Precision Tensiometers / Goniometers

Attension® Theta Optical Tensiometers

Attension Theta Optical Tensiometers by Biolin Scientific are versatile instruments used in R&D and quality control to characterize material surface properties and interfacial interactions between gas, liquid, and solid phases. Also known as contact angle goniometers or contact angle meters, they are instruments of choice to characterize surfaces. The Attension Theta Optical Tensiometers are ideal for a wide range of applications and completely modular enabling users to customize the system to fit their research needs and budget.

Class-Leading Camera

Get the most accurate data with the highest pixel density, frame rate, and field-of-view camera on the market

All-Inclusive Software

Free access to the OneAttension software, with regular updates for the lifetime of the instrument

Modularity

Modular and upgradeable with a wide array of plug-and-play accessories for advanced experiments

Roughness Correction

Automatically correct for roughness on the sample surface at the exact site of the droplet

See available configurations

Attension® Product Options

Attension Theta Optical Tensiometers are able to perform a complete range of automated measurements, which makes them a highly versatile instrument in research, industrial, and QC laboratories. Measurements include: static contact angle with the sessile drop, captive bubble and meniscus methods, dynamic contact angle with the tilted drop and needle-in drop methods, surface free energy, surface/interfacial tension with the pendant drop and reverse pendant drop methods, surface roughness correction with integrated optical profilometry, and interfacial dilatational rheology with the pulsating drop method.

