Quartz Crystal Microbalance with Dissipation Monitoring

QSense™ QCM-D Instruments

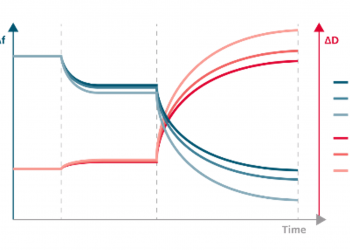

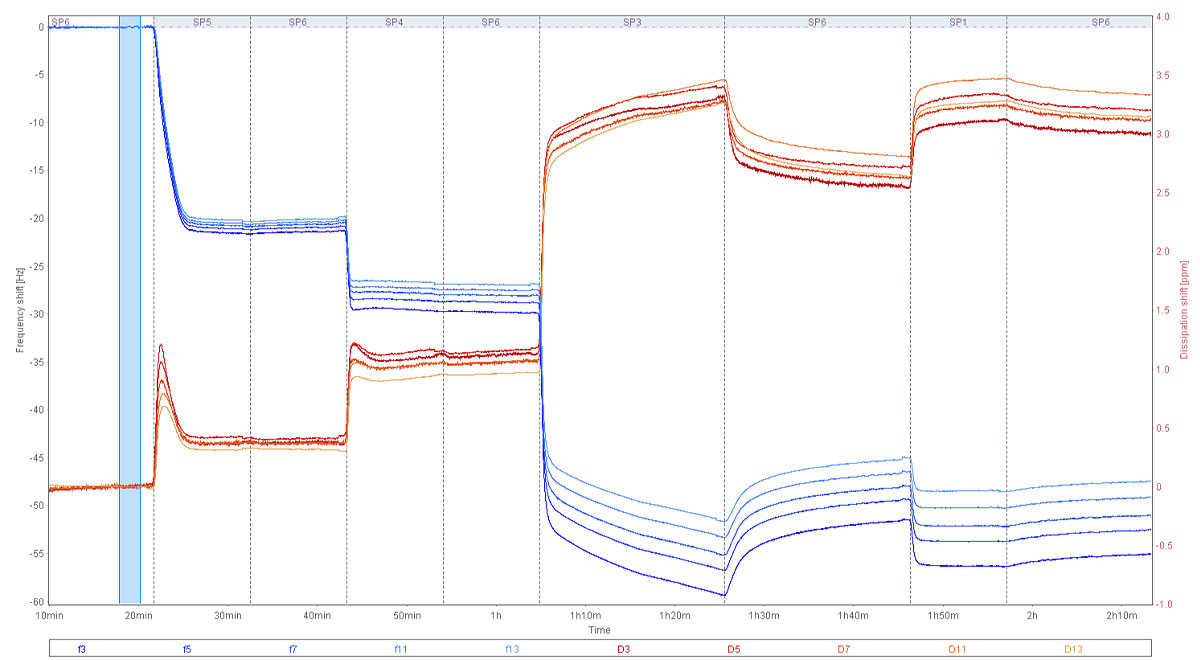

The unique dissipation parameter that defines QCM-D is obtained under non-voltage conditions leading to more stable, long-term signals. With this technique, you can obtain accurate and fast measurements of surface mass and viscoelastic parameters consistently for a wide range of samples, consisting of various combinations of surfaces and sample solutions (aqueous as well as organic media).

Original QCM-D Technology

Developed and commercialized by the founders of QSense – the pioneers of QCM-D

Most Sensitive QCM Instrument

Best signal to noise ratio and baseline stability of any QCM on the market

Viscoelastic-modeling Software Included

The only QCM supplier that offers comprehensive data analysis software including viscoelastic-modeling

Unique Measurement Principle

Non-voltage readout of frequency and Dissipation, superior to other measurement principles including impedance

See available configurations

QSense™ Product Options

The quartz crystal microbalances from Biolin Scientific have earned trust in labs all over the world. With more than 100 sensor coatings available, QSense has enabled the analysis of interfaces, thin-films, and molecular interactions. Through long-term development and experience, the advanced measurement techniques of these instruments have earned a reputation of precision in several industries.

QSense Omni is the new, cutting-edge instrument from the pioneers of QCM-D. Based on established technology, which has supported a deeper understanding of surface and interface interactions for decades, QSense Omni gives you sharper QCM-D data and a smooth journey in the lab.

QSense Pro is the most advanced QCM instrument on the market with full automation and high-throughput enabling enhanced efficiency and reproducibility. You can easily program your measurements in the software and the high precision flow-control ensures effective sample use.

QSense Analyzer produces high-quality data from up to four channels running experiments and measuring in parallel. The smart design with four removable flow modules makes it easy to set up new experiments. QSense Analyzer will quickly become a workhorse in your lab.

QSense Explorer is a versatile instrument with the flexibility to fit any application. Thanks to its modular design, it enables you to extend your measurement conditions with various modules and combine experiments with several other technologies.

QSense Initiator focuses on the fundamental functions and qualities of QCM-D analysis. It produces data with superior accuracy, has a robust design, and enables a wide range of experimental conditions to suit your basic research needs.

The QSense High Temperature Chamber enables QCM-D measurements across a wide temperature range (4 °C – 150 °C). It is compatible with the QSense Analyzer and QSense Explorer, and is fully integrated with QSoft for real-time data acquisition.

The QSense QCM-D systems come equipped with standard flow modules, which enables a wide variety of aqueous and gas-phase experiments. Many other specialized modules are available to support experiments that require the use of additional technologies.

Download the QSense™ QCM-D Product Brochure:

QSense Software

QSense™ DFind Data Analysis Software

QSense Dfind is the reliable and easy-to-use analysis software from QSense. It helps you to quickly and simply extract the information you are looking for, such as mass, thickness, viscoelastic properties, and adsorption rates.

Knowledge Base

QSense™ Applications

– Webinar –

Observing Mixed Ionic-Electronic Transport in Redox-active Polymers

Redox-active polymers have promising applications in electronics and energy…

– App Note –

In Situ Monitoring of the Solid Electrolyte Interphase

A good understanding of different electrochemical processes that occur…

– Blog –

QCM-D vs. SPR – What are the differences, and which technique fits your application?

When choosing between two real-time, surface sensitive, and label-free…