Langmuir & Langmuir-Blodgett Troughs

KSV Nima Langmuir & Langmuir-Blodgett Troughs

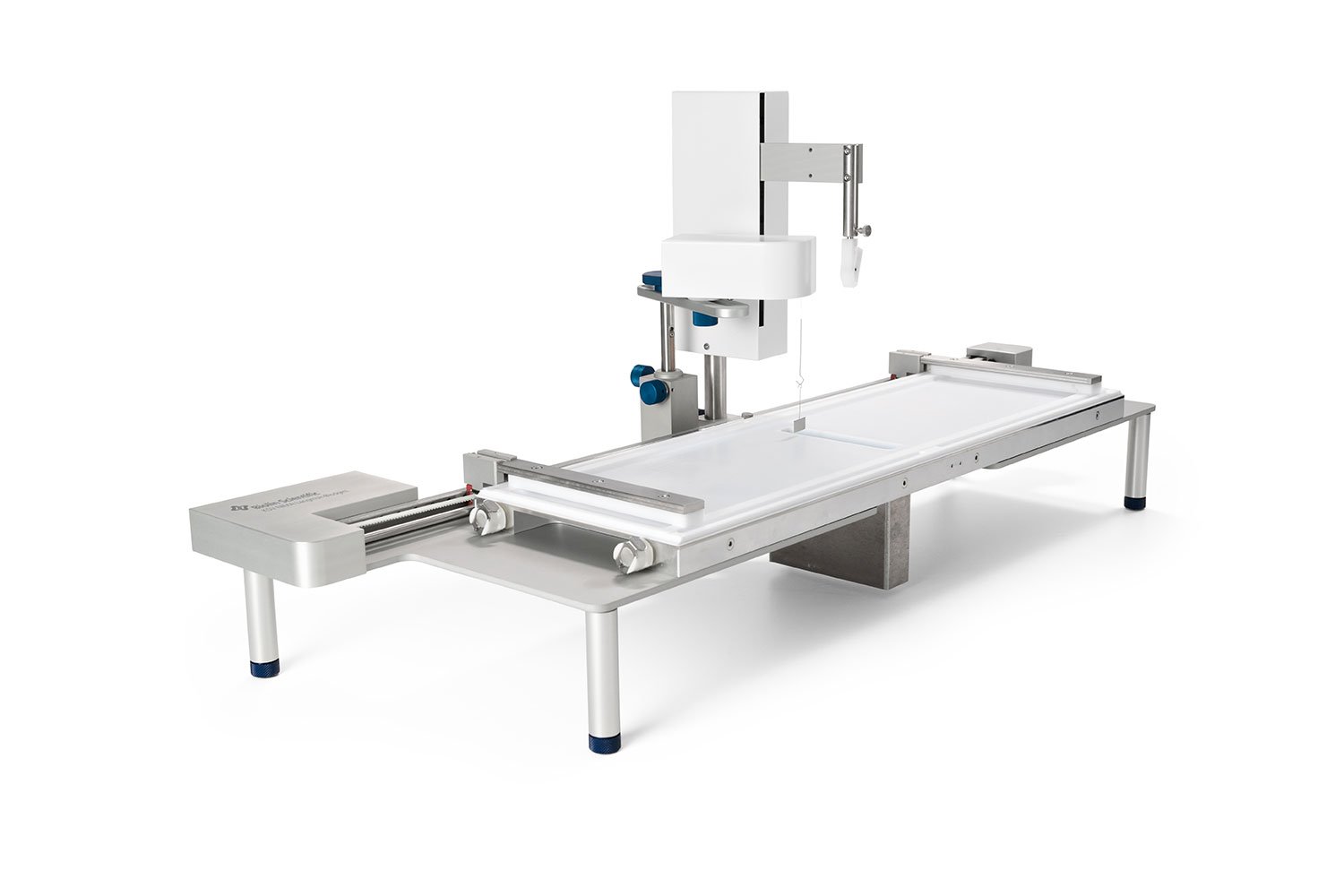

KSV NIMA has the widest selection of Langmuir & LB Troughs of various sizes and functions for creating thin film coatings with controlled packing density. The modular trough systems are designed with a frame capable of fitting multiple trough tops. The result is a flexible, and interchangeable solutions for multiple applications. Troughs can also be customized upon request.

Modularity

With an open, modular design and the widest range of Langmuir & LB troughs on the market, you can build your setup to fit your size and function requirements

Controlled Film Parameters

KSV NIMA instruments offer precise control over molecular packing density and coating thickness, and homogeneity of deposition

Expandability

Build specialized configurations for advanced studies, or add characterization tools such as Brewster Angle Microscopes and Surface Potential Sensors

Download the KSV Nima Langmuir & Langmuir-Blodgett Troughs Product Brochure:

See available configurations

KSV NIMA Product Options

Standard Langmuir Troughs are available in several sizes, small, medium or large and can be configured depending on the area of research. The smaller trough tops are preferable when using expensive molecules. The bigger systems provide more space for characterization instruments and provide a higher compression ratio.

Create thin films at the air-liquid or liquid-liquid interface. Measure surface pressure-area isotherms to determine monolayer compressibility, molecular orientations, and area per molecule at various stages of compression.

