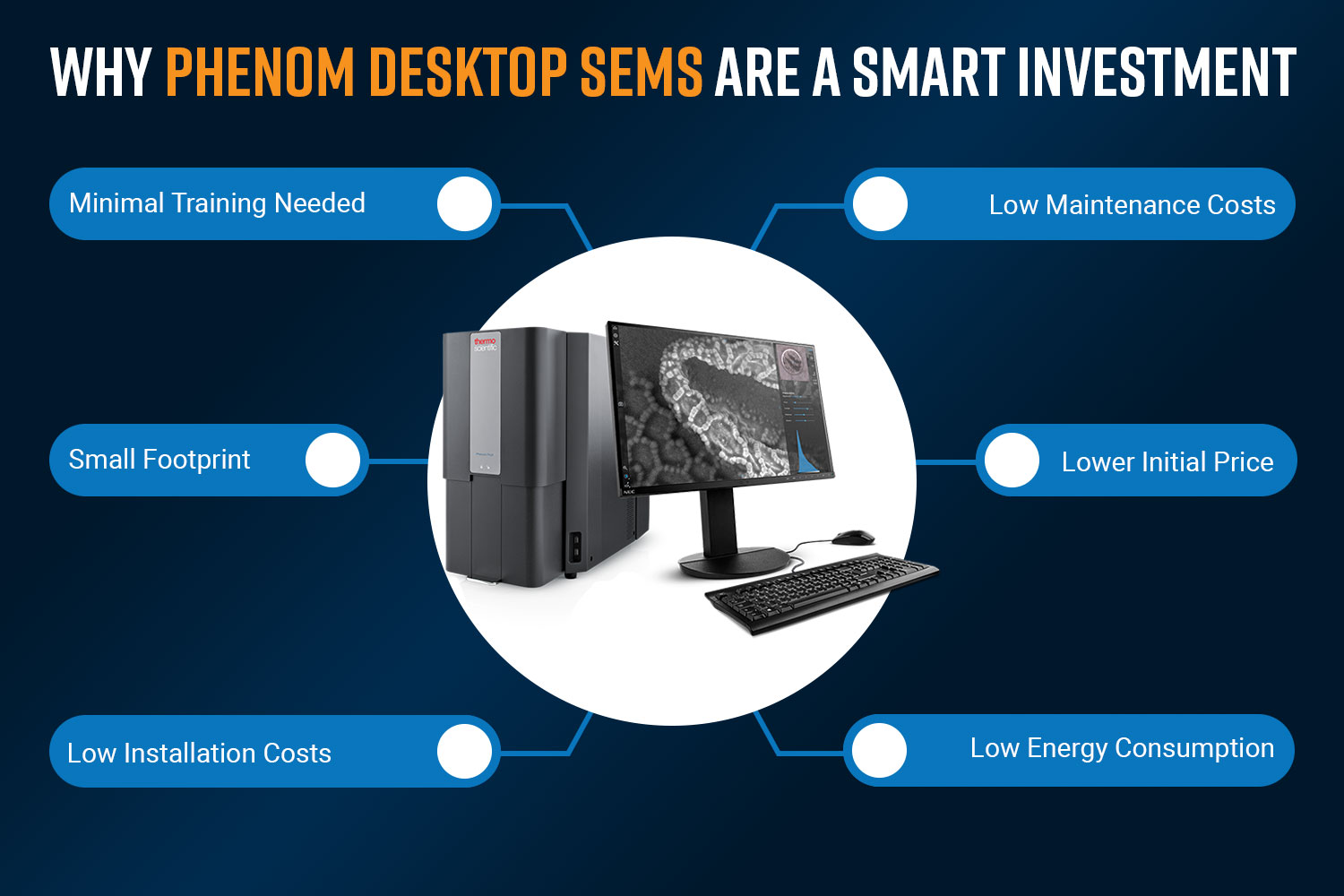

When acquiring a new scanning electron microscope (SEM), it can be challenging to identify a solution that not only delivers exceptional performance but also remains financially feasible. Among the myriad of options available, Phenom Desktop SEMs have emerged as a leader in affordability without compromising on quality or functionality. Widely regarded as the best-selling desktop SEMs on the market, Phenom SEMs embody the capabilities of larger, floor-model SEMs without the barrier of a complex user interface.

