Broad Ion Beam Milling System

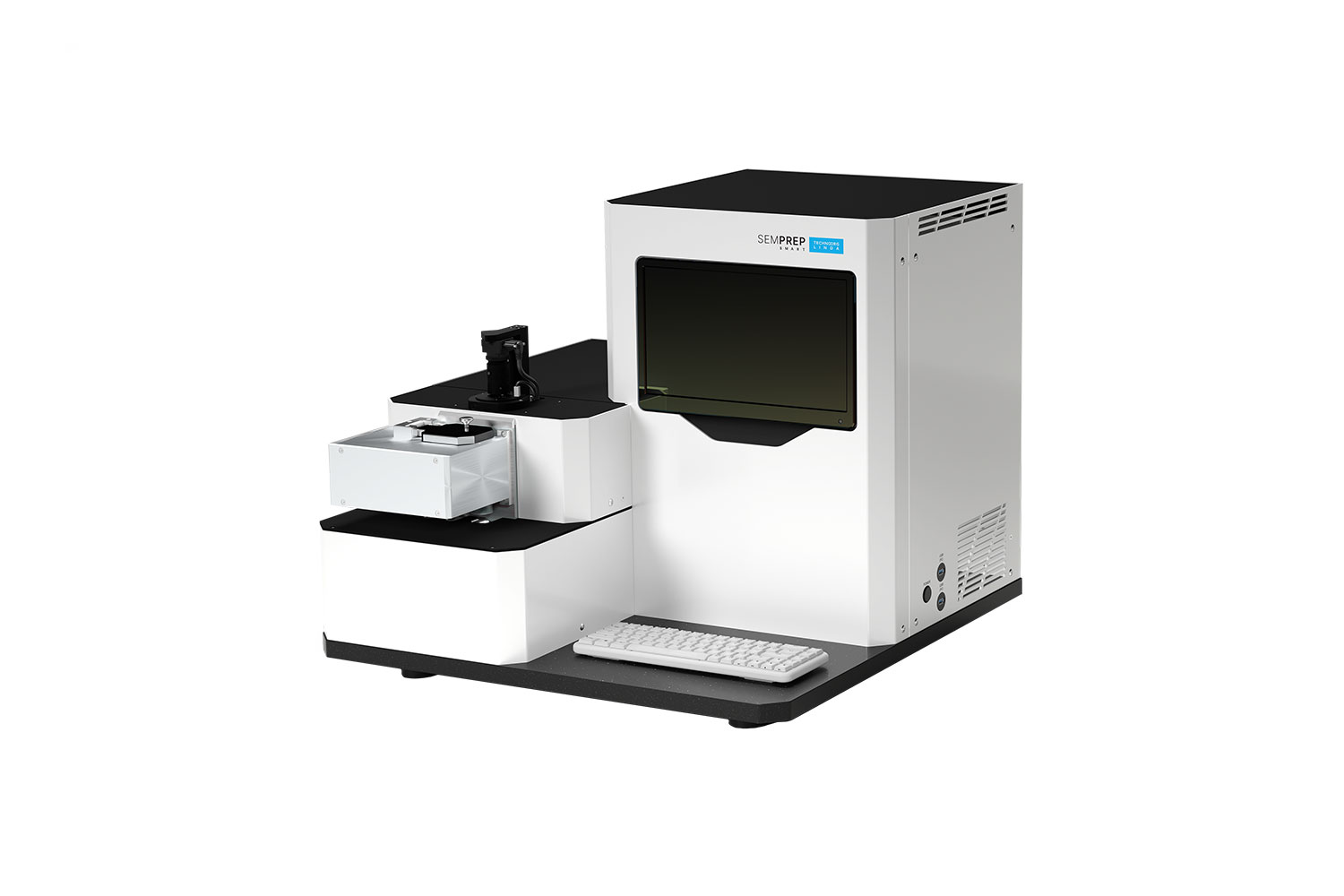

SEMPREP SMART

SEMPREP SMART is a state-of-the-art automated broad ion beam milling system designed for high-quality surface preparation. It produces damage-free, artifact-free cross-sections and surfaces, regardless of what type of material is being polished. Its user-friendly interface and automated workflows enable consistent, reproducible results with minimal operator intervention. SEMPREP SMART unveils the hidden details on a sample surface and elevates SEM, EDS, and EBSD capabilities to the next level.

Widest Energy Range

0.1 – 16 kV

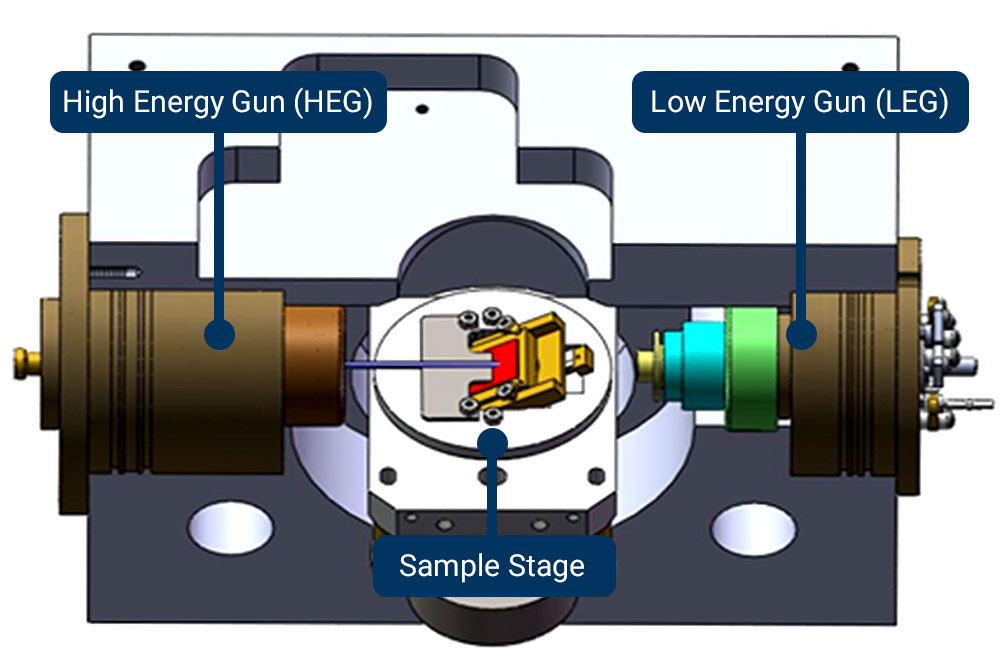

High-energy ion source (2 – 16 kV) and an optional low-energy ion source (0.1 – 2 kV)

Highest Precision

± 1 μm Precision

Sample alignment station and automated stage calibration results in high precision

Gentle Ion Beam

Reduced heat load

Eliminates cooling requirement without compromising surface quality for sensitive materials

Talk to an Instrumentation Specialist Today!

