The development of safe and effective biomaterials has become a critical area of study as modern medicine advances towards fully personalized healthcare. Researchers are constantly striving to improve the efficacy and biocompatibility of biomaterials.

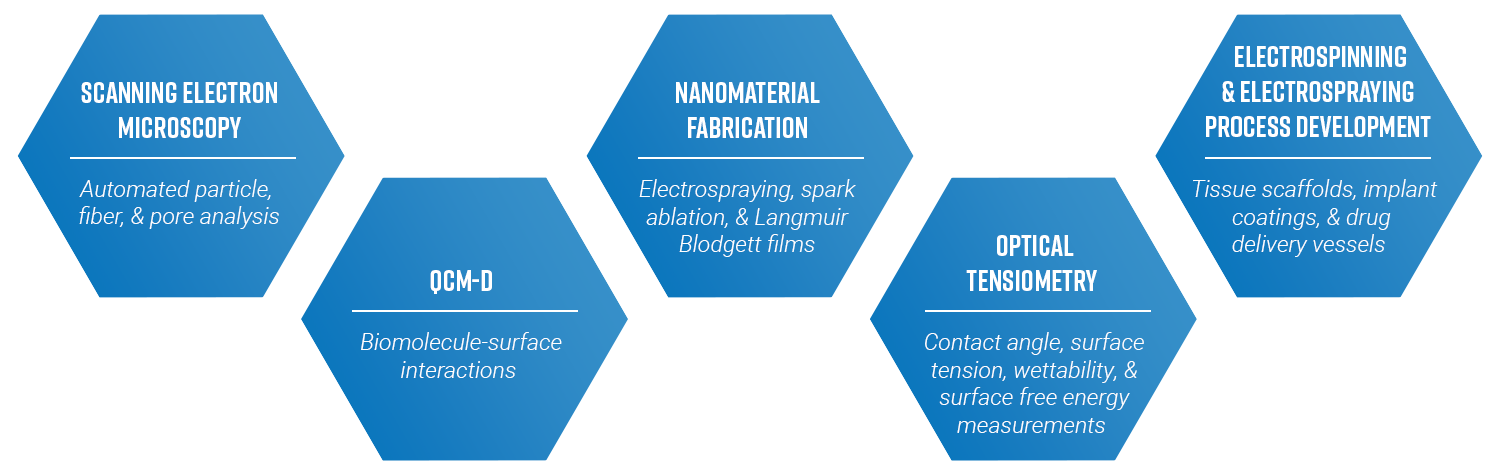

Nanoscience Instruments and our sister company, Nanoscience Analytical, offer several solutions to aid in the development and evaluation of biomaterials:

- Automated SEM (scanning electron microscopy) analysis and the characterization of biomaterials

- Analyzing cleanliness and wettability of surfaces to investigate biocompatibility

- Fabricating tissue scaffolds, coating medical implants, and optimizing encapsulated drug delivery

- Real-time monitoring of surface interactions and biomolecular processes in situ

high resolution Imaging of Delicate Samples with a Field-Emission Desktop SEM

The Phenom Pharos is the only field emission source desktop SEM (scanning electron microscope). Operating on a broad range of acceleration voltages, it eliminates the need for coating and ensures biological and polymer samples remain undamaged.

- Low kV suits imaging of soft biomaterials • 1 kV to 20kV operating voltage range

- < 2.0 nanometer resolution

- Backscattered electron, secondary electron, and energy dispersive spectroscopy detectors

- Auto-script sample tests to acquire results faster and reduce image variation

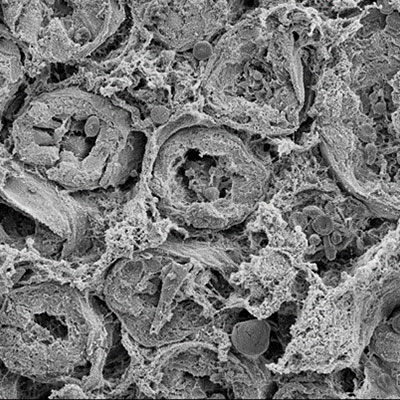

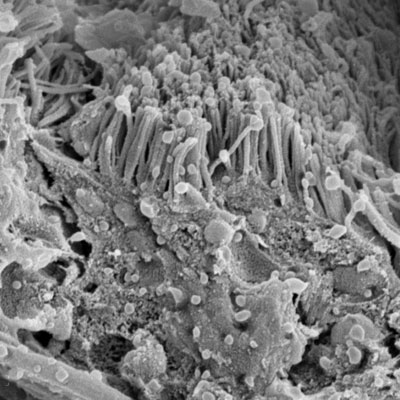

Tissue Sample Imaging

Lung tissue samples imaged with scanning electron microscopy — 2000x magnification (left side) and 30000x magnification (right side).

