Electrospinning & Electrospraying

Environmental Control Unit

Exceptional Environmental Control

Continuously control temperature (18°C to 45°C ± 1°C), relative humidity (10% to 80% ± 3%) and air flow (50 m3/h to 180 m3/h) independently of location or season.

Scaled up Batch-to-Batch Reproducibility

Reproducible fabrication of fibers and particles under clean (ISO-7/ISO-5) and standardized conditions to validate the process to meet standard certification requirements (FDA, ISO, cGMP, GLP, GAMP).

Expanded Material Processability

Temperature and relative humidity (RH) sensitive polymers, solvents, and additives can be easily processed. Allows consistent solvent evaporation for reliable results.

Talk to an Instrumentation Specialist Today!

Electrospinning & Electrospraying

Environmental Control Unit

The environmental control unit (ECU) is an external, self-contained system that introduces conditioned and clean air stream into the fabrication chamber to regulate temperature (T), relative humidity (RH) and air flow of the electrospinning/electrospraying environment during fabrication. Controlling T, RH and air flow of the electrospinning/electrospraying process is of critical importance for obtaining reproducible fiber/particle morphology, increasing sample consistency and throughput, along with aiding on scaling up your process and processing materials requiring a predefined environmental condition.

Reproducible fabrication of nanofibers and nanoparticles by electrospinning and electrospraying can be challenging. The addition of the environmental control unit enhances the capability of the electrospinners primarily by allowing ease of fabrication independent of time and location and preventing clogging. The ECU allows you to expand the list of polymers and solvents that can be used for advanced sample development. The addition of the ECU also makes the process more dependable, repeatable, and scalable, at the same time maintaining safe conditions for the operator.

Advantages of using our ECU:

Environmental Control Unit

Polymers

Polymers sensitive to temperature & relative humidity:

The ability to control the environmental conditions during electrospinning expands the list of polymers that can be processed. These include polymers sensitive to temperature and humidity. Polycaprolactone (PCL), polylactic acid (PLA), polyglycolic acid (PGA), polylactic-co-glycolic acid (PLGA), polyethylene oxide (PEO), polyacrylonitrile (PAN), polyurethane (PU), Gelatin (Gel), Collagen (Clg), and nylon (N6 or N66) are few polymers that can be affected by changes of environmental conditions. These polymers are used in applications like tissue engineering, medical devices, drug delivery, filtration, energy storage, food packaging, among others.

Tightly controlling T, RH and air flow will allow consistent Taylor cone stability, prevent clogging, and open research and production possibilities resulting in consistent and reproducible fabrication independent of time of year and location.

