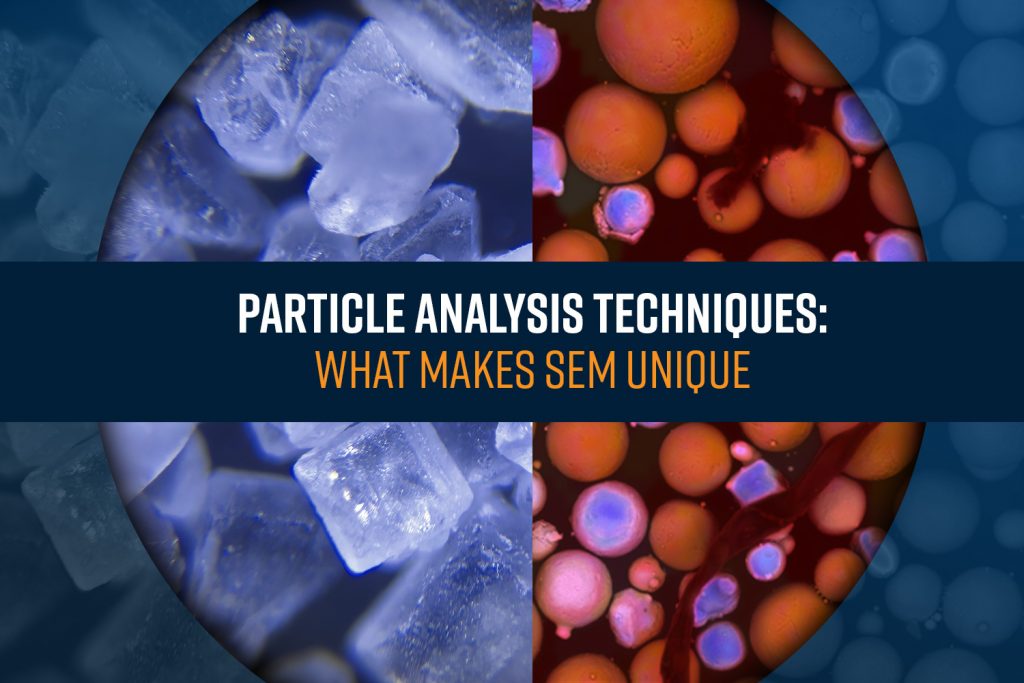

Particle Analysis Techniques: What Makes SEM Unique

Particle analysis involves measuring various characteristics of powders or particulates, including size, shape, and composition. A wide variety of industries rely on particle analysis for ensuring product functionality and safety including the production of automobiles, batteries, pharmaceuticals, and electronics.

