Electrospinning & Electrospraying Equipment

Electrospinning / Electrospraying Systems

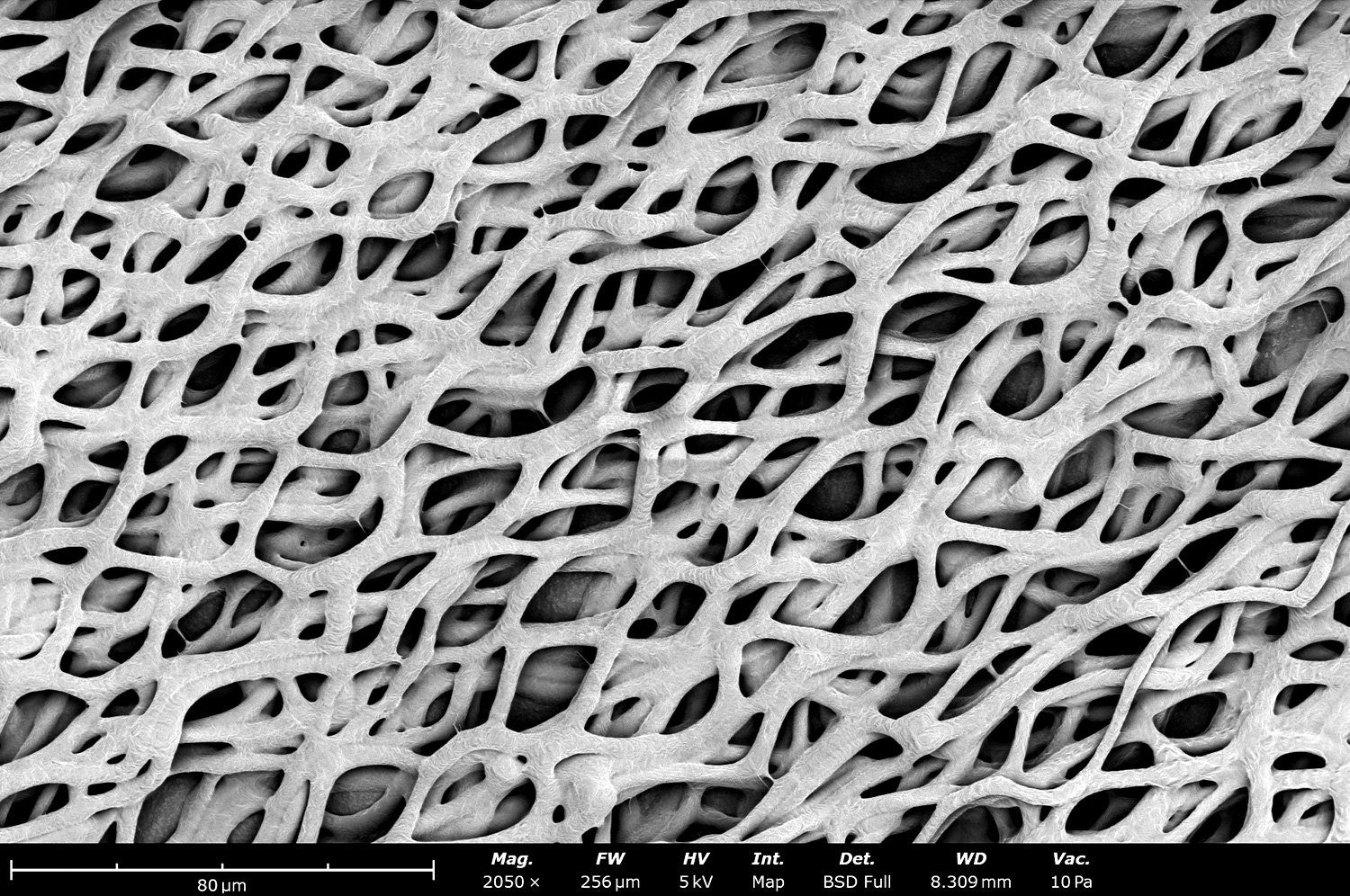

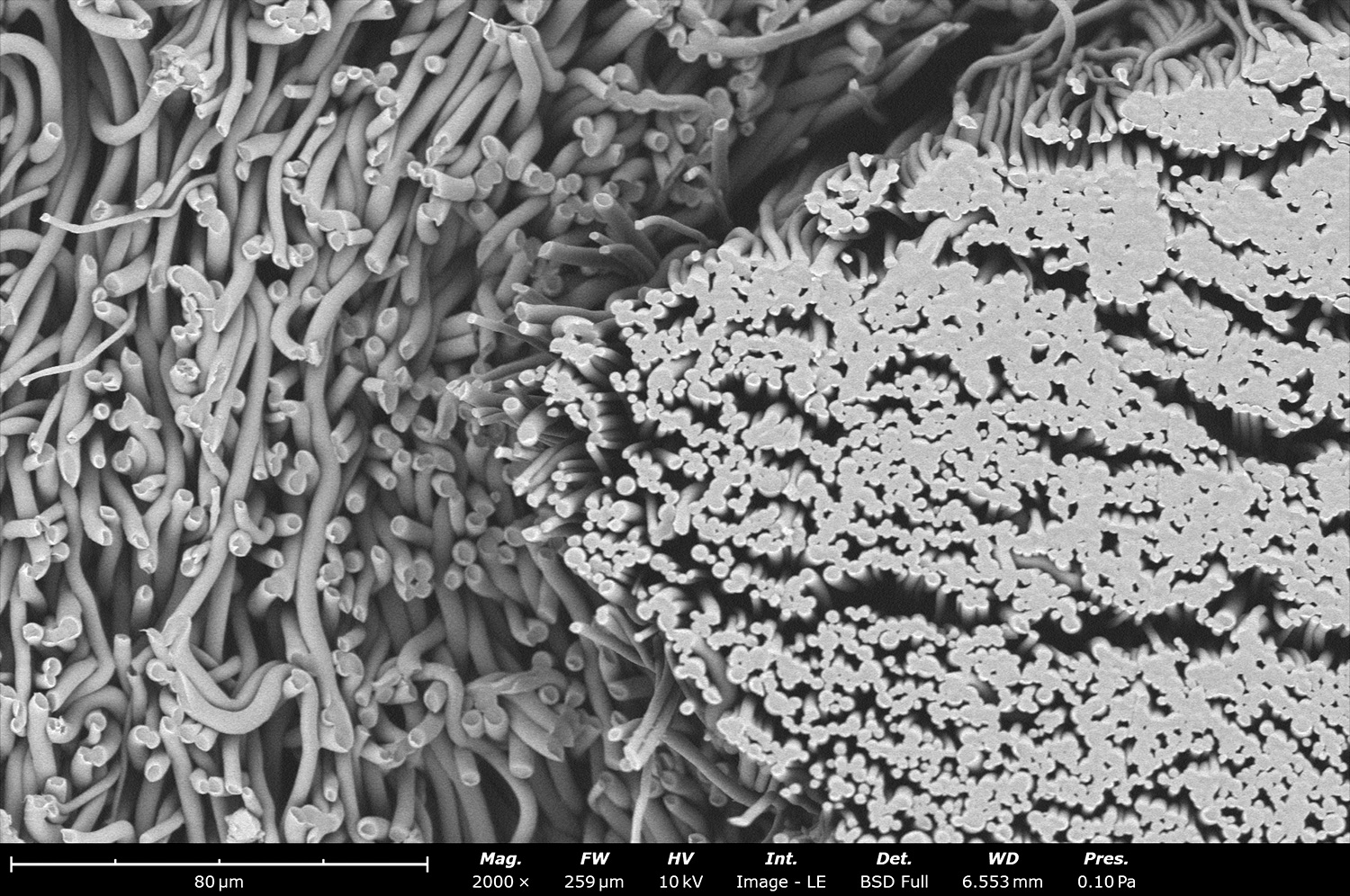

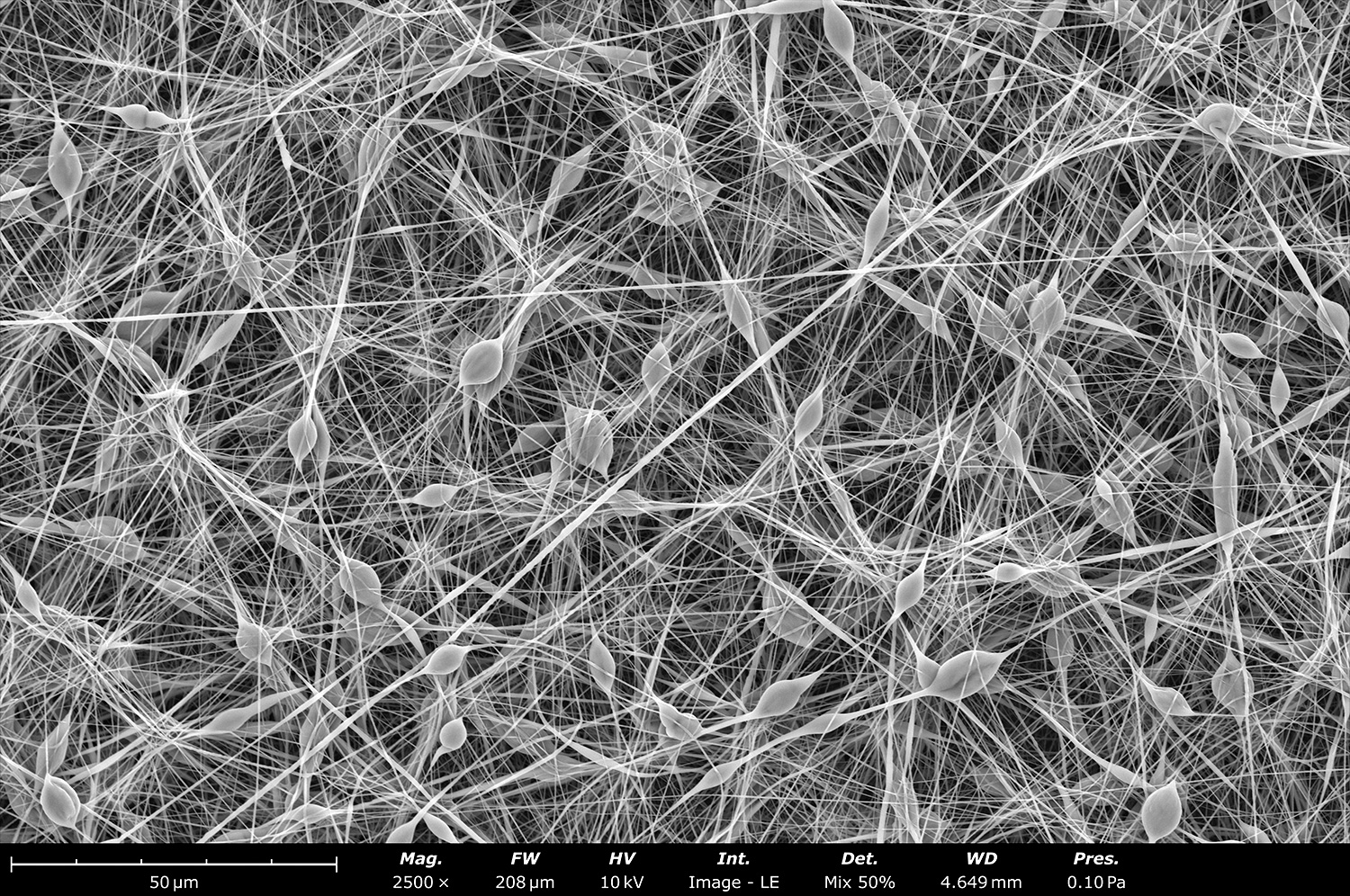

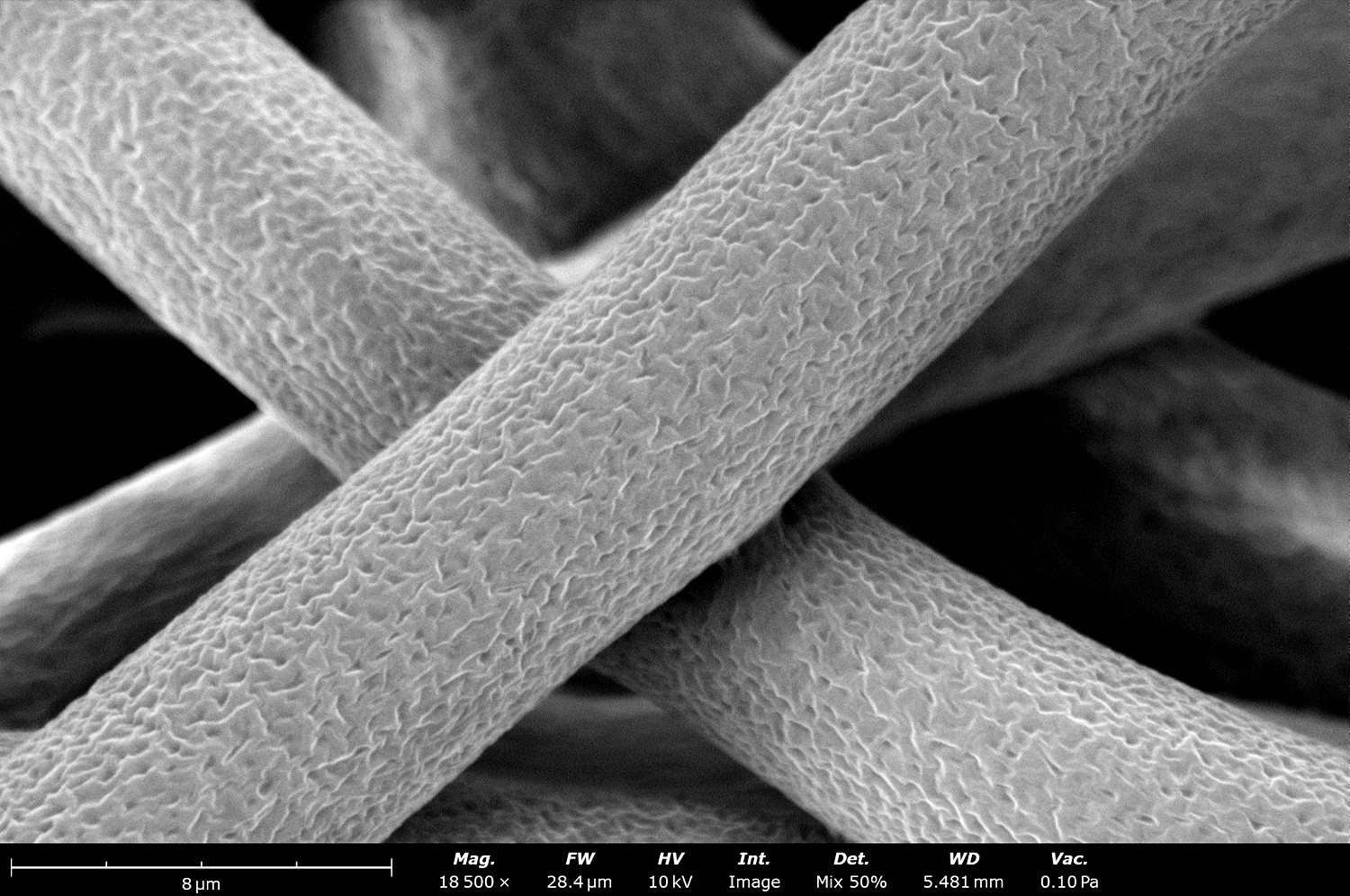

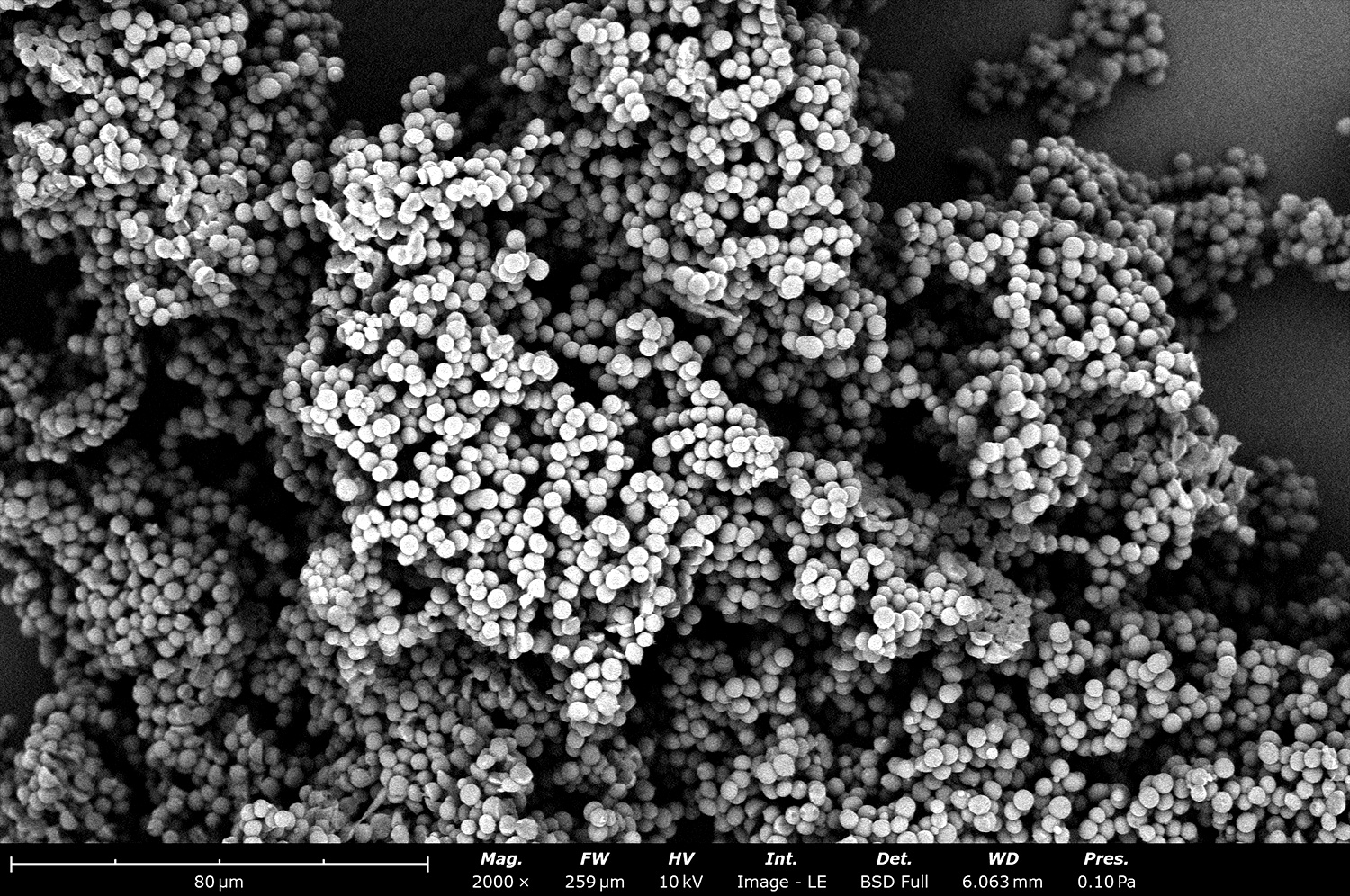

The Spinbox and Fluidnatek brands of electrospinning and electrospraying equipment are the perfect tools for the fabrication of micro and nano-scaled fibers and particles. These machines are designed to optimize control over electrospinning and electrospraying processes, enabling the reproducible fabrication of perfect nanofibers and nanoparticles. Models scale from benchtop systems to fully automated equipment for industrial manufacturing. Capabilities of these machines range from basic, single-needle processing to complex 3D structure fabrication with full environmental control, guaranteeing you will find a configuration that meets your application needs.

Unparalleled Environmental Control

Enables ultimate consistency and reproducibility for exceptional precision and efficiency

Superior Sample Processing

Equipped for simultaneous multi-solution processing, interchangeable emitter and collector types, and challenging solvents

Seamless Scalability

Translate laboratory-scale research to large-scale production processes with ease while maintaining highest sample quality

Download the Fluidnatek Electrospinning Product Brochure:

See available configurations

Standard Electrospinning/Electrospraying equipment

Each piece of equipment generated by Fluidnatek is engineered to produce consistent, high-quality results across the entire equipment series. The systems provide a high level of control over environmental conditions to ensure higher reproducibility year-round. Recipes developed on tabletop units can be transferred to larger volume instruments.