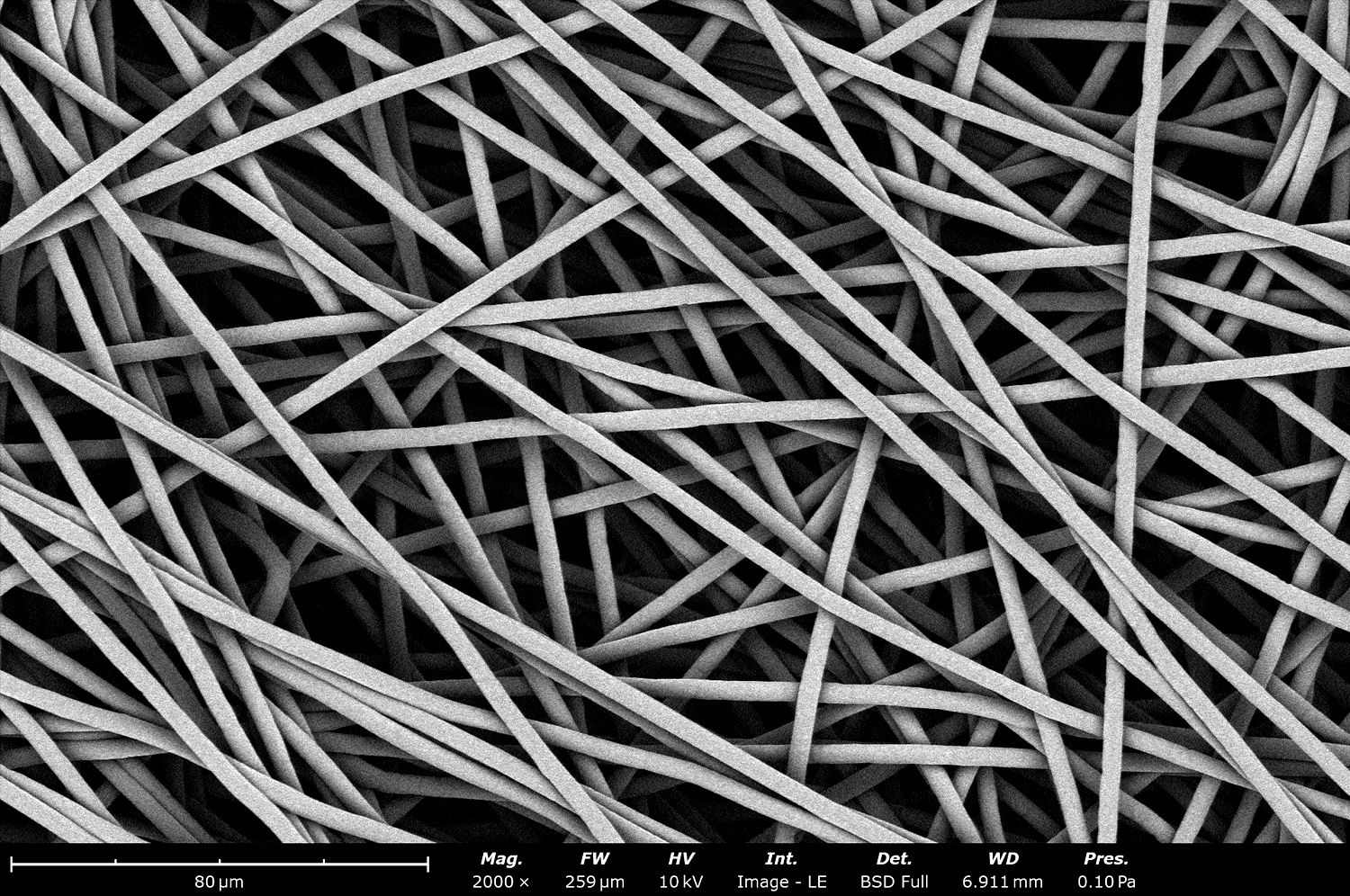

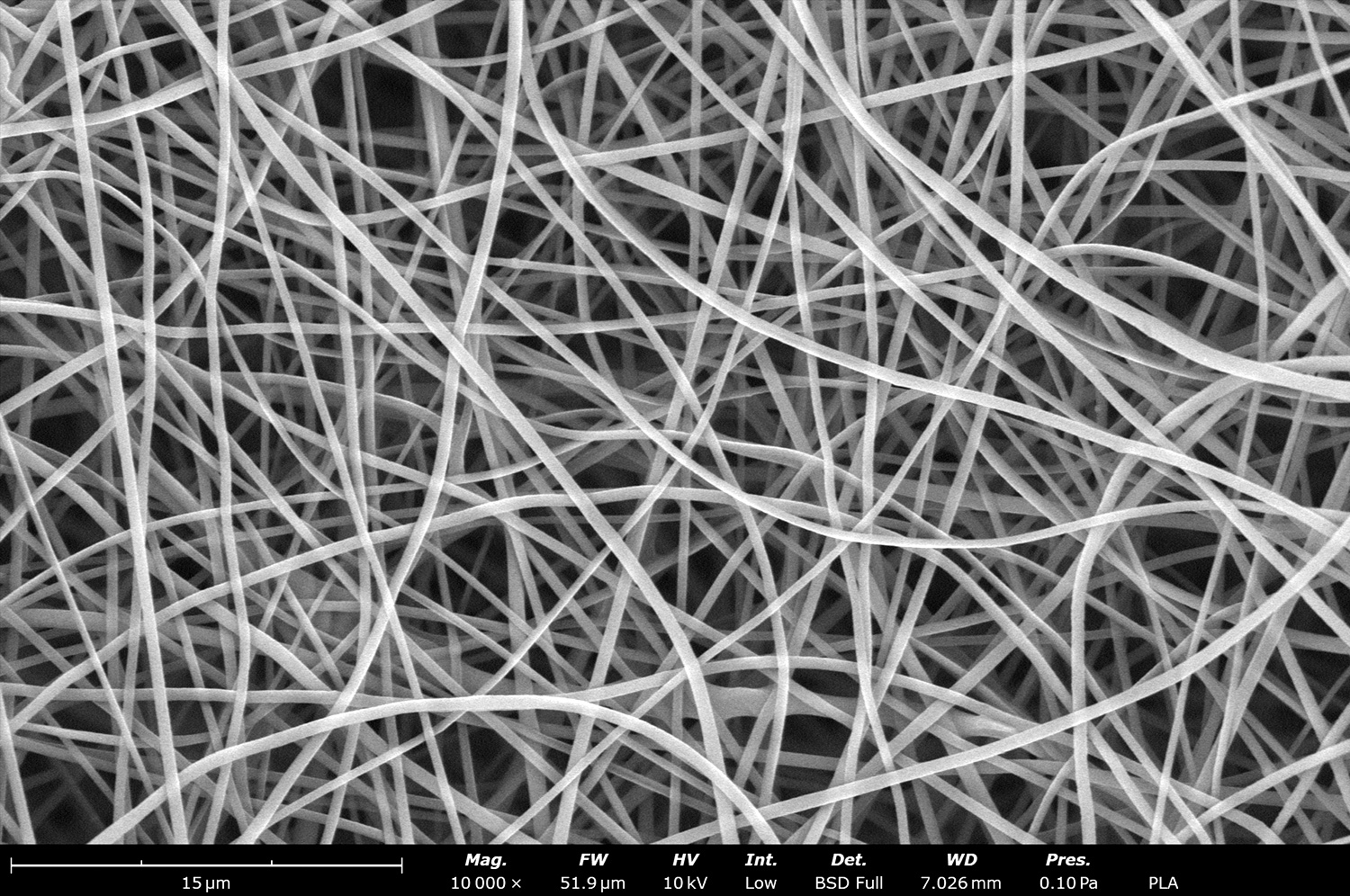

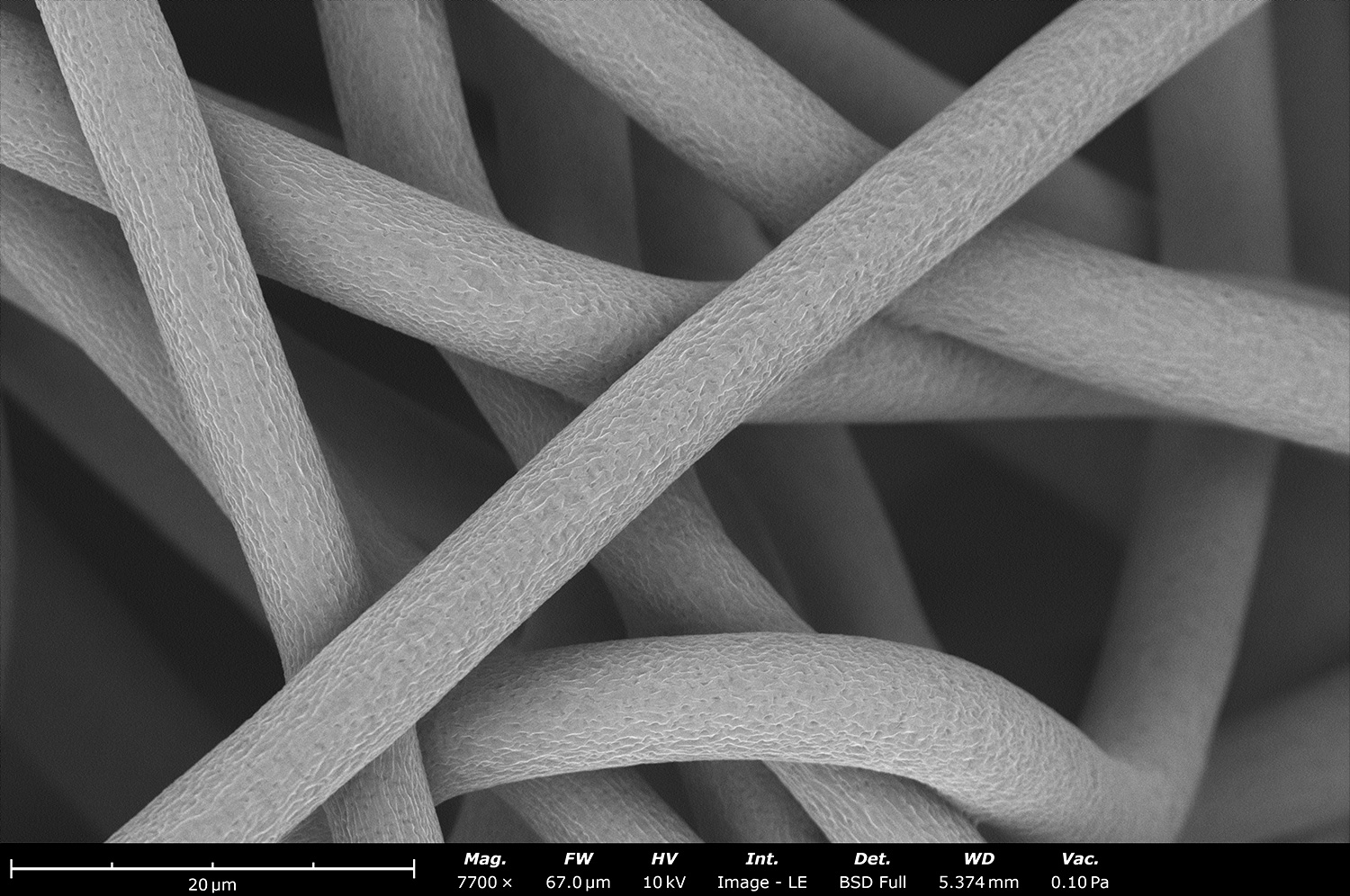

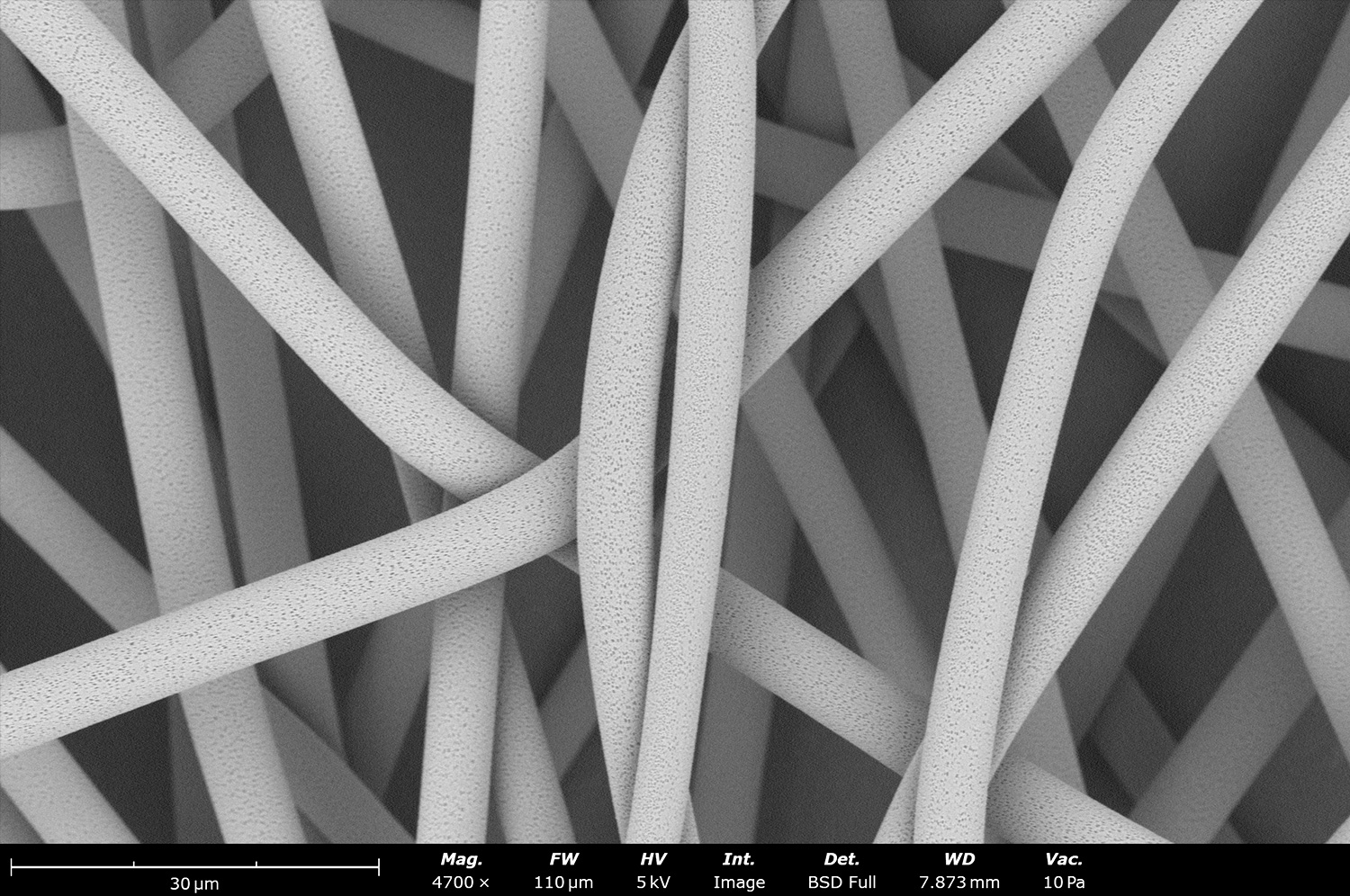

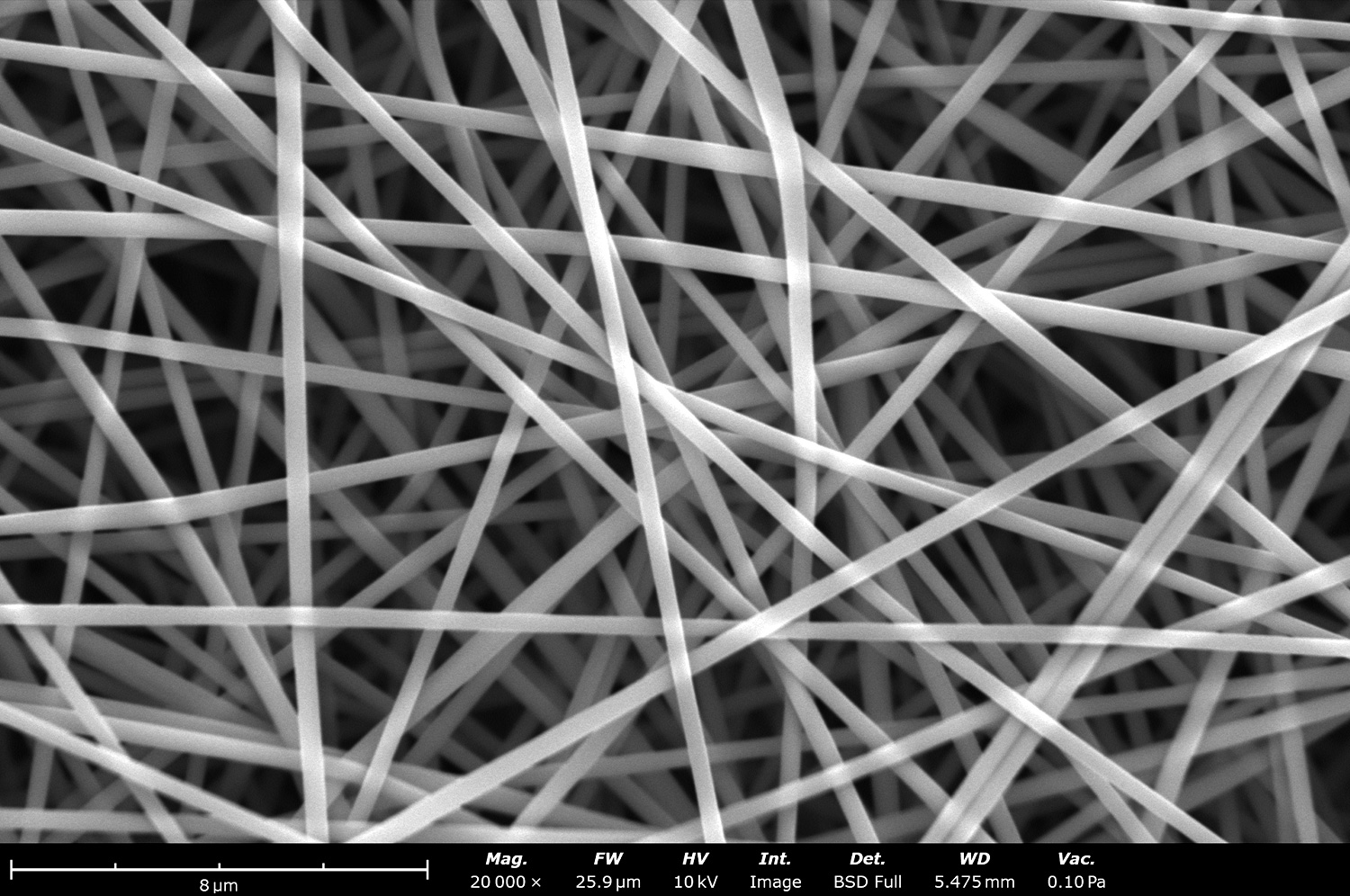

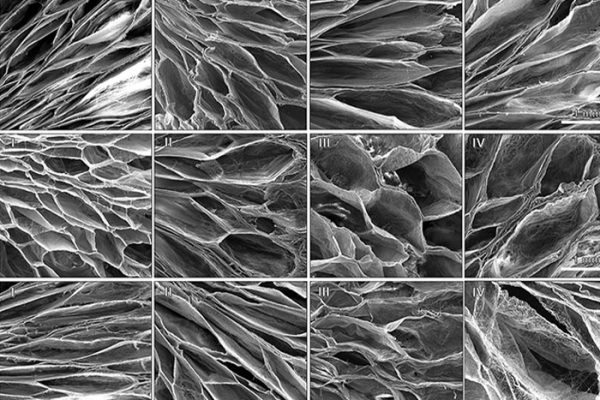

Figure 1 demonstrates the impact of precise control over T and RH on fiber morphology, showing electron micrographs of two defect-free samples produced using different environmental settings.

Figure 1. Electrospun fibers developed under tight conditions with the Fluidnatek technology: a) PCL microfibers at 24°C/40% RH, b) PLA sub-microfibers at 25°C/30% RH.

Polymer with good solvent affinity:

Polymers that have good affinity to solvents can be difficult to minimize the residual solvent unless the right temperature, relative humidity and air flow are used during fabrication. Some examples include Collagen (Clg), Gelatin (Gel), Chitosan and solvents like Hexafluoroisopropanol (HFIP). These natural polymers are used for tissue engineering application and medical devices as they are found in the native extracellular matrix and can be tuned to application needs thanks to the unique capabilities of electrospinning.

The addition of an ECU ensures a wide range of temperature and relative humidity, simplifying the processing of polymer and solvents with good affinity and ensuring proper solvent removal during sample development.