High-precision Broad Ion Beam (BIB) milling system for Electron Microscopy

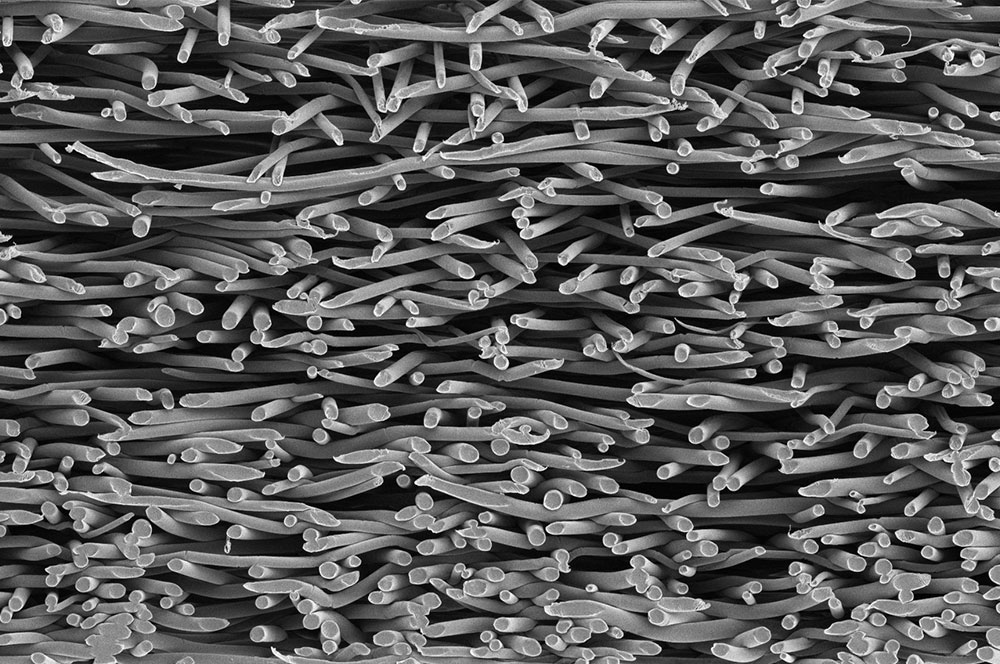

SEMPREP SMART is a versatile, high-precision Broad Ion Beam (BIB) milling system engineered for the preparation of pristine surfaces and cross-sections for Scanning Electron Microscopy (SEM). It delivers damage-free slope cuts and smooth finishes ideal for high-resolution imaging and analytical techniques such as EBSD and EDS. The system comes equipped with a high-energy argon ion source (2 – 16 kV), optimized for rapid, yet delicate, material removal. An optional low-energy source (0.1 – 2 kV), intended for final surface cleaning, can be included for ultra-sensitive specimens such as biological samples.