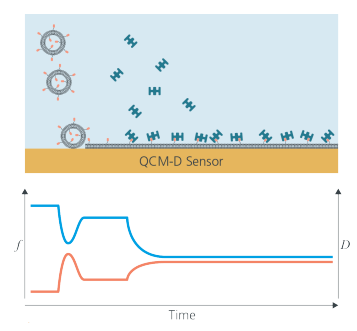

Evaluating Biocompatibility of Implants and Surface Interactions by QCM-D

At its most fundamental level, quartz crystal microbalance with dissipation (QCM-D) is an acoustic biosensor capable of measuring changes in mass at the nanogram level. Its scope of applicability in biomaterials is extensive, enabling real-time monitoring of biomolecular interactions and characterization of biomembranes. Sensors are customizable with different materials and can be adjusted to fit specific research demands, meaning that scientists can tailor the instrument to emulate real conditions. Scientists employing QCM-D can delve into protein adsorption, cell attachment, and the myriad of coatings applied on implants for evaluating and refining the composition of viable biomaterials.

QSense microbalances scrutinize the ways in which biomolecules interact with biomaterial surfaces and open many analytical possibilities for evaluating molecule-surface interactions, biosensors, implants, and drug-delivery vessels.

- Real-time monitoring of mass and viscoelastic properties

- QSoft data-acquisition software captures up to the 13th harmonic for more accurate results

