The beauty of the electrospinning technique is that it allows the production of fibers in different structural organization and morphologies to meet their application needs. Researchers and industries use fibers in applications like drug delivery, tissue engineering, energy storage, textiles, and filtration of different media. Fiber structure and morphology is a really important parameter that needs to be tightly controlled when a consistent and reproducible performance is needed. The electrospinning technique allows the use of different materials like natural and synthetic polymers, and different types of solvents, like water and organic solvents, to properly engineer the sample and obtain desired properties. Here below we show some of the predetermined structural fiber organization and morphologies that can be achieved in a reproducible and consistent manner by using our Fluidnatek systems.

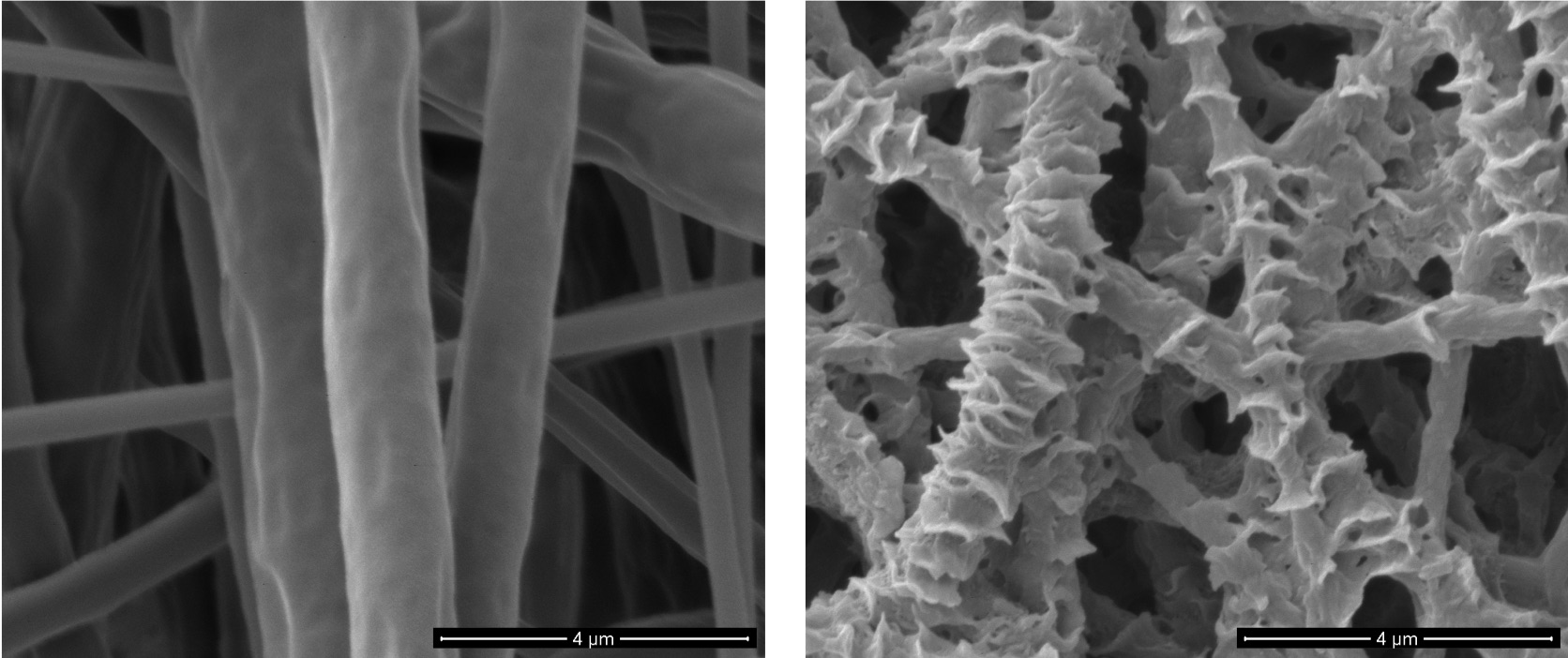

Single-phase vs co-axial electrospinning

Among the most common material structures created with this technique are single-phase and co-axial fibers. In single-phase, the fibers are composed of only one structure that can be composed of but not limited to, one material or a blend of a material with a bioactive substance. While this overcomes limitations of different techniques that do not allow the process of thermolabile products, some bioactive materials need to be protected from the exposed environment. For example, when an electrospun fiber needs to contain a drug that may be deactivated in vivo before it can achieve its timely function, a core-shell structure can be implemented. This way the drug will be enclosed in the core of the fiber allowing the shell to protect it from the harsh in vivo environment before its biological action is needed. Other uses of core-shell fibers include smell suppression, the formation of hollowed fibers, controlled drug delivery, and inorganic fiber production. Multi-axial fibers composed of three or more phases are also a possibility with the electrospinning technique for fiber production.

