Electrospinning & Electrospraying System

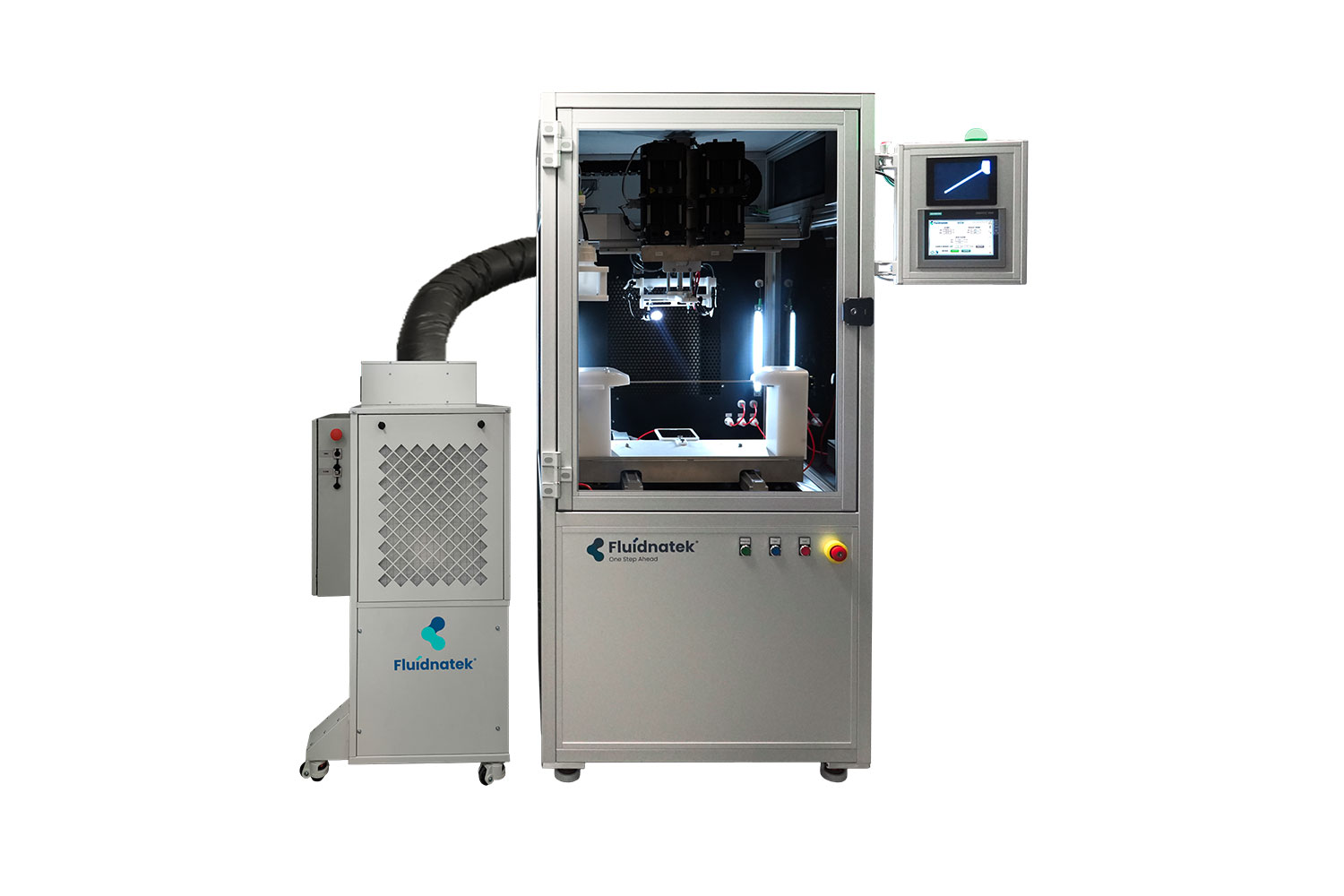

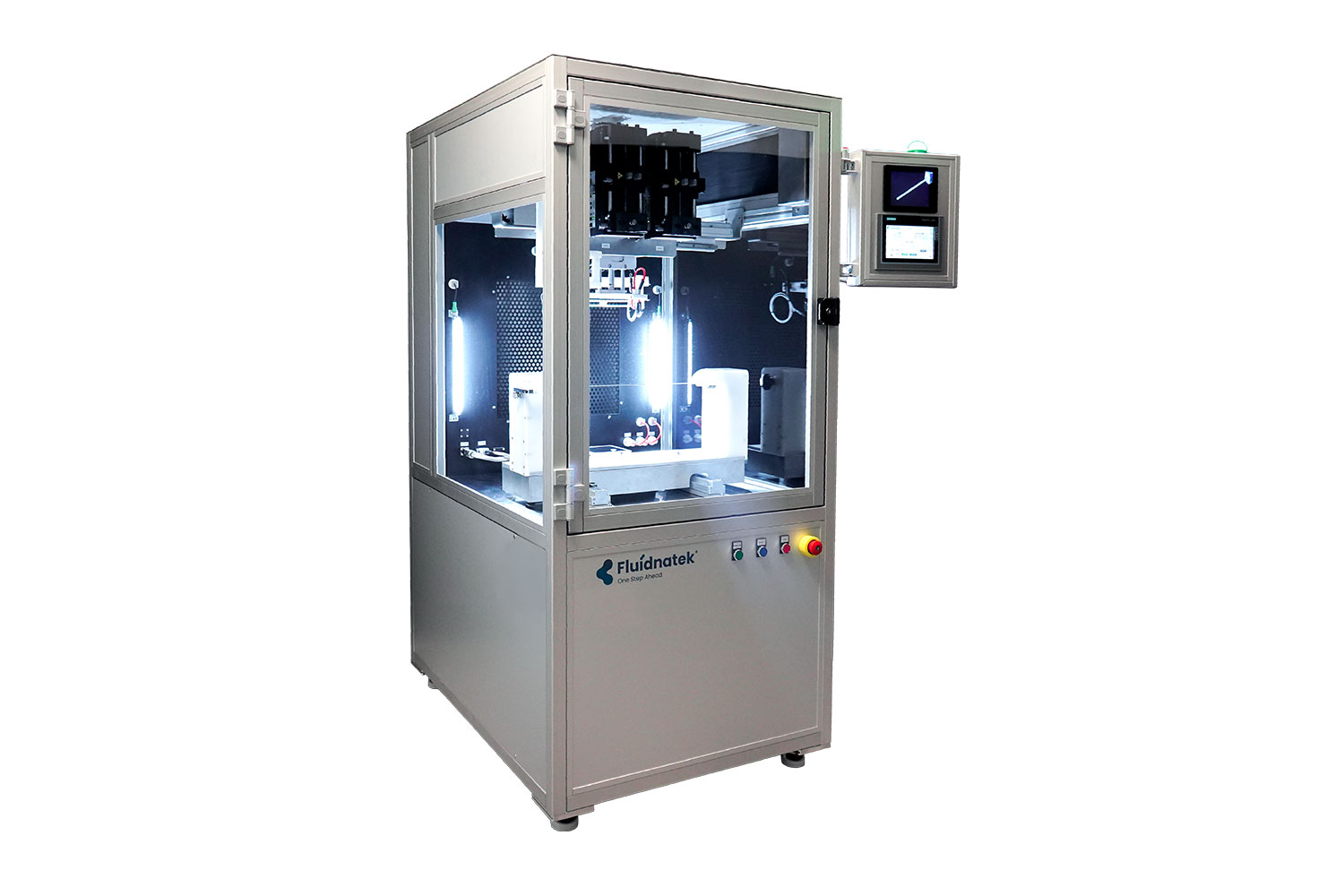

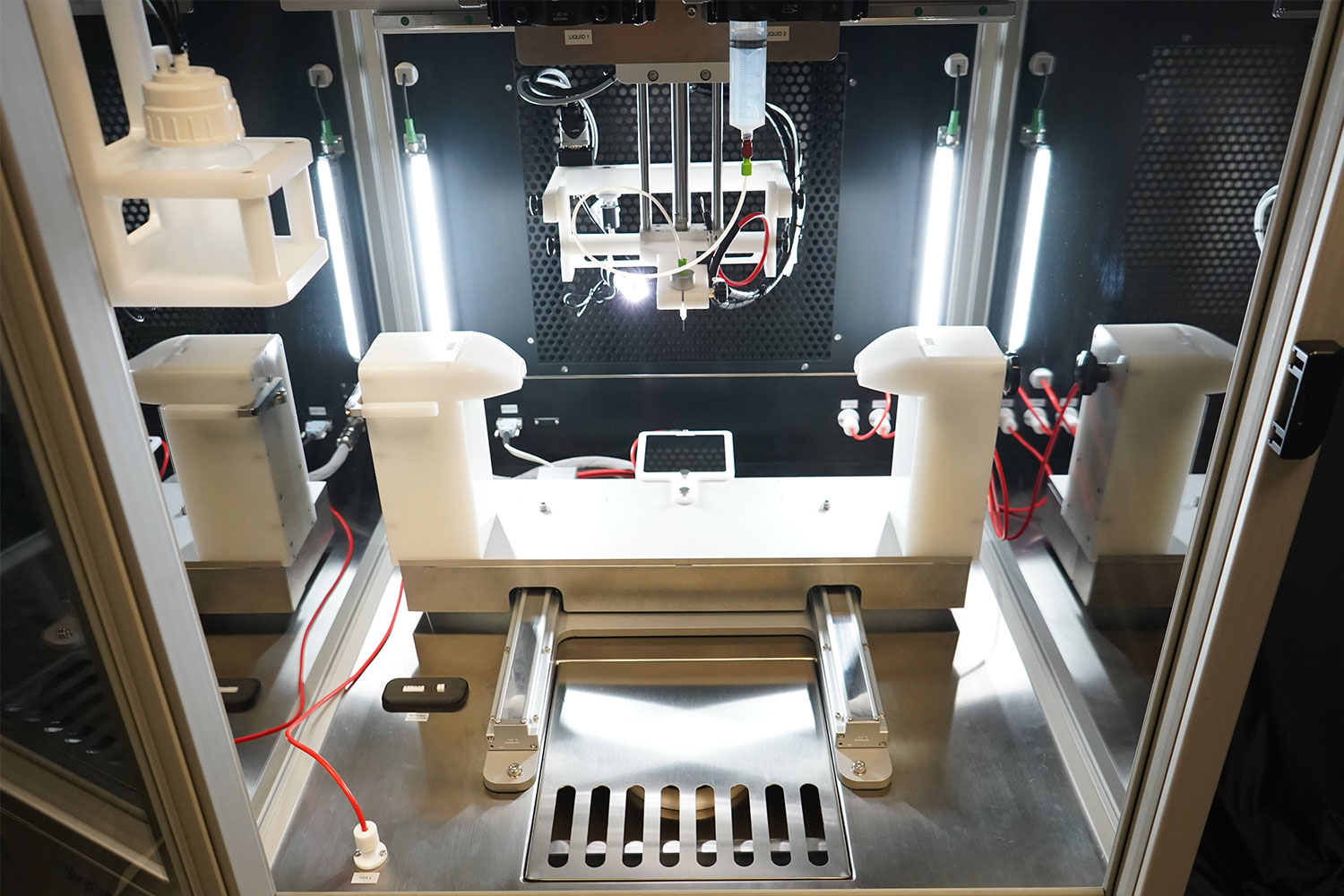

Fluidnatek® LE-100 biotubing

The LE-100 BioTubing system was carefully designed to maintain clean processing conditions for tubular medical device manufacturing. This unique system utilizes HEPA filtration to meet ISO-7/Class 10,000 cleanliness standards. The processing chamber enables the fabrication of longer tubes when compared to the standard LE-100, or faster application of coatings on several medical devices at the same time.

