Scanning Electron Microscopy (SEM) is an indispensable tool in various scientific and industrial fields, providing high-resolution images of sample surfaces. Among the numerous parameters that influence SEM imaging, beam intensity is a crucial factor that directly affects the quality of information gathered from the sample. In this blog, we will delve into the significance of beam intensity in SEM imaging, exploring how it impacts image resolution, contrast, signal-to-noise ratio, and sample integrity.

Understanding Beam Intensity

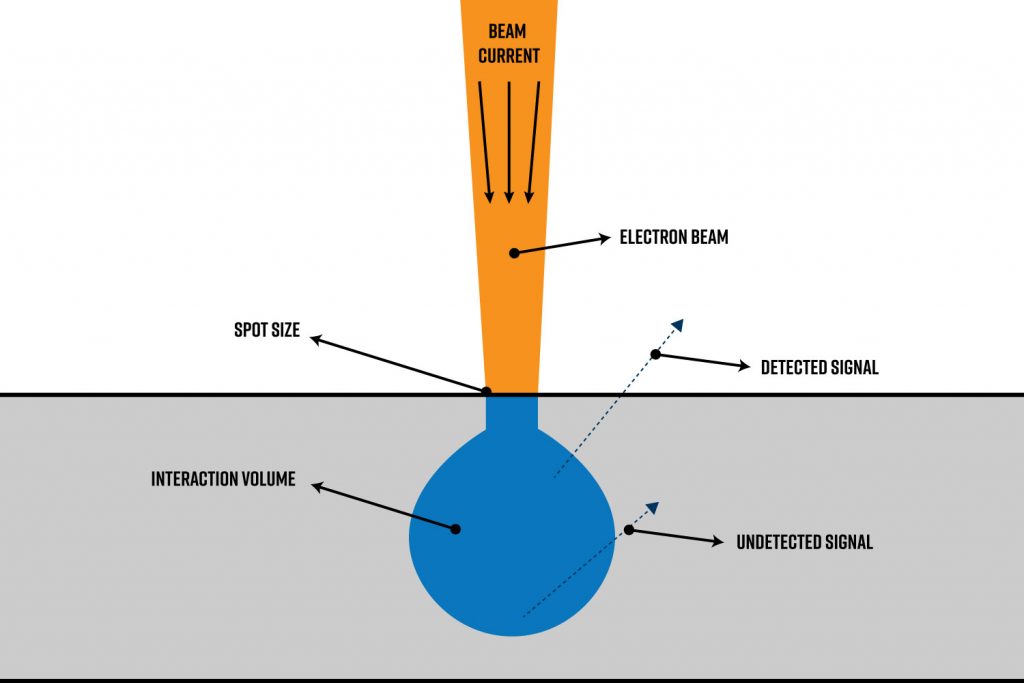

Beam intensity (also referred to as beam current) in SEM refers to the number of electrons in the electron beam per unit time incident on the sample (Figure 1). To grasp how this connects to the operation of the SEM, it’s important to highlight several key points about electromagnetic lenses. The two main types of lenses in a SEM are the condenser and objective lenses. The condenser lens is responsible for demagnifying the beam of electrons generated at the electron source. Condenser apertures can also be used to limit the number of electrons that pass through it. After the condenser lens assembly is the objective lens. The objective lens focuses the beam onto the sample surface.

By adjusting the currents through the condenser and objective lenses the size and intensity of the “probe” (also referred to as spot size) can be finely tuned.1 For SEM, the beam current is often measured in nanoampere (nA) range. Beam intensity is typically chosen based on the desired magnification range. Therefore, beam intensity can vary during an SEM session depending on the size of the features being analyzed and the level of detail required to visualize the sample.

