2025 NanoNews: SEM Edition Q1

We’re pleased to share the latest edition of nanoNews! In the first quarter of the 2025 newsletter, you’ll find our webinar resources, event news, and our newest articles and technical notes – all focused on Scanning Electron Microscopy (SEM).

AISTech 2025 | May 5-7, 2024 | Nashville, TN

Association for Iron & Steel Technology Conference 2025 At Nanoscience Instruments, we empower steelmakers by equipping them with the means to achieve comprehensive inclusion analysis in one automated system: desktop scanning electron microscopy (SEM) combined with energy dispersive X-ray spectroscopy (EDS). Automated SEM-EDS forms the functional backbone of the Phenom ParticleX Steel system, elevating high […]

8 Factors That Affect the Cost of a Force Tensiometer

A force tensiometer is an instrument that uses a highly sensitive analytical balance and specialized probes to characterize several key interfacial properties. Even though it is most used to measure surface and interfacial tension, force tensiometers are capable of a variety of other measurements including contact angle, adhesion and cohesion, critical micelle concentration, and powder wettability.

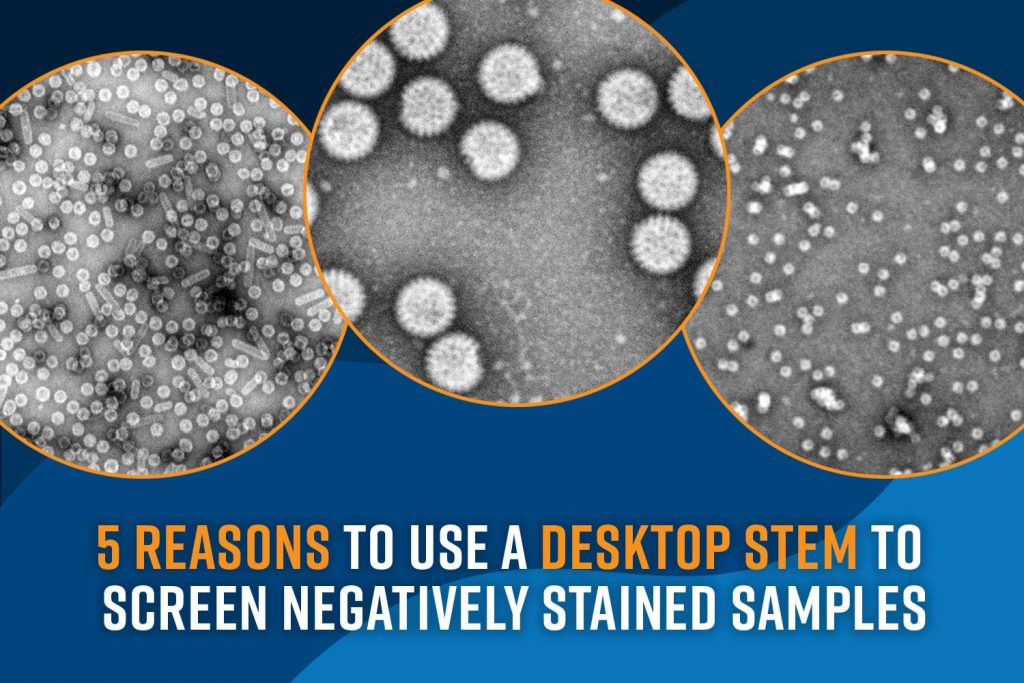

5 Reasons to Use a Desktop STEM to Screen Negatively Stained Samples

Cryo-electron microscopy (cryo-EM) is a powerful imaging technique used to determine the structure of biological macromolecules, viruses, and cellular components at near-atomic resolution. Unlike traditional electron microscopy, which requires heavy metal staining or dehydration, cryo-EM preserves biological samples in their native hydrated state by rapidly freezing them.

Advanced Automation Features of QSense Omni for Maximizing Efficiency

Quartz Crystal Microbalance with Dissipation monitoring (QCM-D) has revolutionized surface science by enabling real-time analysis of molecular interactions. However, traditional QCM-D workflows often involve time-consuming manual processes that introduce variability and inefficiency. In most QCM-D systems, sensor mounting, determining the resonance frequencies, stabilizing the baseline in air, priming the sensor, and establishing the baseline in liquids are performed manually.