- Modules for light microscopy and ellipsometry applications

- Time-resolved interaction kinetics data with 5 ms resolution

Fabricating Nanofibers and Nanoparticles for Biomedical Applications

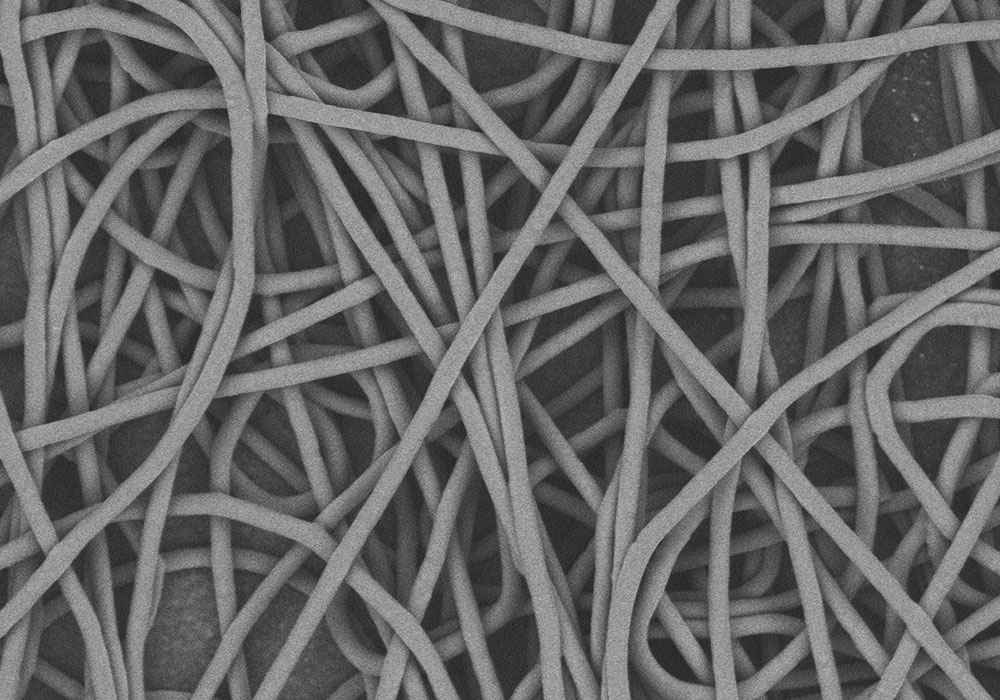

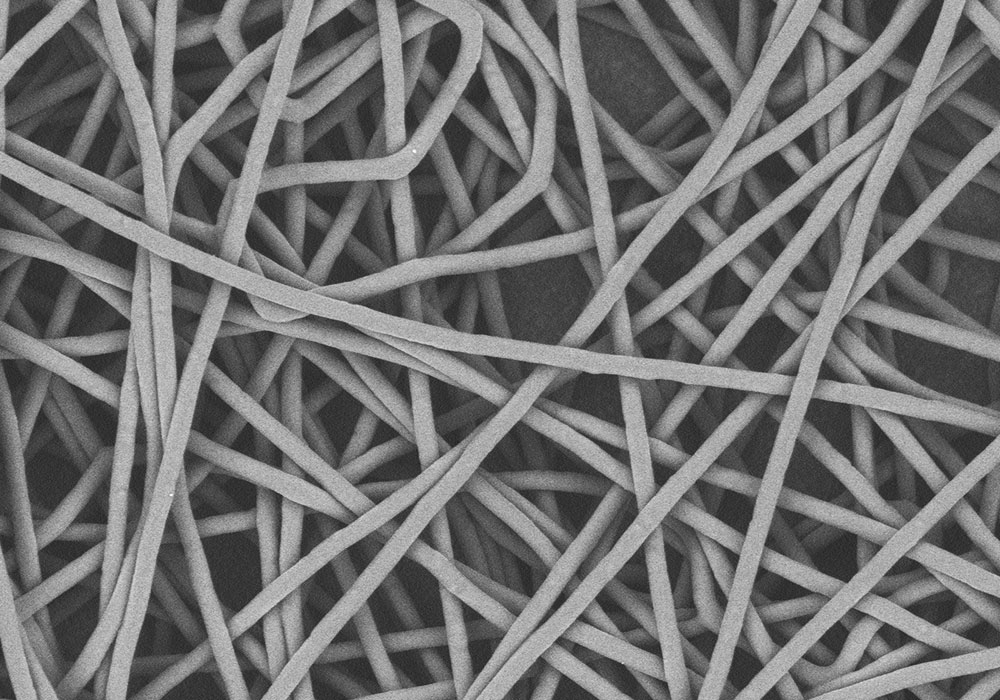

Electrospinning is a voltage-driven process governed by the electrohydrodynamic phenomena to generate fibers (20 nm to 10 µm). Though applicable in a range of disciplines, electrospinning f inds frequent employment in the restoration and substitution of deteriorating tissues. Mimicking the extracellular matrix environment requires the ability to tune fiber diameter, surface morphology, pore size, porosity, among others. The electrospinning technique allows users to tightly control and tune these parameters while achieving batch-to-batch consistency and reproducibility to mimic targeted tissue scaffolds. Tendons, heart valves, and vascular tissue constitute a set of commonly researched tissues where electrospinners yield successful structures. Typical materials for generating these grafting samples include the use of natural polymers like collagen and gelatin, synthetic polymers like polycaprolactone and polyethylene terephthalate, additives like vascular growth factors and even ceramics or metals based on application needs.