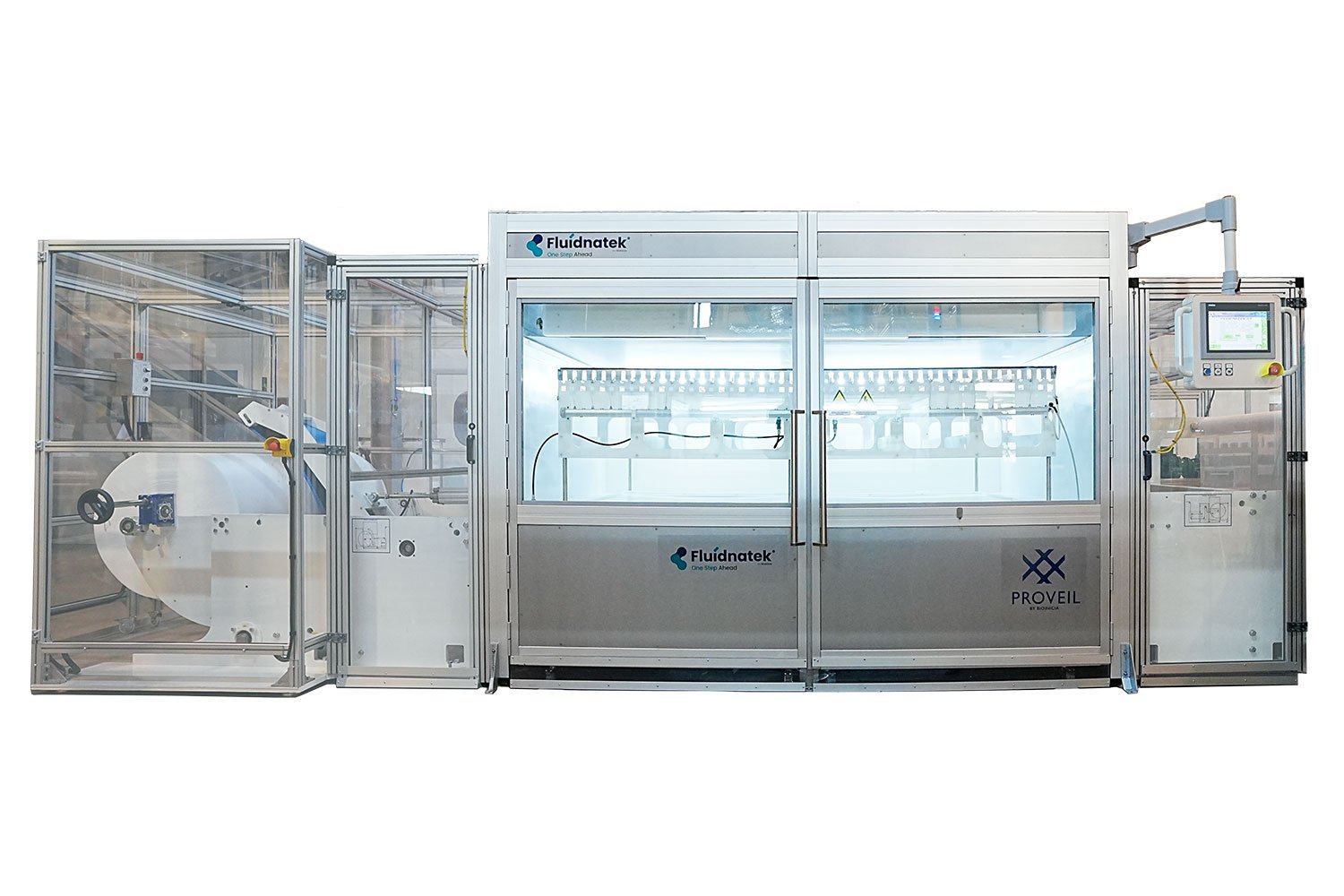

LE-500 is designed for advanced R&D projects and pilot production. Use up to 370 emitters and roll-to-roll collectors to increase throughput.

