The crux of energy storage research concerns optimizing the properties of electrochemical devices to improve efficiency, reliability, safety, and cost – four core concepts that push ceaseless efforts into the battery industry. Since batteries are such a ubiquitous technology, critical to the everyday lives of billions, it is easy to recognize why diagnosing them and revamping them, with respect to those core concepts, are paramount objectives.

Battery components

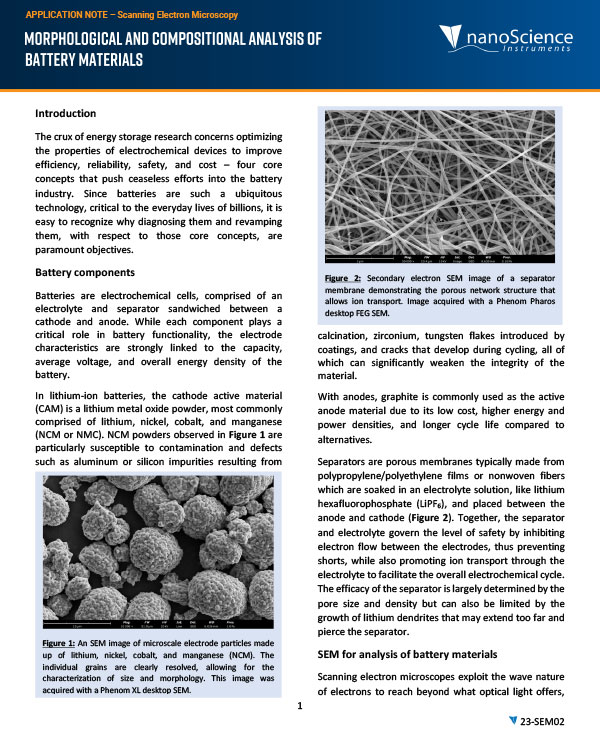

Batteries are electrochemical cells, comprised of an electrolyte and separator sandwiched between a cathode and anode. While each component plays a critical role in battery functionality, the electrode characteristics are strongly linked to the capacity, average voltage, and overall energy density of the battery.

In lithium-ion batteries, the cathode active material (CAM) is a lithium metal oxide powder, most commonly comprised of lithium, nickel, cobalt, and manganese (NCM or NMC). NCM powders observed in Figure 1 are particularly susceptible to contamination and defects such as aluminum or silicon impurities resulting from calcination, zirconium, tungsten flakes introduced by coatings, and cracks that develop during cycling, all of which can significantly weaken the integrity of the material.