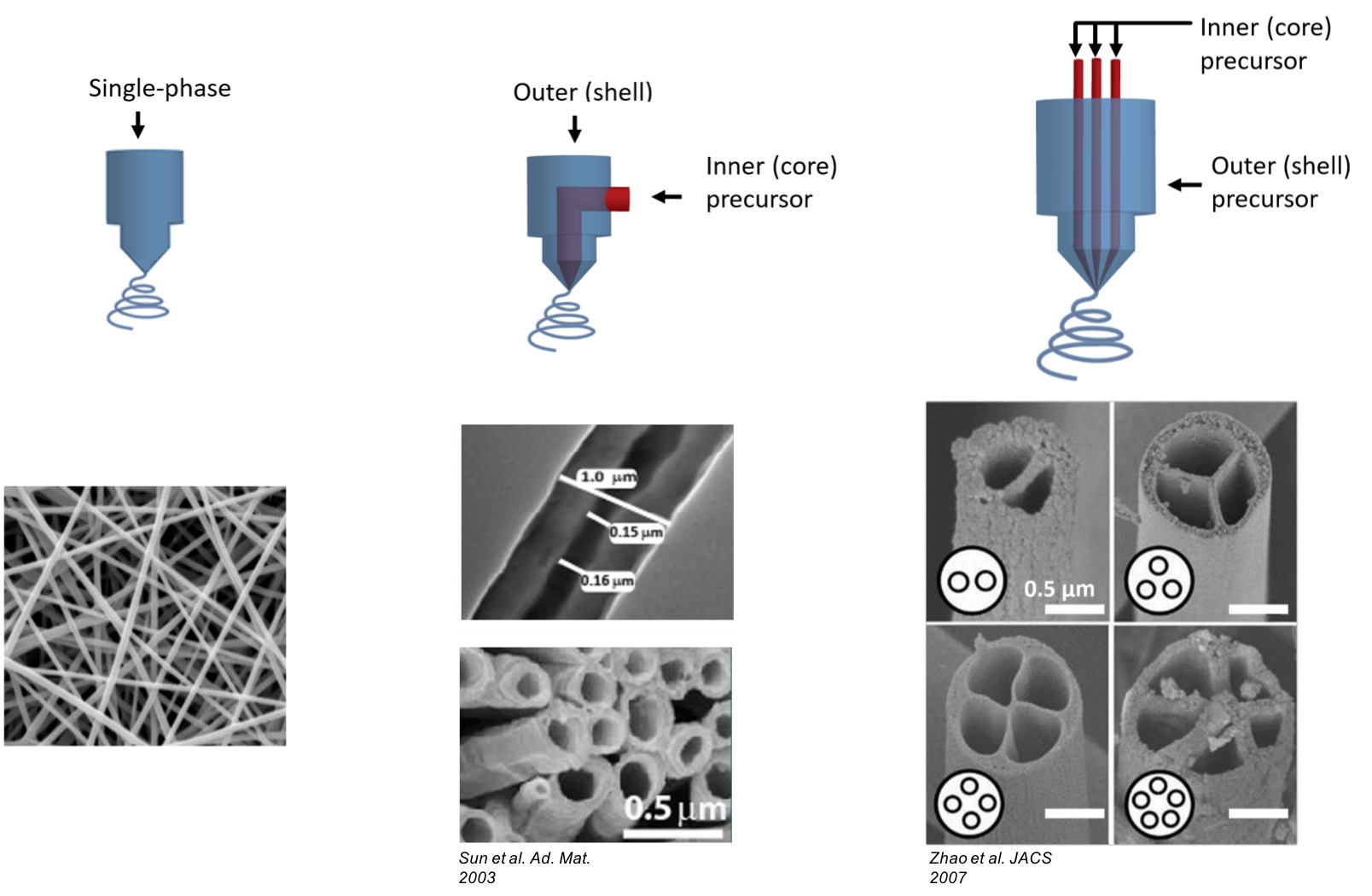

Solvent effects on fiber properties

The versatility of the electrospinning technique allows to easily engineer fiber morphology to desired specifications before, during or post fiber production by controlling different parameters that govern the spinning process. One of the most common cases includes the use of two solvents with different boiling points to spin the same polymer. For example, in the image below we have polycaprolactone (PCL) spun with acetone (left) and dichloromethane (right) while keeping all other parameters constant. It can be seen that the use of a lower boiling point solvent can significantly alter the fiber morphology by increasing fiber diameter and having a rougher surface due to the fast evaporation of dichloromethane during the spinning process. This not only affects the sample morphology, but it also affects the mechanical properties and will improve cell proliferation due to the small porosity across its surface.

