Surface contamination is a concern for a wide variety of industries and their production processes such as polishing, surface treatments, coatings, bonding, and etching. Contamination can arise from a variety of sources, such as process oils and lubricants, aerosolized particles, residues from handling, or chemical reactions like oxidation. Downstream processes like coating applications, chemical and/or mechanical polishing, surface treatments, and mechanical assembly could be affected by these contaminants. The presence of contaminants during the downstream process could lead to a significant waste of time and materials. To prevent large-scale waste and to keep costs in line, tracking the overall level of surface cleanliness is often implemented at various checkpoints throughout the manufacturer’s process. A robust and effective testing protocol can enable a higher level of quality control. An effective testing protocol needs to be sensitive to a wide variety of surface contaminants, be quantitative, and be easy to implement.

Methods for measuring surface cleanliness:

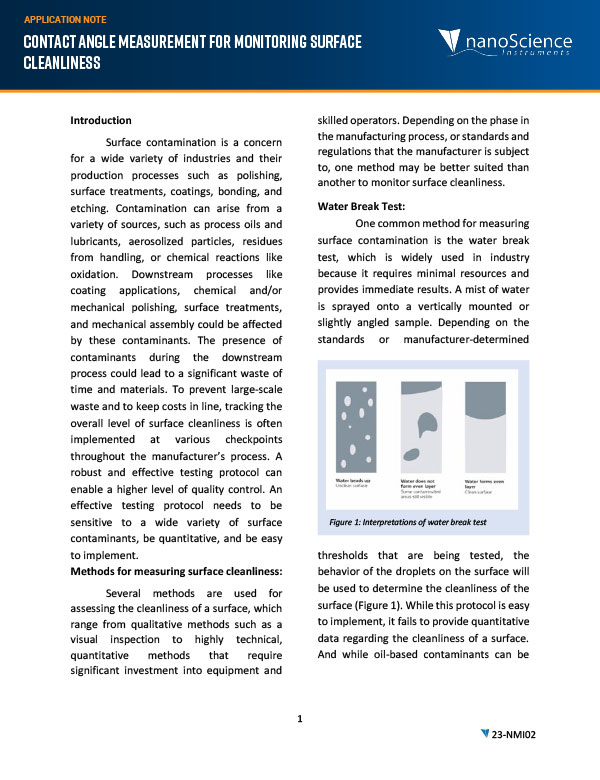

Several methods are used for assessing the cleanliness of a surface, which range from qualitative methods such as a visual inspection to highly technical, quantitative methods that require significant investment into equipment and skilled operators. Depending on the phase in the manufacturing process, or standards and regulations that the manufacturer is subject to, one method may be better suited than another to monitor surface cleanliness.