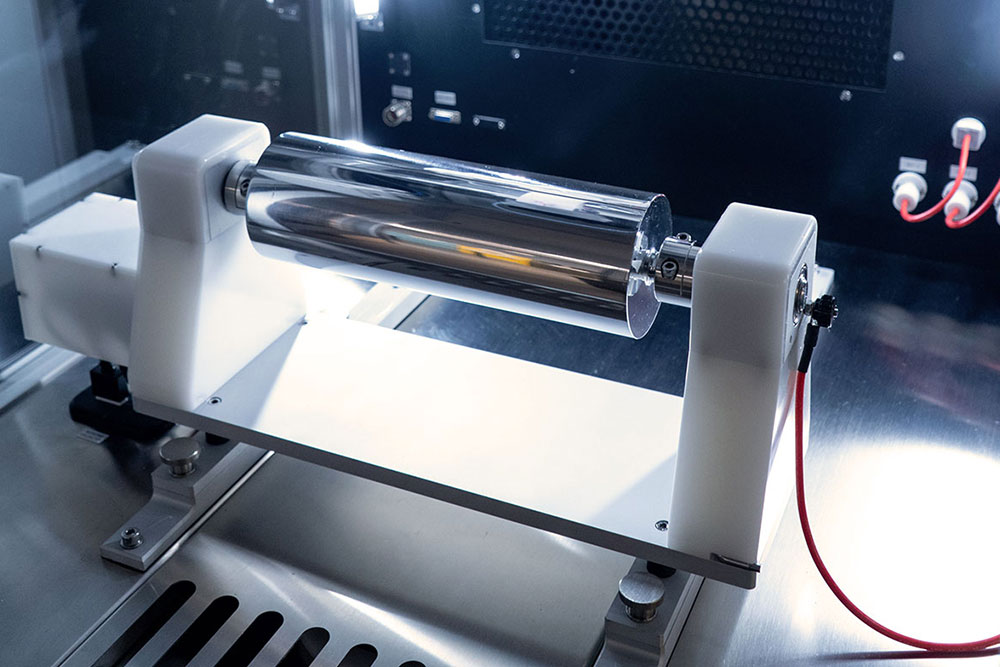

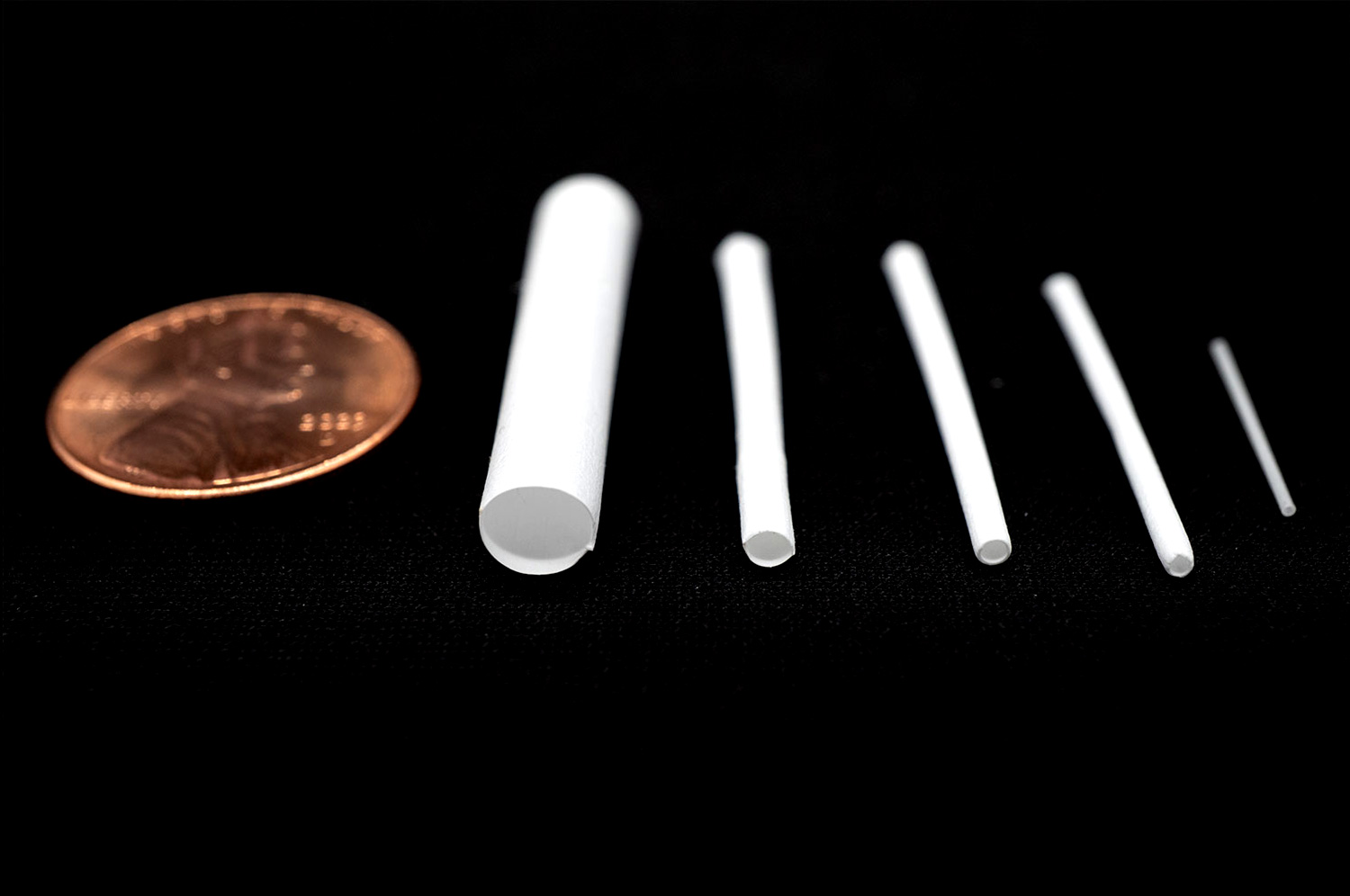

Designed for Tubular Samples

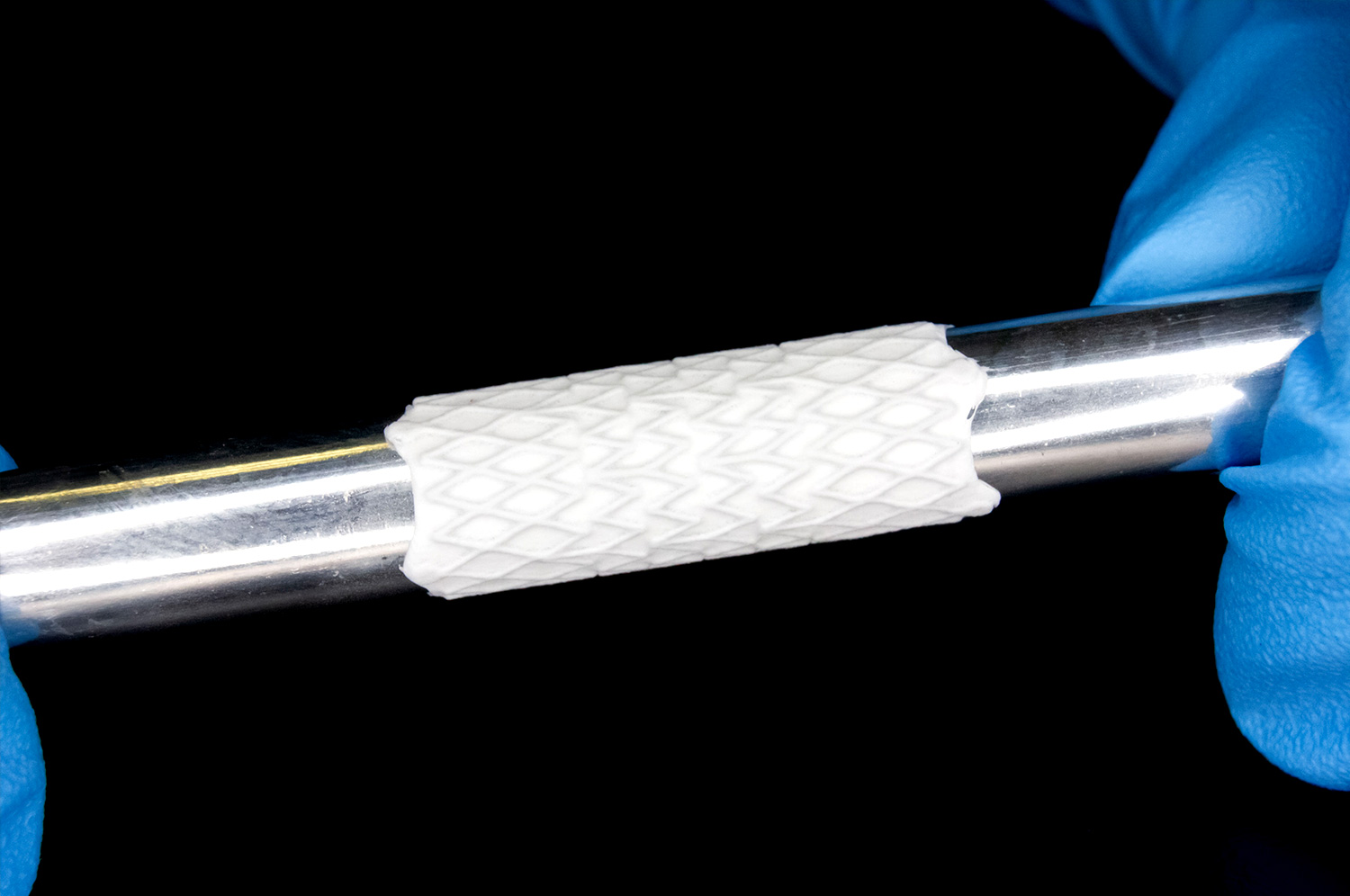

Ideal for the coating of thin-diameter mandrels (<5 mm) for vascular grafts and coating of stents

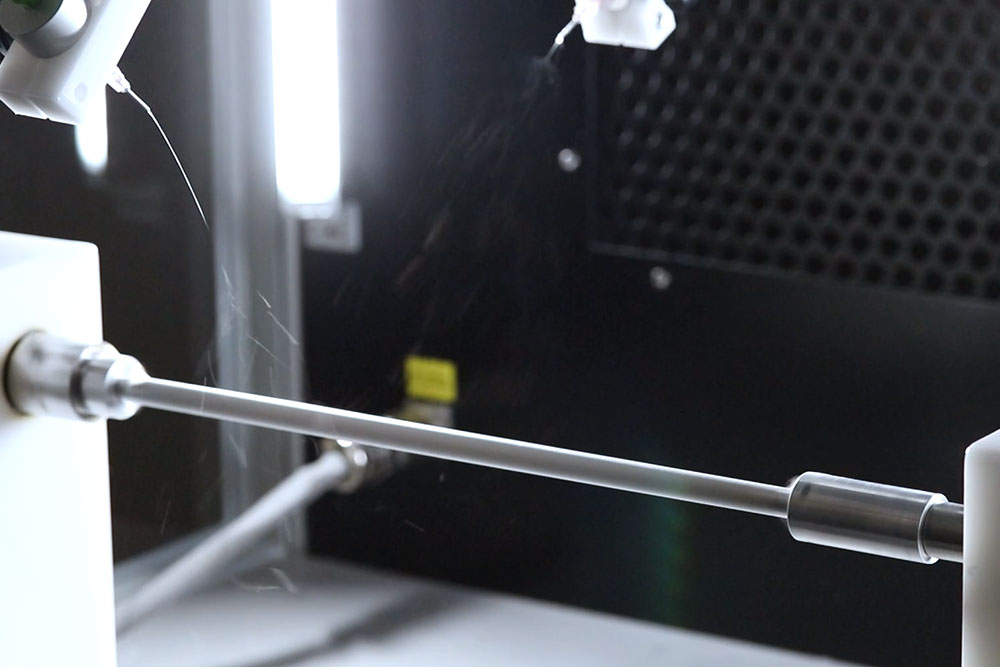

Dual-end Rotating Platform

Eliminate torsional forces on thin mandrels and balances rotation from both ends of the mandrel for consistent deposition

Full Environmental Control

HEPA-filtered unit provides control over temperature (18 – 45 °C), relative humidity (10 – 80%), and air flow (90 – 180 m³/h)

cGMP Certifiable

Leading electrospinning technology for pharma & biomedical processes. cGMP validation processes through IQ/OQ/PQ documentation packages

Explore electrospinning for your application!

Our contract research team offers you access to latest in electrospinning, ideal for initial consultations, proof-of-concept experiments, feasibility studies, method development, and early-stage R&D.

Uniquely Designed for Electrospinning Tubular BioTextiles and Applying Coatings to Medical Products

The Fluidnatek LE-100 BioTubing is an electrospinning system tailored to the needs of medical device companies and biomedical product manufacturers. Supporting cGMP production, the LE-100 BioTubing system is ideal for R&D and small-batch fabrication of fibers and/or particles for biomedical applications. Some examples include applying surface coatings to prefabricated medical devices like stents, balloons, or hernia meshes, and fabricating biocompatible vascular grafts, heart valve prosthetics, nerve conduit supports, or other tubular structures. Its HEPA-filtered environmental control unit (ECU) maintains a clean processing environment and provides tight control over temperature (18 – 45 °C), relative humidity (10 – 80%), and air flow (90 – 180 m3/h), meeting the standards for ISO-7, cGMP, ISO-13485, among others.