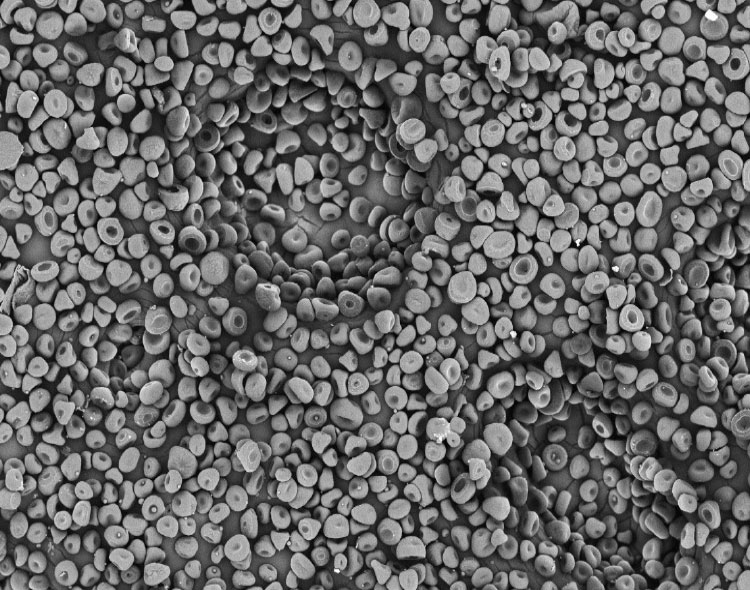

If the concentration of the polymer solution used in electrospinning is below a certain threshold, the instrument produces micro / nanoparticles instead of fibers, and the technique becomes what’s called electrospraying. Electrosprayed particles are viable in a number of expanding research fields like implant coatings, drug deliveries, biomedical imaging, and microencapsulated cell carriers.

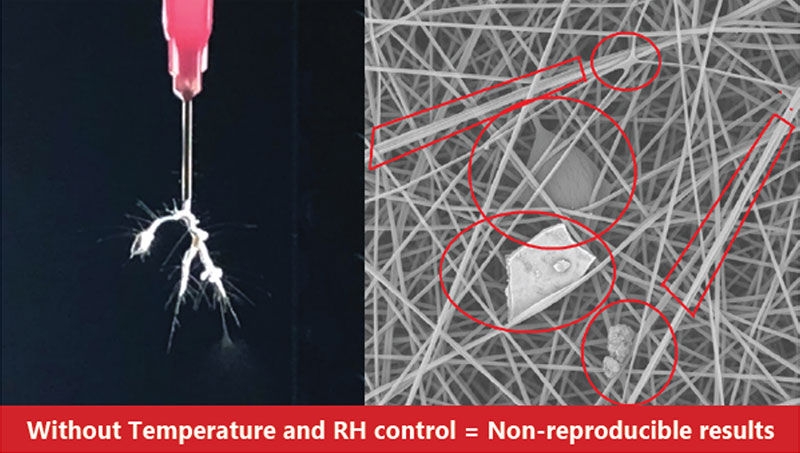

Fluidnatek’s exclusive environmental control unit enables full temperature (T, 18-45°C), relative humidity (RH, 10-80%) and air flow control (50-180 m³/h) during fiber/particle deposition, which ensures a defect-free and uniform microstructure for the final product. This air is filtered through a HEPA filter to maintain clean conditions during manufacturing. By tightly controlling T and RH, the rate of solvent evaporation is properly managed and optimized to have a stable product development and allow to spin easily clogging solutions all year round.