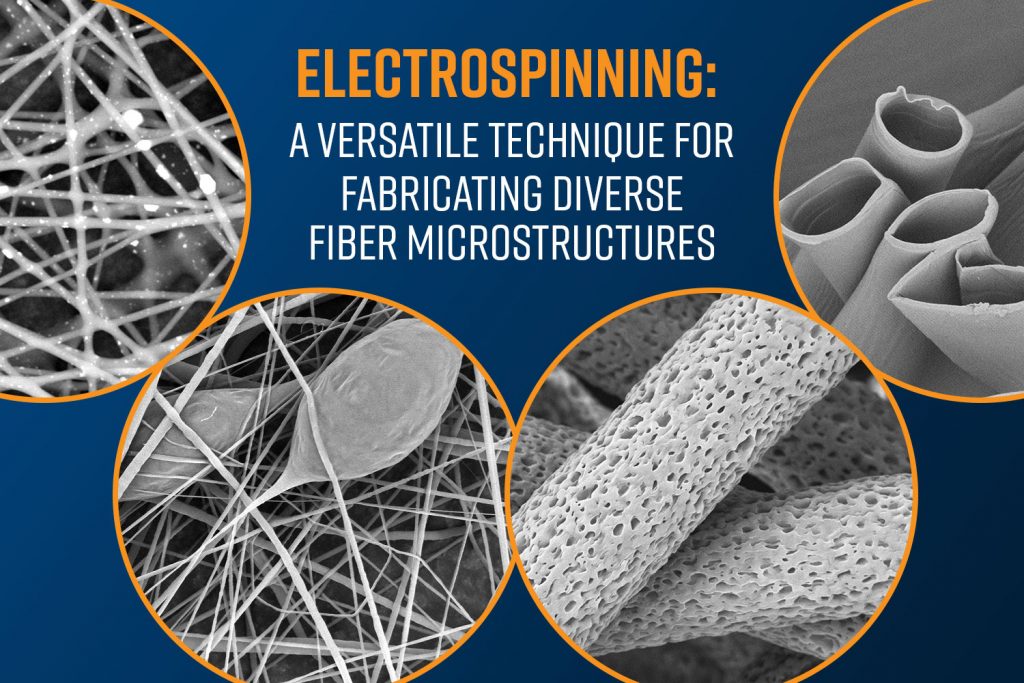

Electrospinning: A Versatile Technique for Fabricating Diverse Fiber Microstructures

Electrospinning is a powerful and versatile technique used to produce nonwoven ultrafine fibers with controlled microstructures. Electrospinning can be used to fabricate fibers of different diameters ranging from 20 nm to more than 10 µm. Fibers can be fabricated from solution, emulsion, suspension, sol-gel or slurry composed from different materials like polymers (natural, semi-synthetic and synthetic), ceramics, metals and/or different types of additives. Its ability to process a wide range of materials and produce fibers with tailored properties has made it a cornerstone in applications like textiles, medical & healthcare, energy, filtration, packaging, automotive, and aerospace.

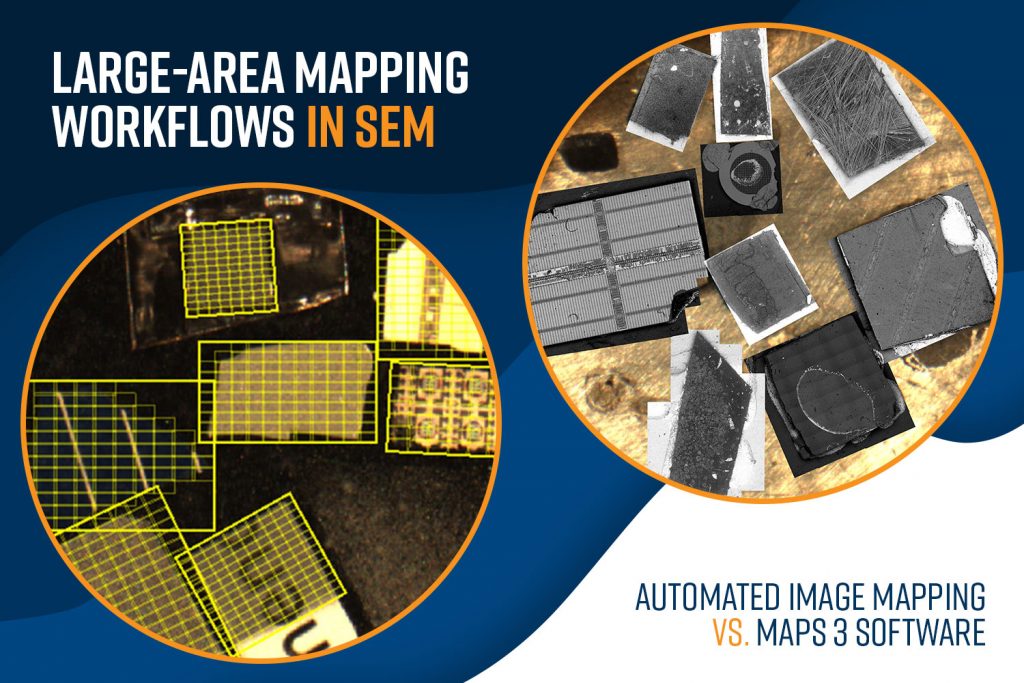

Large-area Mapping Workflows in Scanning Electron Microscopy (SEM)

Large-area imaging in scanning electron microscopy (SEM) is a technique for exploring expansive regions of a sample at high resolution, making it invaluable in fields such as materials science, electronics, and life sciences. However, capturing high-resolution images across large sample areas presents unique challenges, including time constraints and data management. This is where image stitching algorithms come into play, enabling researchers to seamlessly combine multiple high-magnification images into a single, comprehensive view (often referred to as a large-area map). In this blog, we’ll dive into how large-area mapping works, explore various image stitching software and workflows, and discuss how these techniques can improve efficiency and enhance imaging results.

