2-Day QCM-D Short Course | Alexandria, VA | September 2025

2-Day QCM-D Short Courses: Join our specialized 2-day QCM-D (Quartz-crystal Microbalance with Dissipation monitoring) Short Course. Held in Alexandria, VA, this immersive program is designed for both experienced practitioners and newcomers, offering an in-depth exploration of both fundamental and advanced QCM-D techniques. Hosted at our state-of-the-art facilities, the course features hands-on sessions with the latest […]

2-Day SEM Short Course | Phoenix, AZ | November 2025

2-Day SEM Short Courses: Explore the microscopic world in our specialized 2-day Scanning Electron Microscopy (SEM) Short Course. Held in Phoenix, AZ during the fall, this immersive program is designed for both experienced practitioners and newcomers, offering an in-depth exploration of both fundamental and advanced SEM techniques. Hosted at our state-of-the-art facilities, the course features […]

Nanoscience & Xplore Instruments Announce Strategic Partnership for Distribution of Polymer Micro Compounding Equipment

Nanoscience Instruments and Xplore Instruments BV Announce Strategic Partnership for Distribution of Polymer Micro Compounding Equipment in the US New collaboration enhances accessibility to advanced polymer processing solutions in North America Nanoscience Instruments, a leading provider of scientific instrumentation and service solutions for customers in the United States and Canada, is excited to announce a […]

Maximizing Efficiency in Polymer R & D with Microcompounders

In polymer processing and material research, achieving uniform dispersion and distribution of additives and precise formulation control is crucial for developing advanced materials. This is achieved by a process called compounding. Microcompounding Microcompounding is a small-scale polymer processing technique that involves mixing, blending, and modifying polymer materials using a specialized miniaturized instrument. It mimics […]

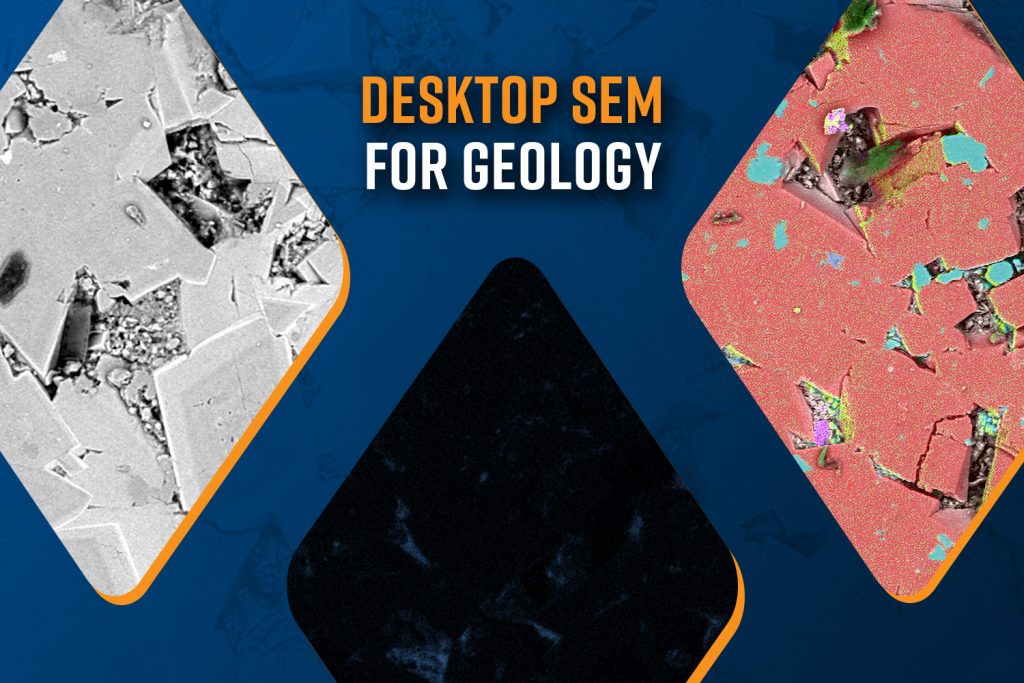

Desktop Scanning Electron Microscopy in Geology

Scanning Electron Microscopy (SEM) is a versatile tool in geology used in high-resolution imaging and chemical analysis of rocks, minerals, and microfossils. SEM provides detailed images of mineral morphology and surface textures, which are essential for identifying minerals and understanding their growth patterns. Studying the deformation features using an SEM helps reconstruct the geological history […]

Enhancing SEM Performance with Ion Milling Technology

In material science, cross-section polishing is a critical method to enable the detailed examination of a sample material’s microstructure. This technique is essential for understanding the composition, properties, and potential applications of various materials, from metals and ceramics to semiconductors and battery materials. By providing a pristine, flat, and highly reflective surface, cross-section polishing enables researchers and engineers to see inside the microscopic world of materials with precision and clarity.