Effects on Image Resolution

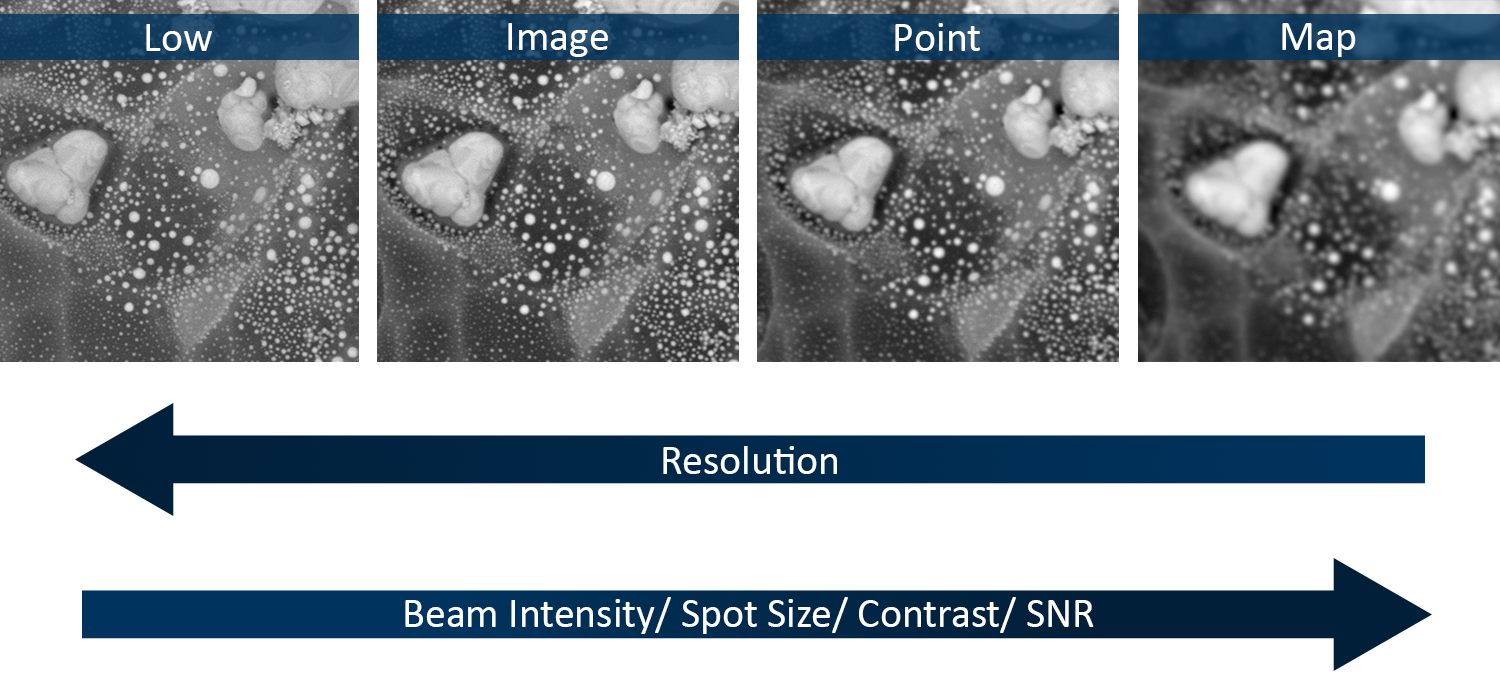

The resolution of SEM images is influenced by several factors, one of the most important being the beam intensity. This is because the beam intensity significantly impacts the resolution through its effect on spot size and interaction volume (Figure 2).

A higher beam intensity typically requires a larger spot size to accommodate the increased number of electrons, which can lead to reduced resolution. Conversely, a lower beam intensity can achieve a smaller spot size, enhancing resolution by allowing finer details to be imaged.

Beam intensity also affects the interaction volume, which is the region within the sample where electrons interact. Higher beam intensity increases the interaction volume due to more electron scattering. This larger interaction volume can blur the image and decrease resolution. Lower beam intensity reduces the interaction volume, confining electron interactions to a smaller area and thus improving resolution by producing sharper images with finer details.

Effects on Image Contrast

Contrast allows for the clear distinction between different features and materials within a sample. Without adequate contrast, it becomes difficult to differentiate between various elements, phases, or structures, leading to less informative images. Image contrast in SEM is largely determined by the interaction of the electron beam with the sample and the subsequent generation of secondary and backscattered electrons. Higher beam intensities increase the number of electrons interacting with the sample, which can enhance the generation of these signals, leading to improved contrast. However, excessive beam intensity can saturate the detectors and reduce contrast, making it difficult to distinguish fine details. Lower beam intensities, on the other hand, may not generate sufficient signal, resulting in images with poor contrast. Therefore, optimizing the beam intensity is needed to accurately visualize surface features such as edges, cracks, and surface topography.

Signal-to-Noise Ratio (SNR)

Similar to contrast, the signal-to-noise ratio (SNR) is a critical factor in SEM imaging that is directly related to the beam intensity. A higher SNR can enhance the clarity and sharpness of SEM images, potentially leading to better resolution, while a lower SNR can result in noisier images with reduced resolution.

Beam intensity plays a significant role in influencing the SNR. Higher beam intensities produce stronger signals, which can improve the SNR and lead to clearer images with less noise. However, there is a competing effect of beam intensity on the interaction volume. Therefore, careful optimization of beam intensity must be carried out to optimize the overall quality of the SEM image.

