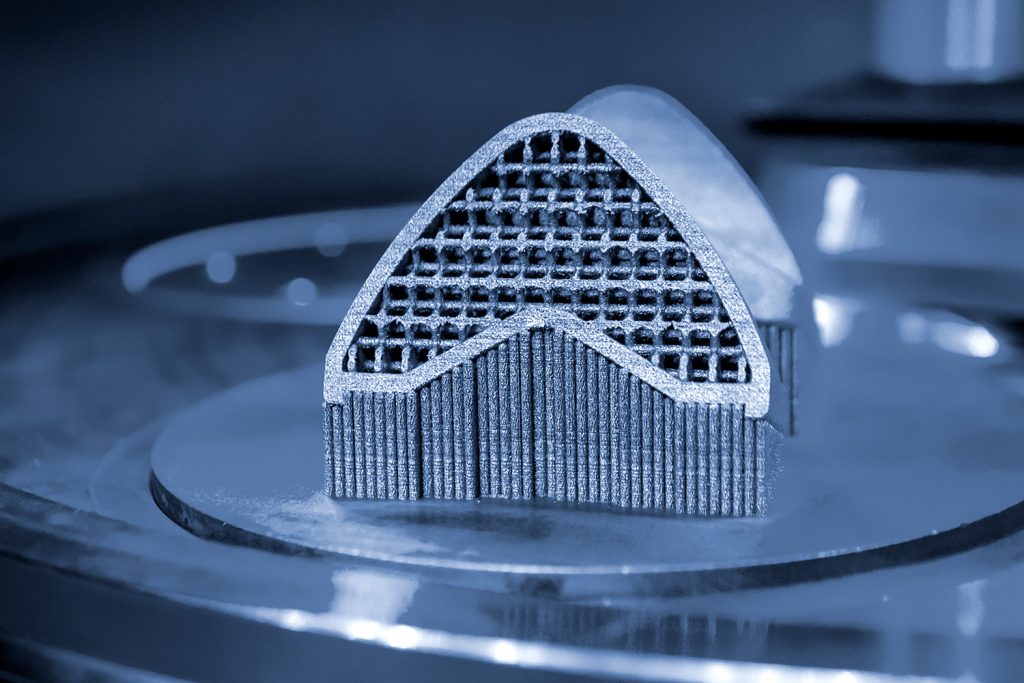

Particle Analysis in Additive Manufacturing

From supersonic jets to prosthetic knees, 3D-printed parts are revolutionizing design and production across industries. Printed components are no longer just prototypes, but now perform critical functions in the realms of aerospace, medical, dental, automotive, and beyond.

International Materials, Applications & Technologies 2023 | Oct. 16-19, 2023 | Detroit, MI

International Materials, Applications & Technologies 2023 Nanoscience Instruments cultivates global partnerships to deliver cutting-edge electron microscopy, surface analysis, and material characterization solutions. Visit our booth for a live, hands-on demonstration of an automated desktop Scanning Electron Microscope (SEM). In conjunction with the Attension line of tensiometers, these unique instruments enable transformative advancements in materials development […]

The Role of Scanning Electron Microscopy in the Automotive Industry

From zippy city scooters to heavy duty haulers, modern automobiles are assemblies of thousands of precisely manufactured components working in harmony to ensure smooth and safe rides. Beneath the sleek exteriors and plush interiors are components that at one point underwent stringent inspection for microscopic defects, particulates, and structures that could negatively impact performance, durability, […]

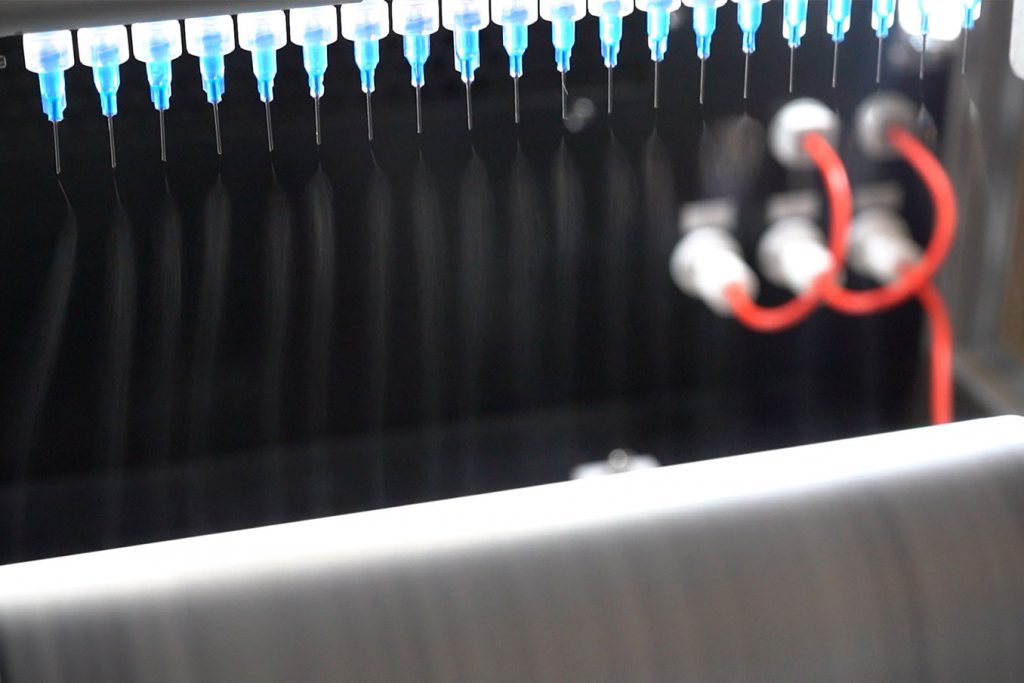

7 Factors to Consider While Buying an Electrospinning Machine

Electrospinning is a versatile nanofiber fabrication technique wherein a polymer solution is charged and ejected from a spinneret under a high-voltage electric field. As the polymer is ejected, the solvent evaporates, and a fine jet of polymer forms, which elongates and solidifies into nanofibers upon reaching an oppositely charged or grounded collector. The resulting nanofiber […]

