Phenom Scanning Electron Microscopes

Software & Automation

Streamline your workflows and unlock the full potential of your Phenom Desktop SEM with tailored software and automation solutions. Designed to enhance productivity, these tools provide advanced image and EDS analysis options, automated data collection, and seamless data management for a wide range of applications. Each solution empowers users of any experience level to achieve consistent, high-quality results with ease. The result: reduced operational costs, actionable insights, and standardized protocols tailored to maximize the capabilities of your Phenom Desktop SEM.

High Throughput

Increase efficiency and reproducibility by automating your workflow

Accessibility

Analyze samples without the requirement of a skilled operator

Data-driven Decisions

Visualize results with customized reporting and make statistically informed decisions

Customization

Choose from off-the-shelf protocols or develop customized workflows

Software Packages

Phenom Software & Automation Solutions

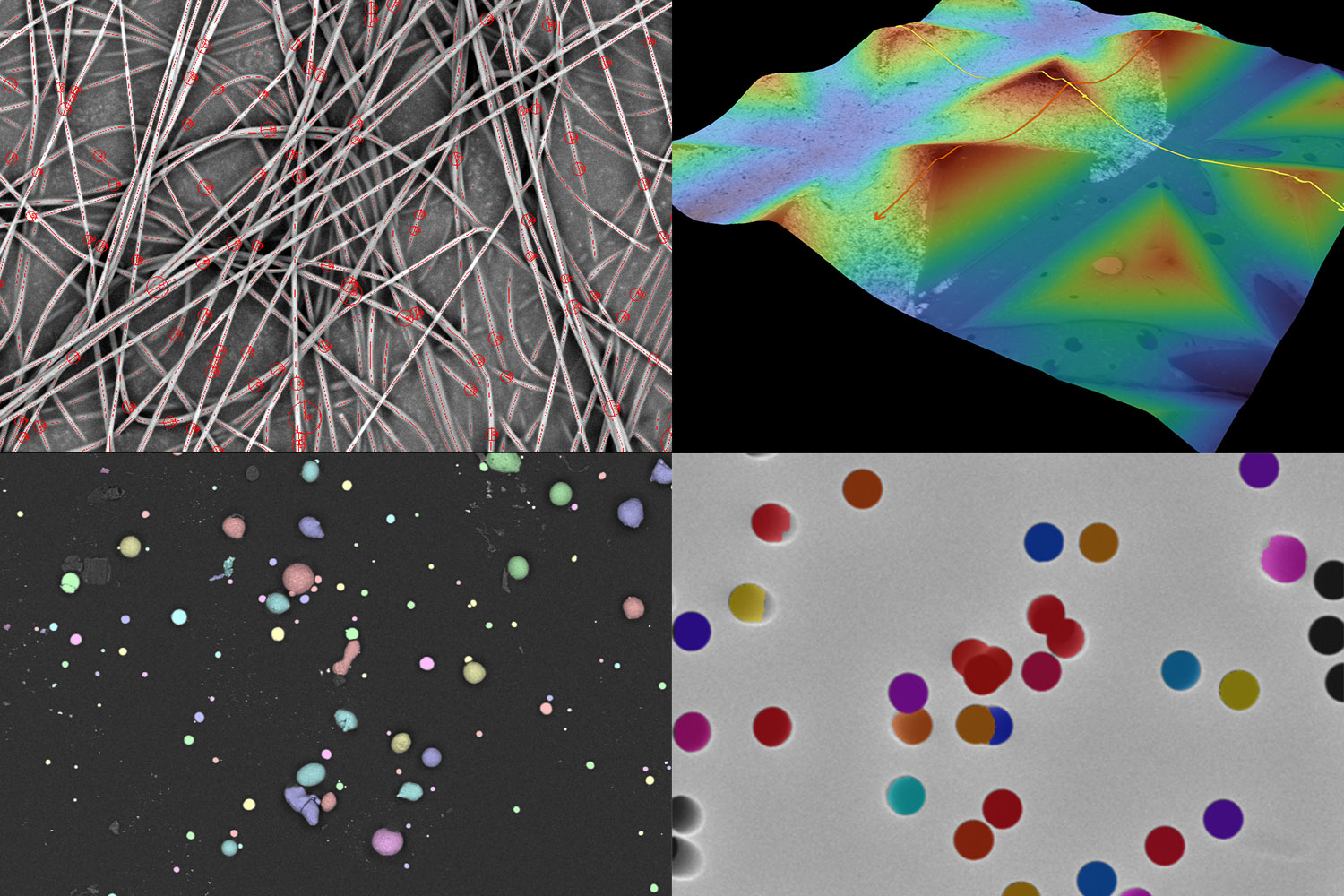

Automate high-throughput surface feature analysis with ProSuite and develop image analysis recipes for precise, quantitative results free from user bias. It includes ParticleMetric, PoroMetric, FiberMetric, and 3D Roughness Reconstruction.

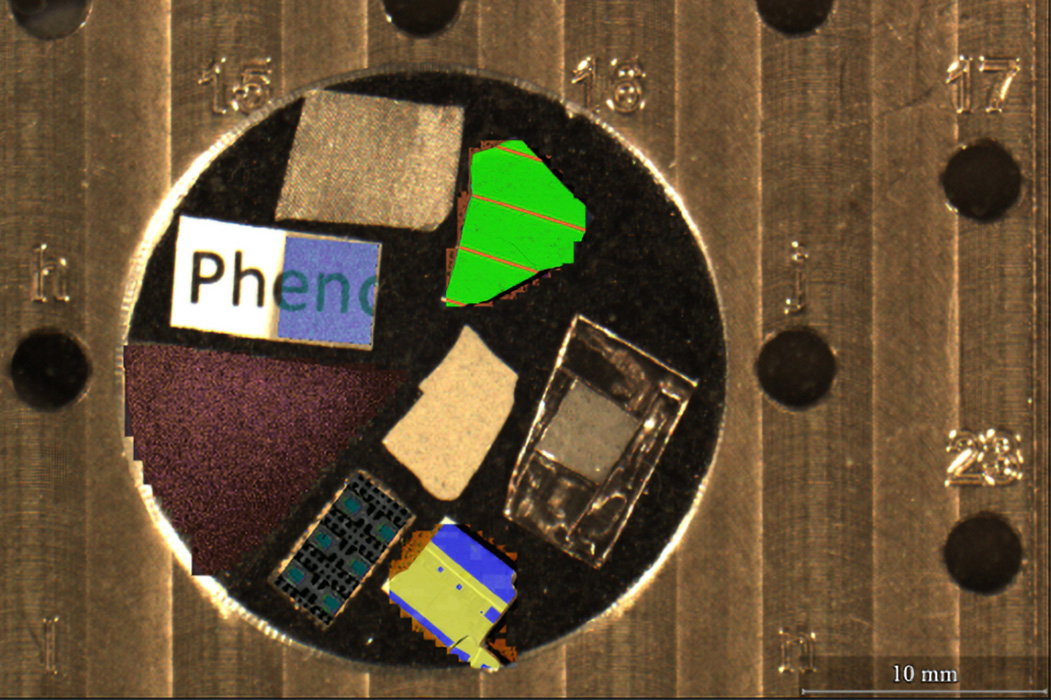

Unlock advanced customization with Python scripting, enabling automated imaging workflows and data acquisition. Scripting offers absolute freedom to dictate which functions the microscope performs, how that action is completed, and in what sequence.

