Scanning Electron Microscopy

Phenom Desktop SEMs

Speed to Data

High sensitivity detectors paired with the fastest vent/load cycle provides an average time-to-image of under 40 seconds

Intuitive

Operation

Imaging parameters and microscope functions controlled through a clear and navigable user interface

Low Cost of

Ownership

Resilient hardware enables low downtime and infrequent source changes, minimizing the overall maintenance cost

Download the Phenom SEM Product Brochure:

See available Configurations

Phenom Desktop SEM Systems

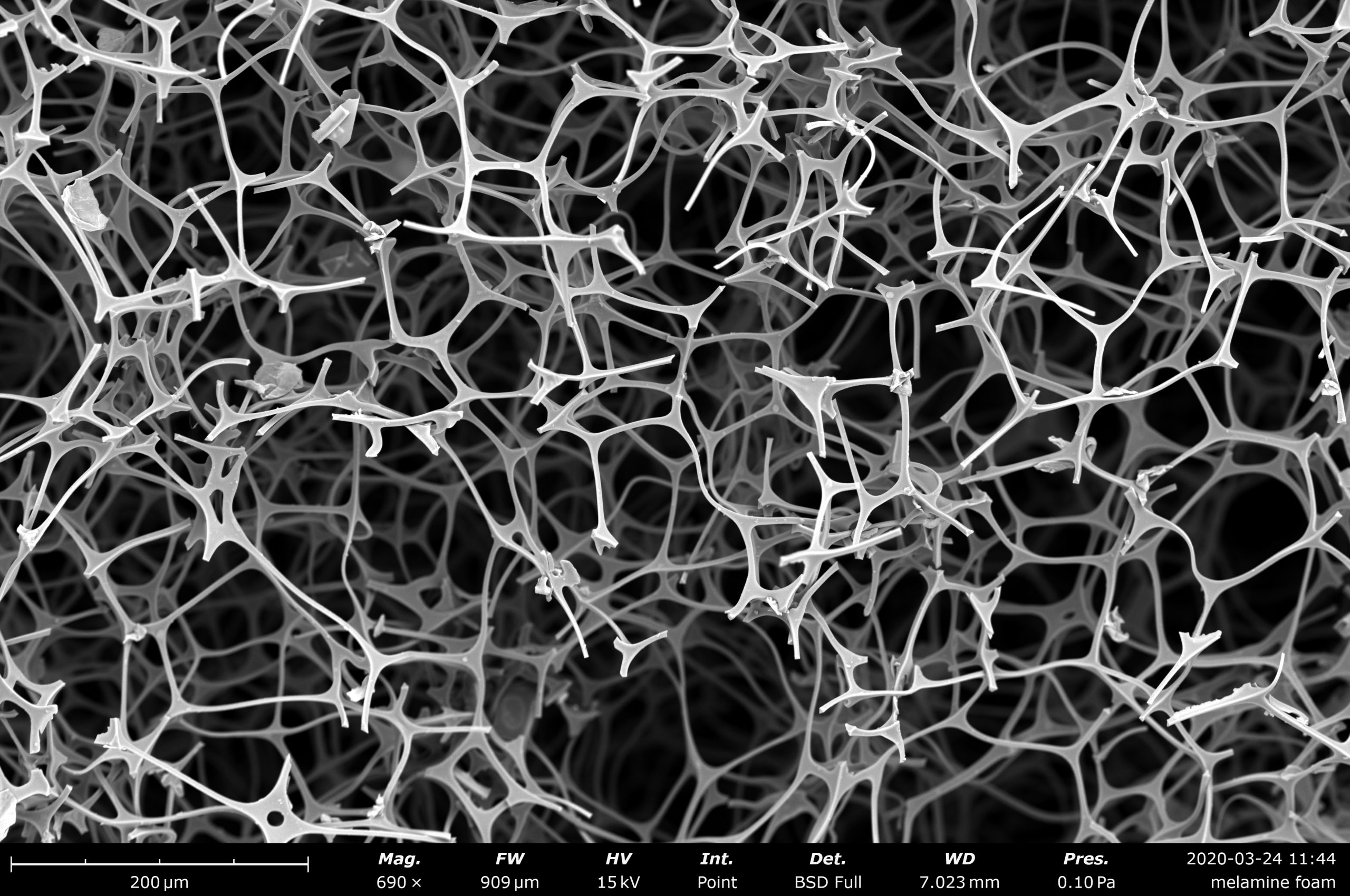

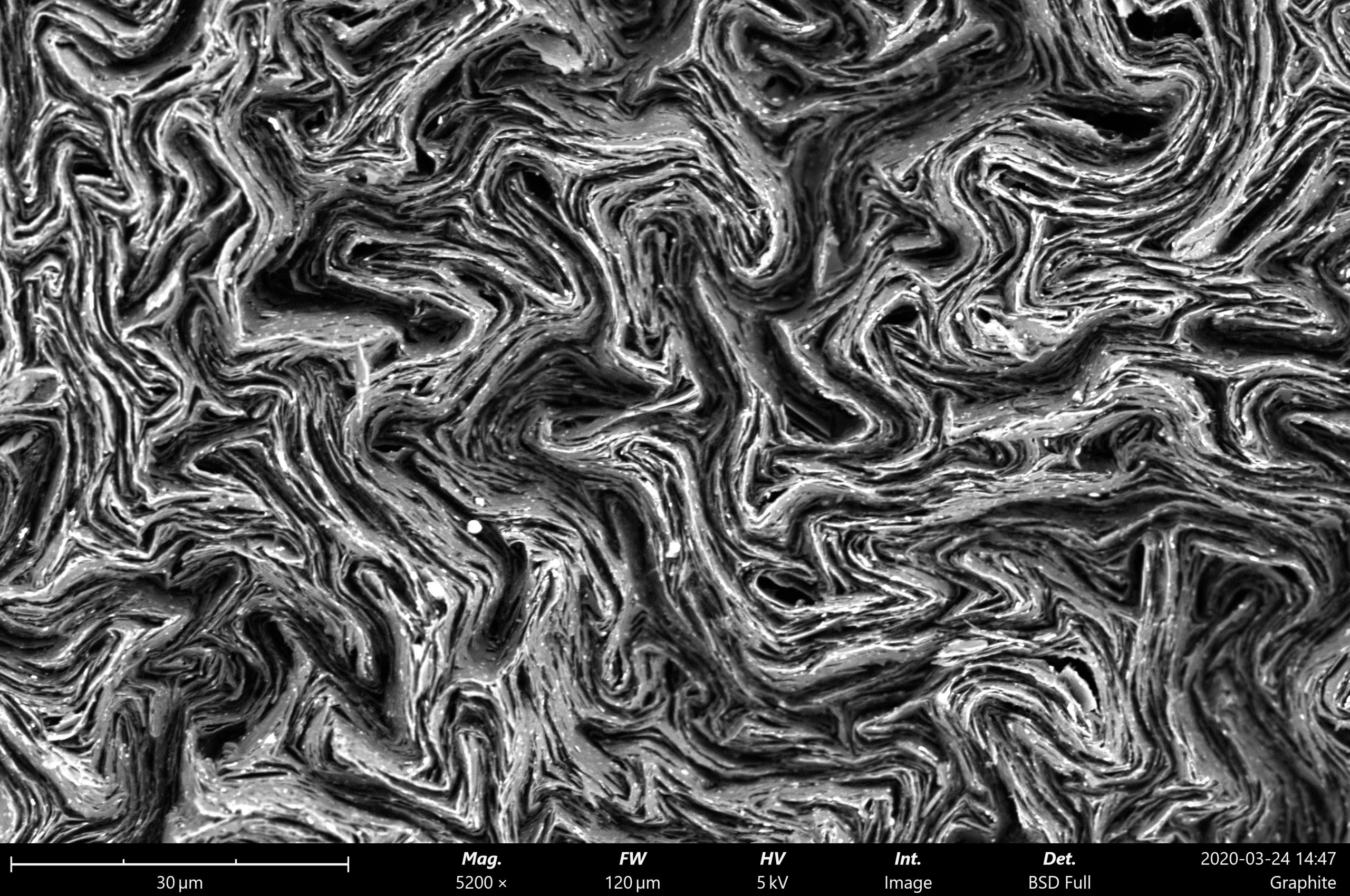

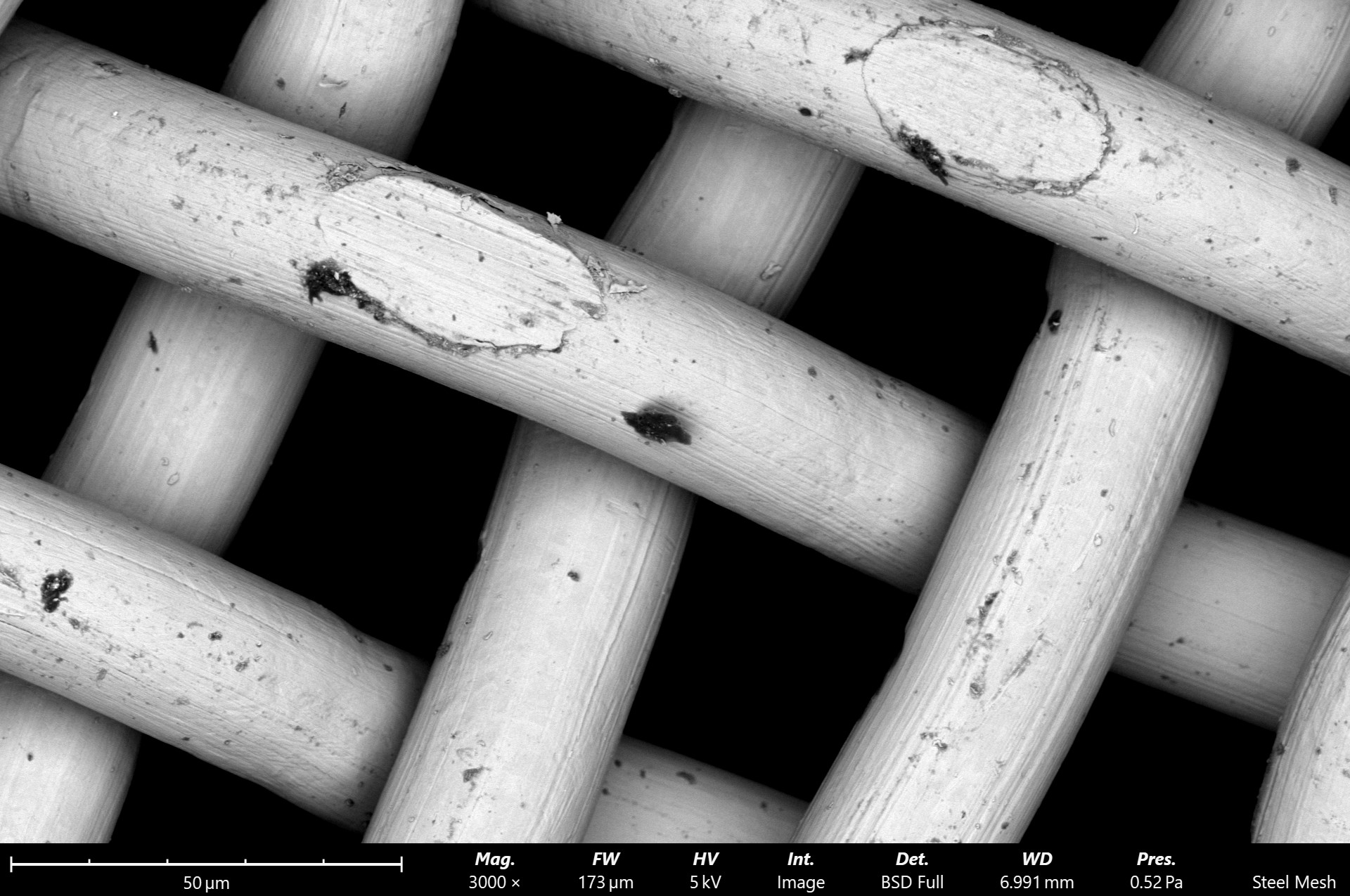

The Phenom desktop scanning electron microscope from ThermoFisher was designed to be the easiest and most intuitive SEM ever built. Advanced electron sources in the form of cerium hexaboride crystals or field emission guns, along with multiple detectors, make it easy to acquire quality data and beautiful images. Imaging and analysis are mere clicks away!