Application Areas:

Fluidnatek® LE-100 biotubing

Product Features

Unique Rotating Collector Platform

Many rotating collectors for electrospinning systems are designed with a single motor on one end of the cylinder that drives rotation. In most applications, this configuration is sufficient, but for small-diameter rotating collectors under 5 mm mandrels and wires, it can lead to problematic torsional forces and wobbling during rotation, that affect the quality and homogeneity of the electrospun sample. The LE-100 BioTubing’s rotating collector platform provides dual-ended drive and applies tension to the mandrel to prevent bowing during rotation. This collector platform allows samples up to 1 cm in diameter and 40 cm in length. It has two drill chuck based adapters, allowing the users to use their own mandrels, providing maximum flexibility for sample development. The platform also has a quick-release mounting system. This allows for efficient mandrel exchange and minimizes handling of finished electrospun products, minimizing setup time, allowing the user to maximize production efficiency

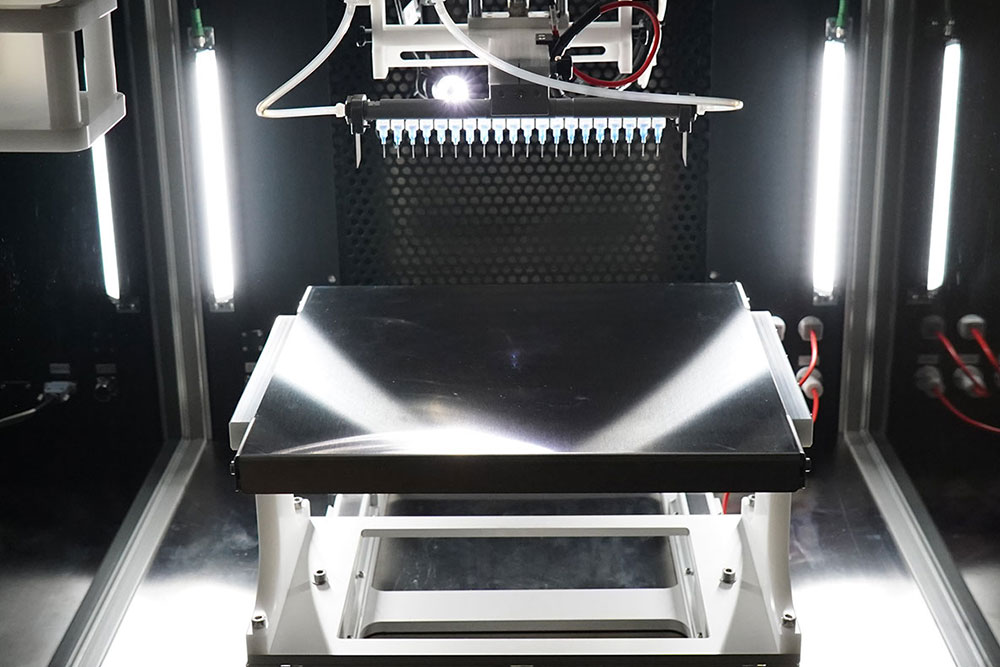

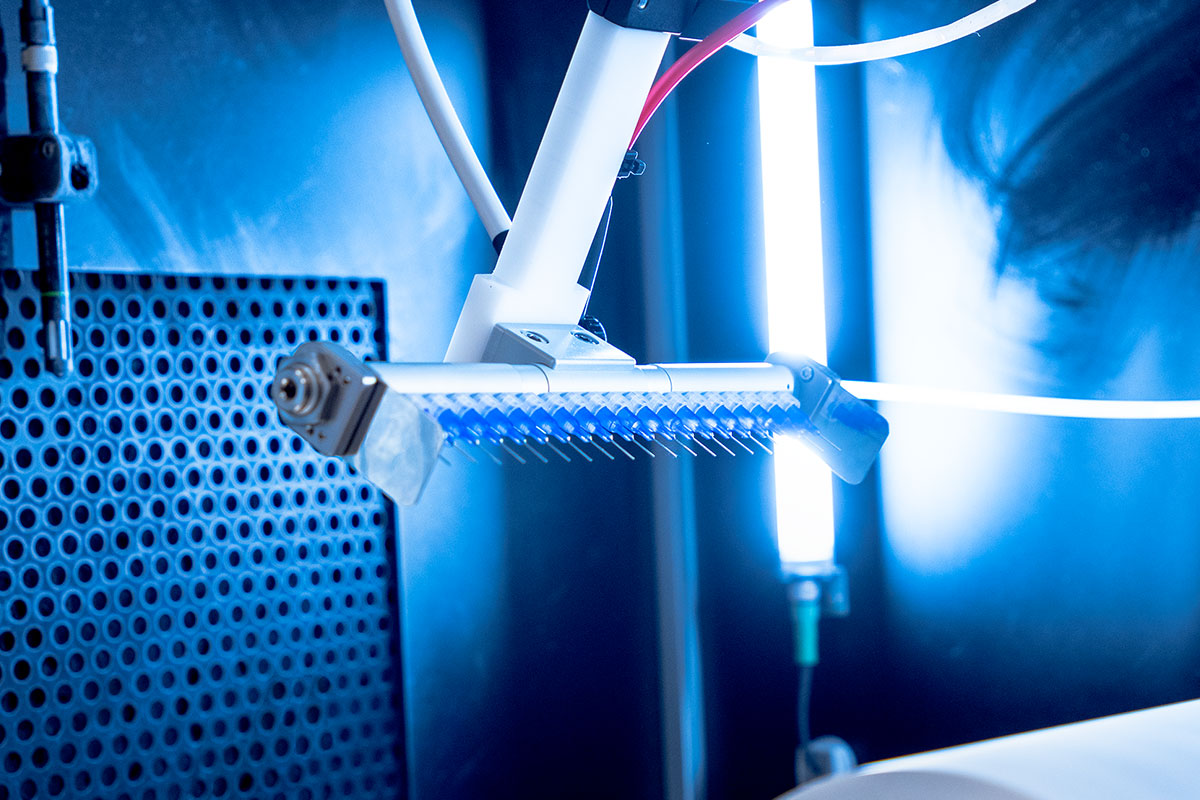

Enhanced Sample Deposition and Uniformity

Consistent electrospinning processes require stable electric fields. The LE-100 BioTubing system has an additional electrode that is specifically designed to be used with the unique rotating collector platform when coating thin-diameter mandrels (<5 mm). This additional high-voltage power supply helps control the electric field and direct the fibers or particles toward the collector. This also helps prevent unwanted alignment effects that often occur when electrospinning onto a thin-diameter mandrel.

Exclusive Environmental Control Unit (ECU)

The Fluidnatek Environmental Control Unit (ECU) regulates temperature, humidity, and air flow within the processing chamber. This ensures consistency and reproducibility of electrospinning experiments, especially when working with difficult solutions, sensitive materials, or in varying ambient conditions. The BioTubing system’s ECU allows users to increase or decrease temperature within the range of 18 – 45 °C and relative humidity between 10% and 80%. Once the air is conditioned, it is passed through HEPA filters to ensure ISO-7/Class 10,000 cleanliness and pumped into the processing chamber at controllable flow rates between 90 and 180 m3/h.