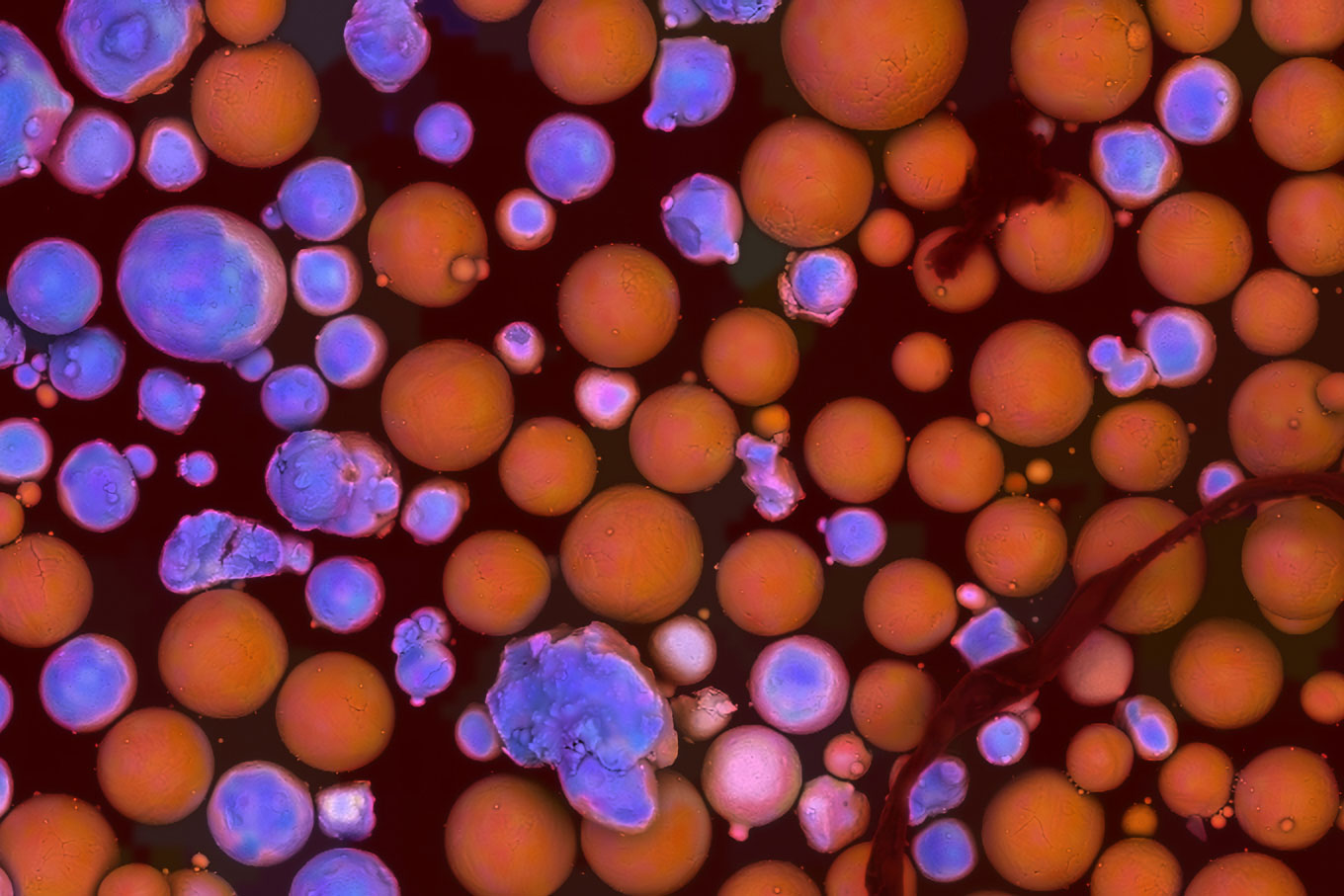

Streamline elemental and phase analysis with integrated data collection and advanced analysis capabilities. ChemiSEM provides real-time elemental mapping during live imaging and ChemiPhase transforms EDS maps into color-coded phase maps.