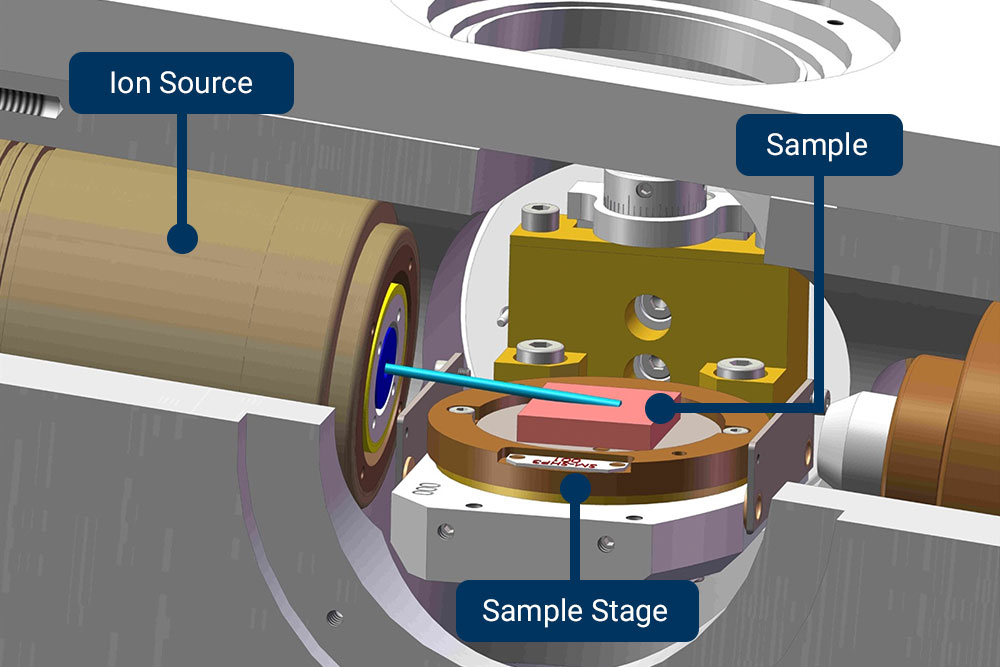

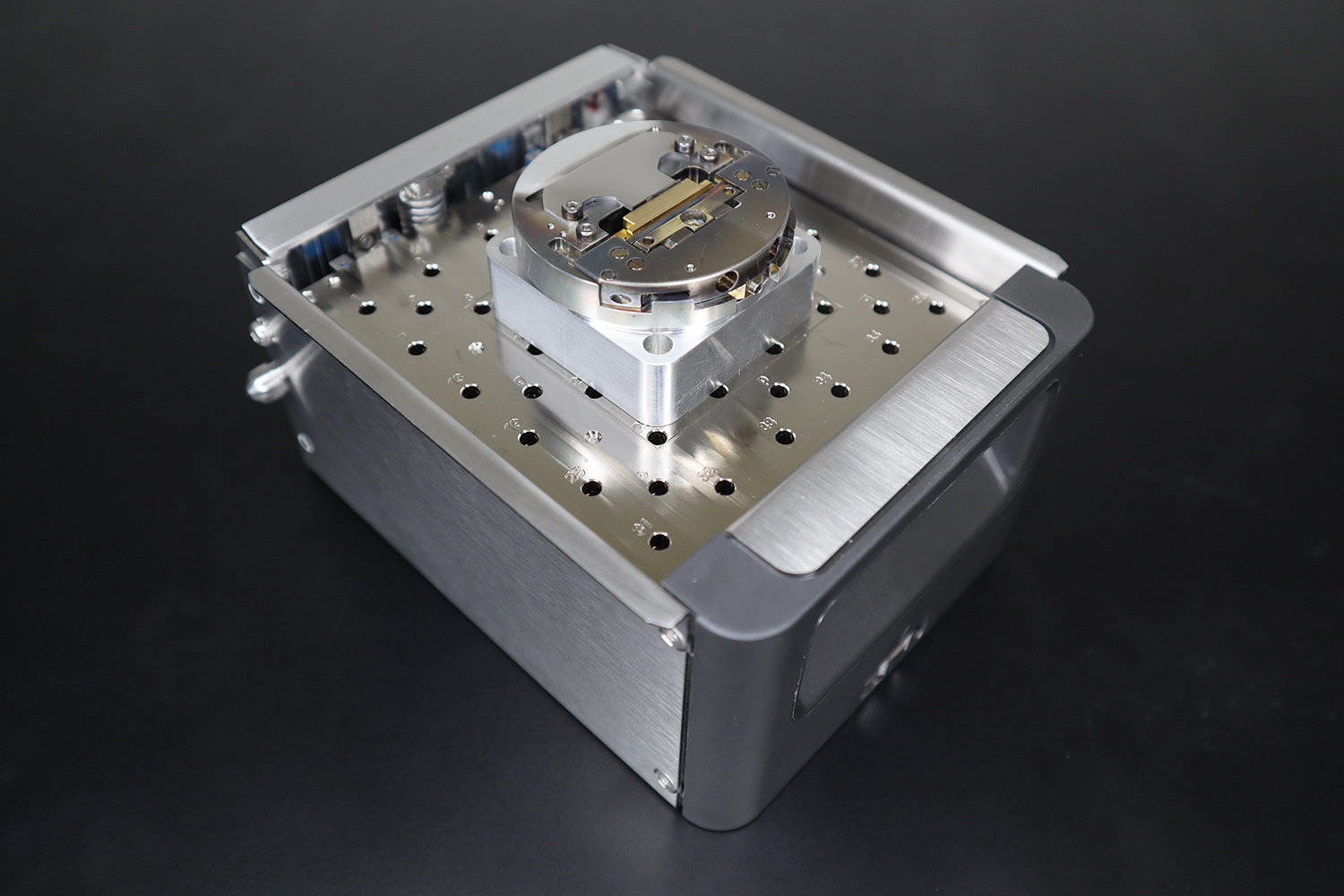

A fully motorized sample stage lies between these two ion guns, capable of perfectly aligning the sample to the ion beam while simultaneously performing in-situ oscillation and rotation during polishing. There’s even a real-time camera viewing the sample stage, aiding in the precision of SEMPREP SMART. The stages design also allows for efficient heat transfer from the sample. Peltier and liquid nitrogen cooling options are available on the SEMPREP SMART for preserving structures of extremely sensitive specimens, but cooling is not necessary in the majority of cases. All of these features are controlled via a simple, yet intuitive touchscreen interface. This combination makes SEMPREP SMART a robust solution for preparing high-integrity samples across diverse and challenging materials.

Application Areas:

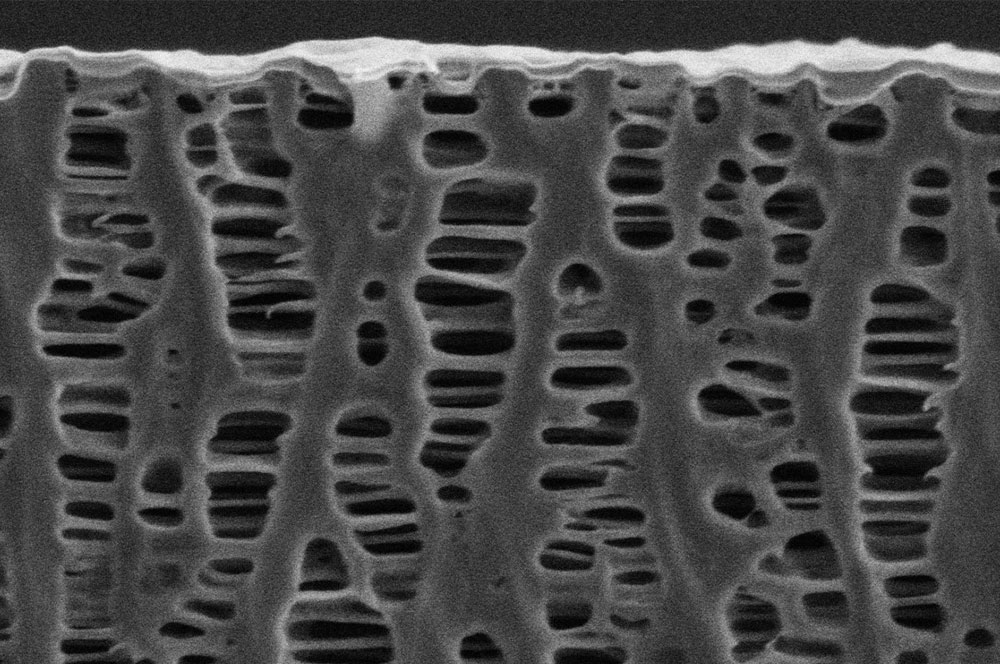

- Batteries & Energy Storage

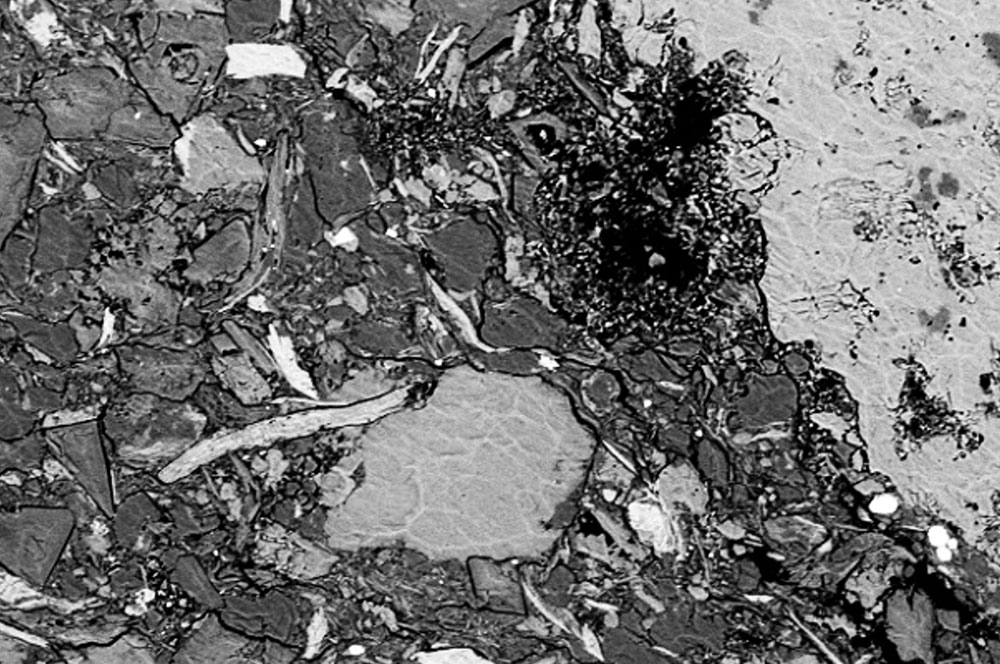

- Geology

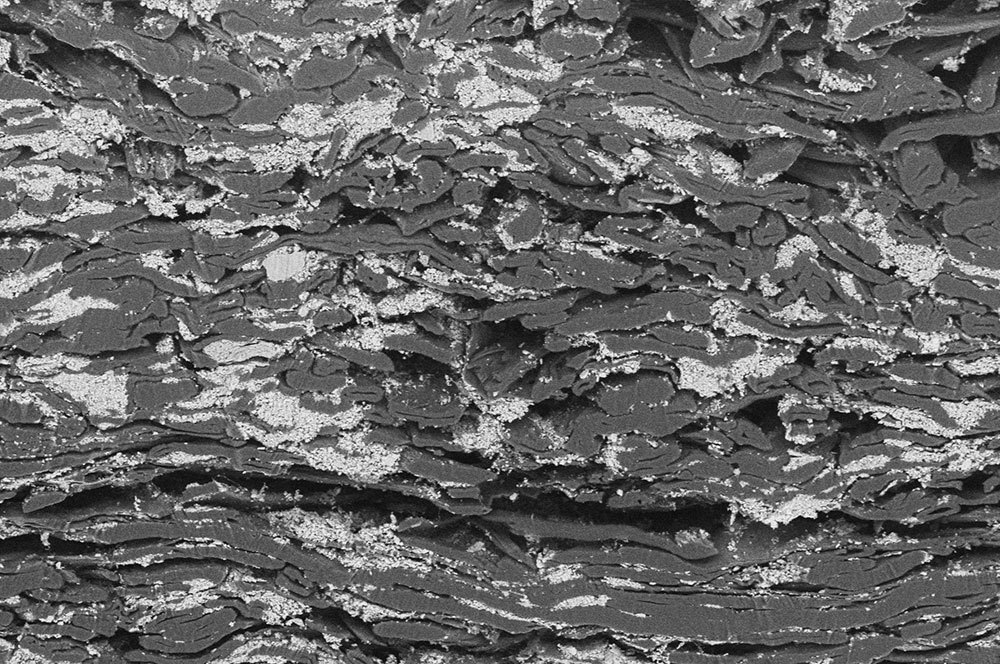

- Metallurgy

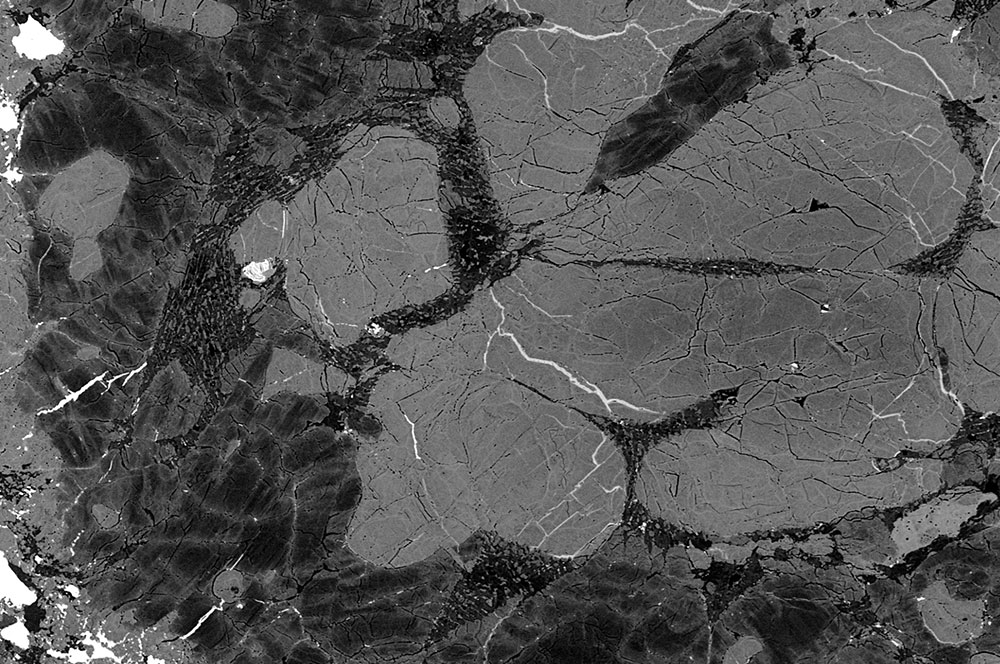

- Semiconductors

Frequently Asked Questions (FAQ):

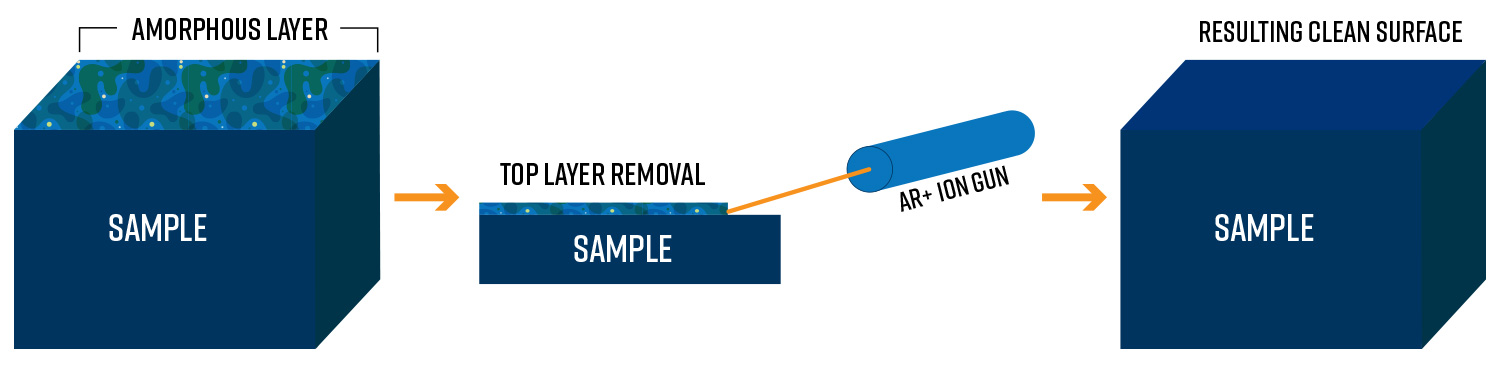

Broad Ion Beam (BIB) Polishing is an advanced sample preparation method that employs a wide, low-divergence ion beam, typically composed of argon ions (Ar⁺), to gently mill and polish the surface of a specimen. This technique is widely utilized to produce flat, high-quality, and damage-free surfaces or cross-sections, making it especially valuable for imaging and analytical techniques such as Scanning Electron Microscopy (SEM), Electron Backscatter Diffraction (EBSD), and Energy-Dispersive X-ray Spectroscopy (EDS).

The ion beam is accelerated at energies of several kiloelectronvolts (keV) and directed toward the sample, physically sputtering surface atoms through controlled ion bombardment. By fine-tuning parameters such as beam energy, incidence angle, and milling duration, users can precisely manage the material removal rate and tailor the depth and surface quality of the polished or cross-sectioned area. It enables uniform surface preparation over large areas (on the millimeter scale) and is compatible with a wide range of materials, including metals, ceramics, geological specimens, polymers, and biological samples.

The core of SEM sample preparation involves revealing the feature or features of interest so that they are easily visible within the microscope. Part of that process includes mechanical preparation via cutting of the sample and/or grinding/polishing of the sample. Mechanical polishing can introduce a number of artefacts, including contamination and deformation, that are difficult to remove with traditional techniques and interfere with SEM analysis. Broad ion beam polishing can easily remove these features; read our blog to learn exactly how:

Broad ion beam polishing and focused ion beam polishing are very similar in principle but quite distinct in execution. The primary characteristics between the two methods are the type of ion source being used and the diameter of the beam. Broad ion beam (BIB) milling generates a wide-area ion beam and commonly uses Ar ions to produce said beam. These are typically stand-alone systems and are excellent for increasing sample throughput. Focused ion beam milling uses a finely focused ion beam for site-specific material removal. Housed within floor model SEMs, FIBs are extraordinarily powerful but come at the cost of expertise and resources. Learn more about the difference between BIB polishing and FIB polishing here:

