Introduction

Superhydrophobic and oleophobic surfaces are receiving increased attention because of their potential to provide breakthroughs in applications such as anti-fouling, self-cleaning, and anti-freezing. Contact angle measurements are often used to characterize the properties of these surfaces. However, the low wettability of these surfaces presents unique challenges when trying to place a liquid droplet for measurement. Additionally, more complex measurements such as advancing (ACA), receding contact angle (RCA) and tilting angle (sometimes called roll-off angle) measurements may be necessary to characterize not just whether a material has a high contact angle, but also whether the material resists liquid adhesion. The Attension Theta Flex is a modular system that has many options for dispensers, needles, and measurement methods to quantify key performance metrics for superhydrophobic and oleophobic surfaces.

How to make Contact Angles on Superhydrophobic and Oleophobic Surfaces

Because superhydrophobic and oleophobic surfaces are so repellant, the probe liquids used for contact angle measurements can be difficult to apply to the surface. To address these demanding conditions, the Attension Theta Flex has a high degree of flexibility in how the droplets can be dispensed and placed so that the user can choose the method that works best for them. Droplet control can be modulated with an automated pipette or syringe pump at a dispensing resolution of 0.1 μL. Disposable tips with hydrophobic coatings are also an option if one is using liquids that interact with standard tips. Three drop placement strategies for sessile drops on repellant surfaces are discussed below.

1. Droplet formation and subsequent stroking of the liquid to the surface

This method is the classical approach to measuring contact angle where a droplet of liquid is formed at the end of a pipette or needle tip and then this droplet is stroked to the surface. The tip is then retracted and the drop remains on the surface. Some superhydrophobic/oleophobic surfaces resist adhesion so much that the liquid remains attached to the needle tip even after stroking the drop to the surface. In this case, another method should be chosen.

A drop attached to a needle is stroked to a superhydrophobic surface

2. Droplet dispensing by adding volume until detachment from the needle tip

A droplet can also be dispensed until it falls off the needle tip and lands on the surface. This may have several disadvantages such as extra energy imparted into the drop such that it may reach a different sessile drop equilibrium state than a contact angle measured by stroking the sample to the surface. A start trigger can be initiated to automatically start measurements, but if this is done the first several frames where the drop is unstable should be ignored for analysis. On the other hand, recording the initial frames where the droplet bounces off the surface provides a powerful illustration of a material’s hydrophobicity. By recording at a high framerate with the Theta Flex, these frames can be saved into a video for a journal submission, marketing collateral, or investor presentation.

A drop is dispensed until it falls from a needle onto a superhydrophobic surface

3. Droplet dispensing in close proximity to the surface

Another approach for contact angle measurement is to bring the dispenser close to the surface and then dispense liquid. If the drop formation favors one side, a region of interest can be selected to force the image recognition software to identify the drop in a specific part of the frame. Dispensing liquid this way in effect provides the ACA of the surface, which is a key parameter to obtain in superhydrophobic applications. The full procedure for measuring the ACA and RCA is described in the following section.

A needle is placed close to a superhydrophobic surface and a drop is dispensed directly in contact with a superhydrophobic surface

Practical Tips for Measurement of Advancing and Receding Contact Angle

A generalized protocol for measuring the ACA and RCA is given on our technique page. For superhydrophobic surfaces, some additional considerations are involved. The specific protocol for these surfaces is described below.

Advancing Contact Angle (ACA)

- Using a 30 gauge needle, dispense the droplet at a slow rate until the drop is as large as possible without falling off the needle.

- Stroke the drop to the surface.

- Place the needle halfway inside the drop, keeping the needle centered as much as possible. While the stage can be adjusted in the x-direction to ensure centering there, you may need to look down on the drop as well to confirm that it is centered in the y-direction as well.

- Record the drop for at least 10 seconds after the droplet baseline starts expanding.

- ACA is measured from the last several frames where the baseline is increasing but the contact angle is constant.

Receding Contact Angle (RCA)

- Slowly remove liquid from the existing drop until the baseline starts receding.

- RCA is measured from the frames where the baseline starts decreasing.

The video below illustrates how this measurement is done using the OneAttension software using the automatic dynamic contact angle function. ACA, RCA, and hysteresis can be automatically determined or manually overridden.

A video displaying how automatic ACA/RCA is performed in OneAttension.

Tilting Angle or Roll-off Angle

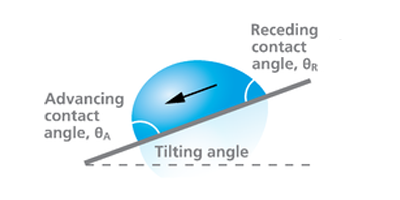

The tilting angle or roll-off angle serves as a performance-based metric of the anti-adhesive properties of a surface. In most anti-wetting and self-cleaning applications, it is key that liquid drops roll off the surface with minimal effort and low tilting angles.

Figure 1 – Schematic of a tilting contact angle. Image courtesy of Biolin Scientific.

The tilting angle of a drop is measured with the stop trigger placed to the left of the drop. As the drop rolls through the trigger, the measurement is stopped automatically.

The Importance of Investigating the Durability of Superhydrophobic Surfaces

One of the biggest obstacles against widespread use of superhydrophobic surfaces is their durability. Because superhydrophobic surfaces are typically generated through a combination of hydrophobic materials and surface topography, it is important to ensure that the topographical features can survive repeated wear. Many surfaces may appear to have superhydrophobic properties when first manufactured, but after wear testing, these samples may lose key anti-adhesive properties. Simply using the static contact angle to measure the surface after wear testing is often insufficient because surfaces may continue to have a high contact angle even after abrasion.2 The contact angle hysteresis (advancing contact angle minus the receding contact angle) may have changed greatly, indicating a loss in the anti-adhesive properties of the surface.

One study measured a fabric modified with a superhydrophobic coating. The fabric was washed 20 times and its static contact angle and contact angle hysteresis was measured. Though a static contact angle of 150° remained relatively constant after each washing step, the contact angle hysteresis decreased dramatically, reaching 60° by the end of the study. This indicates that the drop’s adhesion increased and that the coating became less effective during subsequent wash steps.3 Other researchers have found that wear-induced decreases in hysteresis also manifest themselves in increased tilting angles.2

This study illustrates the importance of measuring not just the static contact angle, but also the advancing and receding contact angles to evaluate superhydrophobic surfaces and coatings. The Attension Theta Flex offers several ways to measure contact angles including automated methods ensuring operator-independent reproducibility. Additionally, the best-in-class camera resolution ensures that you can get the highest accuracy in your measurements. For more information about advancing and receding contact angles, please see our applications page, our on-demand webinar, and our partner’s hosted webinar featuring one of the leading experts on superhydrophobic surfaces, Robin Ras.

Learn More

Watch our on-demand webinars to learn more about contact angle measurements.

References

- Liu, K.; Vuckovac, M.; Latikka, M.; Huhtamäki, T.; Ras, R. H. A. Improving Surface-Wetting Characterization. Science 2019, 363 (6432), 1147–1148.

- Tian, X.; Verho, T.; Ras, R. H. Moving Superhydrophobic Surfaces toward Real-World Applications. Science 2016, 352 (6282), 142–143.

- Zhao, Y.; Xu, Z.; Wang, X.; Lin, T. Photoreactive Azido-Containing Silica Nanoparticle/Polycation Multilayers: Durable Superhydrophobic Coating on Cotton Fabrics. Langmuir 2012, 28 (15), 6328–6335.