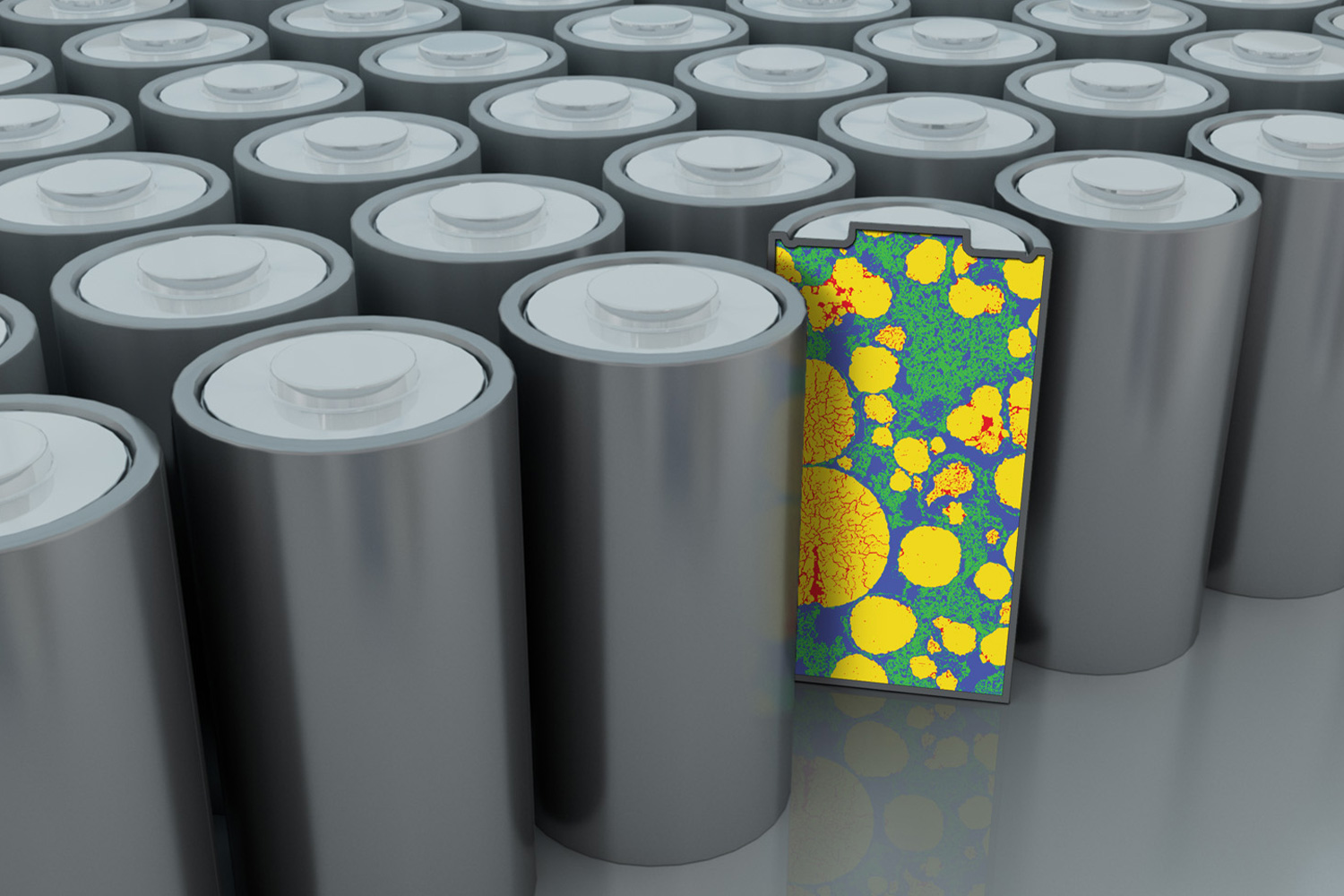

Simplify battery materials inspection with Avizo Trueput by turning SEM data into clear pass/fail reports for production floor quality control. Choose from a library of workflows addressing battery manufacturing challenges like particle size distribution, cracked particles detection, and void/crack analysis.

Talk to an Instrumentation Specialist Today!

Knowledgebase

SEM Knowledgebase

Webinar

Applications for Desktop SEM in Geology

Scanning Electron Microscopy (SEM) has become a vital tool in geology, offering high-resol…

Blog

Desktop Scanning Electron Microscopy in Geology

Scanning Electron Microscopy (SEM) is a versatile tool in geology used in high-resolution…

White Paper

Phenom Pharos: A Compact Desktop STEM for Screening Negative Stained Samples

The Phenom Pharos Desktop SEM/STEM is a compact and affordable solution designed for cryo-…