Advanced Recipe Option

The programmable sequential multi-step recipe function enables automation of processing parameters (e.g. voltage, needle-to-collector distance, flow rate, drum speed, among many others) as a function of time. Users can conveniently pre-program dozens of experimental steps and load the recipe to initiate a new process all from the touch-screen interface on the instrument. It supports two access levels and allows up to 99 users with individual logins and permissions, ideal for validated processes like ISO or GMP compliance. The recipe function also allows offline recipe programming, enabling users to create and upload recipes remotely from a computer, enhancing flexibility and simplifying process automation.

Automated Emitter Motion

Unlike many electrospinning systems, the LE-100 BioTubing system’s syringe pumps are mounted on the same apparatus as the emitter (needle or spinning head). This allows the needle to traverse across the processing chamber without affecting the solution flow. There are several benefits to this configuration. First, it reduces or eliminates tubing for solution flow, minimizing dead volume and preserving expensive additives like biological samples or active pharmaceutical ingredients. Additionally, by translating the needle, the collector can remain in place, which is especially beneficial when using the rotating drum as the increased stability supports higher rotational speeds. It can also be used in combination with the programmable recipe function to automate the process of fabricating a homogeneous, uniform layer of nanofibers or nanoparticles, targeting a specific area of the collector for precision application of coatings. Lastly, when using the Taylor cone camera, the needle will be in focus at all times during needle translation, allowing you to confirm the process is stable at all times.

Regulatory Compliance and Process Validation

The LE-100 BioTubing can be provided with qualification documentation to support validation compliance, including Factory Acceptance Testing (FAT), Site Acceptance Testing (SAT), Installation Qualification (IQ), and Operational Qualification (OQ). These documents facilitate process validation and comply with standards such as Good Manufacturing Processes (GMP), Good Laboratory Practices (GLP), and Good Automated Manufacturing Practices (GAMP), meeting Food and Drug Administration (FDA) and International Organization for Standardization (ISO) requirements.

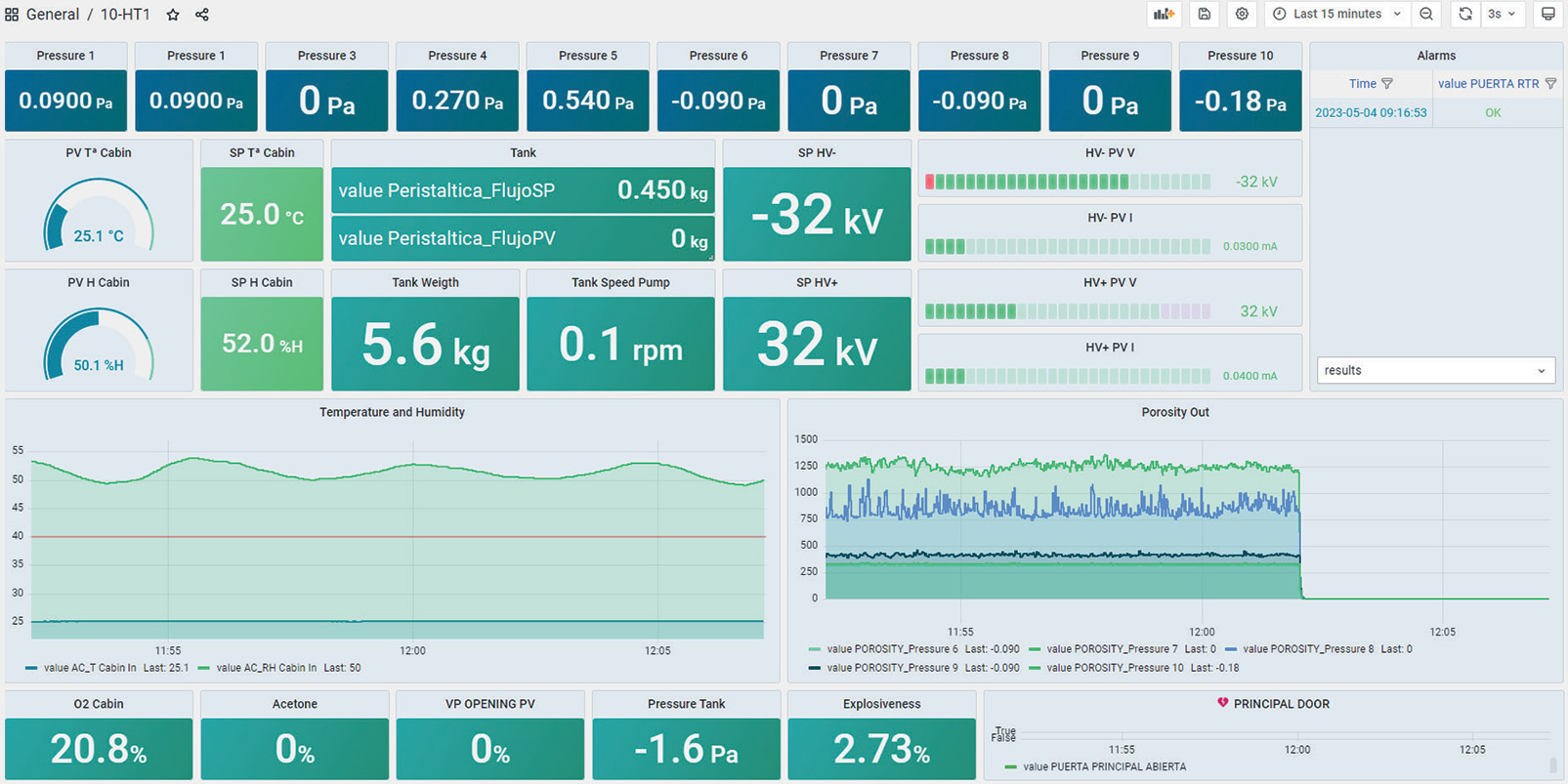

Batch-to-Batch Reproducibility

Consistency must be maintained when fabricating medical and pharmaceutical products to ensure standards and specifications are met. The optional High-definition Process Data Hub enables monitoring of all processing parameters and stages throughout the electrospinning process, along with internal signals of the machine. Some valuable datapoints that are captured continuously include temperature, humidity, voltage, flow rate and rotational speed, and needle translation. The system also senses and documents when the door has been opened or any alarm set by the user that has been triggered. This enables the advanced sensors to monitor parameters and for the user to evaluate how a batch has varied if the samples fluctuate post-development.