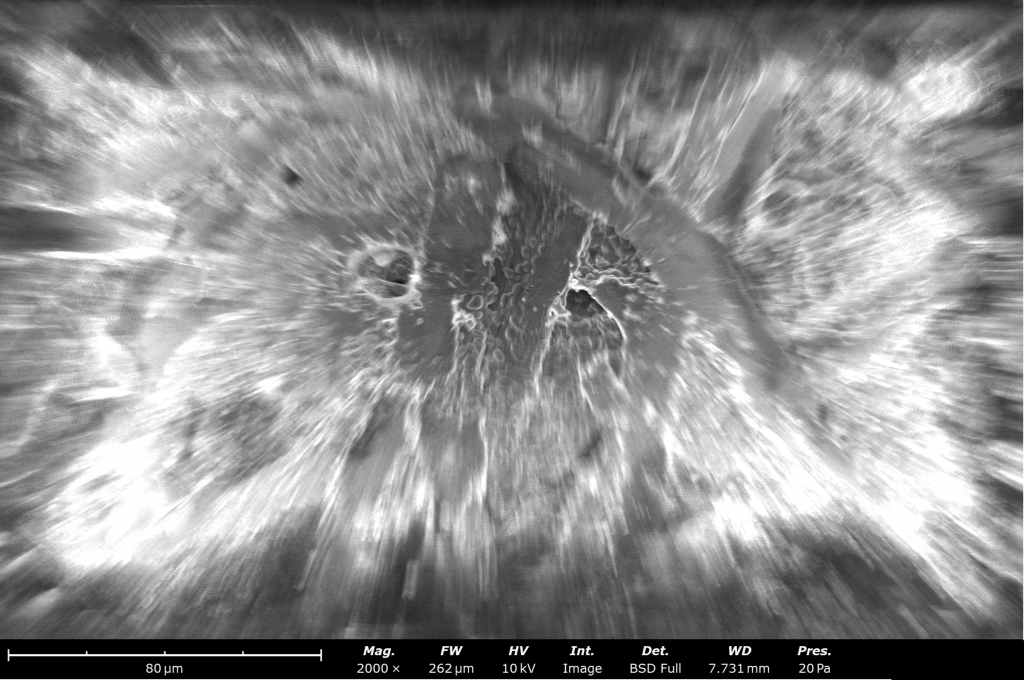

Effects on Sample Integrity

The interaction of the electron beam with the sample can lead to various forms of sample damage, including heating, charging (Figure 3), and physical alterations.2 Higher beam intensities increase the likelihood of such damage, especially for delicate or sensitive samples like biological specimens or polymers. Excessive beam intensity can cause local heating, which may alter the sample’s morphology or composition.

Lower beam intensities reduce the risk of sample damage but may not provide sufficient signal for high-quality imaging. It is crucial to adjust the beam intensity according to the sample’s sensitivity and the imaging requirements to preserve sample integrity while obtaining clear and detailed images.

Practical Considerations and Applications

Selecting the appropriate beam intensity for SEM imaging requires careful consideration of the sample type and the desired imaging outcomes. Here are some practical guidelines:

- Biological Samples: Use lower beam intensities (below 1 nA) to minimize sample damage and charging effects while maintaining sufficient contrast and resolution.

- Metallurgical Samples: Higher beam intensities (1-10 nA) can be used to obtain detailed images and compositional information without significant risk of damage.

- Nanomaterials: Moderate beam intensities (0.5-5 nA) provide a good balance between resolution, contrast, and sample integrity, allowing for detailed surface imaging without excessive damage.

Conclusion

Beam intensity is a pivotal parameter in SEM imaging, directly impacting resolution, contrast, signal-to-noise ratio, and sample integrity. By carefully adjusting the beam intensity, researchers can optimize their imaging conditions to obtain high-quality images while preserving the integrity of their samples. Understanding the significance of beam intensity helps in tailoring SEM techniques to the specific needs of various scientific and industrial applications, enhancing the versatility and effectiveness of this powerful imaging tool.

References

- K. Akhtar, S. A. Khan, S. Khan and A. M. Bahadar Asiri, “Scanning Electron Microscopy: Principle and Applications in Nanomaterials Characterization,” in Handbook of Materials Characterization, Springer, 2018, pp. 113-145. https://doi.org/10.1007/978-3-319-92955-2_4 ↩︎

- R. F. Egerton, P. Li and M. Malac, “Radiation Damage in the TEM and SEM,” Micron, vol. 35, pp. 399-409, 2004. https://doi.org/10.1016/j.micron.2004.02.003 ↩︎