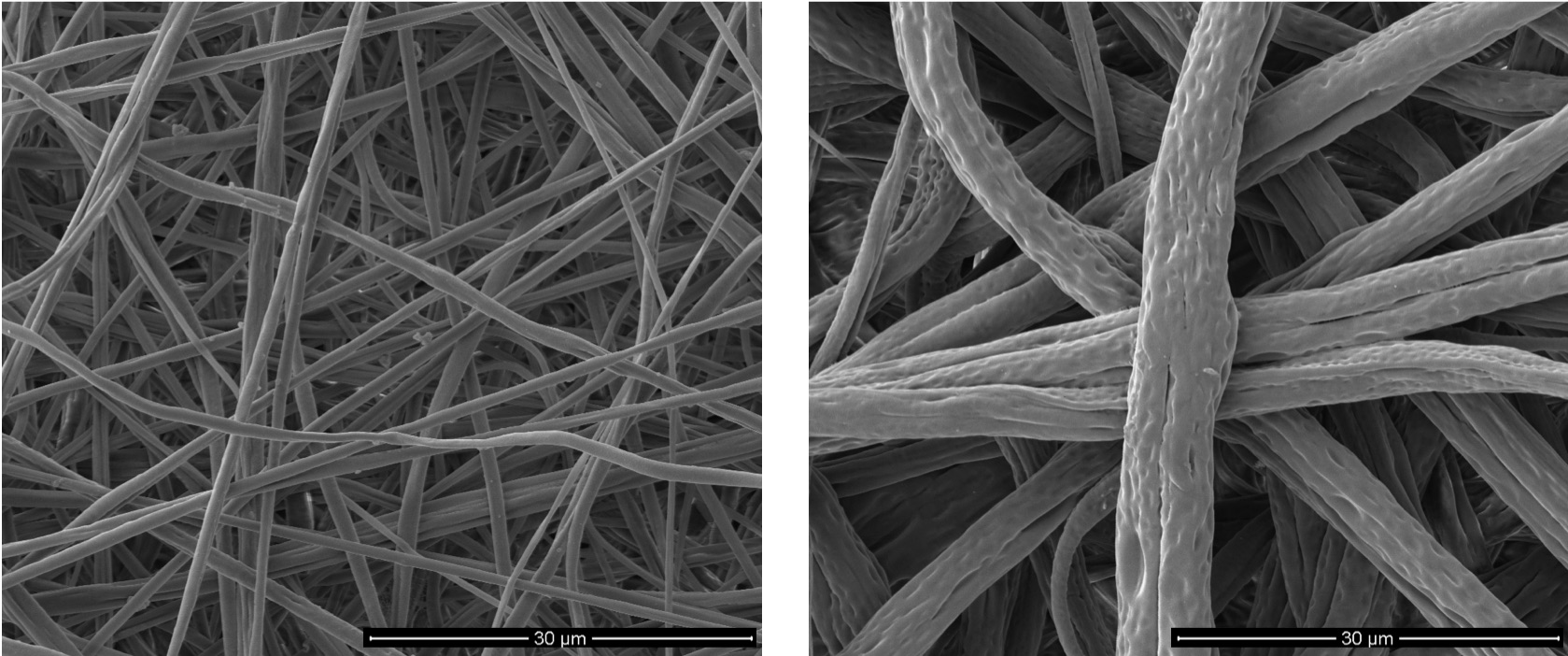

Targeted properties post-fiber processing

Some applications requiring stronger mechanical properties without changing the main polymer of interest are needed. For this, fiber morphology can also be controlled post-fiber production by sintering below the melting point of the polymer used. This will create a fiber-fiber bonding that will increase the mechanical properties of the sample by the hindrance of fiber movement when in tension or compression. The figure below shows how polycaprolactone fibers can be sintered at 