2-Day SEM Short Course | Alexandria, VA | May 2025

2-Day SEM Short Courses: Explore the microscopic world in our specialized 2-day Scanning Electron Microscopy (SEM) Short Course. Held in Alexandria, VA, this immersive program is designed for both experienced practitioners and newcomers, offering an in-depth exploration of both fundamental and advanced SEM techniques. Hosted at our state-of-the-art facilities, the course features hands-on sessions with […]

Medical Design & Manufacturing West 2025 | Feb. 4-6, 2025 | Anaheim, CA

MD&M West – Medical Design & Manufacturing West Nanoscience Instruments and our sister company, Nanoscience Analytical, provide cutting-edge instrumentation and process development services to enhance the production of medical devices and biomedical products such as tissue scaffolds, vascular grafts, wound healing therapeutics, and more. Visit us in Booth #541 to learn about the power and […]

2-Day SEM Short Courses | Phoenix, AZ | February 2025

Explore the microscopic world in our specialized 2-day Scanning Electron Microscopy (SEM) Short Course. Held in Phoenix, AZ, this immersive program is designed for both experienced practitioners and newcomers, offering an in-depth exploration of both fundamental and advanced SEM techniques. Hosted at our state-of-the-art facilities, the course features hands-on sessions with the latest Phenom Desktop SEMs, complemented by expert-led lectures.

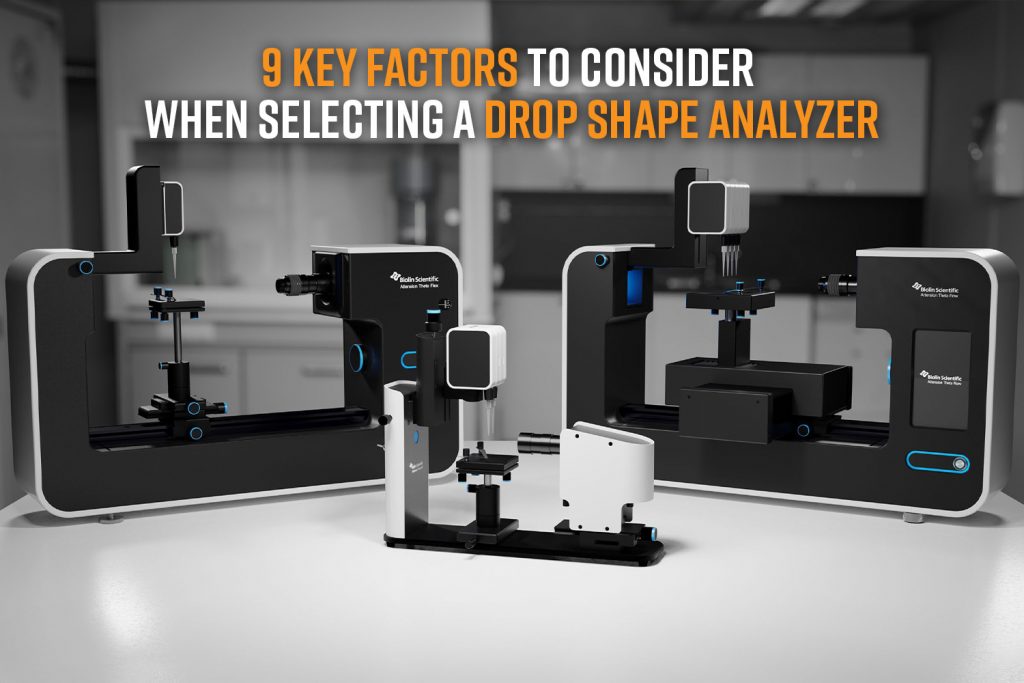

9 Key Factors to Consider when Selecting a Drop Shape Analyzer

Optical tensiometers, also referred to as goniometers, contact angle meters, or drop shape analyzers, are essential tools in materials science, enabling precise measurements of surface and interfacial tension of liquids and solids. Their use spans industries from coatings and electronics to medical devices, impacting research accuracy and industrial decision-making. Choosing the right tensiometer can optimize lab efficiency and improve data reliability. But selecting the right optical tensiometer may seem overwhelming with so many options with different capabilities that are available. Here’s a breakdown of the primary considerations to make an informed investment in the best optical tensiometer for your needs.