In this blog, we delve into why Phenom Desktop SEMs stand out as the budget-friendly choice for discerning buyers. From their compact design to intuitive operation, we uncover the factors contributing to the remarkable cost efficiency of Phenom Desktop SEMs, offering insights into why they have become the preferred solution for those seeking high-performance electron microscopy within reasonable budget constraints.

Breaking it down: 8 reasons why Phenom Desktop SEM has a low cost of ownership

Initial purchase price

The cost of acquiring the SEM itself is a significant factor. The purchase price is influenced by various factors such as achievable resolution, physical size, type of electron source, detectors, specimen mounts, and software. Desktop SEMs lie at the lower end of the cost spectrum starting below $100,000 for an entry-level model. Phenom SEMs represent an incredible value for those interested in obtaining an in-house SEM with comparable performance to many floor model systems and are available in four models that suit a range of applications.

Space and infrastructure

The Phenom Desktop SEM has a compact footprint that can fit atop most surfaces available in labs, offices, or even warehouses and production floors. A standard wall outlet can supply power to the Phenom SEM and unlike high-end electron microscopes, precise climate control and vibrational dampening are not needed. Therefore, for most environments, it is highly likely that no additional costs related to pre-installation facility upgrades would be needed.

Installation costs

Phenom Desktop SEMs can be installed in as little as a day, either by a trained professional or by the tool owners themselves. Since they fit on a tabletop or benchtop surface, installation work will pose minimal disruption to the surrounding environment and business can continue as usual.

Training

The typical training time for learning how to operate any Phenom SEM is about 4-8 hours, depending on the user’s level of prior experience. Since the Phenom User Interface is remarkably intuitive and stacked with single-click functions (e.g., auto-focus, auto-brightness and -contrast, and click-to navigation), mastering the basic workflow as well as learning more advanced functions (e.g., automated image mapping, energy-dispersive spectroscopy, topographic imaging) doesn’t involve a steep learning curve.

Energy consumption

While imaging, an SEM can consume anywhere from several hundred watts to a few kilowatts per hour. The exact energy consumption will be influenced by factors such as accelerating voltage, beam current, vacuum level, and usage duration. Because Phenom SEMs operate at lower accelerating voltages and have a small footprint, their power usage falls on the lower end of the spectrum. When in operating mode, they consume a maximum of 150 W and 120 W when on standby.

Maintenance

SEMs require regular maintenance to ensure optimal performance. The typical maintenance frequency for a Phenom SEM is once every two years and can involve an electron source replacement and preventative maintenance. In contrast, floor model SEMs have routine issues and would require regular maintenance to keep the SEM in working condition. Due to the common occurrence of problems, service agreements are often required for floor model SEMs.

Downtime and repairs

Unforeseen downtime due to equipment failures or repairs can disrupt operations and incur additional costs, such as lost productivity or expedited repair services. The innovative design of Phenom SEMs and their minimal facility requirements ensure that they experience minimal unplanned downtime. Phenom SEMs can handle power fluctuations and failure by automatically recovering (start-up and pump down). All models of Phenom come with uninterrupted power supplies to ensure stable power is supplied to the instrument during brownouts and power surges.

Software and data management

SEMs generate large amounts of data that need to be stored, managed, and analyzed. Costs associated with software licenses, data storage, and data management should be considered. Phenom SEMs come with access to the latest version of the Phenom User Interface and ProSuite software, and all models can be upgraded with Python Programming Interface (PPI) for advanced scripting and automation. The Phenom XL comes standard with PPI and is compatible with ParticleX automation software. One of the benefits of the Phenom is that no software purchases require a subscription to maintain, and once purchased, the software is supported for the lifetime of the instrument at no additional cost.

Key Takeaways

Phenom’s low cost of ownership makes it an attractive solution for bringing SEM in-house to your organization or laboratory. Across the board, the Phenom’s innovative design, small footprint, and advanced capabilities deliver exceptional value for its users:

- Low initial purchase price compared to floor-model systems.

- Installation and training can take place in a few days.

- Can fit on a desktop and can operate in noisy environments.

- Minimal maintenance and unplanned downtime ensure efficient operation.

- Come standard with software that expands capabilities for data collection and analysis.