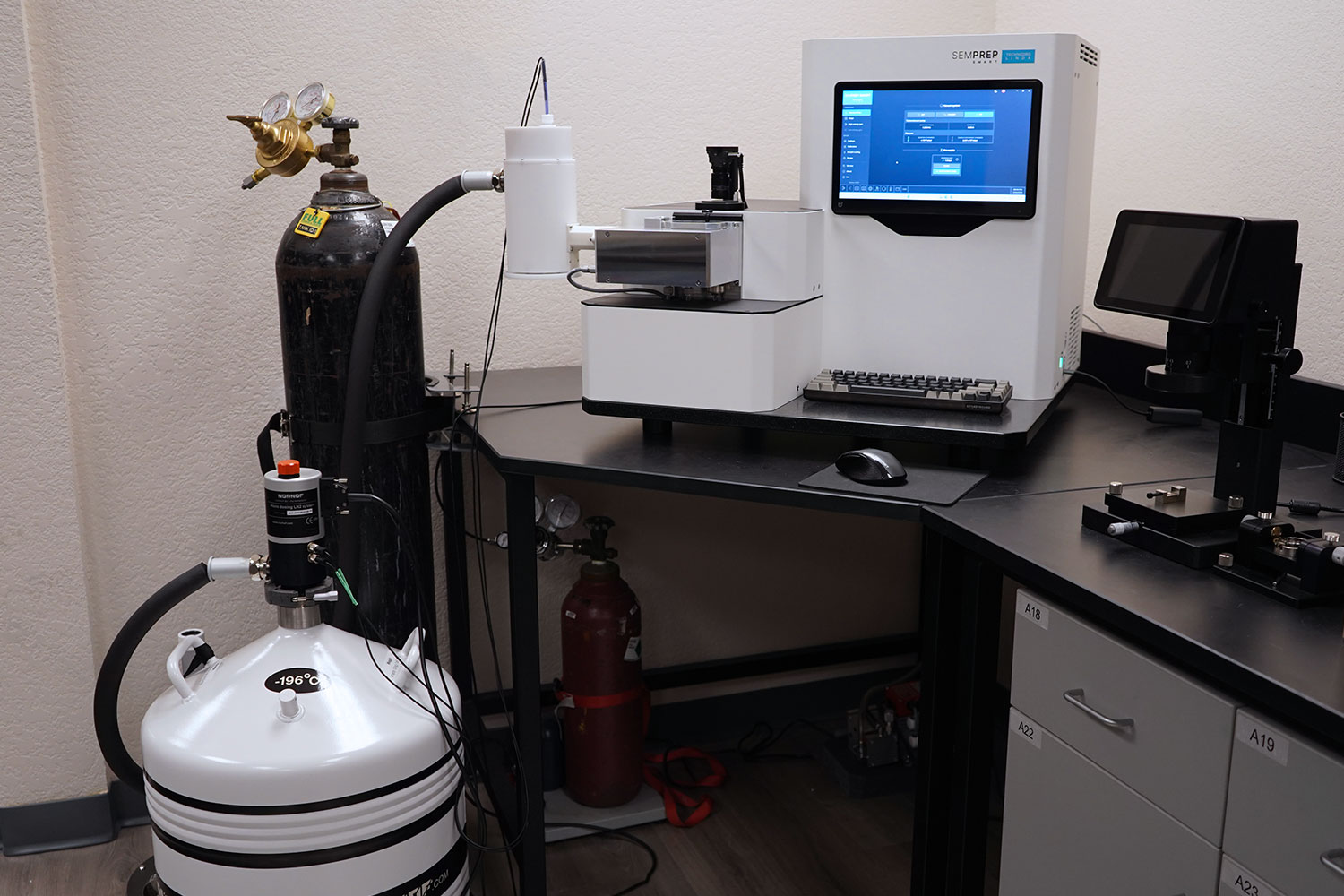

SEMPREP SMART is designed to easily fit within a lab space and has minimal facility requirements. It is a desktop system, so its footprint is small enough to fit onto a lab bench with ease. A steady supply of argon gas is required as well, in order to produce the broad ion beam. Lastly, a standard 110 V outlet is all that is needed for operation of SEMPREP SMART.

Technoorg Linda SEMPREP SMART

Product Features

Widest Energy Range:

SEMPREP SMART features two independent ion sources, providing the broadest energy range available on the market. The standard high-energy ion gun (2 – 16 keV) enables high-speed milling and efficient sample processing while the optional low-energy ion source (100 eV – 2 keV) preserves fine structural details of extremely delicate materials. These sources were designed to produce a net neutral ion beam, reducing the strain on the sample without compromising milling rates. Net neutrality has the added benefit of reducing charge buildup on nonconductive samples, ensuring uniform exposure throughout the milling process. Samples are positioned centrally between the ion sources, enabling seamless switching between high-energy and low-energy modes.

High Precision Staging:

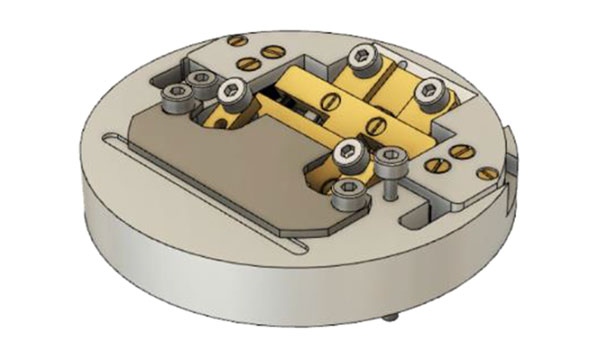

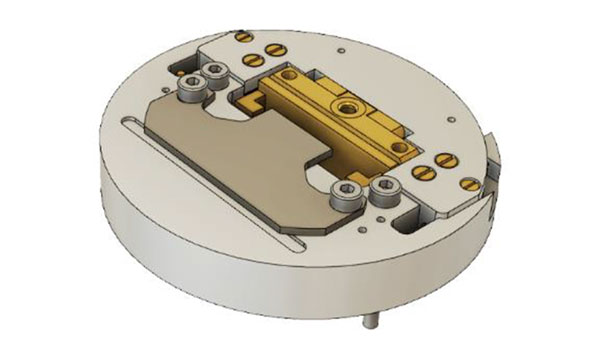

The SEMPREP SMART features a fully motorized sample stage designed for efficient and user-friendly sample exchange. With assistance from the Sample Alignment Station, the stage offers ±1 µm positioning, full 360° in-plane rotation , in-plane oscillation from ±1° to ±360°, and precise tilt control from ±0° to 30° in 0.1° increments. All stage adjustments can be performed while the ion source is active, leading to easier and more efficient milling.