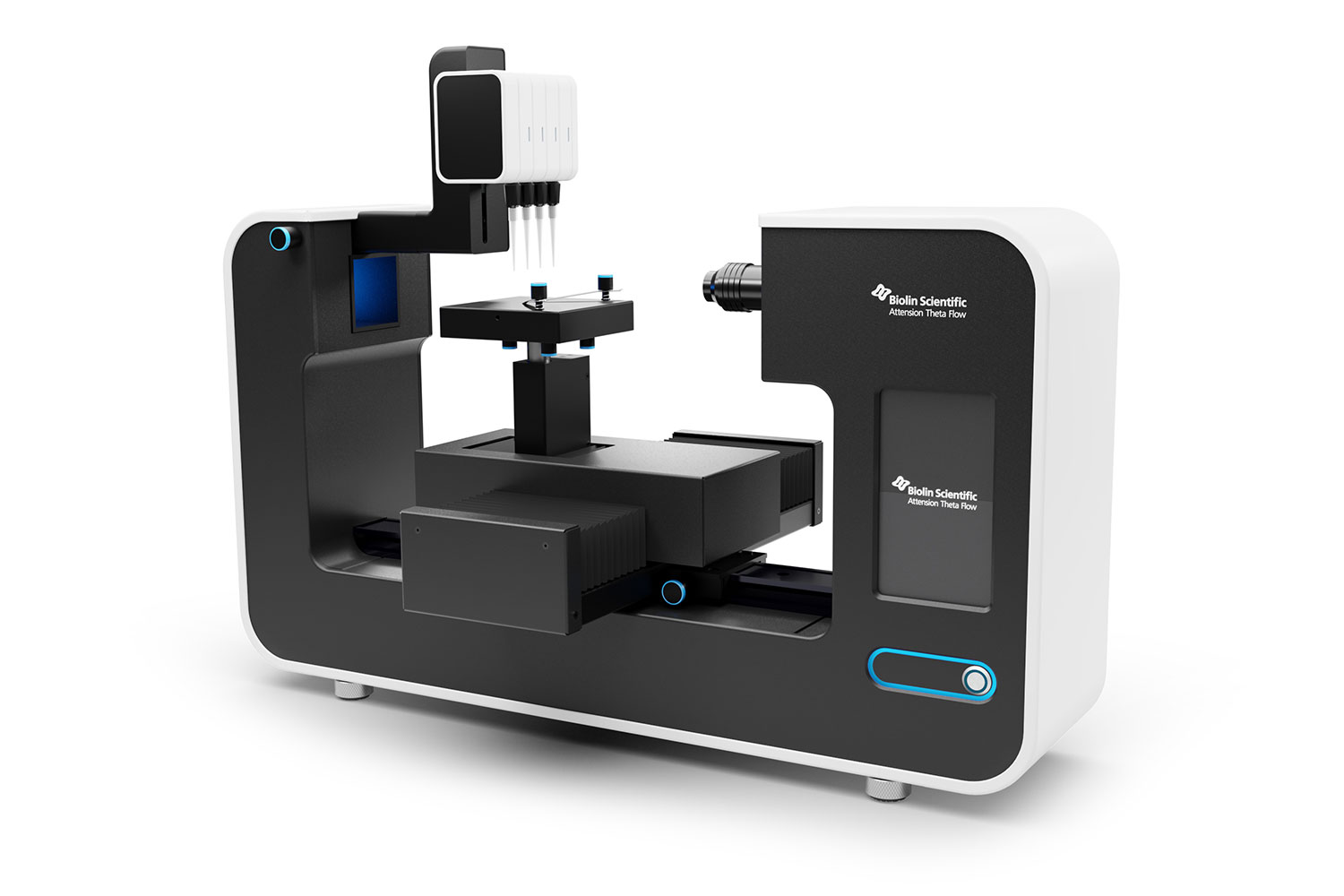

The best-in-class instrument for measuring contact angle, surface tension, surface free energy, dynamic contact angle, and much more. Includes features that remove user bias and streamlines processing with key instrument settings, improving data quality.