58 and 59°C to increase fiber-fiber bonding and concurrently decrease pore size and porosity.

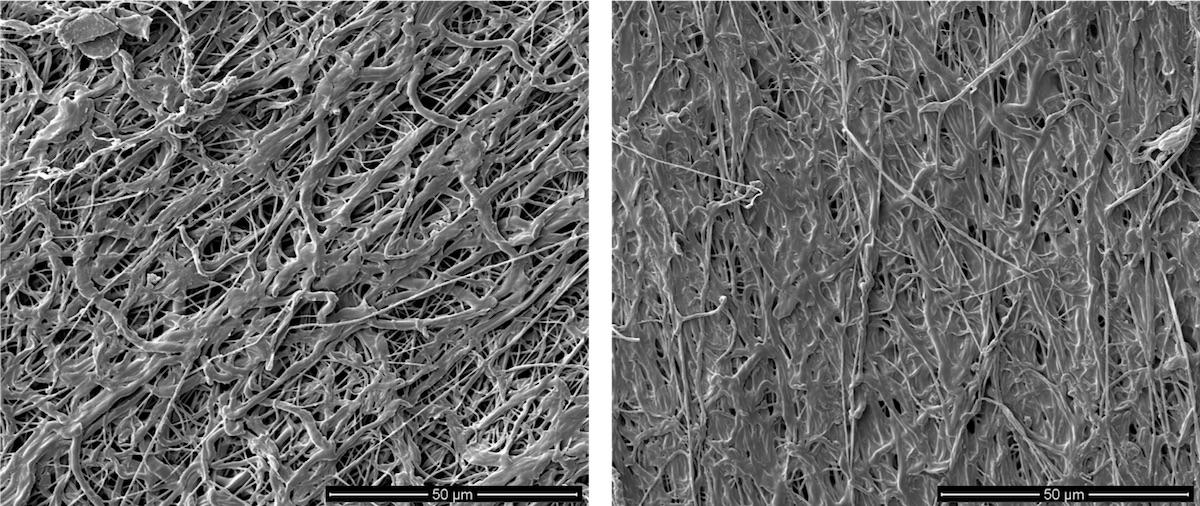

When fibers are created with two, or more, types of material at the same time, fiber morphology can be tailored by selectively removing a polymer with a specific treatment. In the example below a polycaprolactone-polyethylene terephthalate, the blended fiber was treated with acetone to selectively remove polycaprolactone, creating a rougher surface that resembles collagen fibrils typically used in tissue engineering applications.