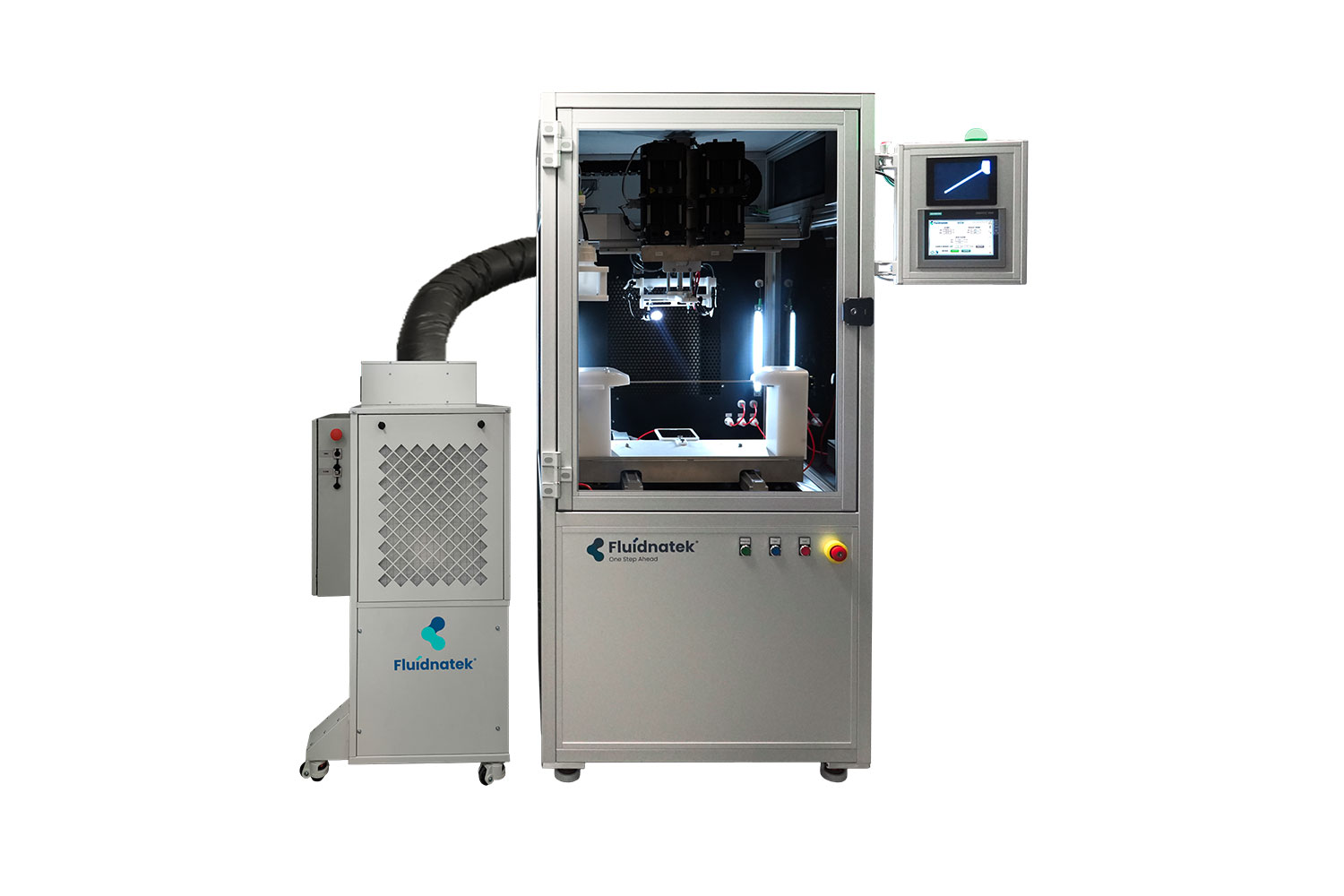

LE-100 is the ideal choice for advanced R&D projects, where experimental capabilities, tighter process control, and larger sample sizes are key.

LE-50 is a compact, benchtop system with advanced, versatile features required for R&D projects. Ideal for proof-of-concept and feasibility studies.

See Biomedical configurations

Biomedical Electrospinning/Electrospraying Systems

The Fluidnatek Biomedical devices are engineered to be used in medical applications like: tissue engineering, medical devices, wound healing and biotextiles. The systems are ideal for use when cleanliness and sterility are essential. The biomedical devices allow for finer process control, increased batch-to-batch consistency and are cGMP and ISO-13485 certifiable.

The unit of choice to coat devices with complex geometric structures. It includes a built-in 3D robotic arm that can hold a medical device or a spinning emitter.

Ideal for coating or fabricating tubular structures such as stents, vascular grafts, heart valves, and nerve conduits. Use very thin mandrels, <1 mm diameter.

Ideal for biomedical companies requiring aseptic sample development for medical products. Ideal for handling cells for personalized treatment development.

other configurations

Entry-level Systems

Ideal entry-level, benchtop system for basic R&D. Cost-effective commercial system with built-in safety measures. Ideal for beginner users with little experience with electrospinning.

other configurations

High Throughput Systems

The Fluidnatek HT Industrial Electrospinning Machine is the ideal industrial equipment for large-scale production of flat sheets. Over 5000 nozzles and a 1.6-meter roll-to-roll collector with conveyor belt.

Applications

Electrospinning & Electrospraying Applications

Electrospun and Electrosprayed materials have been developed for a wide range of applications, including:

- Biomedical & Tissue Engineering

- Batteries

- Medical Devices

- Functional Foods

- Cosmetics

- Drug Delivery

- Filtration & Separation

- Wound Healing

- Functional Textiles

- Fuel Cells

- BioTextiles

- Food Packaging

Knowledgebase

Electrospinning Knowledgebase

Webinar

Advancing sustainable, animal component-free (ACF) materials for cell culture is critical…