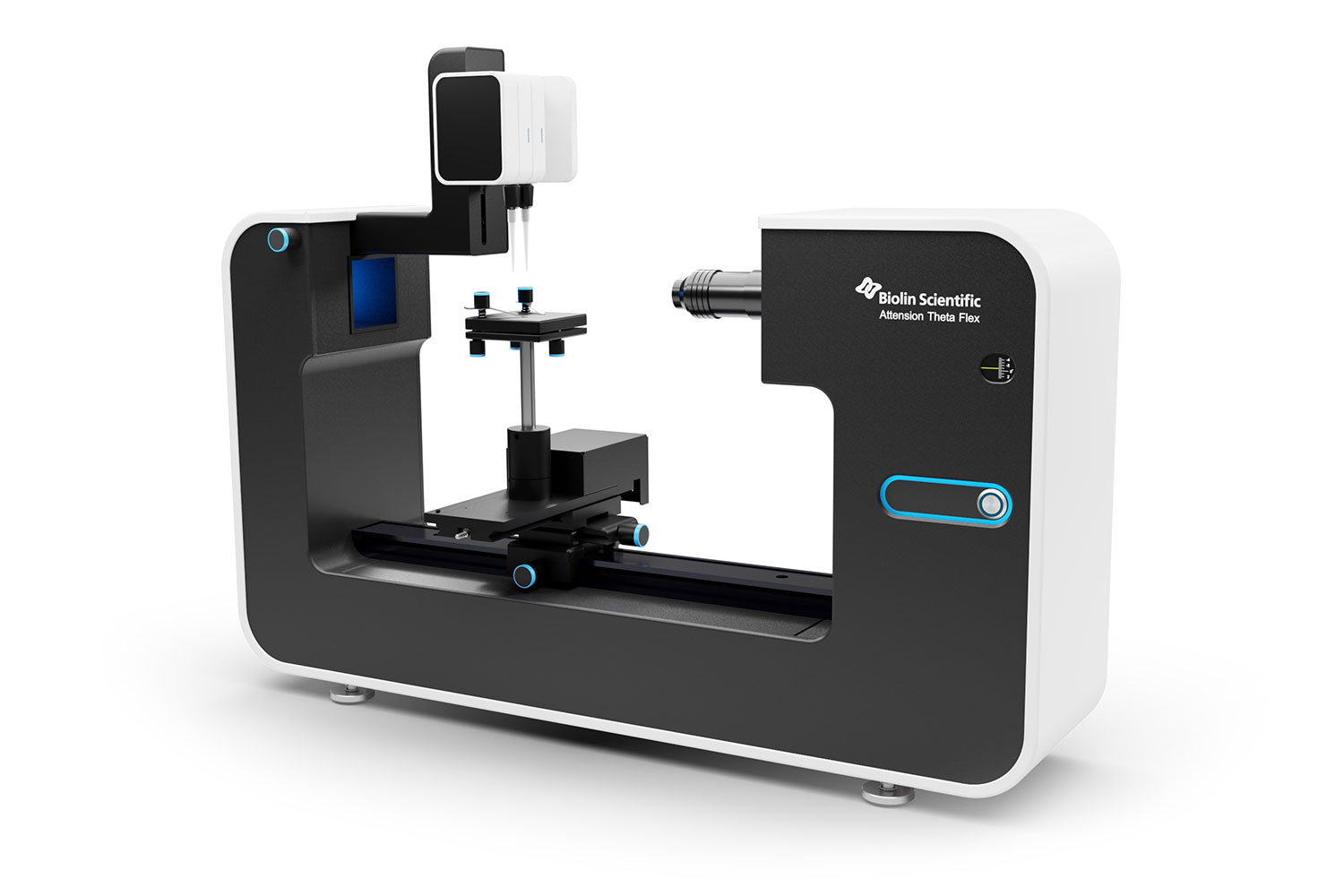

The Theta Flex is an award-winning, advanced, and versatile optical tensiometer for highly accurate measurements of static and dynamic contact angle, roughness-corrected contact angle, surface free energy, surface and interfacial tension, and interfacial rheology.