Fabricate thin films and transfer to a substrate via either Langmuir-Blodgett (vertical) or Langmuir-Shaefer (horizontal) deposition. Controlling the surface pressure of the transfer gives exquisite control over the packing density of the resulting film.

Probe the properties of interfacial layers and collect highly sensitive measurements of interfacial viscoelasticity both at air-liquid and liquid-liquid interfaces. Simultaneously measure and control surface pressure thanks to easy integration with KSV NIMA Troughs.

Langmuir & Langmuir-Blodgett Troughs

Product Accessories

The KSV NIMA Surface Potential Sensor (SPOT) is used for determining molecular orientation changes in Langmuir films. Together with the surface pressure sensor included in all KSV NIMA L & LB Troughs, it gives an in-depth view of the Langmuir monolayer interactions.

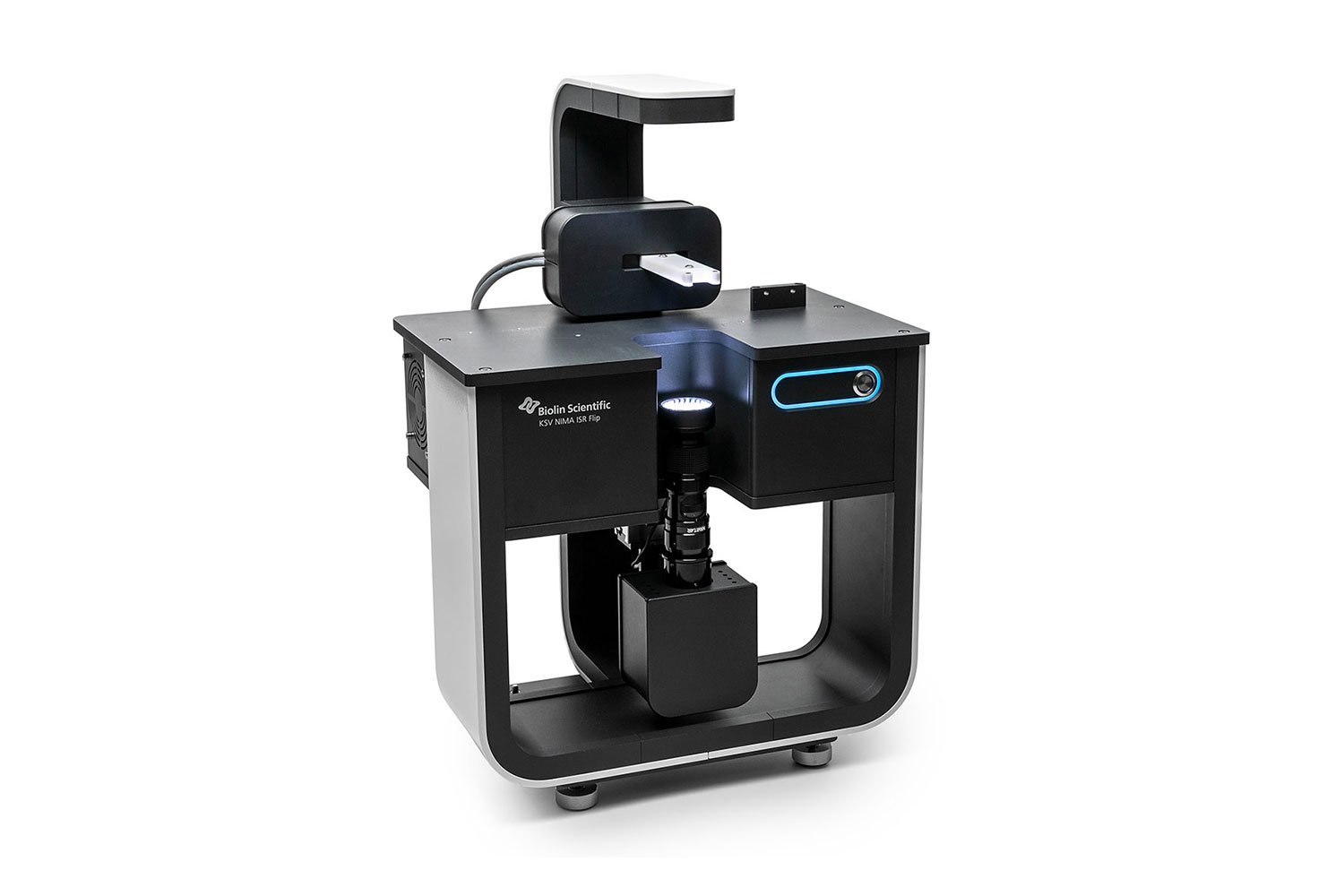

MicroBAM (Brewster Angle Microscope) enables visualization of monolayers, typically at the air-water interface in a Langmuir Trough. MicroBAM provides information on homogeneity, phase behavior, and film morphology without the need for any external agents such as fluorescent dyes.

Quickly and precisely coat large areas of flexible substrates with the KSV NIMA Roll-to-Roll LB trough system, designed for high throughput. In the Roll-to-Roll LB process, a flexible substrate is fed continuously fed into the trough where it passes through the monolayer of nanoparticles or other material.