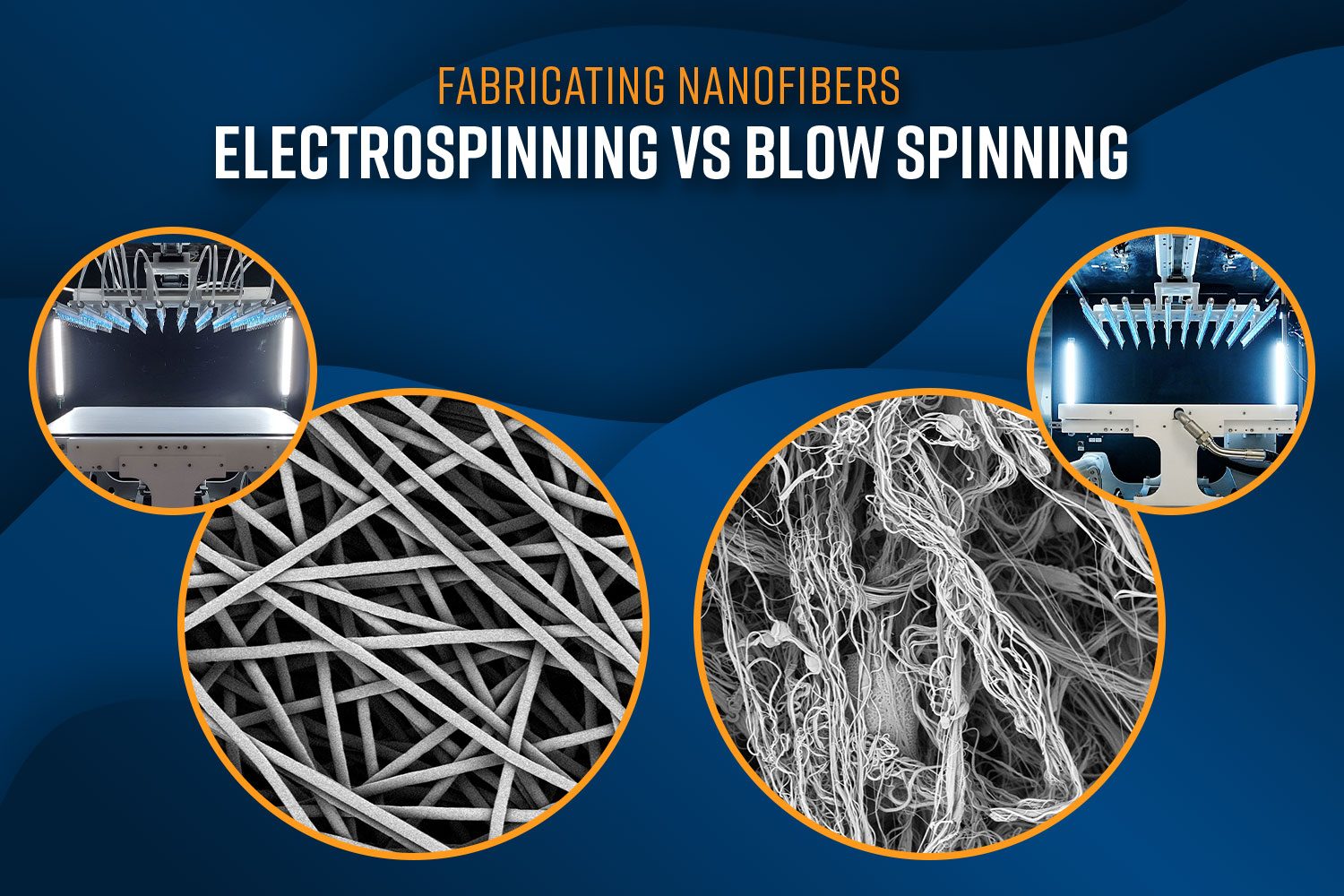

Fabricating Nanofibers: Electrospinning Vs Blow Spinning

Nanofibers, with their high surface area-to-volume ratio, tunable porosity, and mechanical…