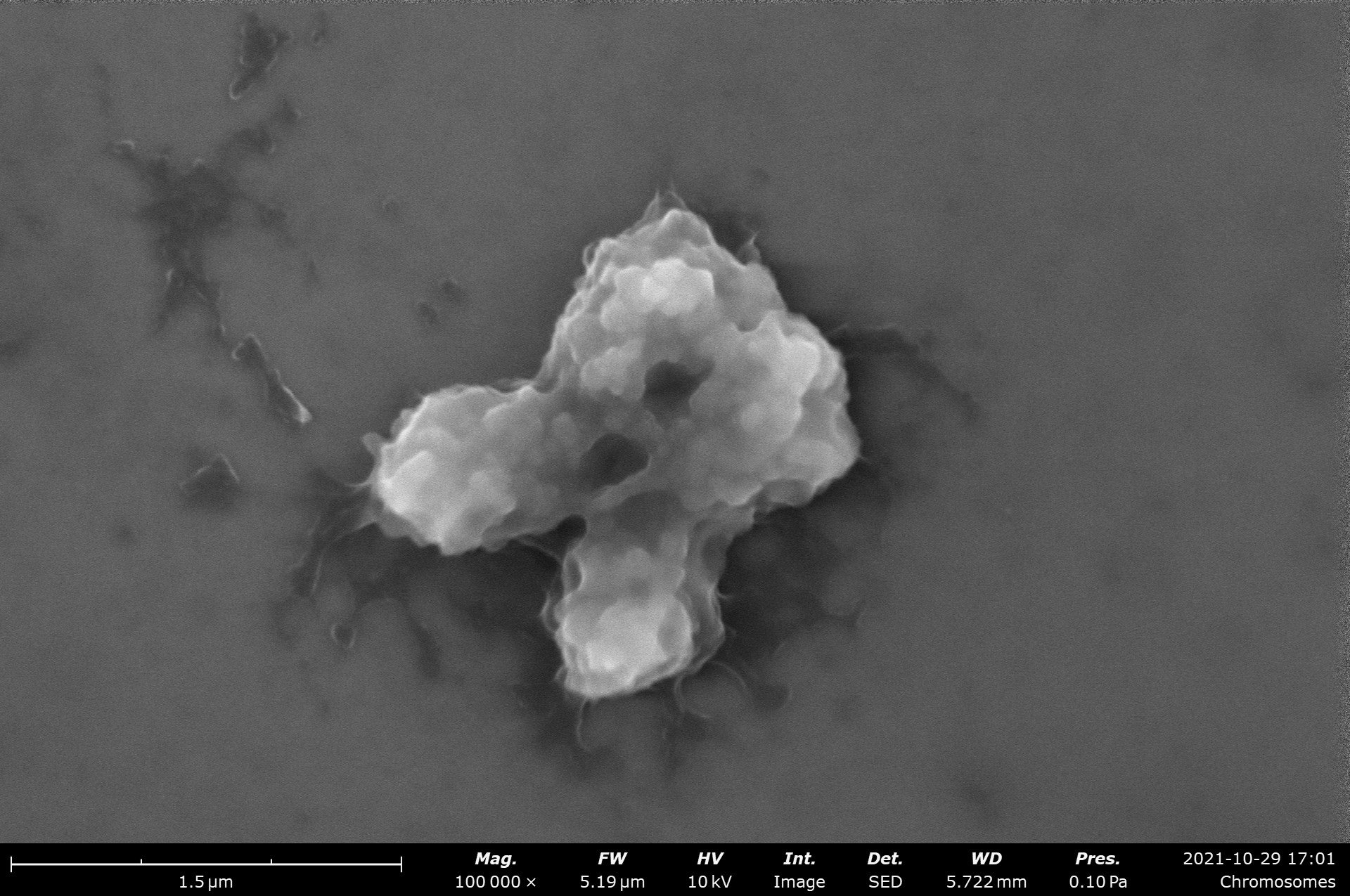

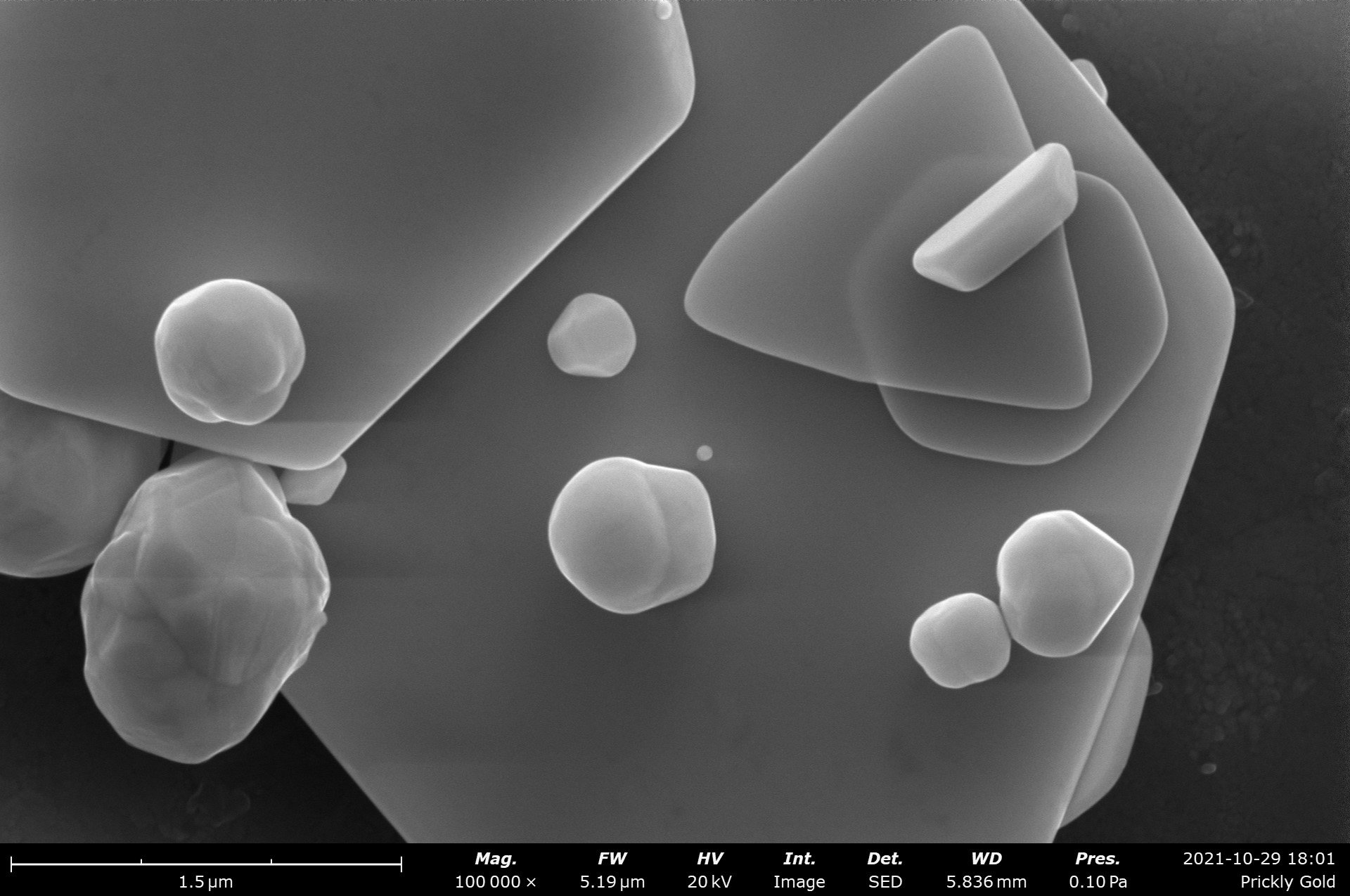

The Phenom Pharos is uniquely equipped with a field emission gun (FEG) and excels in applications demanding high spatial resolution. An unmatched coherent and bright electron beam, low kV accelerating voltage imaging, and automatic drift corrections make the Pharos a competitive alternative to many floor model SEMs.

The Pharos STEM combines a high-brightness FEG source with a fully-integrated segmented STEM detector to generate STEM images with stunning contrast, even at low voltages. This compact desktop STEM-in-SEM system delivers the precision and resolution of nanoscale imaging traditionally reserved for larger, floor model systems.

The Phenom XL has the largest sample capacity of all Phenom instruments, able to contain a high volume of small specimens, a single bulk mass, or anything in between. The XL also serves as the workhorse for an upgradeable automation software package known as ParticleX to push the boundaries of automated electron microscopy.

The Phenom Pro and ProX are the ultimate all-in-one SEM imaging systems, differentiated only by the presence of an integrated energy dispersive X-ray spectroscopy (EDS) detector. The unique and powerful core architecture characteristic of the Phenom line combines with a host of data analysis features to provide the most complete desktop SEM solution on the market.

The Phenom Pure is an entry-level, economical desktop SEM useful for many different applications, whether it be in teaching environments, simple R&D, or for general imaging. The Pure provides a straightforward imaging solution to visualize sample features, surfaces, and structures and is a user-friendly tool to seamlessly transition from light optical to electron microscopy.

An empowered model of the Phenom XL, ParticleX is a powerful quality control tool with automated SEM-EDS workflows for targeted, unbiased data analysis. Packages include: Technical Cleanliness, Steel, Battery, Gunshot Residue, and Additive Manufacturing; all of which comply with industry-relevant reporting standards like ASTM E45 (Steel) and ASTM E1588 (GSR)