Polishing Methods:

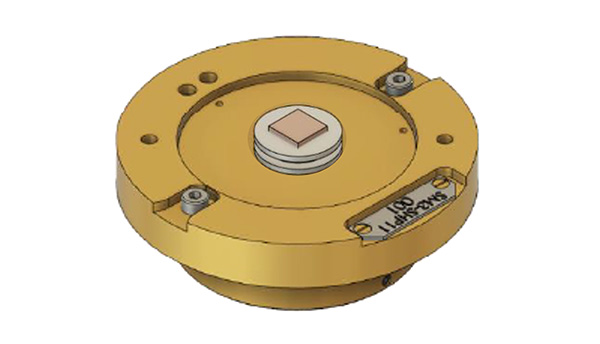

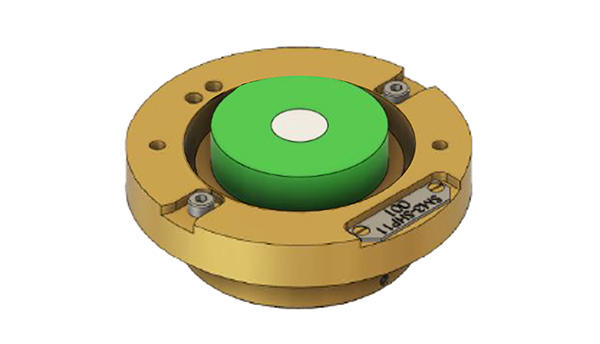

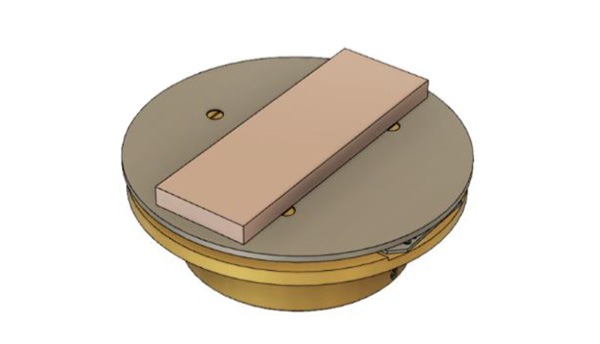

SEMPREP SMART systems are capable of facilitating different polishing methods, broadly separated into two categories based on the type of mill desired. These are referred to as Surface Polishing and Slope Cutting. SEMPREP SMART offers optimized sample holders for both methods, enabling precision mounting and ease of use.

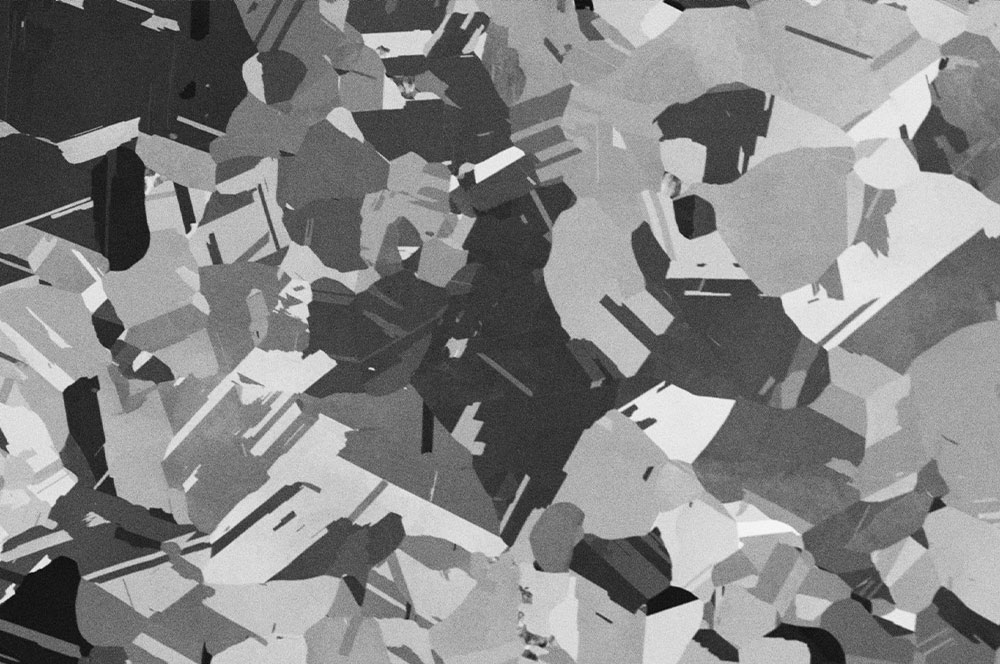

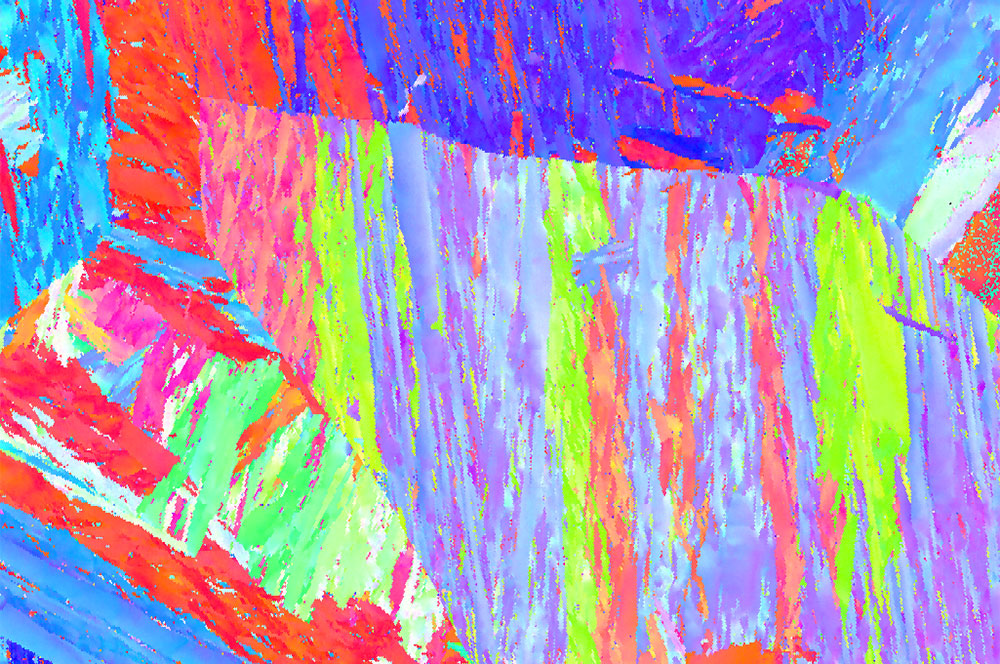

Surface Polishing:

Surface Polishing involves the removal of surface irregularities, contamination, or damage layers to achieve a flat, smooth, and deformation-free surface. This process typically eliminates the Beilby layer, an amorphous layer deposited during the mechanical polishing process. Surface polishing is particularly effective for preparing large or epoxy-mounted samples, ensuring the surface is suitable for Scanning Electron Microscopy (SEM), Electron Backscatter Diffraction (EBSD), and Energy-Dispersive X-ray Spectroscopy (EDS), where surface integrity is crucial for high-resolution imaging and accurate analytical results. A typical surface polish involves tilting the holder to a certain orientation and fully rotating the stage during ion beam exposure, resulting in an overall treated area of over 100mm2. SEMPREP SMART comes standard with a surface polish sample holder, with various insert types to accommodate a wide range of sample types.