Versatile Emitter and Collector Options

The LE-100 BioTubing offers versatility through a wide range of compatible materials, solvents, and electrospinning configurations. Researchers have the flexibility to experiment with various materials (polymers, ceramics, metals, additives or their blends), emitters (single-phase, coaxial, triaxial, multi-needle, needle-less, among others), spinning orientations (vertical, angled, horizontal), and collectors (flat plate, drum, mandrel, and dummy collector) to fabricate nanofibers and particles with different properties for numerous applications all in a single integrated electrospinning unit.

Support & Service

Top-tier comprehensive US-based support and service for the LE-100 BioTubing and accessories, including installation assistance, training, maintenance, and technical support are available to help users maximize the performance and reliability of the equipment.

Fluidnatek® LE-100 biotubing

Product Accessories

High Definition Process Data Hub

Collector Variety

The system includes a specialized collector designed for small diameter mandrels and a dummy collector. It also offers optional upgrades to rotating drums and/or a flat plate collector. These options facilitate the production of aligned fibers, tubular structures, and large-area nanofiber sheets.

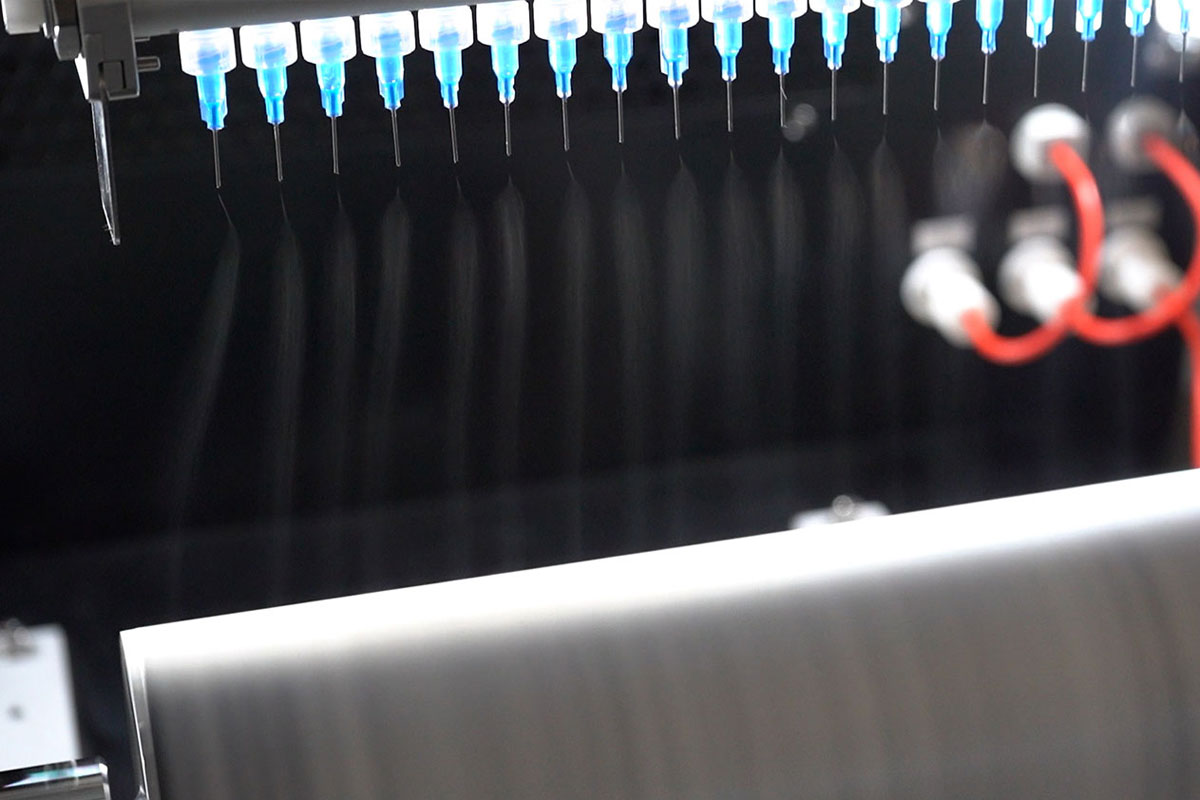

Syringe Pump Options

The LE-100 BioTubing comes with a twin-channel syringe pump. A second twin-channel syringe pump can be added as an optional upgrade. They can be used for single-phase or coaxial processing, or to process two different materials with independent voltages. These pumps accommodate batch volumes ranging from 1 mL to 560 mL, providing flexibility for diverse experimental setups. Linear forces up to 330 N allow users to operate with high-viscosity solutions for the most challenging applications.

High Voltage Options

The LE-100 BioTubing is equipped with four bipolar high voltage supplies, allowing users to operate at voltages from -30 to +30 kV. Two bipolar voltages can be used for two separate needle setups, and the remaining two can be used for the collectors (main collector and dummy collector). These configurations enhance process flexibility for complex material deposition, including proper sample adhesion when coating different samples or substrates. They also allow for the reorganization of functional groups in the material at the molecular level, enabling the processibility of solutions that exhibit longer jets.

Advanced Emitter Options

Optional linear multi-emitter spinning heads, available in single-phase or coaxial configurations, enable high-throughput production. Field deflectors can be added to improve deposition uniformity across wide collectors.

Motion and Positioning Controls

Automated X, Y, and Z-axis motion systems allow precise control over emitter & collector positioning and distance. These features improve sample consistency and enable the production of uniform coatings or complex structures. Samples can be easily coated on specific areas by fully controlling each axis on the touch screen panel

Process Optimization Tools

Accessories such as a solvent-gas jacket system, gas-assisted electrospinning modules, and Taylor cone visualization systems enhance process stability, especially when working with volatile or high-viscosity solutions. To further enhance process control, Industry 4.0-oriented software features enable continuous real-time monitoring of all machine parameters, with updates every second. These capabilities allow users to remotely visualize the machine’s operation and conduct in-depth analyses of each batch, facilitating improved traceability and reproducibility.

For added standardization, a batch ID feature can be implemented to streamline process documentation. Furthermore, an optional Audit Trail upgrade logs all events occurring during machine operation, providing a comprehensive record that supports quality assurance and compliance requirements.

Software and Data Management

The LE-100 offers advanced software capabilities, including multi-user access, recipe management, data logging, and batch control. Optional upgrades, such as the High-Definition Process Data Hub, allow real-time monitoring of over 20 parameters.