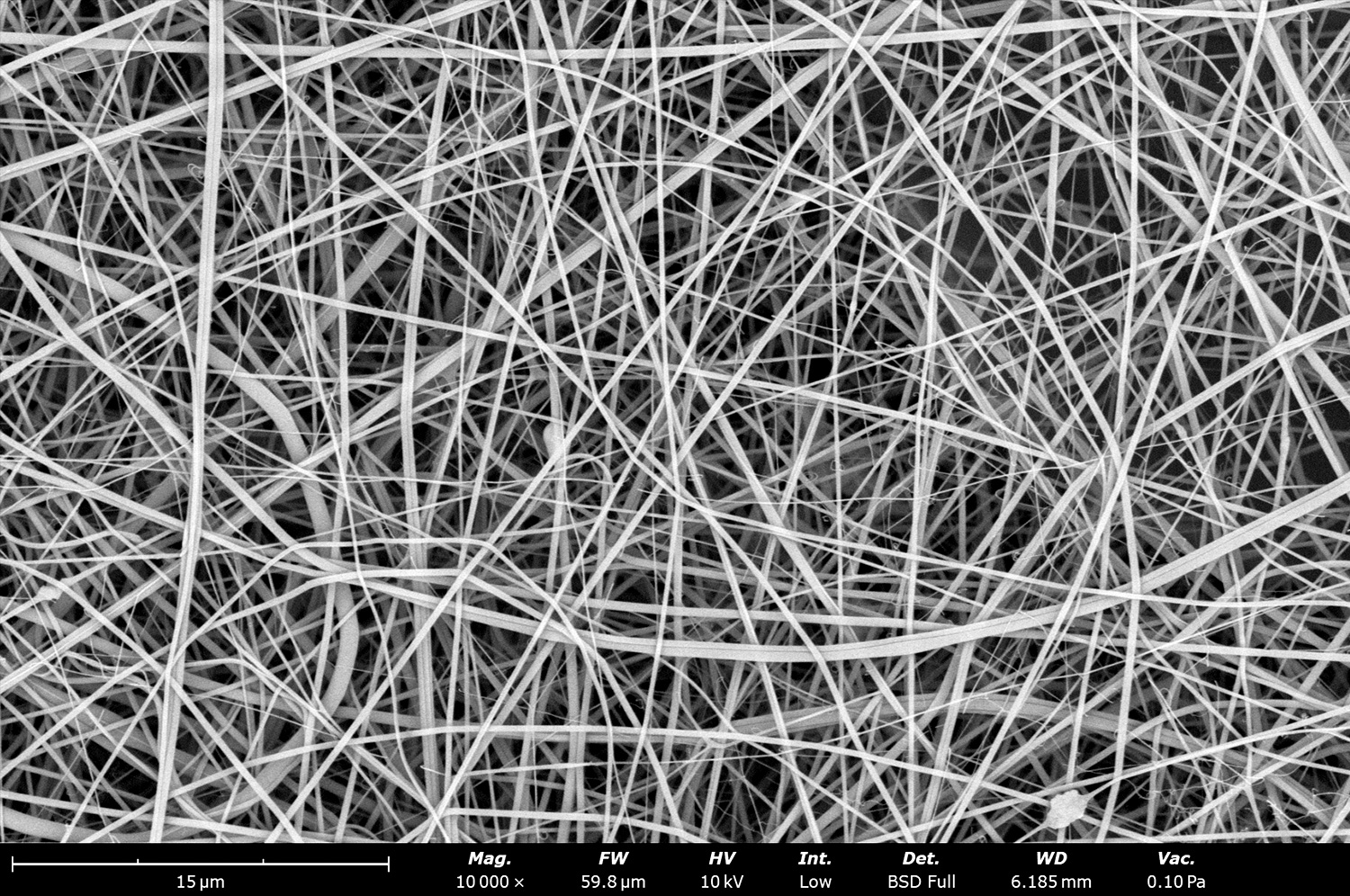

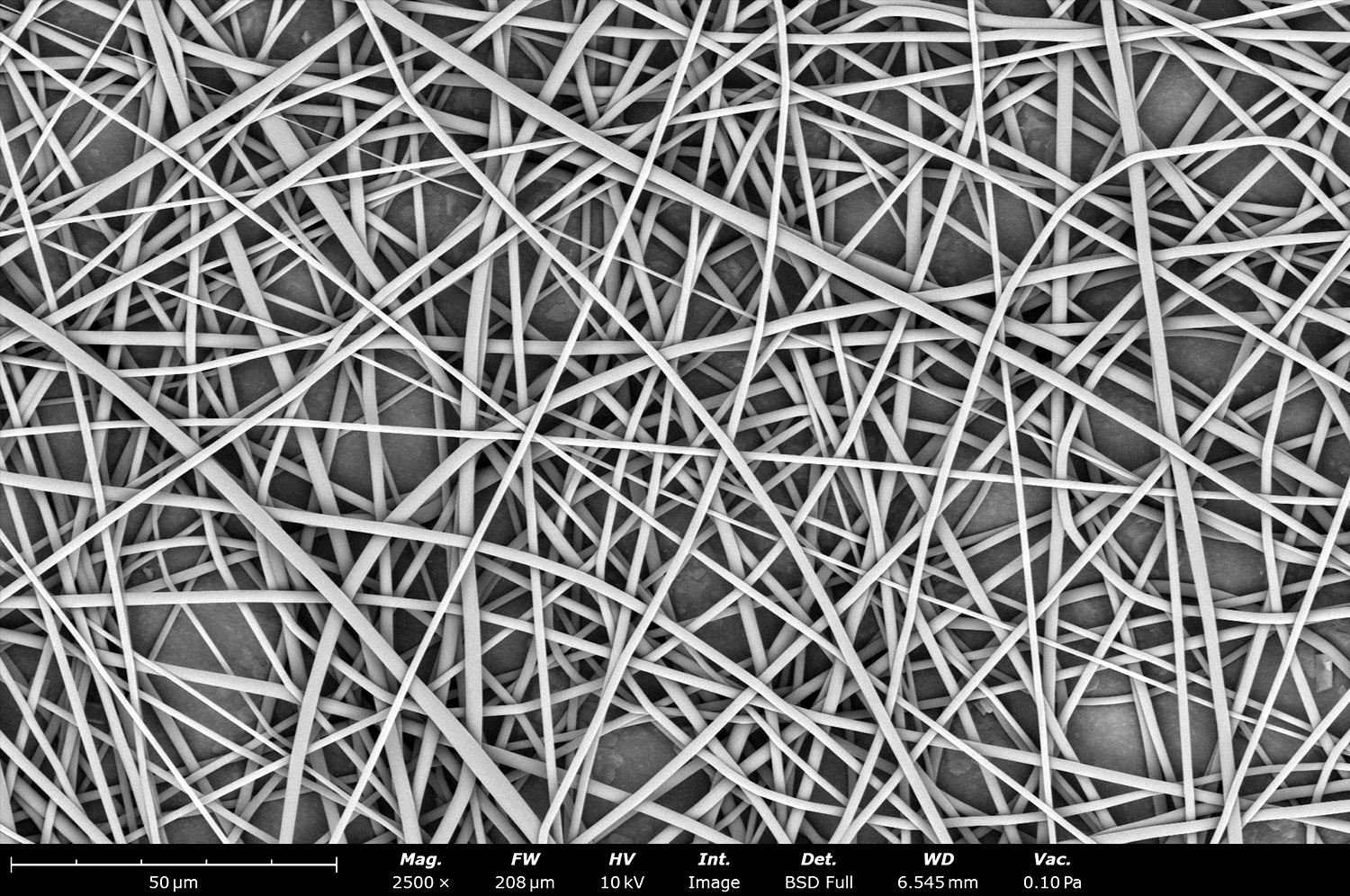

Figure 2 shows the collagen and gelatin fibers processed with HFIP under tight environmental conditions. Operating at low relative humidities can cause needle clogging and dripping. Preventing needle clogging and dripping was possible for collagen when increasing the humidity up to 63%, allowing for constant electrospun fiber production (Figure 2a).