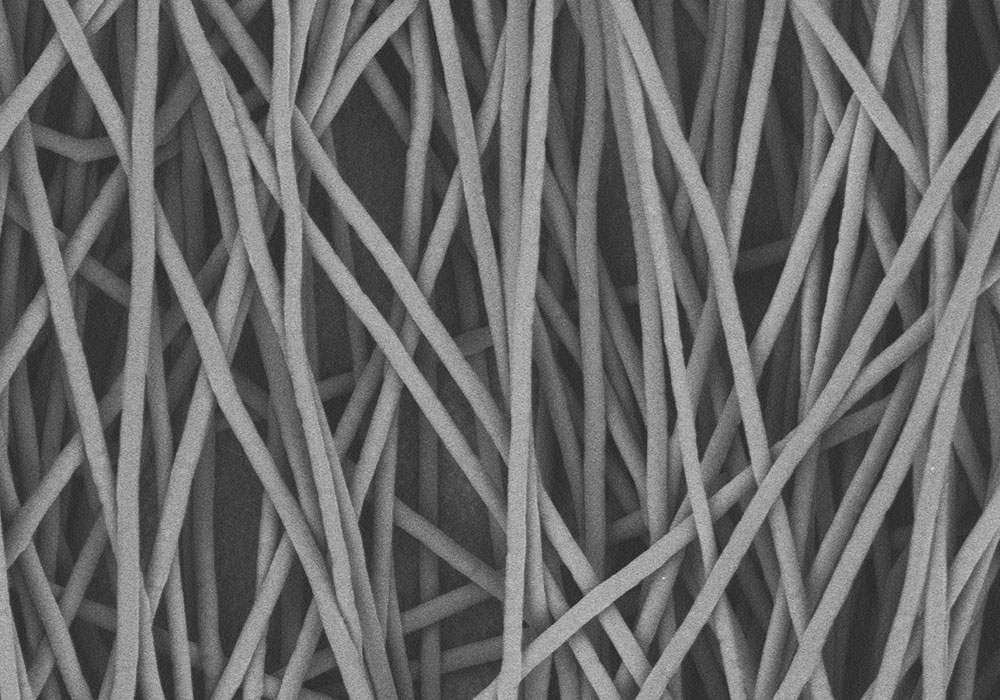

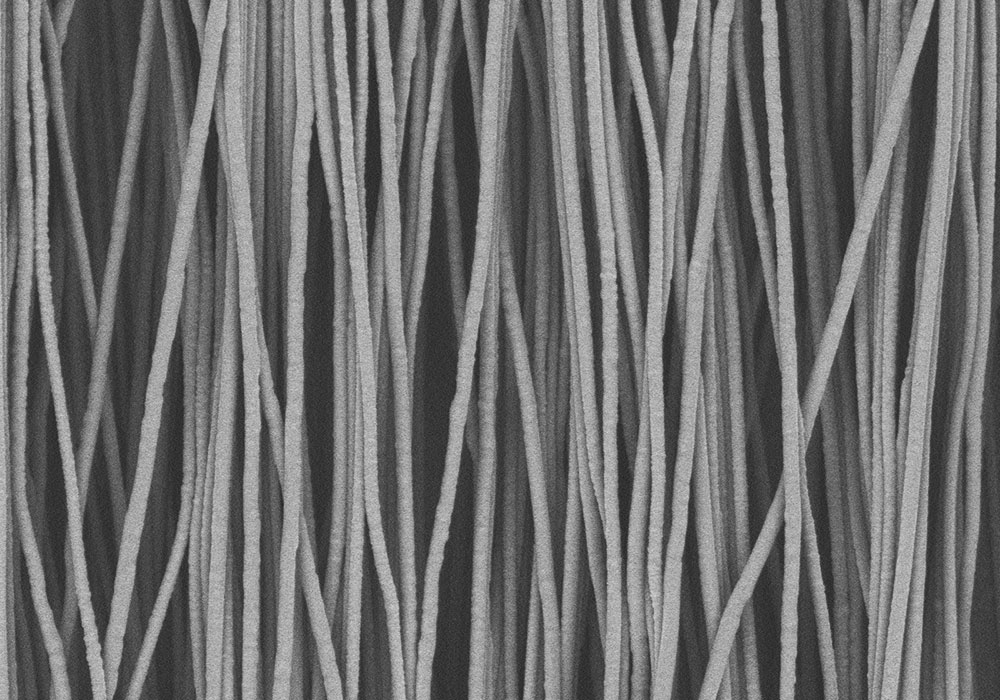

Electrospun Fiber Orientation

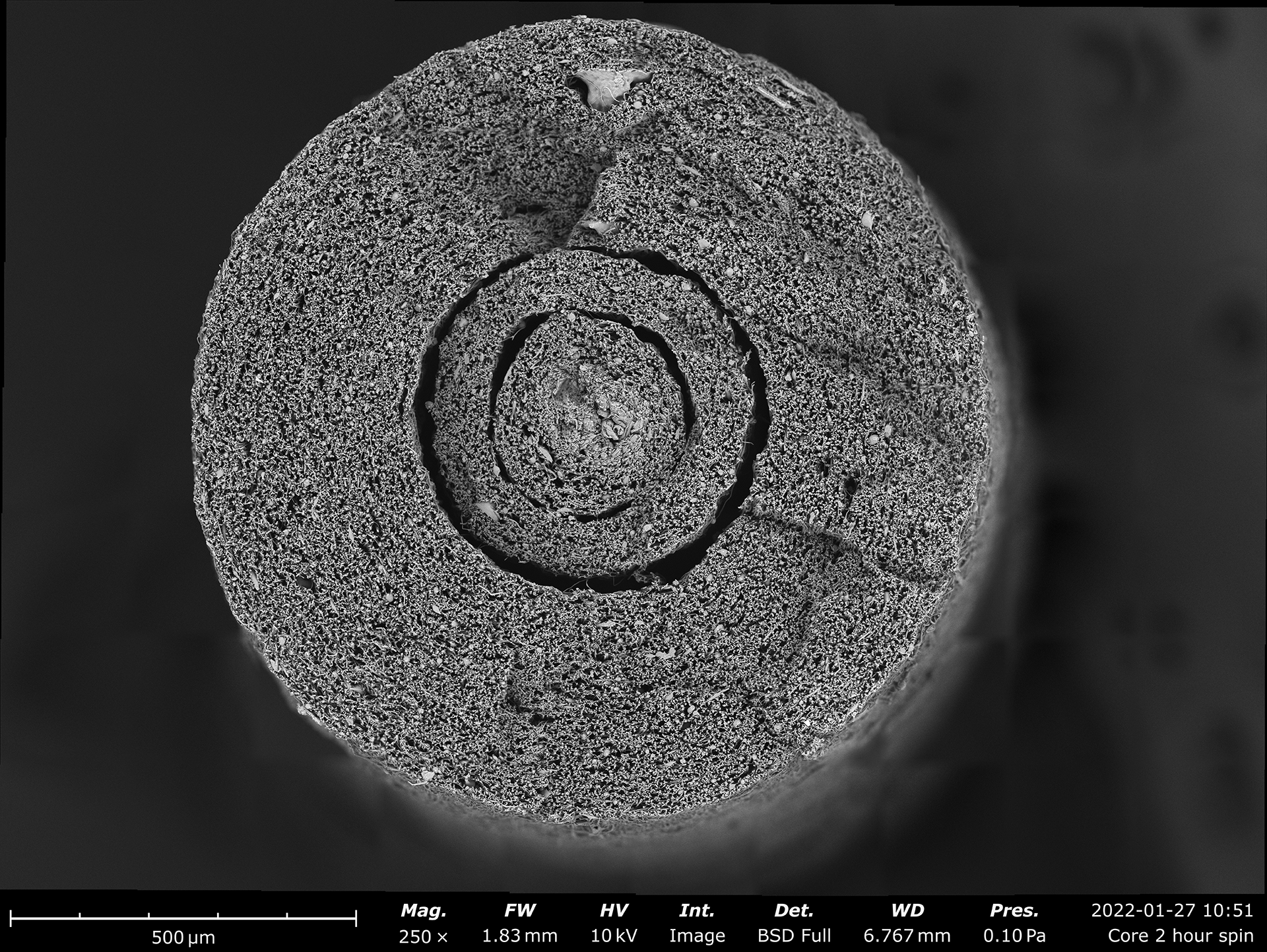

Electrospun fibers exhibit a proportional relationship between their degree of alignment and the collector’s angular speed, allowing room for flexibility in choosing how fibers are aligned