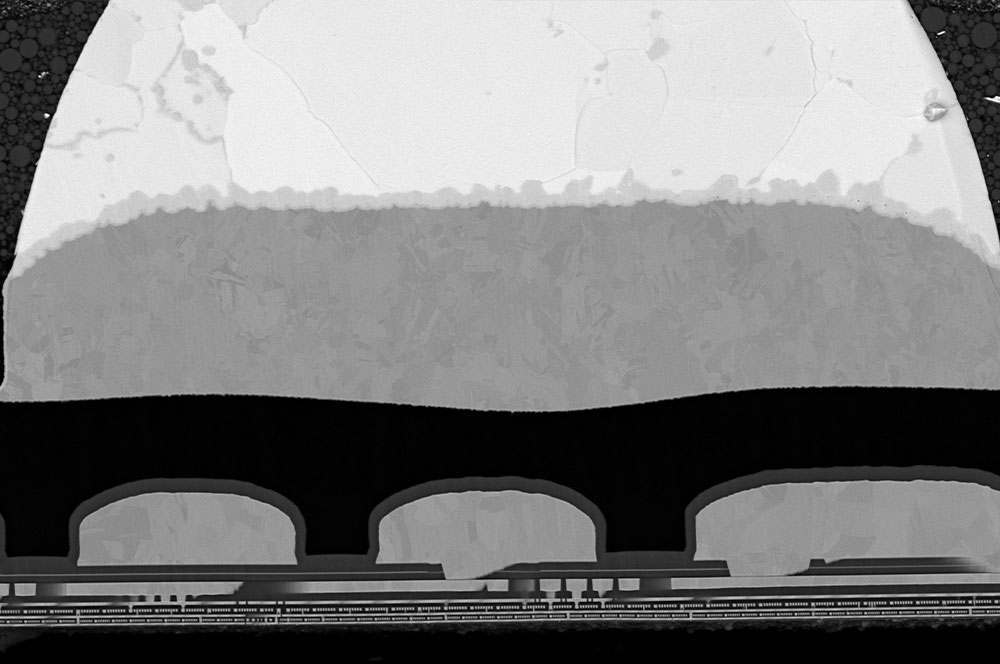

Slope Cutting:

Slope Cutting creates a shallow-angle cross-section of the sample by ion milling at a low incidence angle, revealing subsurface features, layer structures, and buried interfaces with minimal distortion. Samples are mounted behind a beam-blocking mask, allowing only a small portion of the sample to be exposed. This ensures all but the intended milling area is protected from the beam, reducing overall treatment time. Typical slope cutting involves oscillating and tilting the stage to ensure a new, uniform surface is created after ion beam bombardment. SEMPREP SMART offers two different types of slope cut holders, one pre-tilted at 30° and one at 90°. The 30° holder enables fast, artifact-free milling anywhere on the sample surface, making it ideal for users aiming to avoid mechanical polishing or to expose surface interfaces. The 90° holder provides a true perpendicular cross-section, ideal for detailed structural analysis.

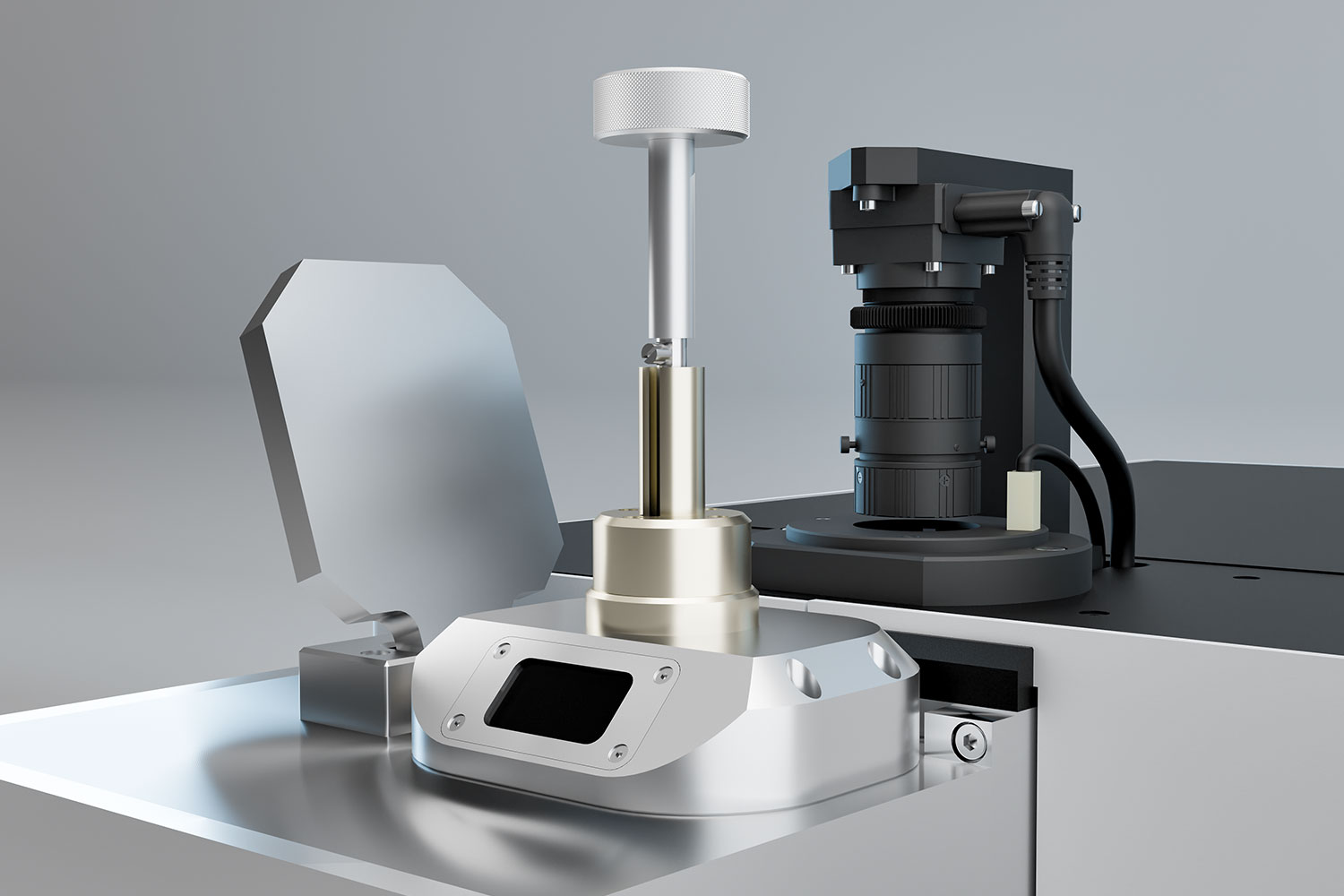

To ensure the sample is positioned perfectly prior to ion milling, the Sample Alignment Station (SAS) is used to align the sample in the holder. This digital microscope includes a high-resolution sensor, sleek touch screen interface, and platforms to assist in sample positioning.