Medical Device & Manufacturing Minneapolis 2023 | Oct. 10-11, 2023 | Minneapolis, MN

Nanoscience Instruments and our sister company, Nanoscience Analytical, provide cutting-edge instrumentation and process development services to enhance the production of medical devices and biomedical products such as tissue scaffolds, vascular grafts, wound healing therapeutics, and more.

Applications of SEM in Semiconductor Device Failure Analysis

Failure analysis (FA) is an essential methodology that engineers use in the development process of semiconductor devices, like the CPU found in your smartphone or laptop. It involves the application of multiple analytical tools to isolate the root cause of a particular failure mode to prevent it from happening in the future. Failure modes describe how a device is failing by not meeting a certain electrical, mechanical, or visual specification.

Decoding the Best Phenom SEM for Your Needs

Scanning electron microscopy (SEM) is an incredibly adaptable analytical method that generates high-resolution images by scanning a focused electron beam across the surface of a sample. Inside the SEM instrument, a range of detectors captures various signals produced during the interaction between the electron beam and the sample, enabling the visualization of surface microstructure and elemental composition. Compared to optical microscopes, the exceptional resolving capacity of SEMs establishes them as an essential instrument across numerous industries, particularly those working with functional materials.

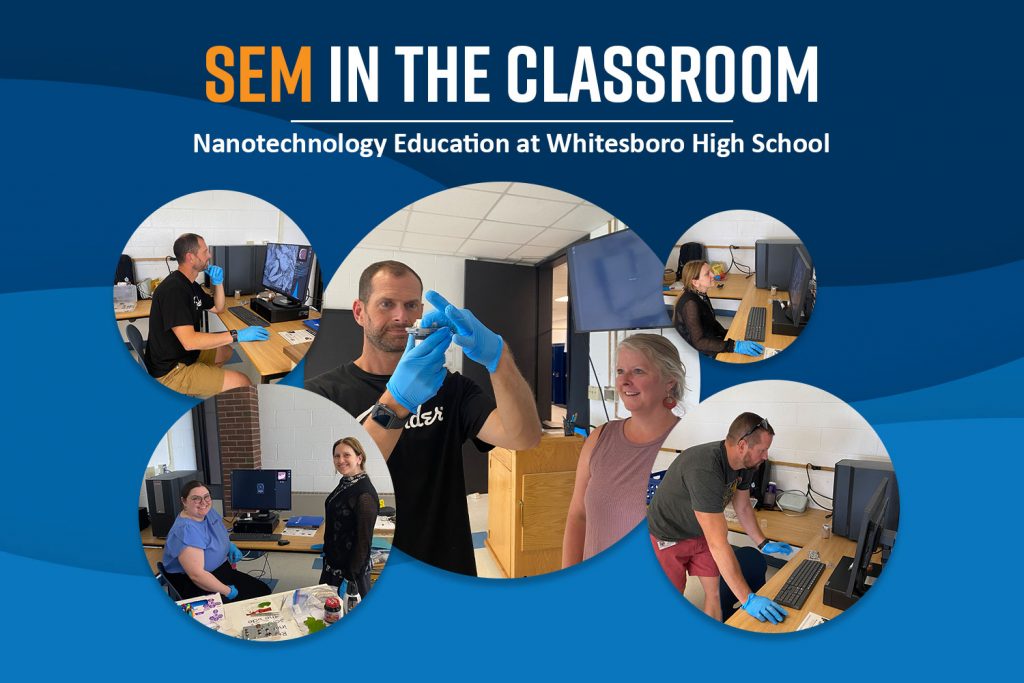

Igniting Young Minds: How Whitesboro High School Brought Nanotechnology to Life

Imagine being able to visually explore the nanoscale structures of bugs, pollen, cells, minerals, and more. To zoom thousands of times closer than the naked eye and study intricate details spanning just billionths of a meter. A scanning electron microscope (SEM) is a versatile tool which makes use of an electron beam to scan the surface of a sample to make this vision an achievable reality. Making sense of such small scales requires grasping dimensions exponentially smaller than our direct experience, and an SEM provides a powerful lens to explore these landscapes.

The Advanced Materials Show 2023 | Oct. 3-4, 2023 | Columbus, OH

Nanoscience Instruments cultivates global partnerships to deliver cutting-edge electron microscopy, surface analysis, and material characterization solutions. Visit our booth for live, hands-on demonstrations of industry leading Tensiometers and automated desktop Scanning Electron Microscopes (SEMs). These unique instruments enable transformative advancements in materials development and manufacturing workflows for optimizing your next-generation materials.

10 Reasons to Use Electrospinning

Electrospinning is a voltage-driven material fabrication process that can be used to produce micro to nano-scale fibers. The electrospinning process is a combination of interacting electric, hydrodynamic, and surface tension forces resulting in “electrohydrodynamic phenomena” which affect the electrospinning solution as a high voltage is applied. The most common basic setup involves a spinneret, high voltage source, material (e.g., polymer) in solution within a reservoir, and a grounded or charged collector.