Knowledgebase

SEM Knowledgebase

Webinar

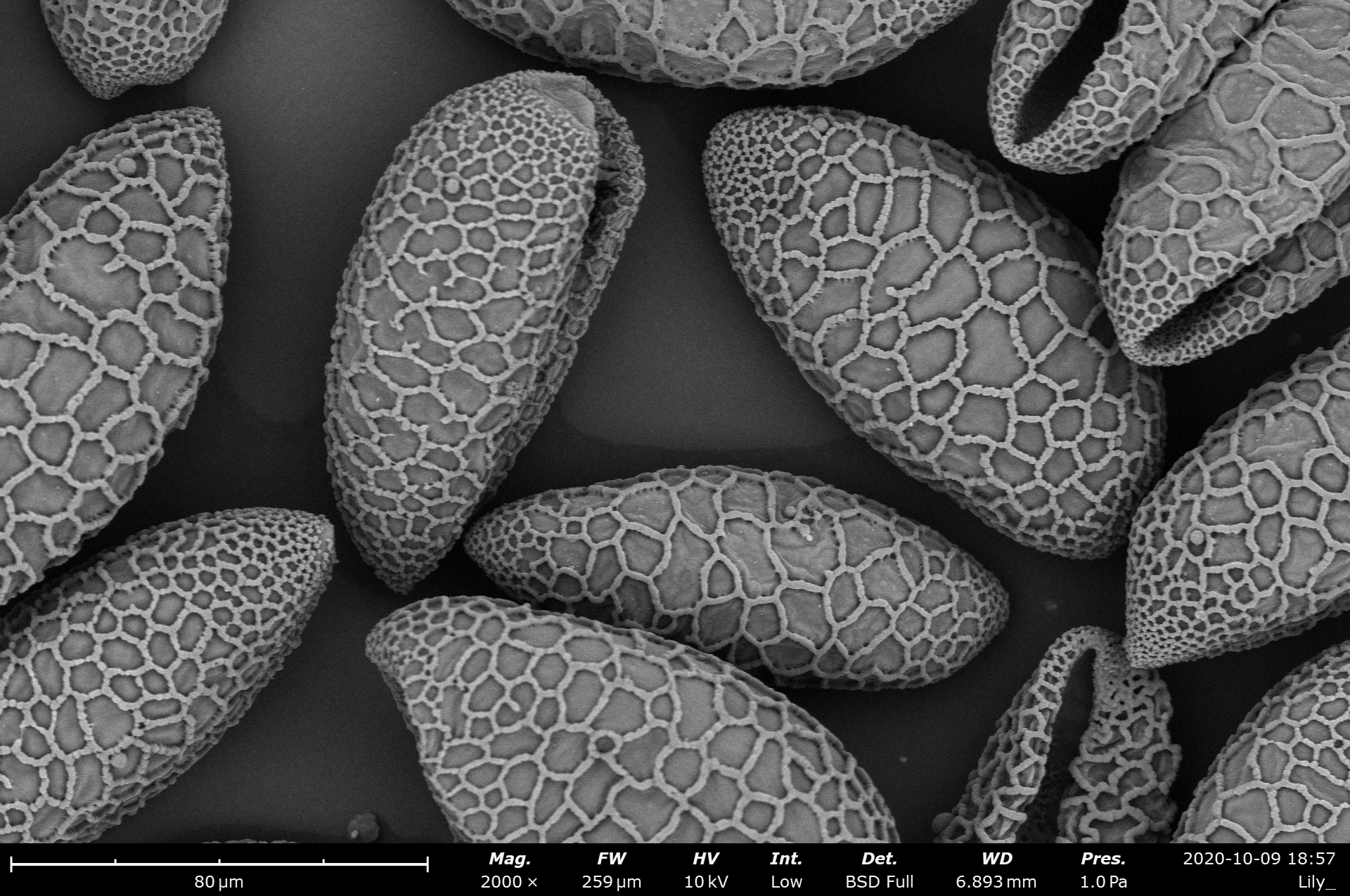

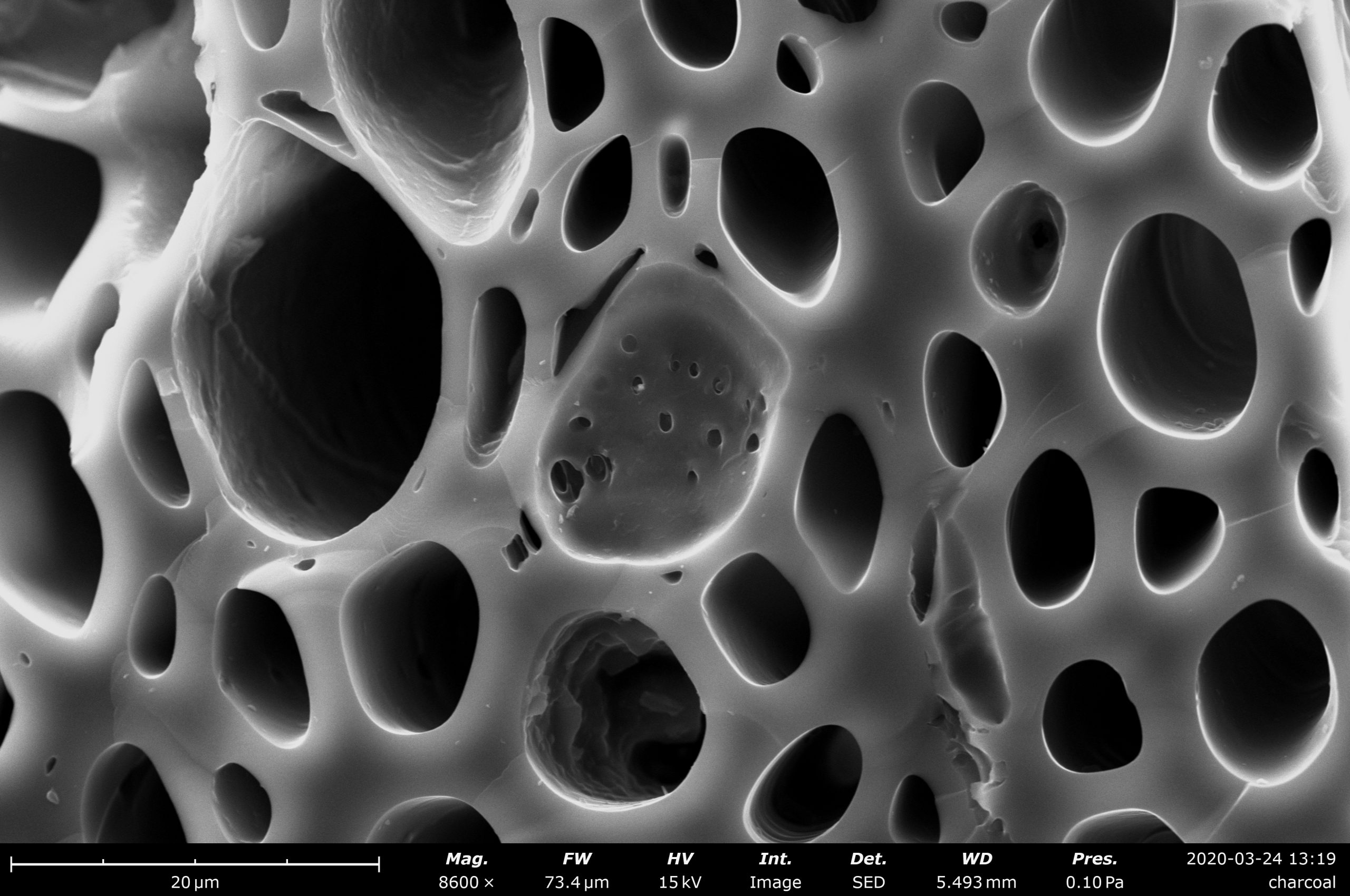

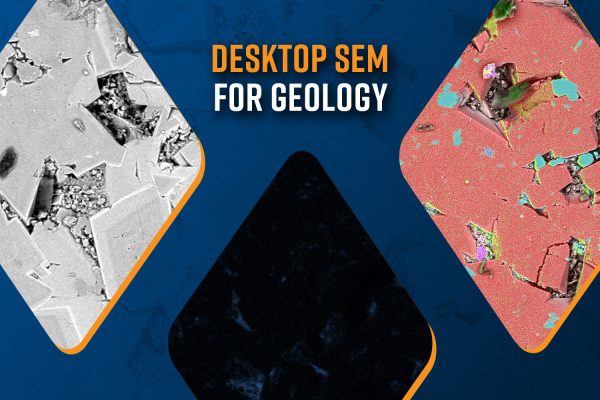

Applications for Desktop SEM in Geology

Scanning Electron Microscopy (SEM) has become a vital tool in geology, offering high-resol…

Blog

Desktop Scanning Electron Microscopy in Geology

Scanning Electron Microscopy (SEM) is a versatile tool in geology used in high-resolution…

White Paper

Phenom Pharos: A Compact Desktop STEM for Screening Negative Stained Samples

The Phenom Pharos Desktop SEM/STEM is a compact and affordable solution designed for cryo-…