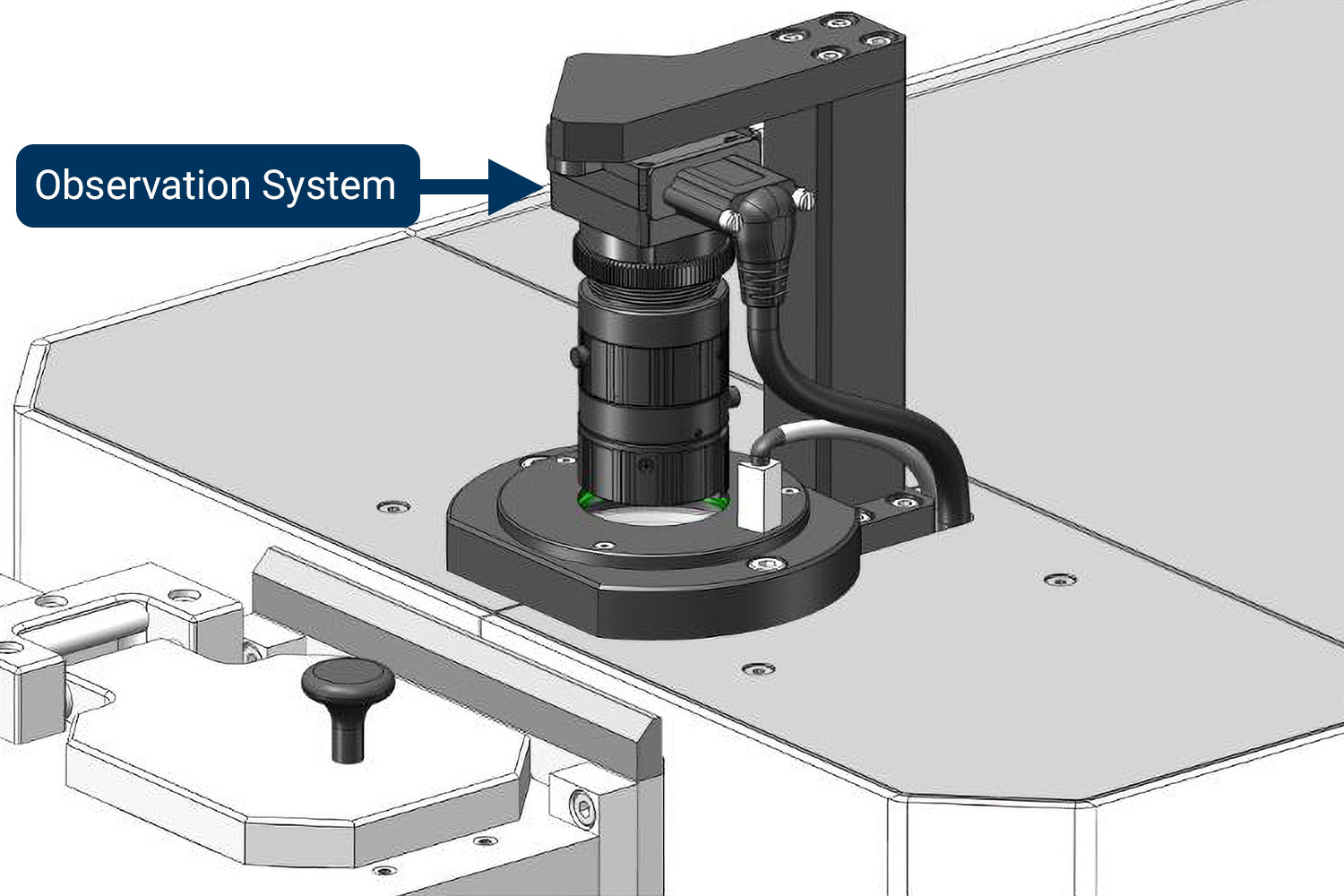

Observation system:

SEMPREP SMART systems include a CMOS camera mounted above a dedicated viewing port, allowing real-time monitoring of the milling process. To protect the viewing window from contamination by sputtered material, the port is fitted with a protective shutter. With the shutter open, users can observe the surface milling progression directly through the camera, enabling precise process control and optimization.

Cooling options

Sample cooling is not always necessary with SEMPREP SMART, thanks to the optimized design of the ion sources and sample stage. These systems come standard with passive cooling, achieved via a thermal wire bundle that conducts heat away from the sample stage. However, there are still some applications that will require active cooling to preserve sample integrity. SEMPREP SMART provides two active cooling options: Peltier cooling and liquid nitrogen cooling.

The Peltier option maintains the sample stage at approximately 0 °C, offering an effective solution for preventing thermal damage, which is particularly useful in labs without access to liquid nitrogen. For highly heat-sensitive or biological specimens, liquid nitrogen cooling is recommended, as it keeps the sample well below 0 °C for maximum thermal protection. LN2 systems utilize a 35-liter dewar equipped with a liquid nitrogen pump, which is automatically controlled through the SEMPREP SMART control interface, making it simple and easy to use.

Easy-to-use operation:

SEMPREP SMART is designed for users of all experience levels, featuring an intuitive graphical user interface that simplifies navigation and streamlines the polishing workflow. The system supports fully automated operation, allowing users to program and save custom protocols for frequently used sample types, enabling consistent, intervention-free preparation with high reproducibility. Users can easily create, edit, and manage these protocols to meet specific application requirements. Additionally, SEMPREP SMART includes automated stage and beam alignment, ensuring that the ion beam is precisely centered on the target milling area. This functionality enhances accuracy and enables precise polishing of defined regions on the sample. The control software also automatically manages the active cooling of the sample, whether using Peltier or liquid nitrogen.

AI Assisted Milling:

To enhance the ease of use of SEMPREP SMART, AI assisted milling can aid in finding the optimal parameters for broad ion beam polishing any kind of material. AI assisted milling conducts real-time, online searches for milling parameters, accessing a large database for the best results. It also looks exclusively at data collected from SEMPREP SMART systems, ensuring consistent and reliable results. Recipes can be created immediately from these suggestions, applied to the next polishing run, and then saved for future use. This feature will be making its way onto SEMPREP SMARTs in the very near future!

Technoorg Linda SEMPREP SMART

Product Accessories

Vacuum Transfer Unit

Research on materials that are sensitive to ambient atmosphere has been increasingly common in recent years. To aid in this, SEMPREP SMART has the option of including a vacuum transfer unit (VTU), maintaining sample integrity during transfer between the glove box. The system comes with a vacuum capsule and load lock cover, making sample loading/unloading easy and fast. The VTU is designed to ensure the sample remains protected and contamination free during all stages of handling and transfer, making it an essential component for maintaining sample integrity in advanced material science applications.

Sample Alignment Station:

The Sample Alignment Station (SAS) is designed to assist users in accurately locating and positioning specific regions of interest on a sample and loading it into the slope cut holders. It features a digital microscope designed specifically for slope cut holders, enabling precise targeting of the desired milling area. The SAS is equipped with a high-resolution imaging sensor , a touchscreen monitor for intuitive operation, specialized lighting that simulates the ion beam angle, and a USB port for capturing and saving images. This setup ensures accurate and efficient sample alignment for high-quality milling results.

Phenom XL Insert:

Broad ion beam (BIB) polishing is widely used to create cross sections for structural analysis in SEMs. Optimal milling parameters depend on both sample geometry and elemental composition, making careful monitoring essential to achieve high-quality surfaces. The Phenom XL insert for the SEMPREP SMART slope cut holder simplifies this process by enabling quick and accurate screening of ion-milled samples without the need to reposition them. By maintaining the sample’s alignment relative to the beam, users can continue milling at the exact same location if further processing is required. This combination of precision and convenience enhances efficiency in SEM sample preparation workflows.

Technoorg Linda SEMPREP SMART

Product Knowledgebase

Webinar

Practical SEM and Ion Mill Applications for Semiconductor R&D to Production

Scanning Electron Microscopes (SEMs) and Cross-sectioning/Polishing tools play a vital rol…

Broad Ion Beam vs. Focused Ion Beam Polishing: Choosing the Right Technique for Sample Preparation

When preparing samples for electron microscopy, the choice of method directly impacts the…

White Paper

Cross-Section Polishing for Microanalysis

Characterizing internal structures using a surface analysis technique like scanning electr…