The Battery Show South 2025 | April 16-17, 2025 | Atlanta, GA

Nanoscience Instruments provides solutions for battery development applications through cutting-edge instrumentation and analytical services. Visit our booth for live demonstrations of desktop SEM with automated workflows designed for structural and chemical analysis of battery materials, and learn about our surface characterization tools, battery cyclers & potentiostats, and process development and analytical services.

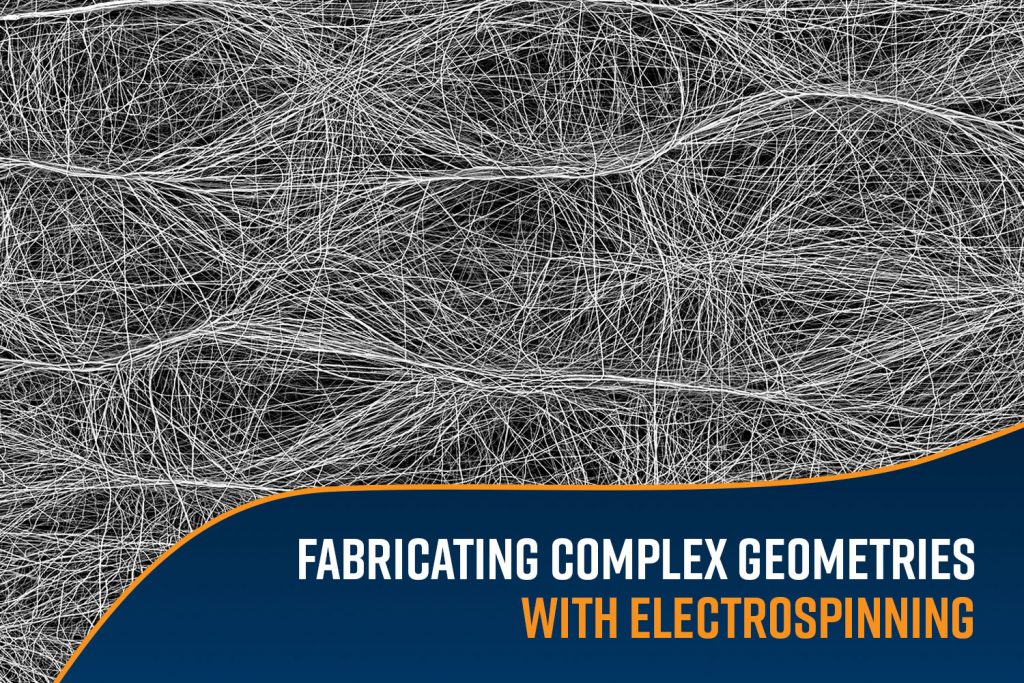

Fabricating Complex Geometries with Electrospinning

Electrospinning has emerged as a transformative technique for fabricating fibrous materials with highly controlled geometries. This method, characterized by its ability to produce ultrafine fibers from various materials, has garnered widespread attention across industries, including healthcare, energy, and materials science. A particularly exciting aspect of electrospinning is its capacity to create complex geometric structures composed of nanoscale and microscale fibers, which significantly enhance their functionality for advanced applications. Traditional electrospinning produces planar surfaces composed of randomly oriented fibers but advancements in the field have enabled the fabrication of more sophisticated structures. In this blog we will delve into some of the complex geometric structures that can be fabricated by electrospinning and their different applications.

5 Benefits of Scanning Electron Microscopy for Particle Analysis

Particle analysis is a critical process in many industries, from pharmaceutical formulation and nanomaterials development to forensic investigations and industrial manufacturing. Understanding the size, shape, and composition of particles plays a crucial role in ensuring product quality, optimizing performance, and meeting regulatory requirements.

Unmatched Sensitivity: How QSense Omni Redefines QCM-D Performance

Interactions at surfaces and interfaces are crucial in many fields, including environmental science, biopharmaceutical research, materials science, catalysis, and nanotechnology. The ability to detect minute changes in mass, viscoelastic properties, and interfacial phenomena can be crucial in determining the success of groundbreaking research. Understanding these interactions allows for the design of better materials and devices with tailored properties.

American Chemical Society (ACS) Spring 2025 | March 24 – 26, 2025 | San Diego, CA

ACS – American Chemical Society Meet us in Booth #3625 at the American Chemical Society’s Spring Meeting! In the meantime, we invite you to explore our wide range of solutions and services for chemists, including: Nanomaterial Fabrication Systems Nanomaterial Characterization Tools Process Development & Analytical Services To learn more about the capabilities of our dedicated Analytical […]