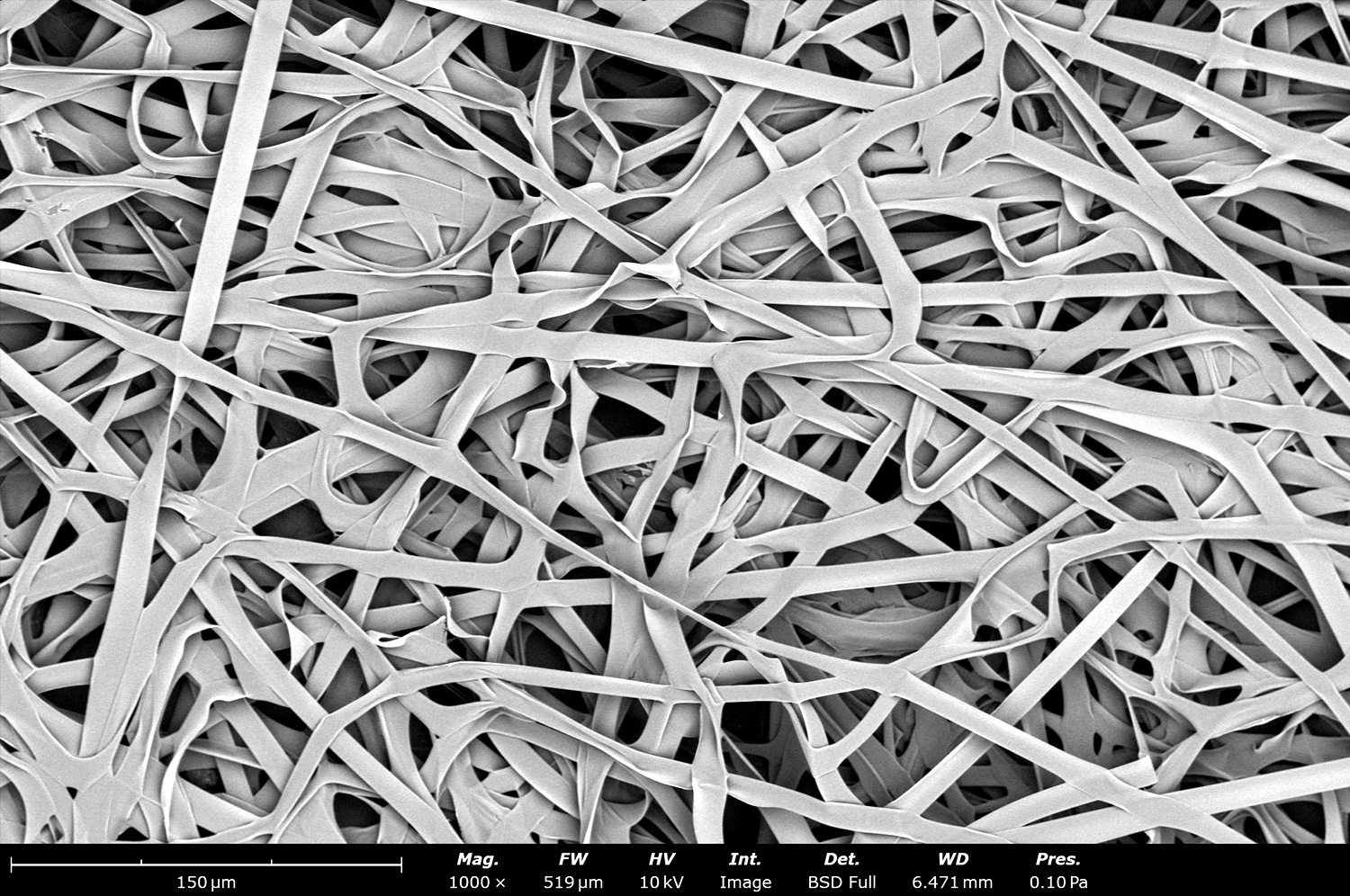

In the other case, gelatin microfibers from HFIP blended with acetic acid were obtained at lower humidity (35% RH). In this case, the solution and processing parameters were optimized to allow for ribbon shaped structures (Figure 2b).

Figure 2. Electrospun natural fibers fabricated at defined environmental conditions. a) Collagen fibers at 22°C and 63% RH, b) Gelatin fibers fabricated at 25°C and 35% RH, both dissolved in HFIP.

Environmental Control Unit

Solvents

The ability to control the environmental conditions during electrospinning expands the list of solvents that can be used.

Solvents with high evaporation rate:

Acetone (Ace), dichloromethane (DCM), chloroform (CHF), methyl acetate (MA) and ethyl acetate (EA) are commonly used for electrospinning and electrospraying. Due to their high vapor pressure, thereby high evaporation rate, needle-clogging, or secondary jetting can happen (Figure 3a). This will result in inconsistent fabrication and batch-to-batch reproducibility becomes challenging. Environmental control enables the use of these solvents by choosing the appropriate conditions to prevent needle-clogging (Figure 3b).

Figure 3. A polymer solution with low boiling point processed under different relative humidity levels: a) 25°C, 35% RH causing clogging, and b) optimized conditions of 25°C, 50% RH allowing for stable process and preventing clogging.

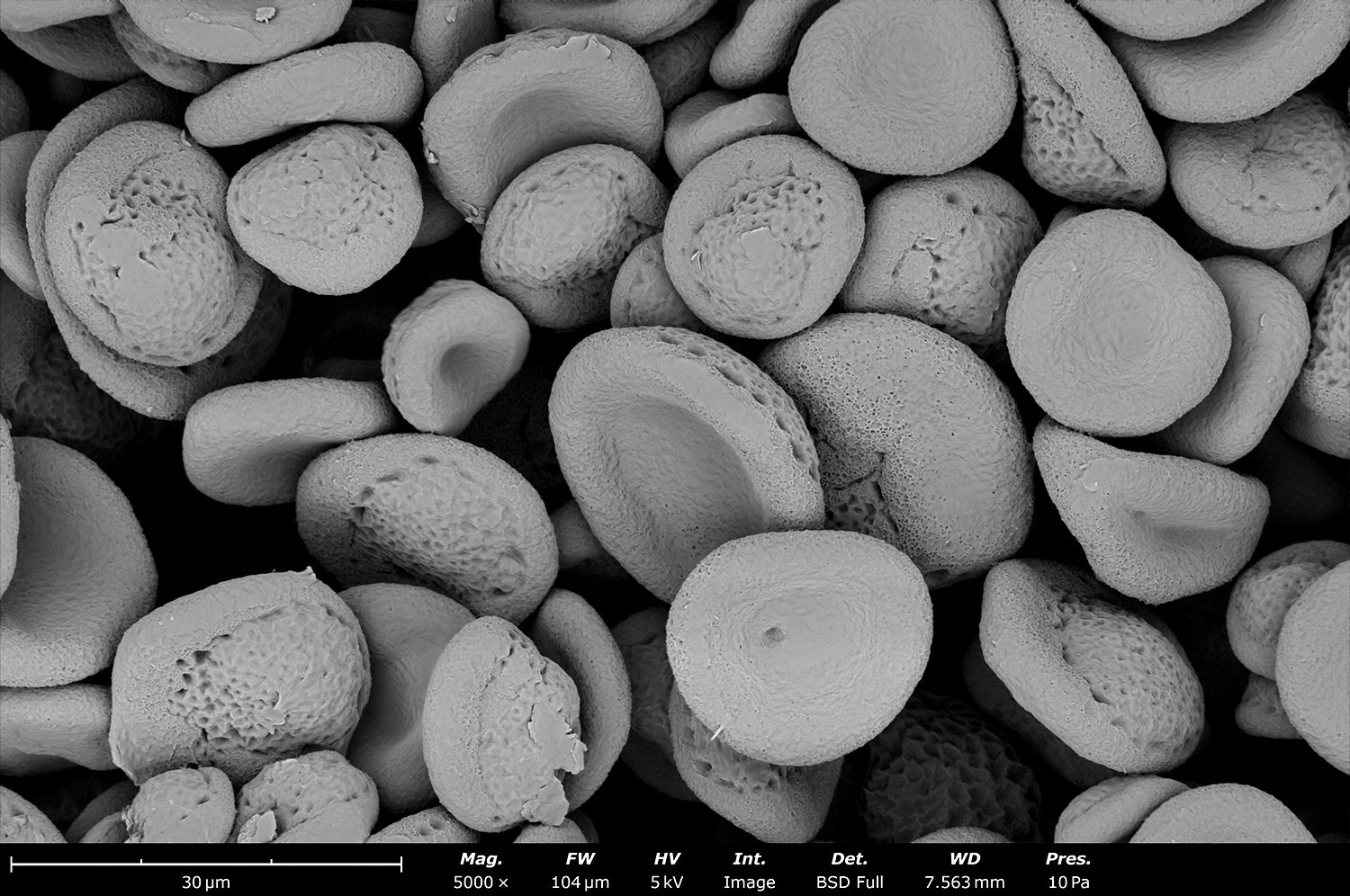

Figure 4 shows three examples of typical PCL and PLA fibers/particles developed with high vapor pressure solvents. These materials are biocompatible and commonly used for tissue engineering, medical devices and drug delivery. Without controlling temperature and RH, fabrication of these fibers or particles would not be possible on a consistent basis.