Fluidnatek® LE-100 biotubing

Electrospinning & Electrospraying Applications

Tissue Engineering

Electrospun nanofibers are used to create scaffolds for tissue engineering applications. These scaffolds mimic the extracellular matrix, providing a supportive environment for cell growth and tissue regeneration. They are prevalent in wound healing, bone regeneration, nerve regeneration, and more.

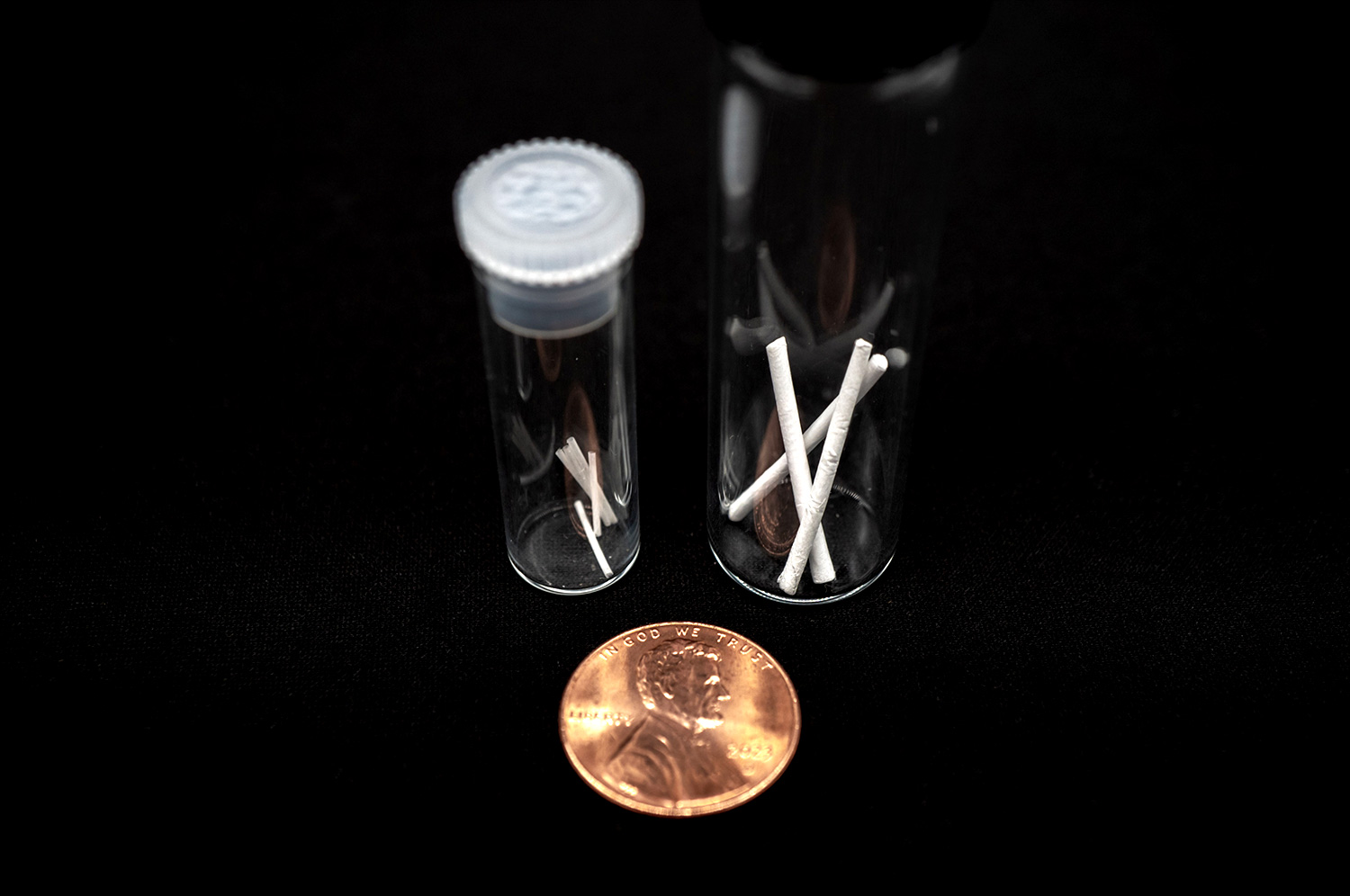

Bio Textiles

BioTextiles are fibrous materials used in healthcare and biomedical applications. Electrospinning offers a highly customizable method of fabricating biotextiles, allowing careful tuning of mechanical, chemical, and biological properties of the nanofibrous material. Electrospun biotextiles are typically biocompatible and can be fabricated from polymers or organic materials that are biodegradable or bioresorbable. Electrospun yarns can be loaded with active pharmaceutical ingredients (APIs) to create drug eluting sutures,

Medical Devices

Whether as coatings for prefabricated structures, active ingredient additives, or total device fabrication, medical devices implement electrospun nanofibers and particles for enhanced therapeutic effectiveness. These fibers and particles can allow for improved performance in mechanical properties, biological microenvironment control, cellular integration, and many more application-specific advantages.

Drug Delivery

Electrospun fibers and/or particles can be loaded with drugs or therapeutic agents and used as drug delivery systems. Precisely controlled electrospinning parameters allow the high surface area-to-volume ratio and tunable properties of nanomaterials, providing controlled release of drugs, making them suitable for targeted and sustained drug delivery.

Fluidnatek® LE-100 biotubing

Product Knowledgebase

Webinar

Advancing sustainable, animal component-free (ACF) materials for cell culture is critical…

Blog

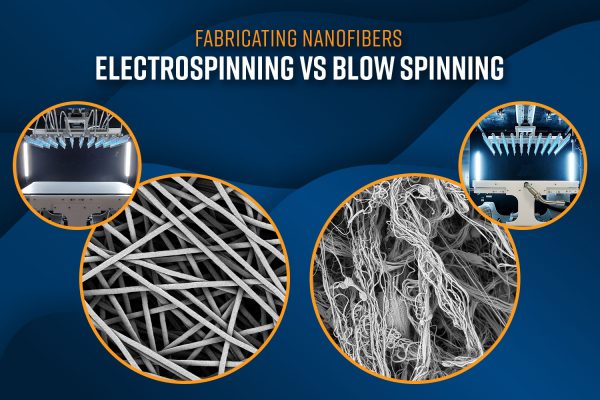

Fabricating Nanofibers: Electrospinning Vs Blow Spinning

Nanofibers, with their high surface area-to-volume ratio, tunable porosity, and mechanical…

White Paper

Fabrication and Characterization of Electrospun Fibers

Polymer fibers are produced from synthetic or natural polymers and engineered to deliver a…