Contamination can have a wide variety of undesirable effects in manufacturing processes such as polishing, surface treatment, coating application, and etching. Some sources include finger oils from handling, atmospheric dust and dirt, and process lubricants. While best practices such as personal protective equipment use and appropriate transportation will help keep samples clean, it maybe necessary to apply precleaning steps to ensure a reproducible level of cleanliness. Post cleaning, surfaces may require testing to confirm whether they are ready to proceed to the next step. The ideal test measurement is quantitative, sensitive, fast, automated, and easy to interpret. Contact angle is one such measurement that can fulfill these requirements.

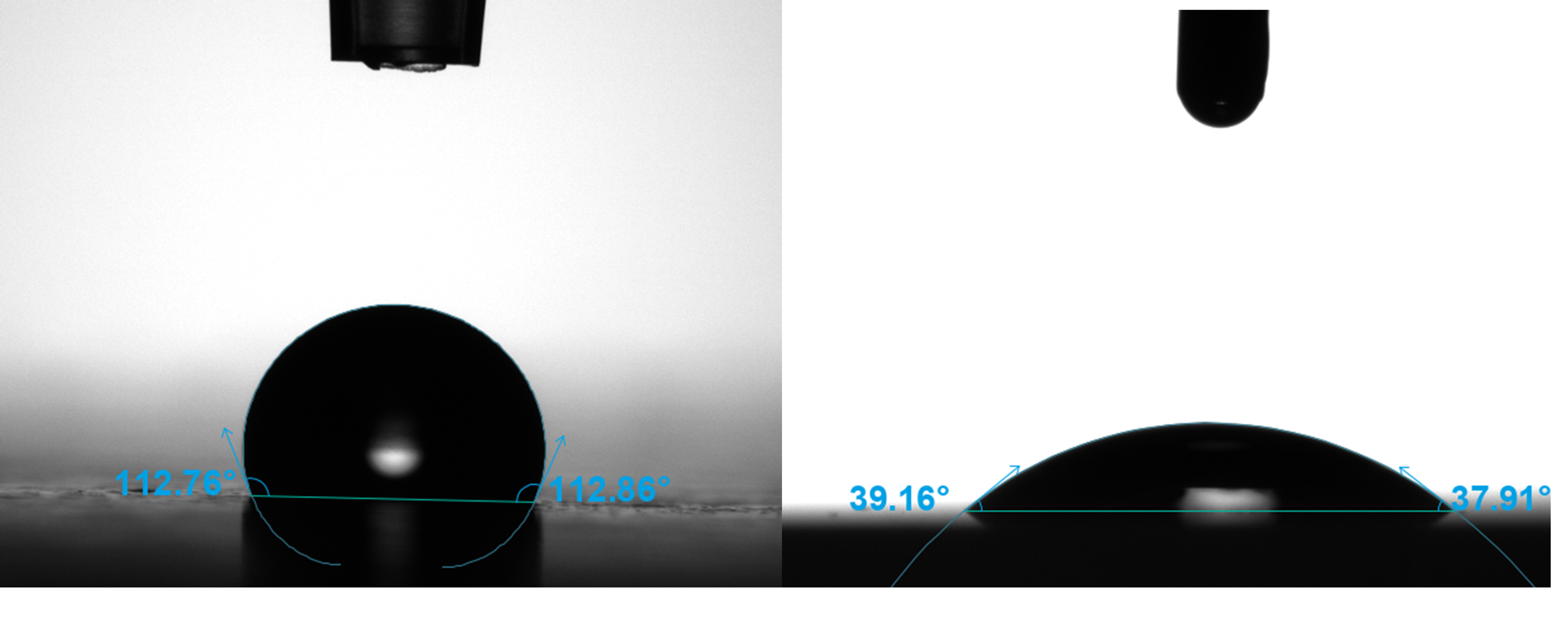

Contact angles represent the equilibrium condition when a liquid drop is placed onto a surface. Water is most commonly used as a probe, and how much the water “balls up” indicates how much the surface repels or attracts the water. Surfaces where the drop becomes more spherical are hydrophobic and typically have contact angles of 90° or greater. Conversely, surfaces where the water droplet spreads readily are hydrophilic and have contact angles less than 90°. Probe liquids are very sensitive to any molecules that are present on the surface, so unexpected differences in the contact angle, or even in the left and right sides of the droplet, typically indicate the presence of a contaminant. For non-porous, non-reactive surfaces, contact angle equilibrium is reached in a fraction of a second and measurements can be taken quickly.

Quality Control and Quality Assurance via contact angle

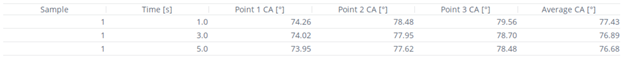

The Theta Flex optical tensiometer has automated features for drop dispensing, drop placement, and substrate movement to allow for several contact angles to be measured in quick succession. A high-speed camera is used as a recording device to take images of the drop. Contact angles can be measured automatically with the bundled OneAttension software, where each frame is analyzed for its left and right contact angle. Additionally, OneAttension has a Batch Contact Angle feature that allows for contact angles to be taken at a specified time during the recording process. The measurements can be repeated the desired number of times so that replicates and averages can be obtained for each sample in an automated, repeatable fashion. An automated sample movement stage can be added to the measurement to further reduce the amount of user interaction needed to provide repeatable data. Each measurement is automatically timestamped so that the data can be easily tracked from day to day. This streamlined data reporting is ideal for quality assurance and quality control where sample trends can be observed over minutes, hours, days, and weeks. To further provide ease-of-use and operator-independent controls, a bar code scanner can be used to assign samples a bar code or QR code. Once the operator scans this code, previously saved measurement recipes will be automatically loaded into the software.

The Theta Flex optical tensiometer and the OneAttension software represent a powerful tool for those interested in tracking the quality of their surface processes. Its automated hardware and software features allow for repeatable testing and monitoring. To see the Theta Flex batch contact angle measurement in action, please see the video below.