White Paper

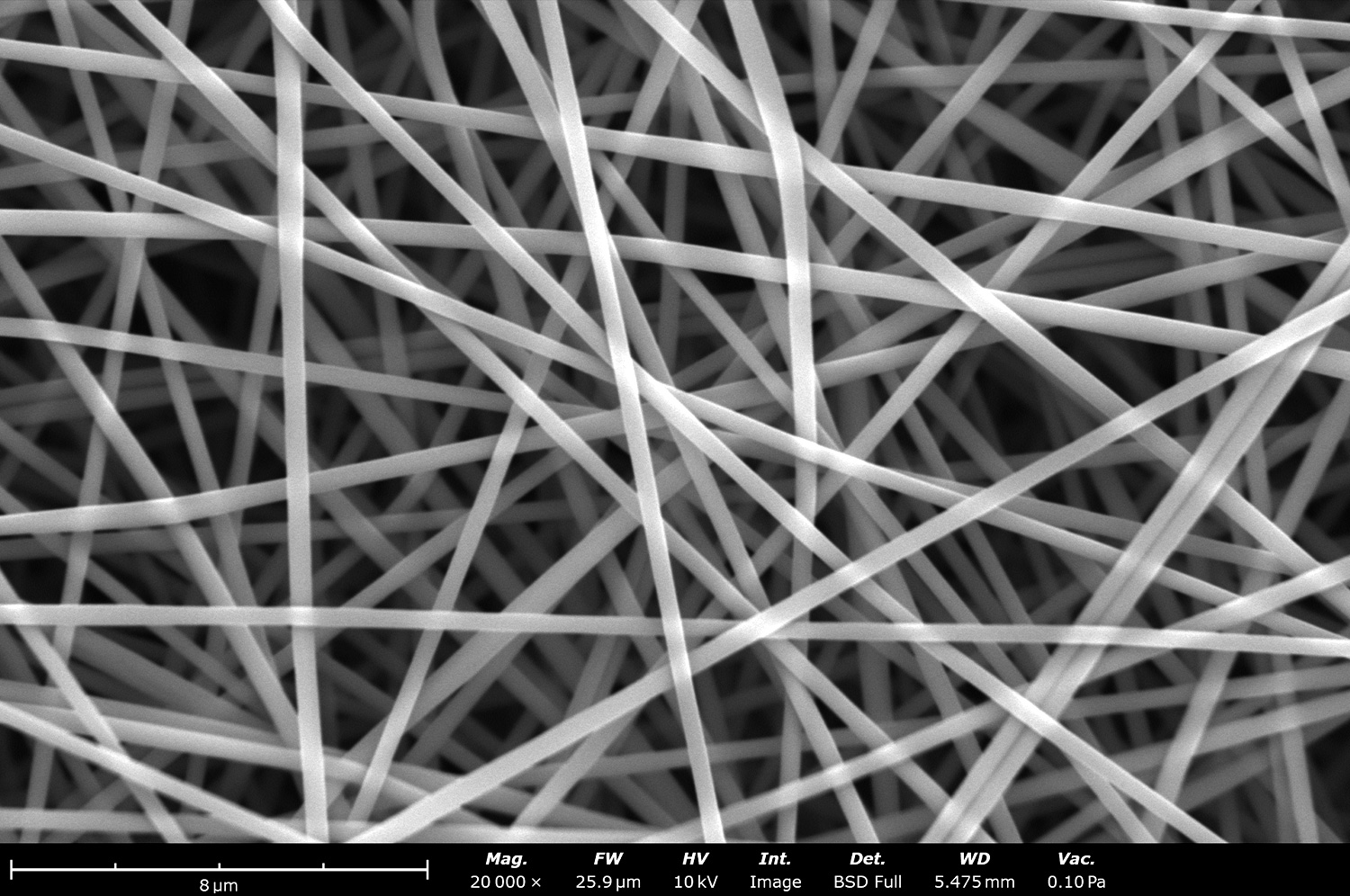

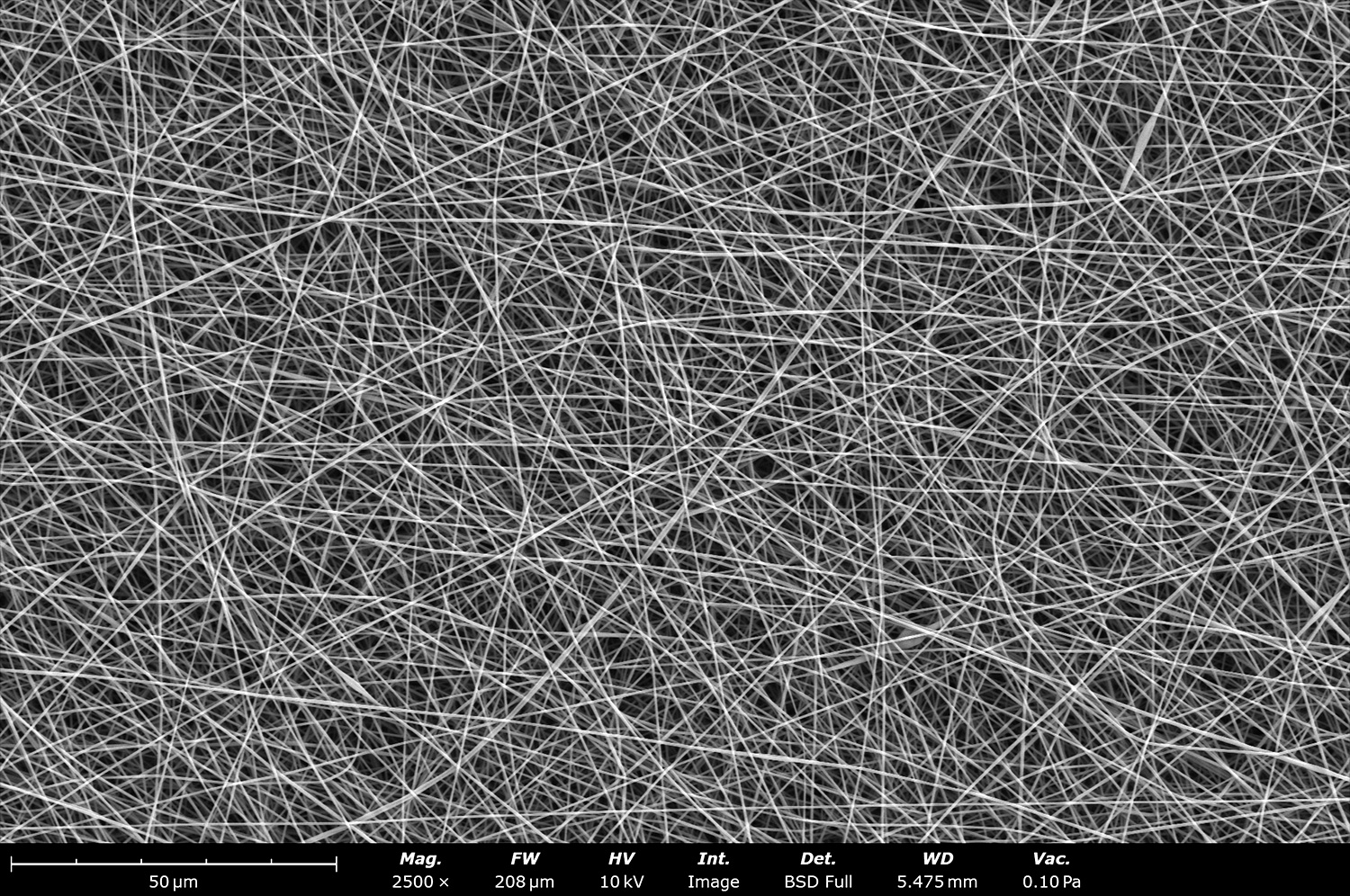

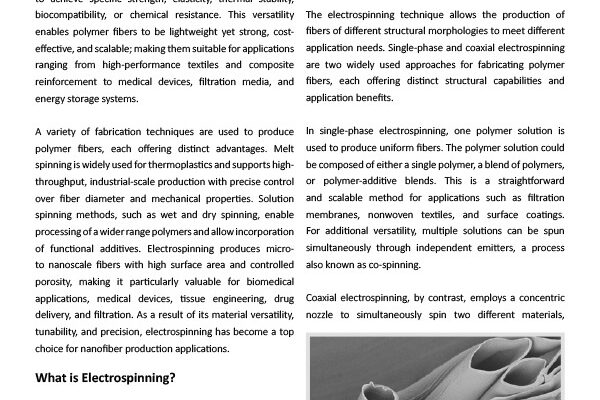

Fabrication and Characterization of Electrospun Fibers

Polymer fibers are produced from synthetic or natural polymers and engineered to deliver a…