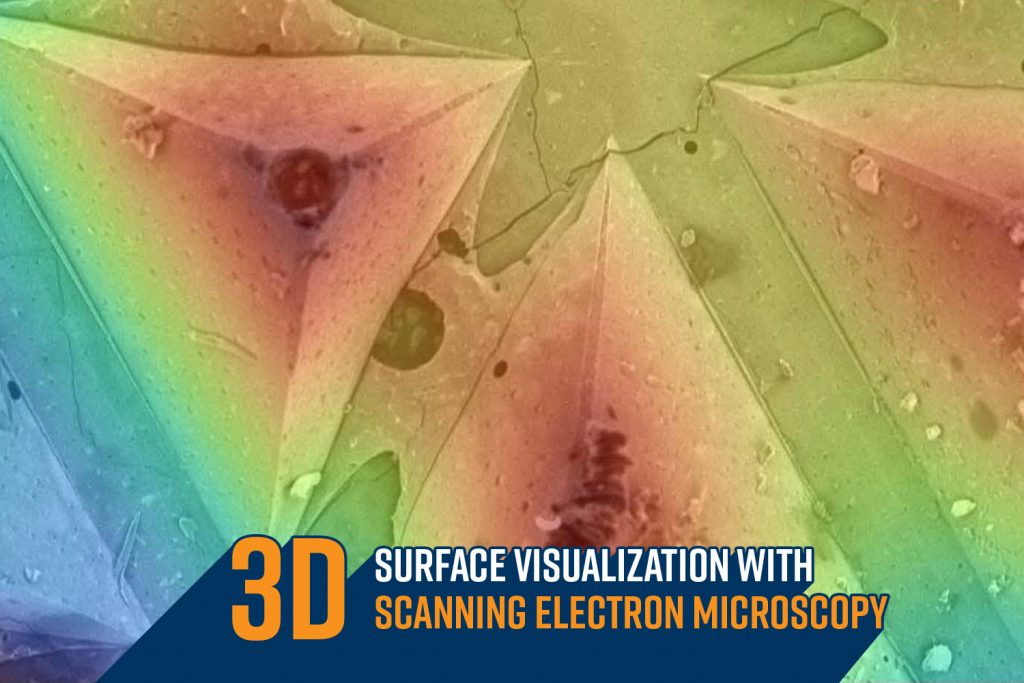

Unlocking New Dimensions: 3D Surface Visualization with Scanning Electron Microscopy

Scanning electron microscopy (SEM) has long been a cornerstone in material science, biology, and engineering for its ability to provide high-resolution images of a sample’s surface. The technique involves rastering a focused electron beam across the sample surface and detecting the various signals generated by beam-sample interactions to produce two-dimensional (2D) images. Beyond conventional imaging, […]

ISTFA 2024 | Oct. 29-31, 2024 | San Diego, CA

Visit our booth at the International Symposium for Testing and Failure Analysis to discover how our cutting-edge microscopy solutions can elevate your material analysis. Get hands-on with the best-selling Phenom Desktop SEM, featuring ChemiSEM technology that allows you to simultaneously visualize sample morphology and elemental distribution for rapid, actionable insights. Learn about the SEMPrep Smart Ion Mill, an advanced tool for preparing artifact-free cross-sections of even the most delicate structures. Additionally, explore the services of our sister company, Nanoscience Analytical, which offers expert contract sample analysis, including SEM, contact angle measurement, and beyond. Let our specialists show you how these solutions can enhance your failure analysis processes.

The Battery Show 2024 | Oct. 8-10, 2024 | Detroit, MI

Nanoscience Instruments provides solutions for battery development applications through cutting-edge instrumentation and analytical services. Visit our booth for live demonstrations of desktop SEM with automated workflows designed for structural and chemical analysis of battery materials, and learn about our surface characterization tools, battery cyclers & potentiostats, and process development and analytical services.