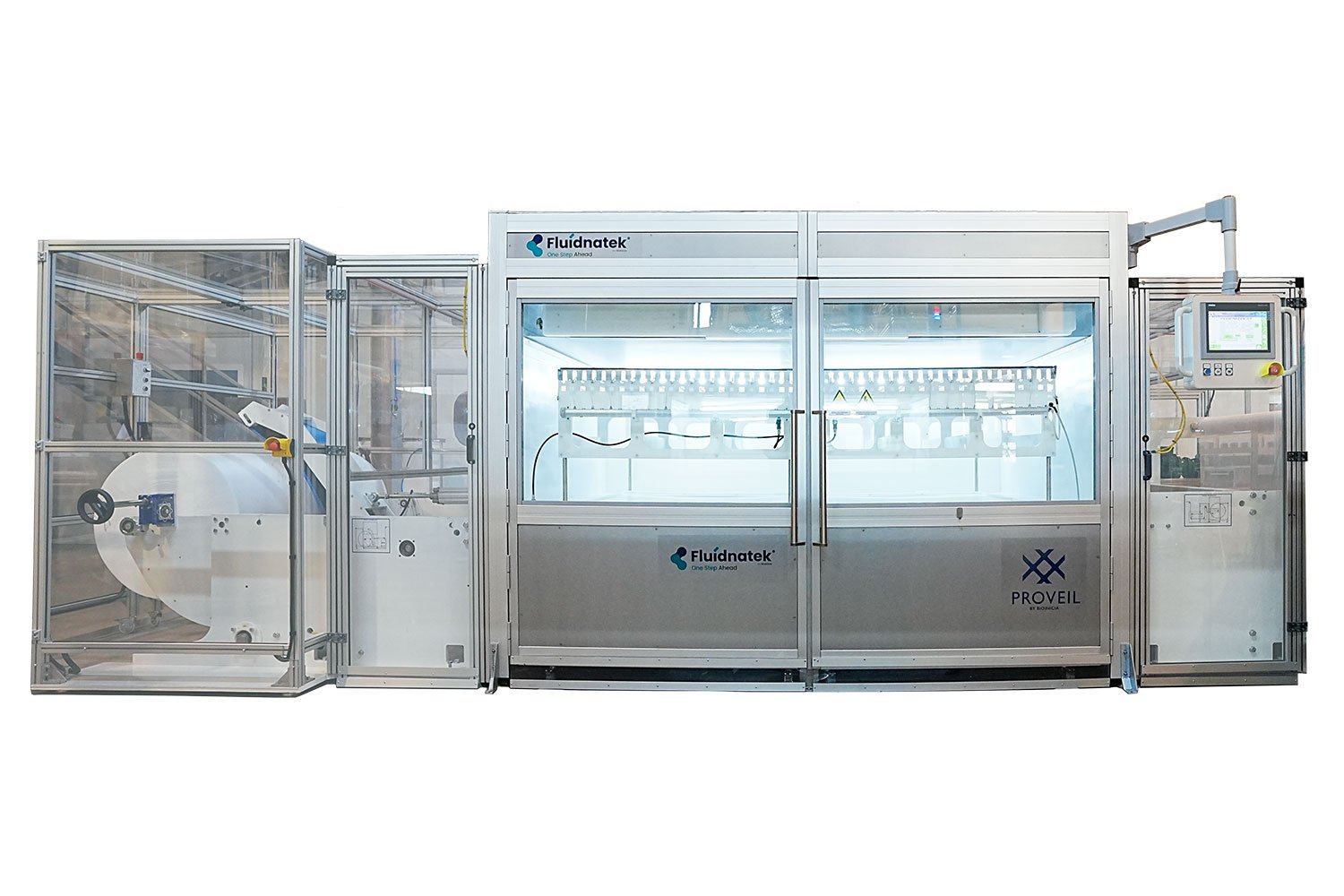

The Fluidnatek LE-50 is the ideal benchtop instrument for advanced R&D for the development of new biomaterials and formulations. This unit boasts impressive features for its size, including optional environmental control unit to allow sample reproducibility, dual sample processing with independent voltages to generate two types of materials simultaneously, and automated needle motion in X & Y directions for ease of solution optimization.

The Fluidnatek LE-100 is the equipment of choice for cGMP production of high-value particles, stent coating, artificial blood vessels and 3D-shaped electrospun fiber samples relevant to the biomedical and pharmaceutical industries. The design of this system and its size makes it suitable for a vast range of applications where experimental flexibility, tighter process control, and larger sample size are important. With over 21 accessories able to be implemented at any time, including measuring sample thickness in real time, this unit is ideal for advanced development projects, beta-release, and other pre-market introduction activities.

The Fluidnatek LE-500 is a powerful tool for commercializing electrospun and/or electrosprayed biomaterials and biomedical products. These units allow for ease of scalability to generate samples 50 cm wide on a roll form by implementing up to 370 simultaneous needles and 10 liters of solution for a semicontinuous sample processing. Similar to all other units, the LE-500 can be upgraded to meet cleanroom and sterile production processing for personalized medicine product development.