2-Day SEM Short Course | Alexandria, VA | September 2025

2-Day SEM Short Courses: Explore the microscopic world in our specialized 2-day Scanning Electron Microscopy (SEM) Short Course. Held in Alexandria, VA, this immersive program is designed for both experienced practitioners and newcomers, offering an in-depth exploration of both fundamental and advanced SEM techniques. Hosted at our state-of-the-art facilities, the course features hands-on sessions with […]

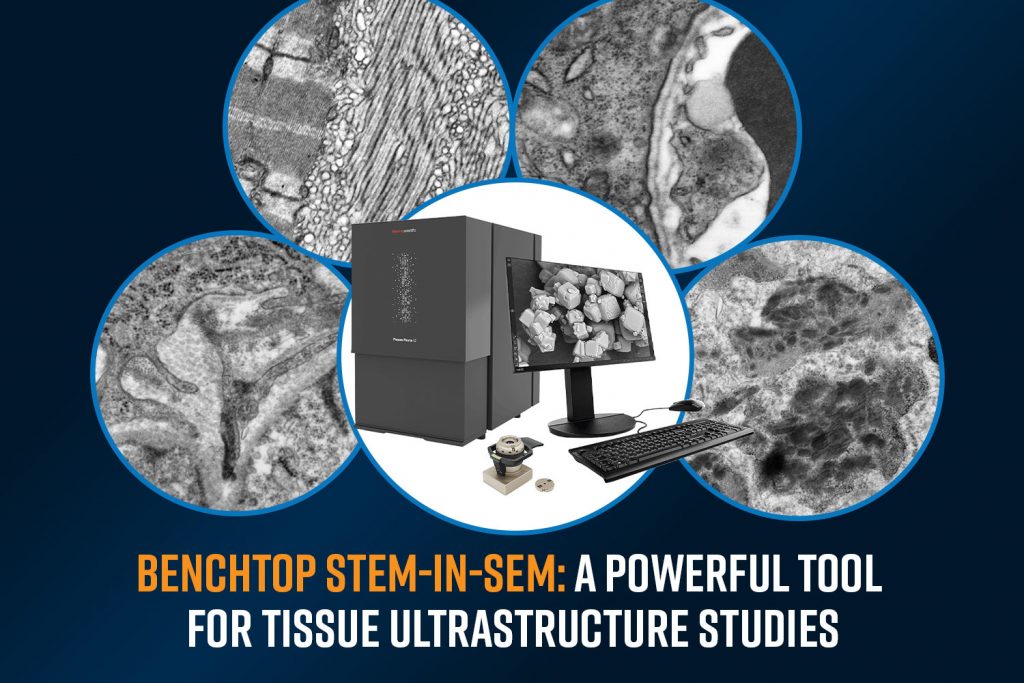

Benchtop STEM-in-SEM: A Powerful Tool for Tissue Ultrastructure Studies

Understanding the ultrastructure of biological tissues is essential for advancing medical research, disease diagnostics, and drug development. Traditionally, histological techniques such as optical microscopy have been the standard for tissue analysis. While these methods provide valuable insights, they are often limited in resolution, making it difficult to visualize fine structural details at the nanometer scale. […]

Essentials of Polymer Compounding

Polymer compounding is a fundamental process in materials engineering that involves blending polymers with various additives to enhance their properties and performance. This allows manufacturers to tailor polymer materials to meet specific requirements for different industries including automotive, aerospace, healthcare and consumer goods. By tailoring the mechanical, thermal, and chemical properties of polymers, their range of applications can be significantly increased.

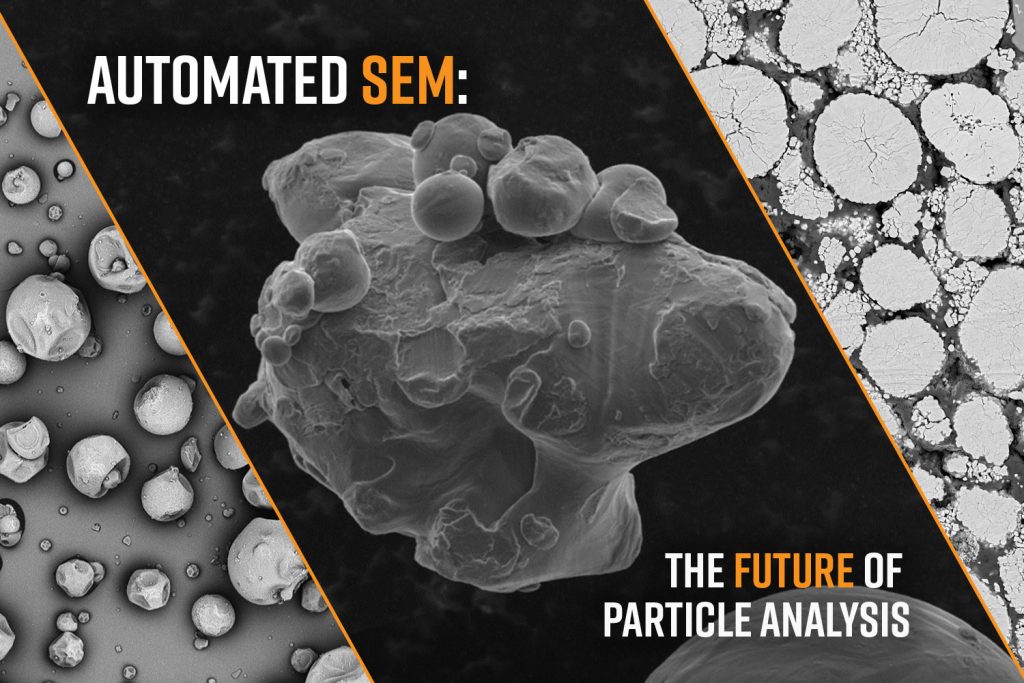

Automated SEM: The Future of Particle Analysis

Particle analysis involves characterizing the size, morphology, and composition of powders and particulate matter to describe their properties in a precise and statistically significant manner. Some of the most common areas where particle analysis is critical are in advanced manufacturing, forensic analysis, and environmental applications. Among the different techniques for conducting particle analysis, scanning electron […]