Figure 4. Electrospun fibers and electrosprayed particles fabricated from high vapor pressure based solvents under tight environmental conditions a) PCL in DCM at 25°C, 40% RH, b) PLA in DCM at 25°C, 50% RH and c) PCL in MA at 22°C, 60% RH.

Solvents with low evaporation rate:

Acetic acid (AA), Dimethylformamide (DMF), Dimethyl acetamide (DMAc), Water (W), N-Methyl-2-pyrrolidone (nMP), among others, can be hard to process due to the low evaporation rates. This is because the solvent does not fully evaporate from the fabricated materials making them adhere to one another. The environmental control unit increases temperature and decreases humidity to process these types of solvents with ease and prevent, or minimize, residual solvent on the fabricated materials.

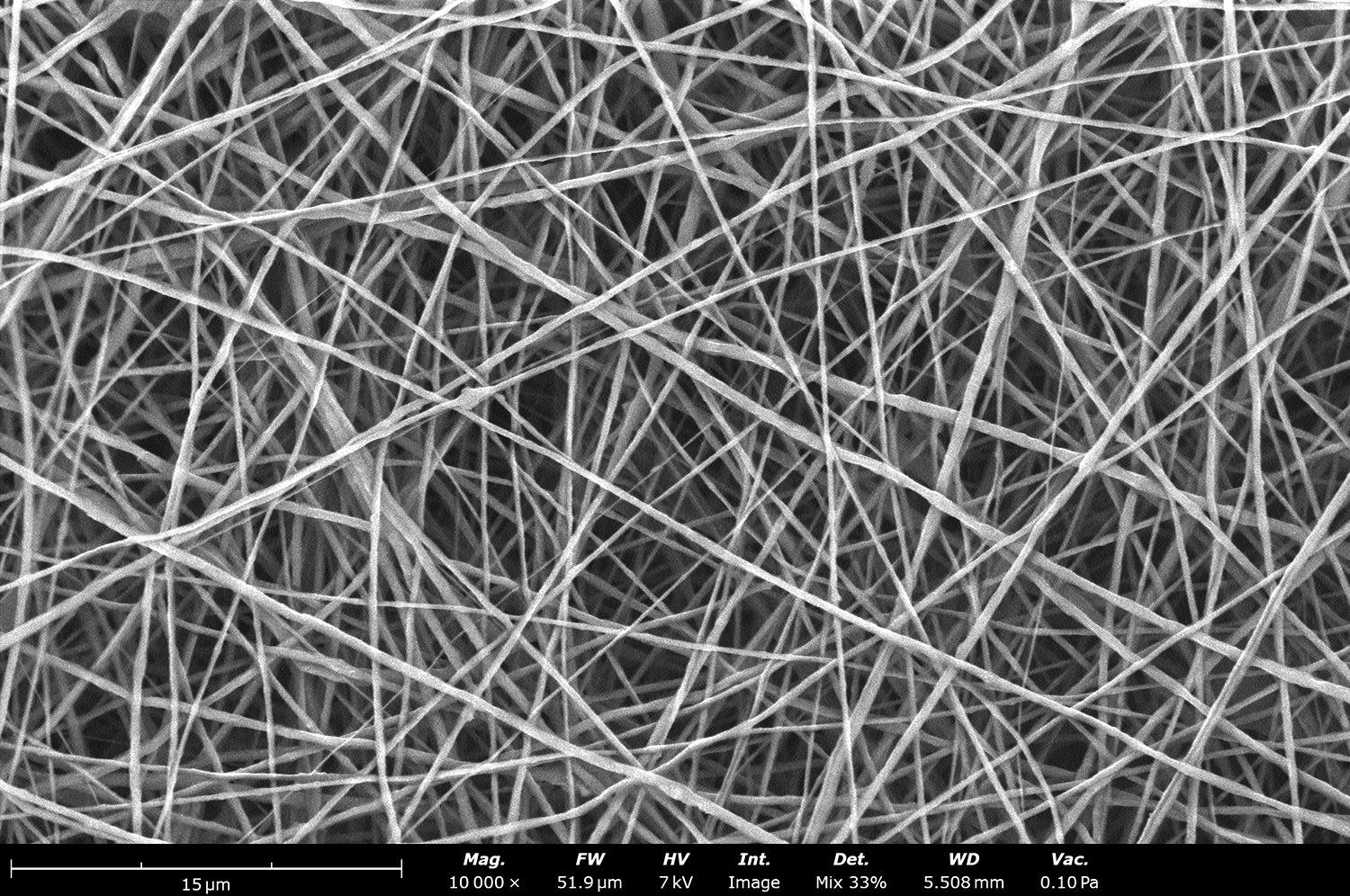

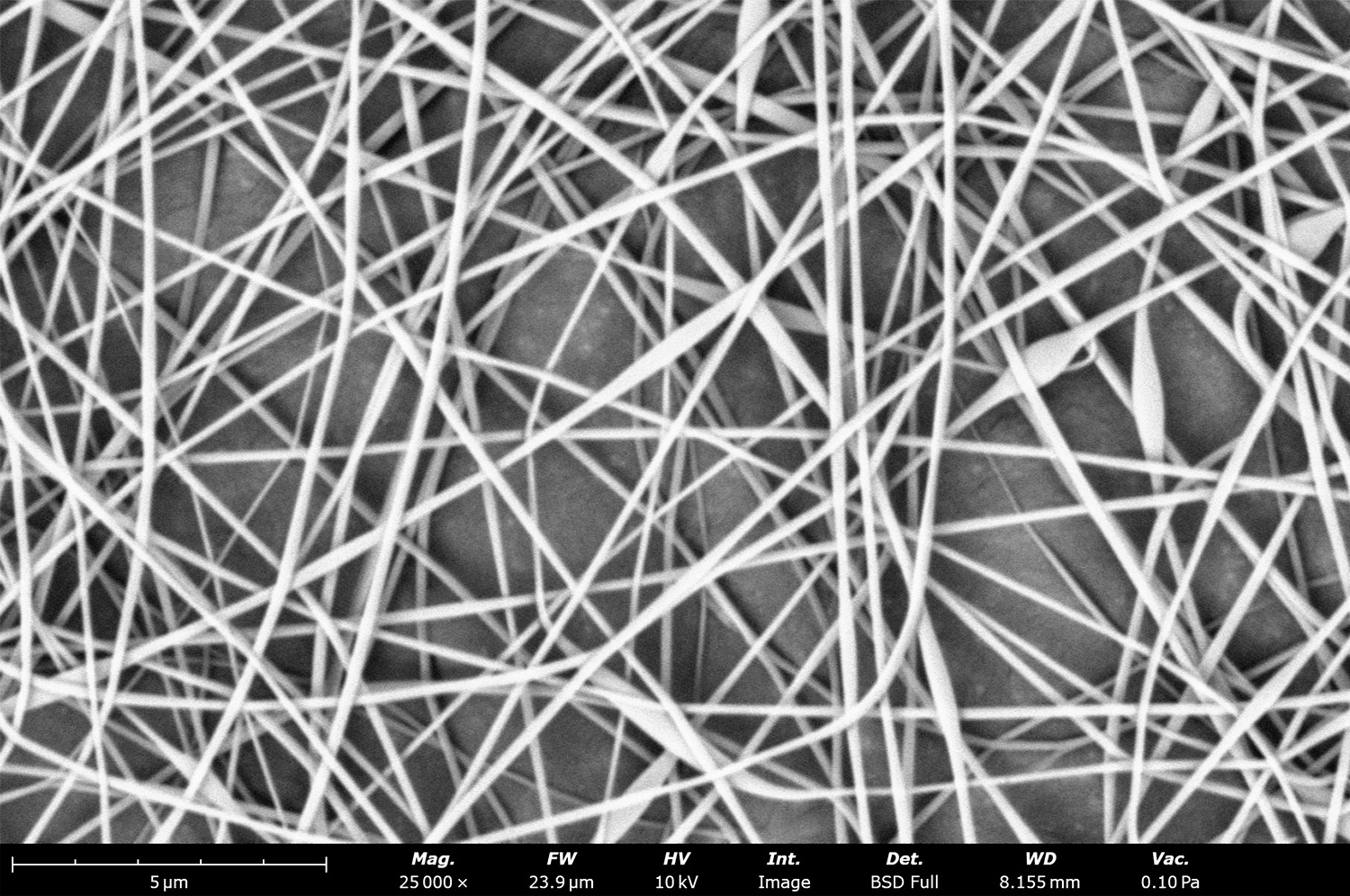

Polyethylene oxide (PEO) is commonly used as a sacrificial polymer when fabricating fibers and particles of materials that are not spinnable by themselves. Figure 5a shows SEM micrographs of fibers of PEO dissolved in water. At low humidities water can evaporate quickly, allowing the fabrication of larger fiber diameter, while at high humidities, water evaporates slower, allowing the fine tuning of the microstructure and obtain smaller fiber diameter.

Figure 5. Electrospun synthetic polymers dissolved in low vapor pressure solvents under tight environmental conditions using the ECU: a) PEO in water at 28°C, 40% RH, b) PAN in DMF at 25°C, 40% RH, c) Thermoplastic polyurethane in DMAc at 24°C, 43% RH.

Polyacrylonitrile (PAN) is a polymer typically used for hot-air filtration or as a precursor to carbon nanofibers for use in applications like energy storge and fuel cells. Figure 5b shows fibers fabricated from PAN in DMF. Temperature and relative humidity was adjusted to maximize PAN production, prevent fiber-fiber bonding and minimize residual solvent for this type of material.

Thermoplastic Polyurethane (TPU) is commonly used to coat medical devices thanks to its stability and ideal mechanical properties for implantable metals like stents and heart valves. The medical devices with TPU coating need to have the capability to be crimped onto smaller diameter requiring flexibility. Controlling temperature and RH is crucial to prevent possible fiber-fiber bonding that will hinder the crimping capability of TPU. Figure 5c shows the microstructure of thermoplastic polyurethane fibers fabricated from DMAc.

Environmental Control Unit

Additives

Several of the additives that are commonly used in electrospinning including proteins, amino acids, peptides, live cells, or active pharmaceutical ingredients can be sensitive to temperature or relative humidity. At high temperatures, the native structure can be lost and at high humidity levels hydrolysis could occur, thereby rendering the additive ineffective. In electrospraying, additives like surfactants and salts are used to improve particle metal particle suspension that will be affected if temperature and relative humidity are not ideal. The environmental control unit will have the capability to tightly control the process from 18°C to 45°C (±1°C) and 10% to 80% (±3%) relative humidity to prevent any undesired effect when using thermolabile additives.

Environmental Control Unit

Fiber properties

While developing a process for fabricating fibers/particles by Electrospinning/Electrospraying, it is important to optimize the process so that the final products have defined properties and that they are consistent and reproducible. Uniform fiber morphology is crucial to maintain proper mechanical properties like tensile strength, modulus, elongation, suture retention strength and burst pressure. Environmental control plays a critical role in developing optimized processes.

For example, fabricating gelatin fibers at 25°C and 70% results with beaded fiber microstructure (Figure 6a). At high humidities, the water in solution does not evaporate properly, decrease solution viscosity and the polymer does not fully elongate, causing the beaded structures. These beaded structures will affect the mechanical properties, pore size, porosity and possible drug release.

Figure 6. Gelatin fibers fabricated at different relative humidity levels. a) 25°C, 70% RH and b) 25°C, 35% RH. Fibers fabricated at high RH levels shows beaded structures while the one fabricated at lower humidity levels are smooth, round, elongated fibers.

Optimizing the electrospinning process and using a lower relative humidity of 35% to fabricate the gelatin fibers results in rounded gelatin fibers (Figure 6b). At the lower humidity levels, the solvent evaporation is optimized, allowing for the jet to elongate properly and solidify at an ideal rate.

Another key parameter affecting fiber properties is temperature, which works in cohort with relative humidity and solvent properties. If the solution viscosity decreases significantly with increased temperature, the fiber diameter is likely to decrease. This is because the solution viscosity decreases allowing the polymer chains to move faster and resulting in thinner fibers. However, a significant increase in evaporation rate with increased temperature could result in an increase in fiber diameter.

In general, electrospun fibers of hydrophilic polymers at low temperature and high relative humidity will have smaller diameters, while high temperature and low relative humidities will result in large fiber diameter. For hydrophobic polymers when processed at high relative humidities, porous structures will be present on their structure as water droplets can accumulate on the surface of the polymer. The presence of pores on the fiber structure will be considered defects, causing a decrease in mechanical properties.

Environmental Control Unit

Scalability

Environmental control is critical while attempting to scale up the electrospinning process from feasibility studies to pilot scale production. The stability, repeatability and reproducibility of the process depends on the environmental conditions, in addition to several other factors.