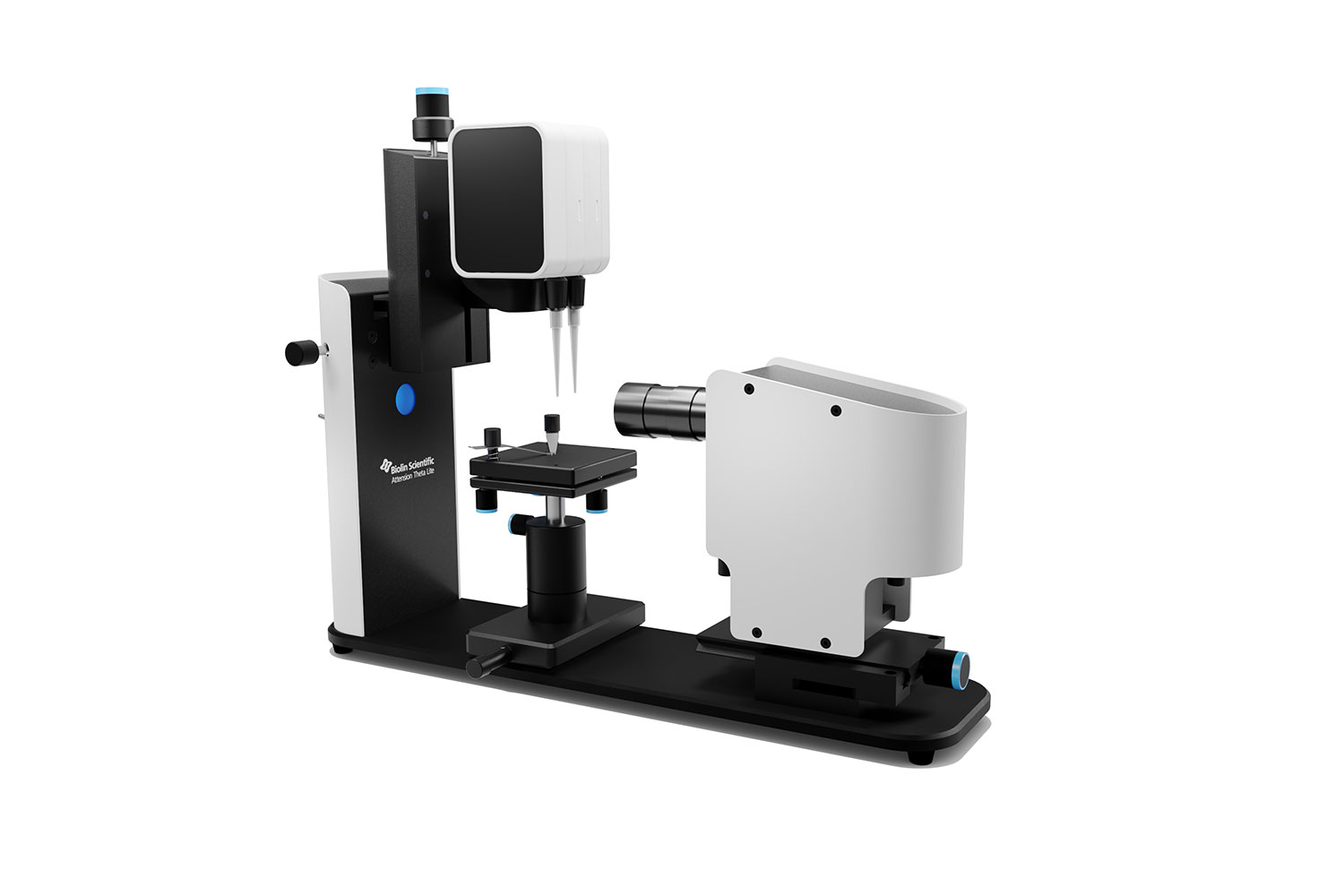

The Theta Lite is a compact, entry-level and accurate optical tensiometer for static and dynamic contact angle, surface free energy and much more. Ideal for basic research and quality control but boasts the same precision and all-inclusive software as our more advanced Theta Series systems.

Download the Attension® Theta Product Brochure:

Theta Measurements

Possible Theta Measurements

Contact Angle Measurments

This video will demonstrate a contact angle measurement with Attension Theta Flex. Attension Theta Flex automatically deposits droplets and analyzes the contact angle for immediate, accurate results.

Dynamic Contact Angle Measurement

Dynamic contact angles on the Theta optical tensiometers are a powerful method to quantify the level of heterogeneity of a surface, adhesion, and surface cleanliness. This video shows how the tilting and needle-in methods are carried out with the OneAttension software.

Surface and Interfacial Tension Measurement

This video will demonstrate a surface tension measurement with Attension Theta Flex. Attension Theta Flex automatically forms a pendant drop of desired size and determines the surface/interfacial tension from its drop shape.

Meniscus Contact Angle Measurement

When measuring the contact angle on small rods or fibers, traditional droplet sizes can be inadequate. This video introduces the special meniscus measurement mode with the Theta optical tensiometers that analyze the meniscus shape on rods, plates, or fibers to automatically measure the contact angle.

Batch Contact Angle Measurement

Contact angle measurements with water are an excellent tool for surface quality control. This video highlights how the batch contact angle measurement mode can be used for simple and efficient surface quality control measurements with the Theta optical tensiometers.

All-inclusive Software

One Attension Software

OneAttension is an all-inclusive software that enables immediate access to all measurement capabilities with no need to purchase and install separate software modules. One software for all contact angle, adhesion force, drop shape, interfacial tension, interfacial rheology and tensiometry measurements with quick and intuitive user interface.

Knowledge base

Attension® Common Applications

– Webinar –

How Clean is Your Surface? Contact Angles as a Measure of Cleanliness

Is your surface clean? Is surface cleanliness critical to…

– App Note –

Contact Angle Measurement for Monitoring Surface Cleanliness

Surface contamination is a concern for a wide variety…

– Blog –

How Surface Roughness and Wettability Affects Biocompatibility

When biomedical devices are developed or optimized, biocompatibility is…