Fluidnatek Knowledge base

– Webinar –

Advancements in Electrospun Scaffolds: Transitioning from 1D/2D Sheets to 3D Structures

Electrospinning has emerged as a leading platform for generating…

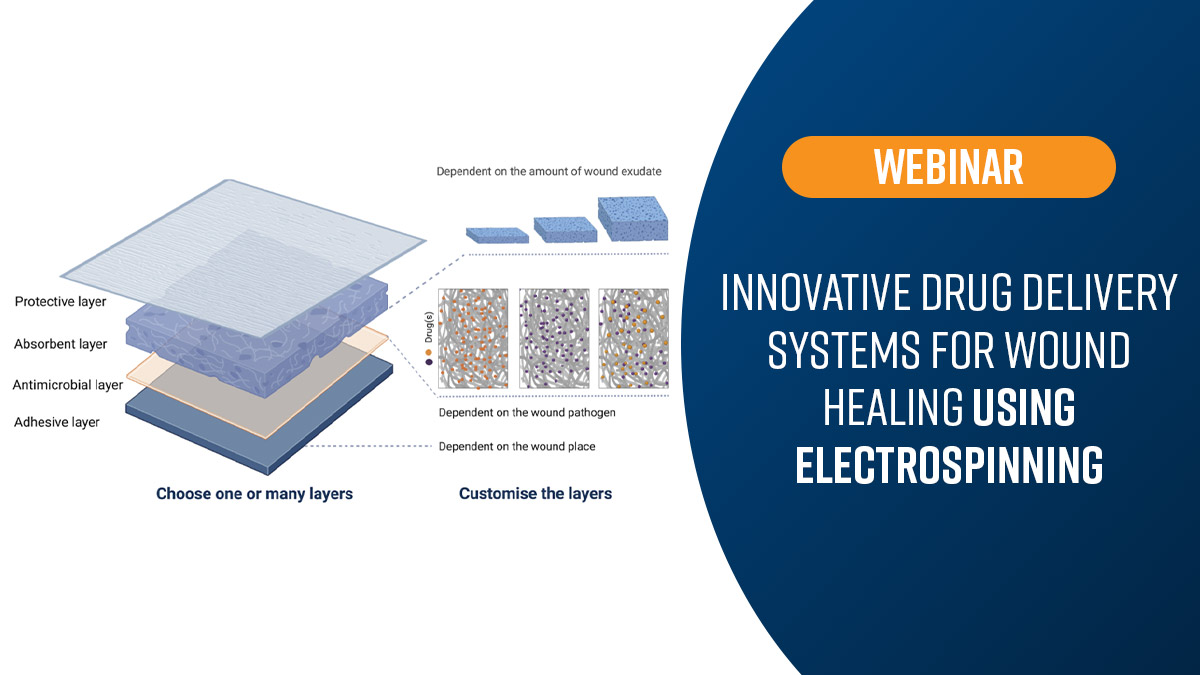

– Webinar –

Innovative Drug Delivery Systems for Wound Healing Using Electrospinning

Chronic wounds and wound infections are a major problem…

Product Brochure

Product Overview

The Equipment of Choice for Industrial Manufacturing and Commercialization

The Fluidnatek HT Industrial Electrospinning Machine is the ideal industrial equipment when large scale production and sample reproducibility are needed. This industrial electrospinning line capitalizes on the know-how and experience in the field of materials processing by Bioinicia.

Industrial-Scale Production

Designed for production of electrospun and/or electrosprayed nanomaterials at commercial quantities. Use up to 5,500+ needle emitters, load up to 60 Liters of prepared solution, and reliably run the machine 24/7

Full Environmental Control for Maximum Process Consistency

Control temperature and relative humidity in the processing chamber to ensure consistency across batches of nanomaterials produced, and actively exhaust fumes as your solvent evaporates

Fluidnatek HT Features

The Fluidnatek HT provides state-of-the-art features for industrial-scale production and commercialization of electrospun products under GMP conditions with reproducible performance. The HT system has been engineered to operate 24/7, leveraging 5,500+ simultaneous needles, a 1.6 meter wide roll substrate, and up to 60 L of solution for uninterrupted processing of large batches. Batch-to-batch consistency is easily maintained, and temperature and relative humidity can be tightly controlled thanks to the environmental control unit (ECU). Some of the safety features include an actively regulated exhaust system, which removes solvents continuously and dynamically, preventing them from escaping the spinning chamber. If flammable solvents are to be used, the Fluidnatek HT allows you to work under an inert atmosphere (with very low oxygen concentration) to further increase safety measures for the user and the facility.

- Industrial scale production unit for product commercialization

- Industrial Roll-to-Roll system

- Touchscreen controls

- Bottom-up configuration

- Primary high voltage power supply for the emitter

- Secondary high voltage power supply for the collector

- Gravimetric controlled continuous solution feeding system

- 10 kg/h+ solution mass flow rate (solution dependent)

- Non-spill quick connectors

- Environmental Control Unit ECU (temperature and relative humidity)

- Single-phase multi-emitter spinning head

- Safety shut-off switches in the access door

- Actively regulated exhaust system

Talk to an Instrumentation Specialist Today!

Fluidnatek HT

Optional Upgradeable Features

- Process data hub for recording 20+ process parameters to properly monitor sample production

- Sample thickness measurement in real time

- Gas and solvent vapor-assisted processing

- Engineered accessories to meet application requirements

- Secondary spinning stage with independent power supply