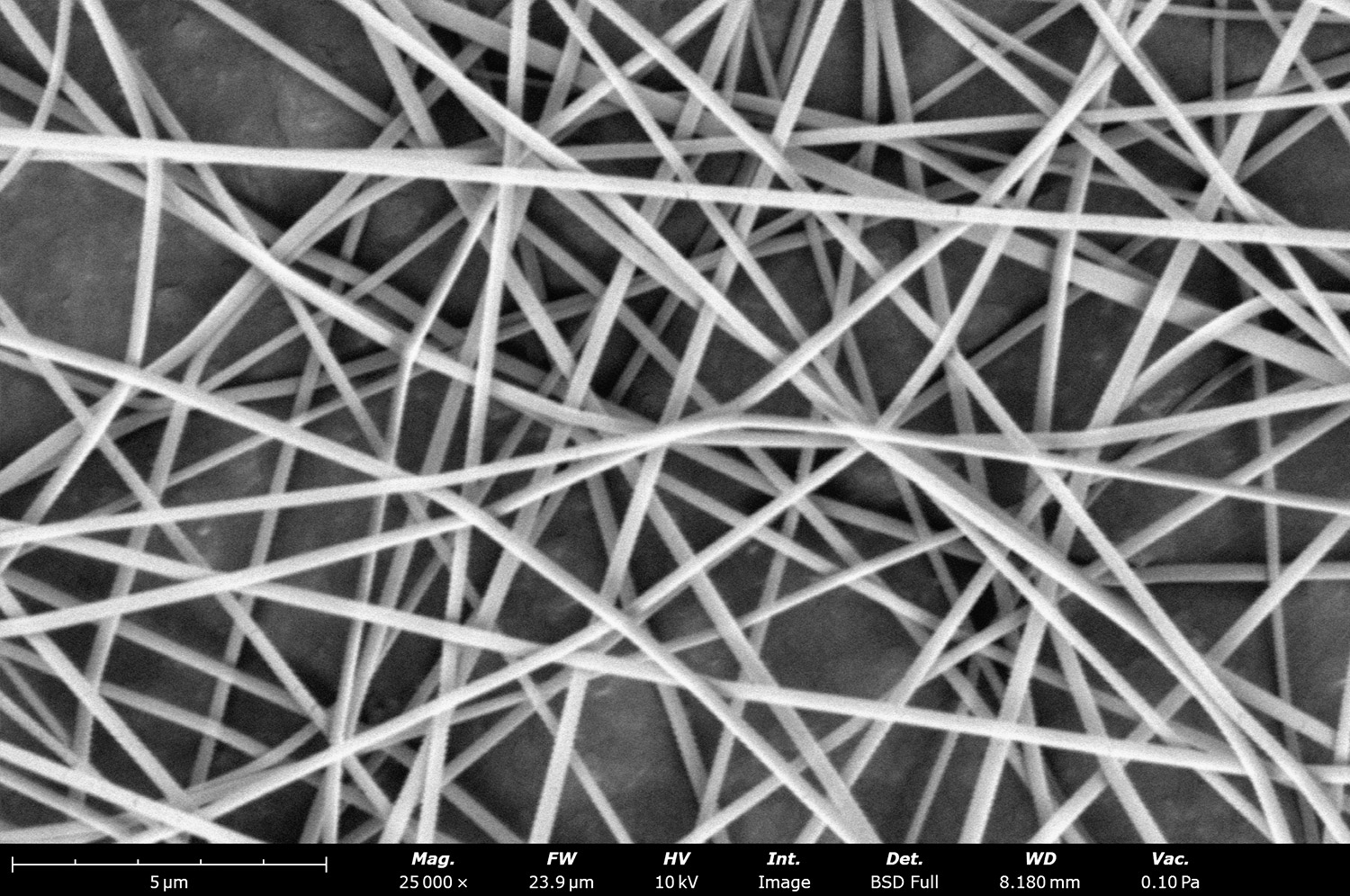

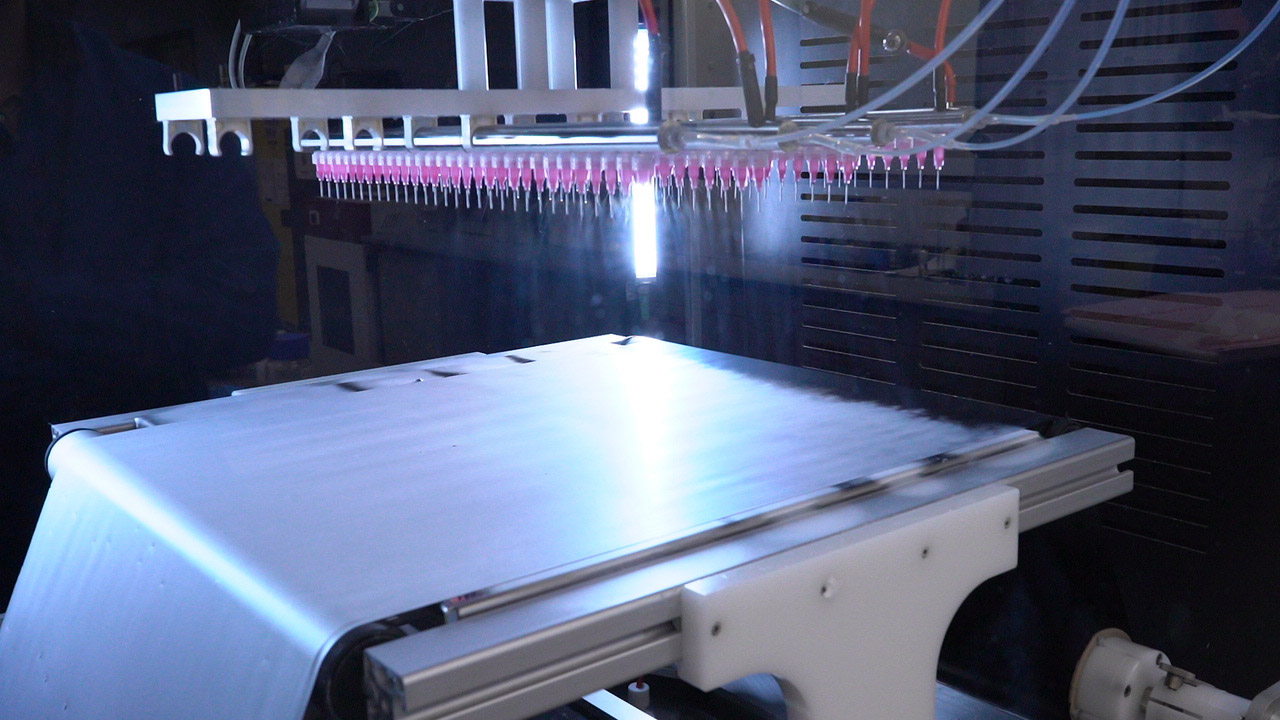

To illustrate the importance of environmental conditions on scaling up electrospinning process, fibers of polyacrylonitrile (PAN) in dimethylformamide (DMF) were fabricated using 60 needles. The optimal conditions were determined to be a flow rate of 30 mL/h (0.5 mL/h per needle) when using environmental conditions of 25°C, 35% relative humidity and an air flow of 90 m3/h.

When trying to scale up from 60 to 120 needles, the flow rate was increased to 60 mL/h to maintain the same flow rate of 0.5 mL/h per needle. Using the same environmental conditions resulted in defects, commonly known as stacking and cross-stacking (Figure 7a). Stacking can be defined as fibers that start accumulating, or stacking, from the collector all the way to the needle. On the other hand, cross-stacking can be defined as the fibers that are accumulated between fibers coming from separate needles.

Figure 7. Effect of temperature and relative humidity on PAN scalability: a) clear examples of stacking and cross-stacking defects present. b) optimized T, RH and air flow without defects.

To overcome these defects, environmental conditions were optimized, and stable process was observed at 40°C, 18% RH and air flow of 120 m3/h (Figure 7b). The results are summarized in Table 1. The higher temperature and lower humidity increased the evaporation rate, and the higher air low rate removes the evaporated solvents faster from the chamber.

Control of environmental conditions (T, RH and air flow) allows the aid of solvent removal, prevent needle clogging or other defects during production, and allows residual charge dissipation. Optimization of environmental condition not only stabilizes the process but an increase in electrospun throughput can be achieved (Table 1), opening possibilities to translate the process towards industrial scale production. All these combined allow you to use the environmental control unit to easily translate a solution from the R&D, to process development, to pilot scale, and industrial scale production.

| Needles | Flow Rate | Environmental conditions | Result |

|---|---|---|---|

| 60 | 30 mL/h | 25°C, 35% RH, air flow of 90 m3/h | Stable process |

| 120 | 60 mL/h | 25°C, 35% RH, air flow of 90 m3/h | Stacking & cross-stacking defects |

| 120 | 60 mL/h | 40°C, 18% RH, air flow of 120 m3/h | Stable process |

| 120 | 120 mL/h | 40°C, 18% RH, air flow of 120 m3/h | Stable & increased throughput |

Environmental Control Unit

Safety

Safety should be of paramount importance in electrospinning systems since it can often be necessary to use flammable polymers, solvents or additives. The environmental control unit offers a couple of safety features to effectively maintain a stable and safe condition.

Actively regulated exhaust system

Differential pressure sensors are implemented in a control loop with an extraction fan to ensure optimum ventilation at a slightly negative pressure is maintained within the chamber. If the ventilation is interrupted, the system safely shuts down to prevent potential build-up of hazardous solvent vapors. This system works in coordination with the environmental control unit to always maintain a stable process with temperature (18°C to 45°C ± 1°C), relative humidity (10% to 80% ± 3%), and air flow (50 m3/h to 180 m3/h).

inert atmosphere

If large volumes of highly flammable or explosive solvents are being used, the ECU can be implemented with an open loop nitrogen gas port. Combined with an oxygen sensor this can ensure that safe limits are maintained. The user can define the oxygen concentration limit and the system will ensure that the limits are maintained.

Fluidnatek LE-50

Product Knowledgebase

Webinar

Advancements in Electrospun Scaffolds: Transitioning from 1D/2D Sheets to 3D Structures

Electrospinning has emerged as a leading platform for generating nanofibrous materials who…

Blog

Fabricating Nanofibers: Electrospinning Vs Blow Spinning

Nanofibers, with their high surface area-to-volume ratio, tunable porosity, and mechanical…

White Paper

Controlling the Orientation of Electrospun Nanofibers for Tissue Engineering

Electrospinning is a versatile and promising technique for fabricating nanofibrous scaffol…