What if you could quickly and easily customize the porosity, flexibility, and strength of your tissue scaffolds to mimic the properties of native tissue more closely?

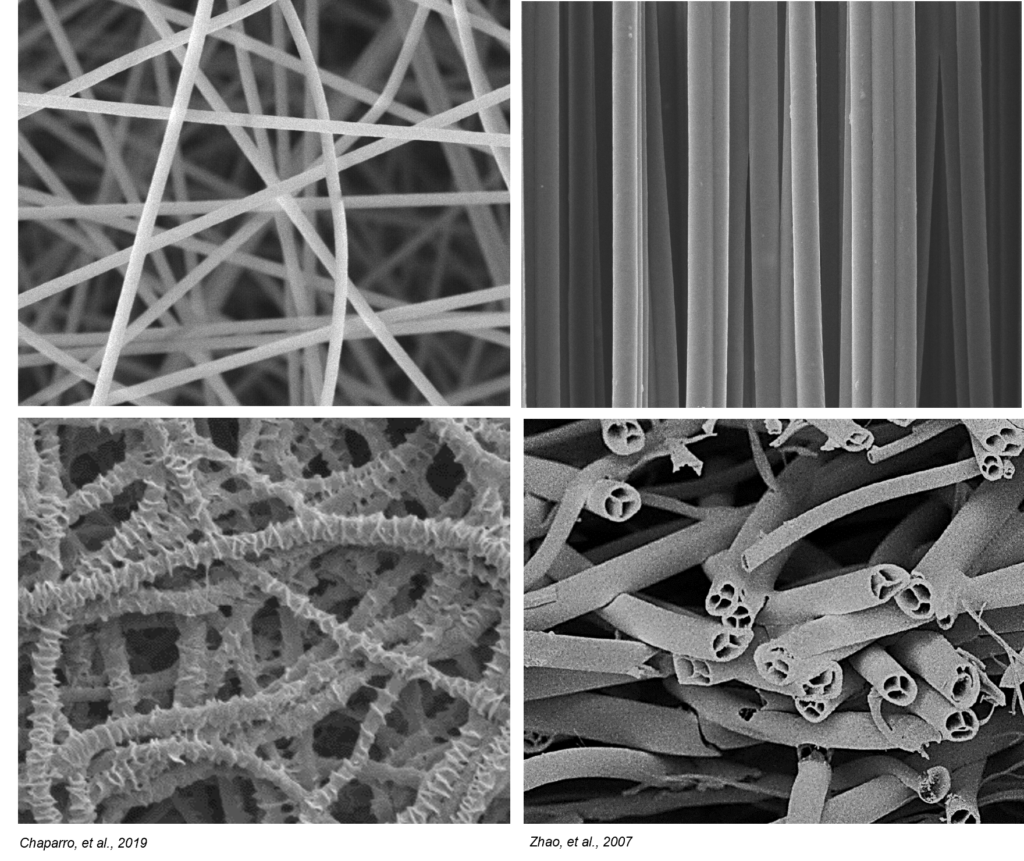

Fabricating tissue scaffolds to meet specifications with batch-to-batch consistency can be a challenge, especially with tubular structures like vascular, neural, tracheal, and urological conduits. However, even though many tubular structures have complex layers in native tissue, electrospinning and electrospraying can repeatably generate high quality tubular tissue scaffolds.

One example is native vascular tissue, which is composed of three layers with vastly different properties. The inner layer is endothelial tissue and forms a semi-permeable membrane. The middle layer is primarily smooth muscle and must be flexible enough to control the pumping of blood. The outer layer is strong connective tissue which supports the internal layers and protects against high fluid shear and pressurization.

Fabricating these structures using electrospinning allows users to tightly control and easily tune the porosity, fiber alignment, and mechanical properties of a sample to mimic vascular tissue. In addition, electrospinning provides a fast workflow, and is a room-temperature process, supporting fabrication using thermally sensitive materials.

To achieve a repeatable sample of tissue scaffold, precise control of ambient temperature and relative humidity must be maintained throughout the fabrication process. In many cases, regulatory standards also require sterile conditions for biomedical product fabrication. Most electrospinning systems lack the advanced features necessary to deliver reproducible and scalable results, let alone maintain sterility throughout fabrication.

With Fluidnatek’s electrospinning systems, you can meet FDA, cGMP, and/or ISO-13485 standards with ease. The Fluidnatek LE-50 ProSterile and LE-100 Bio are the only electrospinning systems designed specifically for sterile processing, and they support a streamlined workflow with precision control over all processing parameters.

These instruments are made of stainless steel with no crevices or gaps and feature a glove-box vacuum chamber which helps maintain ISO-5 (Class 100) conditions at all times. In addition, the LE-50 ProSterile vacuum chamber is designed to remove traces of solvents, which eliminates the need for post process sterilization, and enables packaging of final products under sterile conditions inside the chamber.

Other key benefits include:

- Compliance with ASTM F3510-21 guidelines which mandate proper environmental controls during development of tissue engineering medical products

- System configurations that support embedding or encapsulating drugs to coat stents for controlled drug delivery

- Highly reproducible nanofiber fabrication thanks to the Environmental Control Unit (ECU), which gives users precision control over temperature, relative humidity, and air flow settings

To see the Fluidnatek systems in action and learn more about how you can achieve, and mimic perfect tissue structures every time, watch the video below. This video showcases the unique capabilities of the Fluidnatek LE-100 Biotubing, which was designed specifically for biomedical applications. As the video highlights, the LE-100 Biotubing can be configured to support the development of electrospun samples for a wide variety of applications, including: stent coating, tissue grafts and scaffolds, and many more.