The Fluidnatek HT is equipped to operate 24/7 with over 5,000 simultaneous needles, 60-liters tank of refillable solution for uninterrupted industrial-scale production, and electrospun biomaterial sample development in roll form with a width of 1.6 meters. Safety is key for industrial electrospinning production. The HT has been engineered to offer several state-of-the-art features, including low oxygen content using nitrogen when flammable solvents are needed and active exhaust to always maintain a negative pressure to properly remove evaporated solvents (all Fluidnatek models offer this). This unit also monitors all electrospinning parameters and internal signals in the unit to properly monitor and scale sample production on all developed batches.

Investigating Wettability of Biomaterial Surfaces

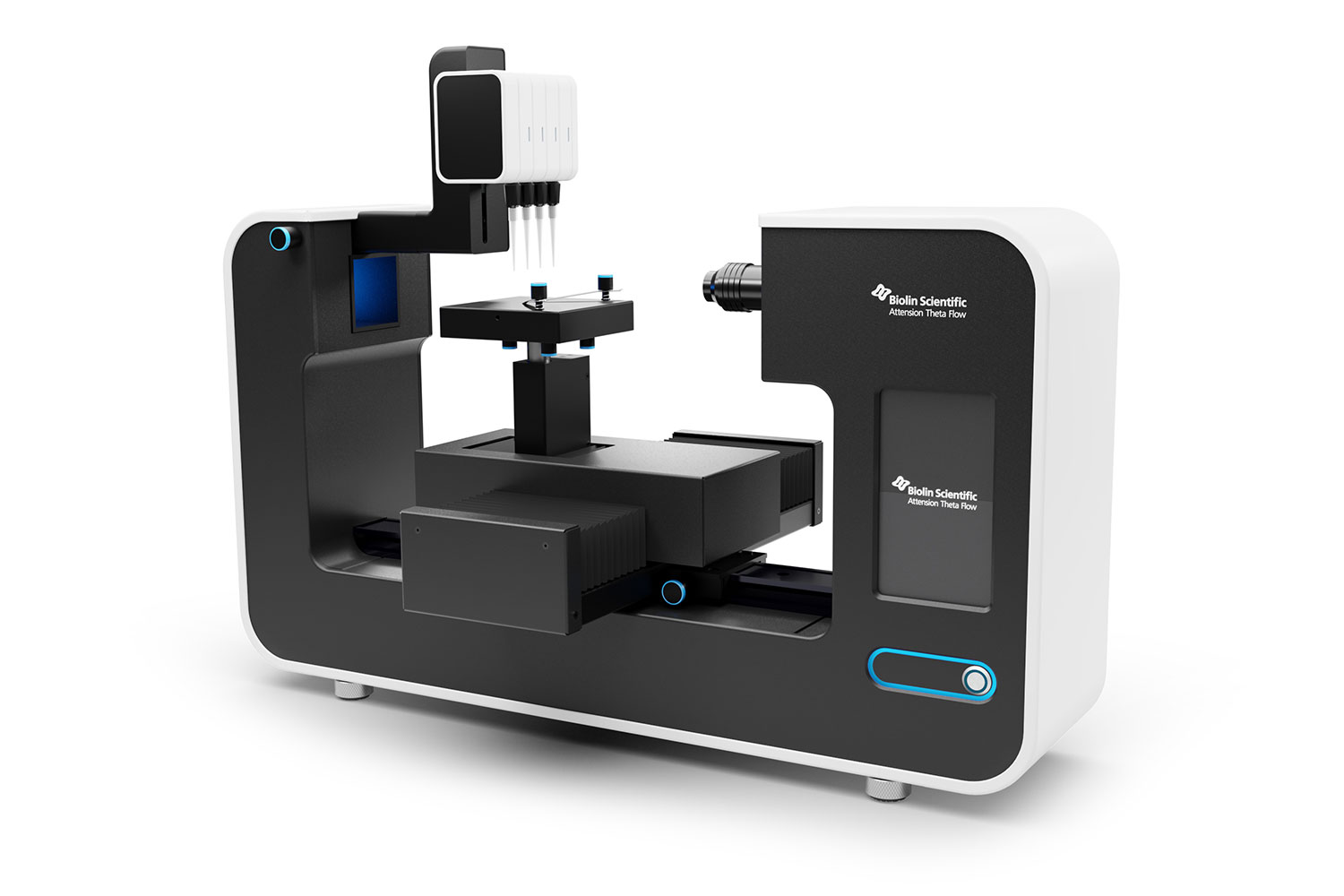

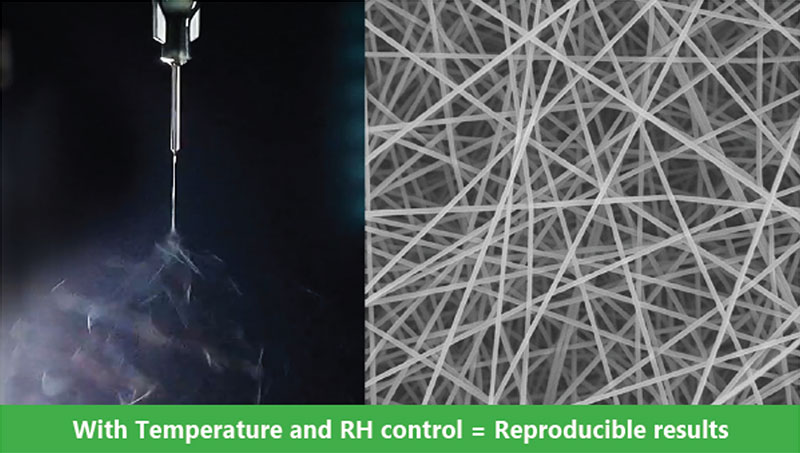

The Attension Theta Flow optical tensiometer delivers accurate, traceable, and repeatable contact angle measurements data across experiments with minimal user intervention. A host of features that automate or sense key instrument settings such as ambient temperature, relative humidity, and camera tilt, among others, ensure a faster workflow and consistently reproducible results.

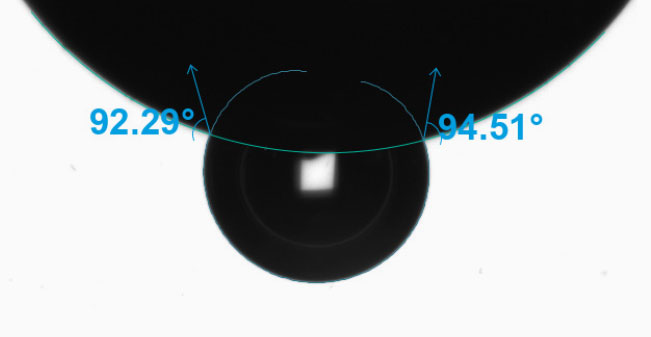

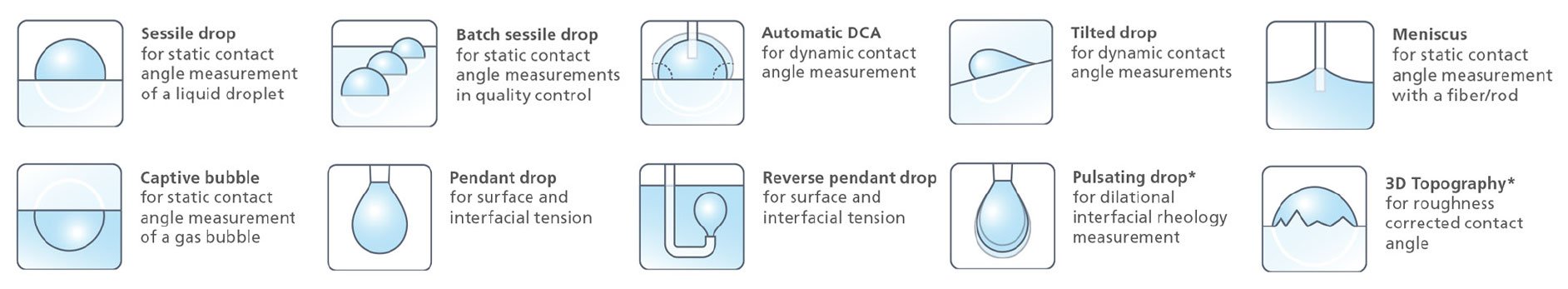

- Automated protocols for contact angle, surface tension, surface free energy, and 3D surface roughness

- Theta Topography module enables wettability testing on biomaterial surfaces with roughness-corrected contact angle

- Best-in-class camera with software controlled autofocus provides superior droplet image definition and sharp contrast for the most accurate baseline measurements

- The comprehensive OneAttension software provides real-time visualization of results and seamless data acquisition and analysis

Nanoscience Analytical capitalizes on over 18 years of expertise in advanced instruments for microscopy and surface analysis from our sister company, Nanoscience instruments. Our staff have varied backgrounds in chemistry, biochemistry, materials science, physics, and engineering, with over half of them having earned Ph.D.’s in their respective fields. Our mission is to deliver laboratory solutions to accelerate scientific innovation while being committed to quality, transparency, and sustained partnership with our clients. We represent an efficient, competitively priced source of sophisticated analytical services targeted at our client’s needs.

What We Do

Nanoscience Analytical provides Process Development for fabricating Nanomaterials and Analytical Services supported by expert scientists in a lab with the latest technologies. We provide our clients with focused, expert guidance and access to multiple, complementary analytical techniques and solutions.

Our expertise in synthesizing nanofibers & nanoparticles provides an efficient path to explore novel materials and their usefulness for many diverse applications. Our analytical capabilities include electron microscopy, tensiometry, optical profilometry, quartz crystal microbalance with dissipation monitoring and Langmuir Blodgett troughs.